Patents

Literature

52results about How to "Reduce fouling speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cleaning agent for strong adhesion stain and its application

InactiveCN1597896ASimple production processLow costOrganic detergent compounding agentsNon-ionic surface-active compoundsInorganic saltsFuel oil

The invention is a strongly adhesive fouling detergent and its application, composed of inorganic salt, anionicsurfactant, nonionic surfactant, dispersant, penetrating agent, and anti-sedimentation agent, and as used, it is only necessary to mix with water in a certain proportion. It can effectively eliminate fouling on the pipeline wall to make the pipeline smooth, reducing oil transporting pressure and increasing oil output, the corrosivity is extremely low, and it forms passive film on the pipeline wall to reduce fouling speed, having no pollution to the environment. It can be used to wash other metal surfaces, fuel oil devices.

Owner:山东恒冠化工科技有限公司

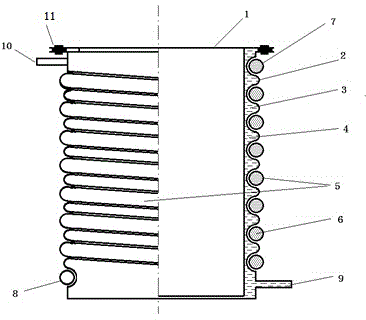

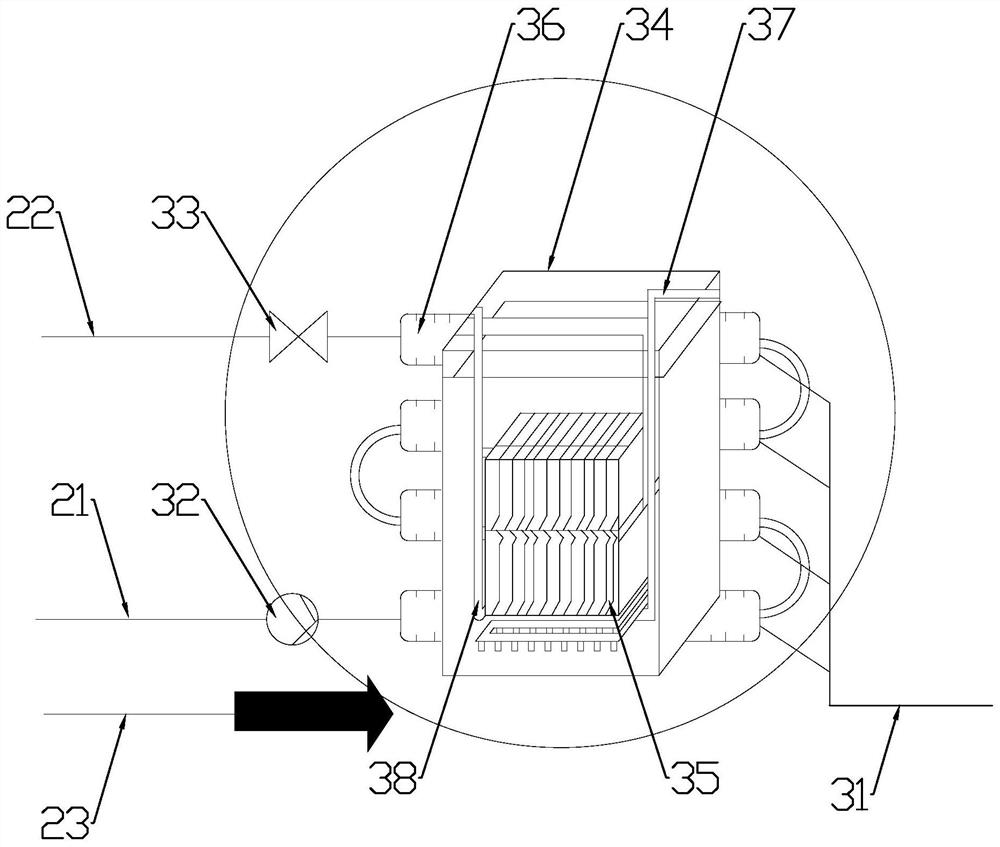

Heat exchanger of heating pump for heating water

InactiveCN104019680AImprove heat transfer efficiencyEnsure Hygienic StandardsStationary tubular conduit assembliesWater flowEngineering

