Anti-scaling method for calcium chloride production

A calcium chloride, anti-scaling technology, applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc. Speed, the effect of extending the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

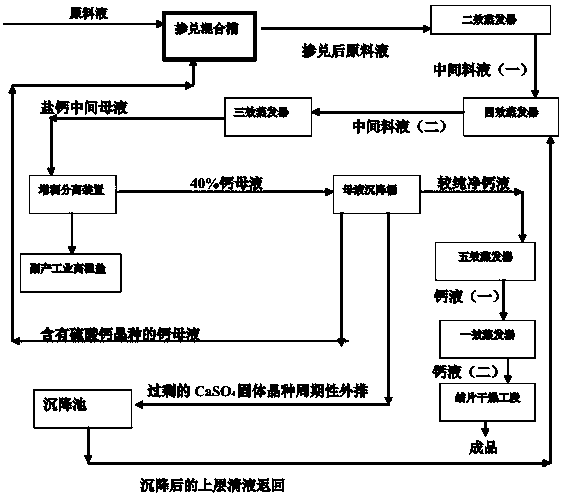

[0015] Reference figure 1 , This embodiment uses a five-effect evaporation system, including the following steps:

[0016] (1) The waste liquor of soda ash ammonia distillation containing 15% (wt) of calcium chloride and 9% (wt) of sodium chloride is used as the raw material liquid, and the two-effect evaporator is used as the first-effect evaporator to feed, and the intermediate material is obtained by evaporation and concentration Liquid (1), its composition includes: calcium chloride 21% (wt), sodium chloride 8% (wt), sodium chloride crystal 4.5% (wt), calcium sulfate crystal 0.015% (wt), and then through four effects Evaporator evaporates and concentrates to obtain intermediate feed liquid (2), its composition includes: calcium chloride 34% (wt), sodium chloride 3% (wt), sodium chloride crystal 18% (wt), calcium sulfate crystal 0.018% ( wt), and then enter the three-effect evaporator for evaporation and concentration to obtain the intermediate mother liquor of calcium salt. ...

Embodiment 2

[0020] Reference figure 1 , This embodiment uses a five-effect evaporation system, including the following steps:

[0021] (1) Use the soda ash ammonia distilled waste liquid containing 15.5% (wt) of calcium chloride and 8.5% (wt) of sodium chloride as the raw material liquid, and the two-effect evaporator is used as the first-effect evaporator to feed, and the intermediate material is obtained by evaporation and concentration Liquid (1), its composition includes: calcium chloride 22.5% (wt), sodium chloride 8.5% (wt), sodium chloride crystal 4.0% (wt), calcium sulfate crystal 0.015% (wt), and then through four effects The evaporator evaporates and concentrates to obtain the intermediate liquid (2), which consists of calcium chloride 35% (wt), sodium chloride 2.8% (wt), sodium chloride crystal 19.5% (wt), calcium sulfate crystal 0.015% ( wt), and then enter the three-effect evaporator for evaporation and concentration to obtain the intermediate mother liquor of calcium salt. Its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com