The invention discloses a heat exchanger of a heating pump for heating water. The heat exchanger comprises an inner bucket and an outer bucket, wherein the inner bucket is embedded in the outer bucket; a water flow channel for water flow is formed between the inner and outer buckets; a water flow inlet is formed in the bottom of the outer bucket; a water flow outlet is formed in the top of the outer bucket; the water flow inlet and the water flow outlet are distributed at two sides of the outer bucket; a spiral groove is pressed in the outer peripheral wall of the outer bucket; and a heat exchange structure in which a heating work medium flows is arranged in the spiral groove. The heat exchanger of the heating pump for heating water has the beneficial effect that heated water and the work medium of the heating pump flow in a complete counter-current manner and the flow speeds are relatively high; the heat exchange efficiency of the heat exchanger is greatly improved; the scale formation speed is reduced; the heat exchanger adopts an open type structure, the inner and outer buckets can be detached and the washing and descaling operations can be conveniently realized, so that the heat exchange efficiency and the sanitary standard of high-temperature hot water are guaranteed, an effective solution for large scale application of a water heater of a high-temperature heating pump is provided and the energy-saving effect is remarkable.

Owner:江苏乐普四方科技有限公司

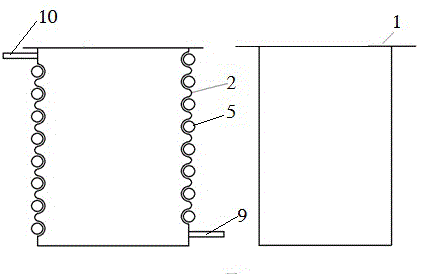

Cooling evaporating treatment method and cooling evaporating treatment apparatus of high boiling point liquid

PendingCN108046356AShort processReduce difficultyGeneral water supply conservationWater/sewage treatment by heatingBoiling pointLower grade

The invention discloses a cooling evaporating treatment method of a high boiling point liquid. The cooling evaporating treatment method comprises: heating a high boiling point liquid by using a low-temperature heat source; carrying out heat transfer and mass transfer through direct contact between low boiling point non-condensable gas used as a circulating carrier gas and the high boiling point liquid, wherein the circulating carrier gas reduces the steam partial pressure and the evaporation temperature of the high boiling point liquid; and carrying out steam stripping and evaporation on the heated high boiling point liquid to concentrate the high boiling point liquid so as to obtain a concentrated liquid, and carrying out cooling condensing on the saturated circulating carrier gas to obtain a condensed liquid. According to the present invention, through the low-temperature evaporation characteristics, the utilization efficiency of the low-temperature heat source is improved, the influence of corrosion caused by the corrosive medium is reduced, and the low-grade material can be used; and with the method and the apparatus, the fouling speed of the equipment and the pipeline are slowed down, and the continuous operation time is prolonged, such that the investment in the equipment is reduced, and the routine maintenance cost is reduced.

Owner:上海首济化工科技有限公司

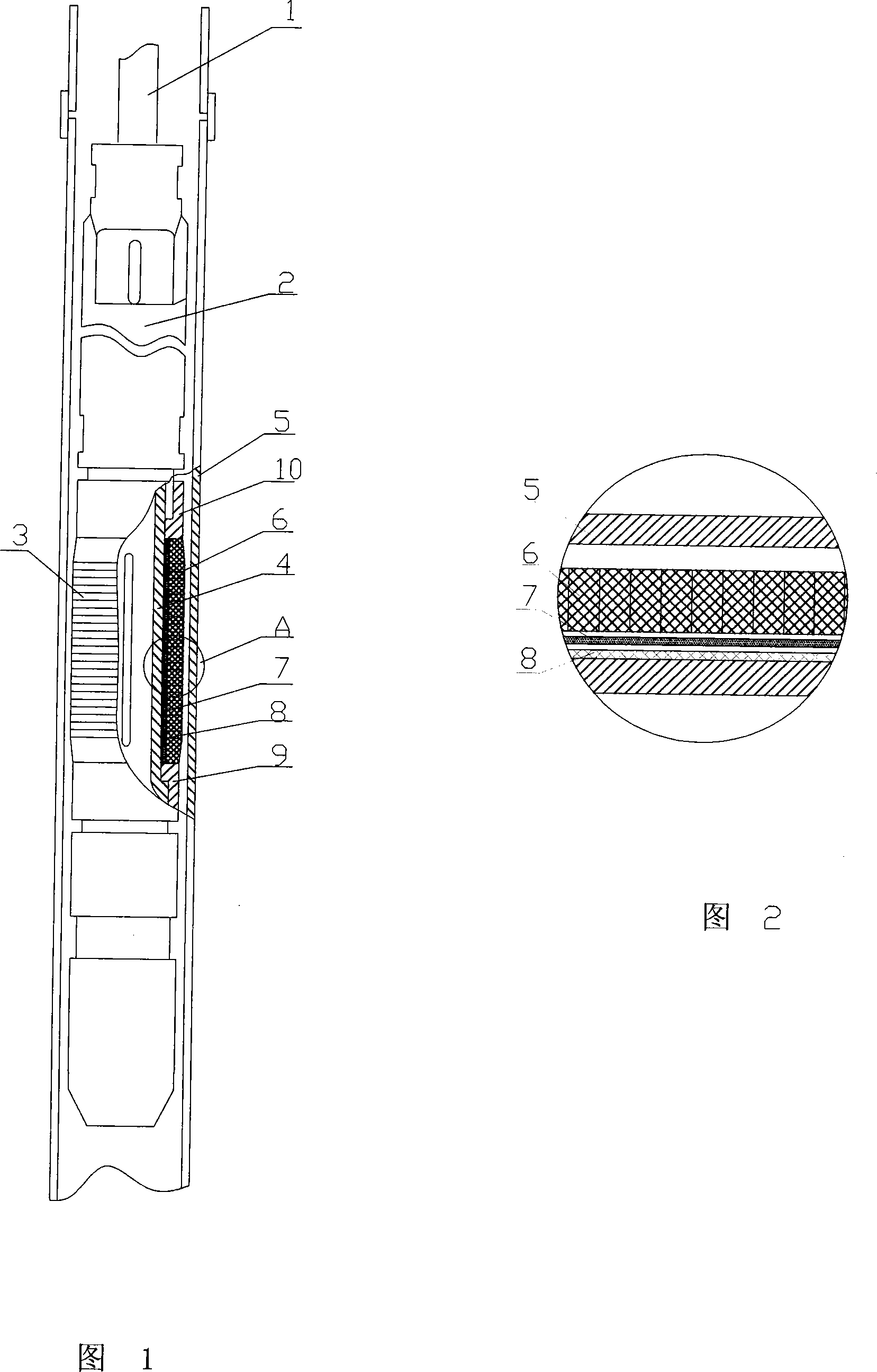

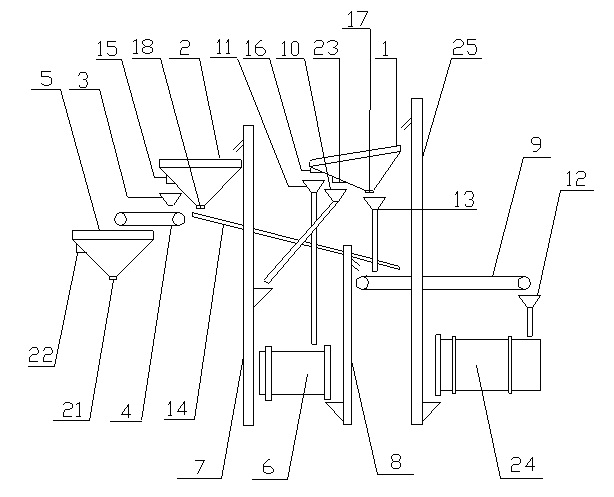

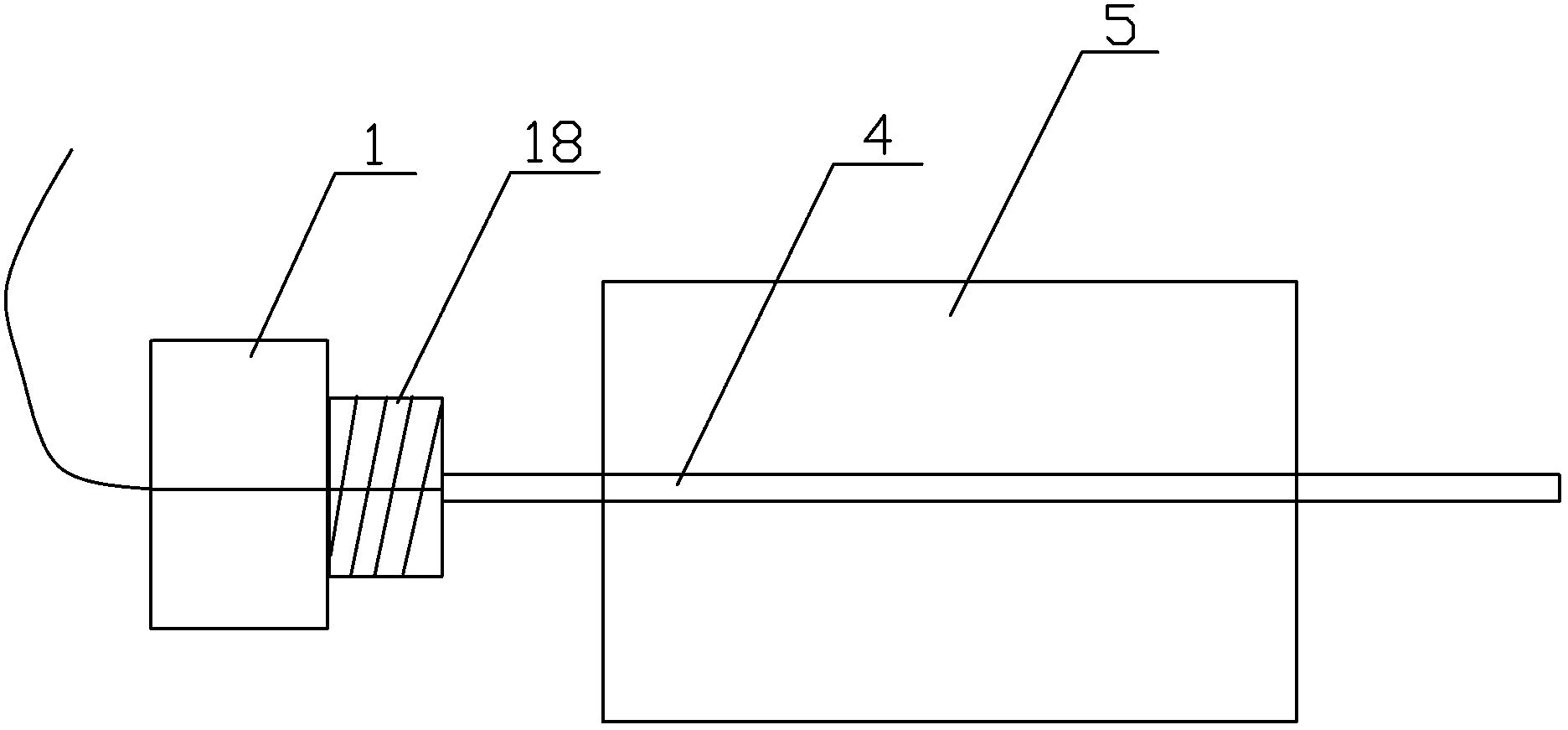

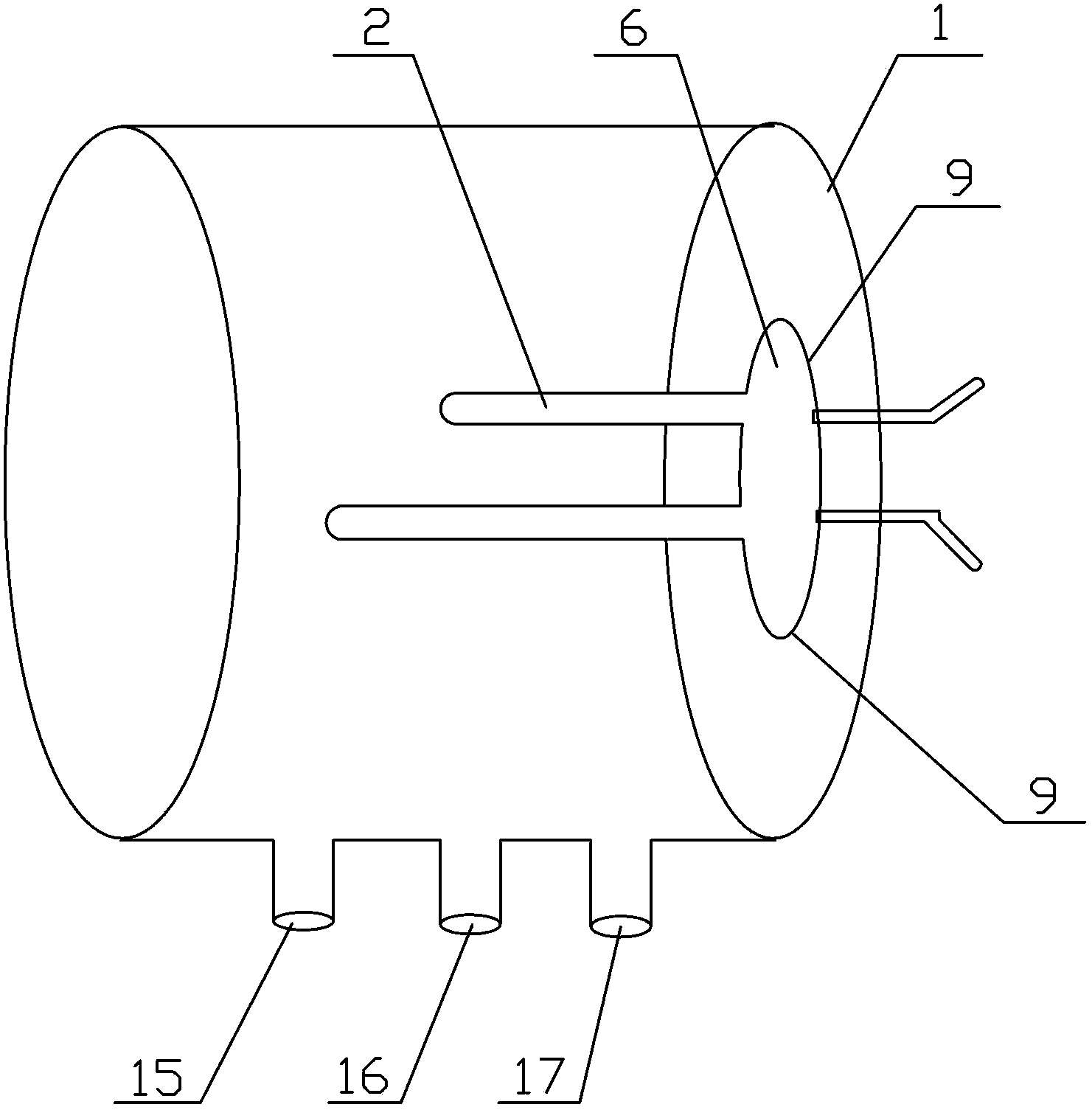

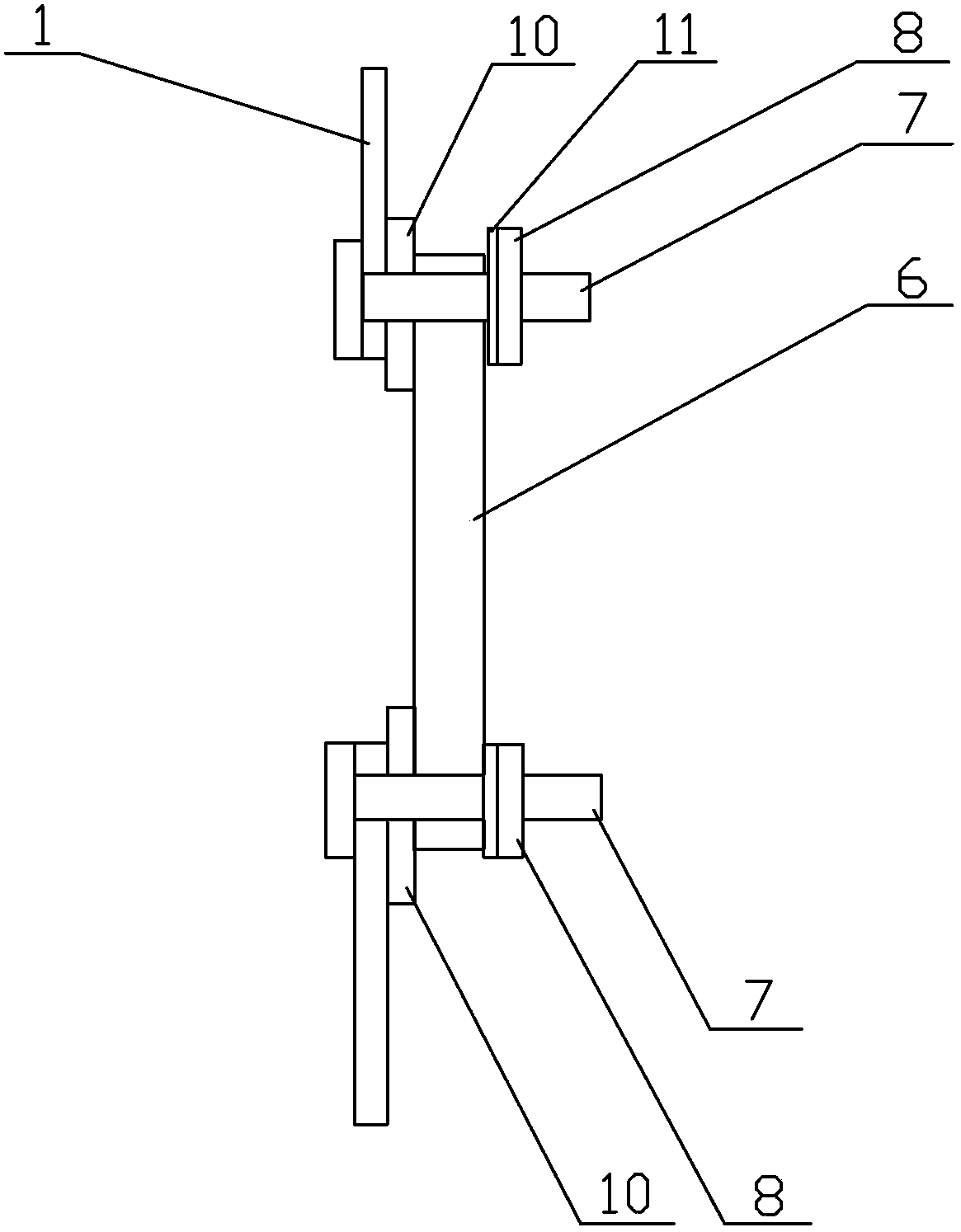

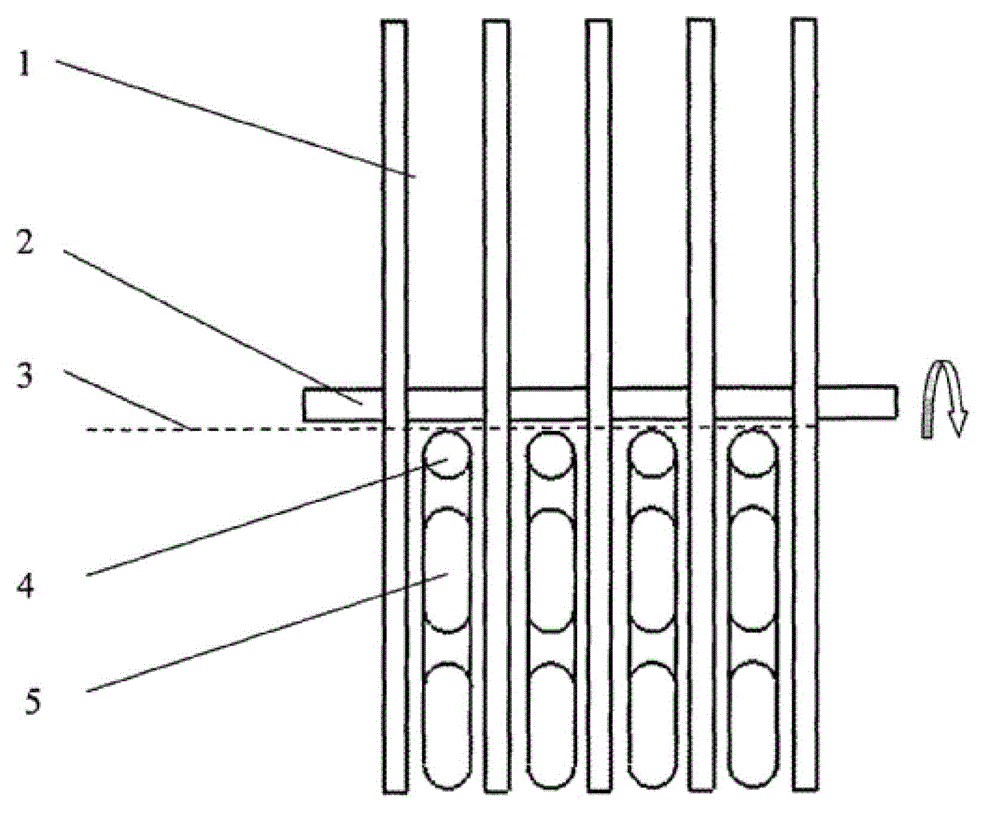

Chemical composite driving antiscaling soft plunger oil pump

ActiveCN101109376AReduce fouling speedImprove and improve adaptabilityPositive displacement pump componentsFlexible member pumpsEngineeringMechanical engineering

The invention discloses a chemical compound driving and antiscaling oil pump of soft plunger, which comprises a pump cylinder (5) and a plunger body (3). In the pump cylinder (5), the plunger body (3) is placed; in the plunger body (3), a central support (4) is placed. Out the central support (4) that is provided with a long strip-like hole, the inner layer of the liner for the plunger body (8), the outer layer of the liner for the plunger body (7), and a seal ring (6) are looped sequentially; the upper and lower end of the inner layer of the liner for the plunger body (8), the outer layer of the liner for the plunger body (7), and the seal ring (6) are provided with upper and lower lock nuts (10, 9); the central support (4) is threadedly connected with the upper and lower lock nuts (10, 9). The plunger oil pump can effectively prevent any pump blocking, prolong to the max. extent the time period between two maintenances, also improve the pump efficiency and reduce the production cost.

Owner:PETROCHINA CO LTD +1

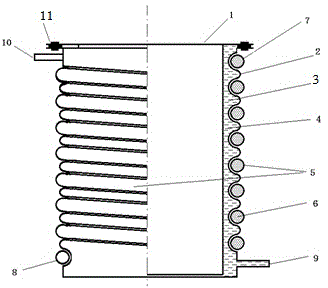

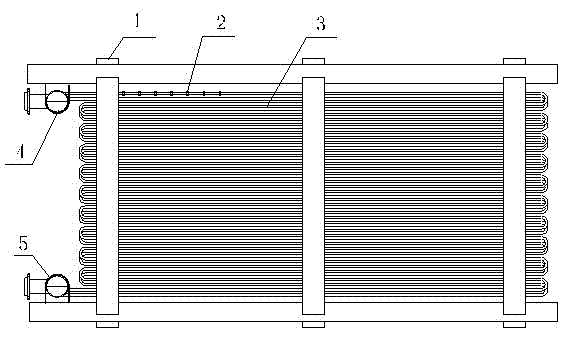

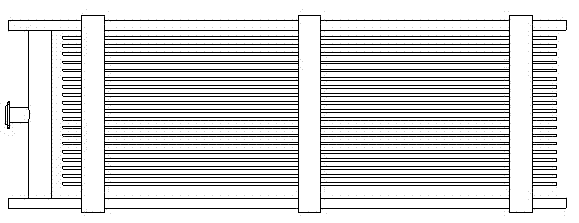

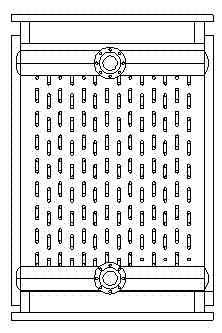

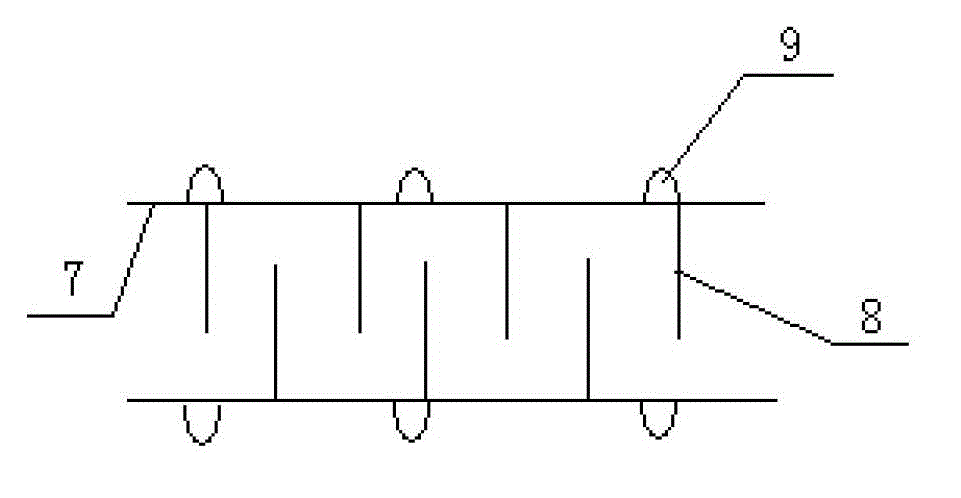

Anti-corrosive anti-scaling high-efficiency heat exchanger

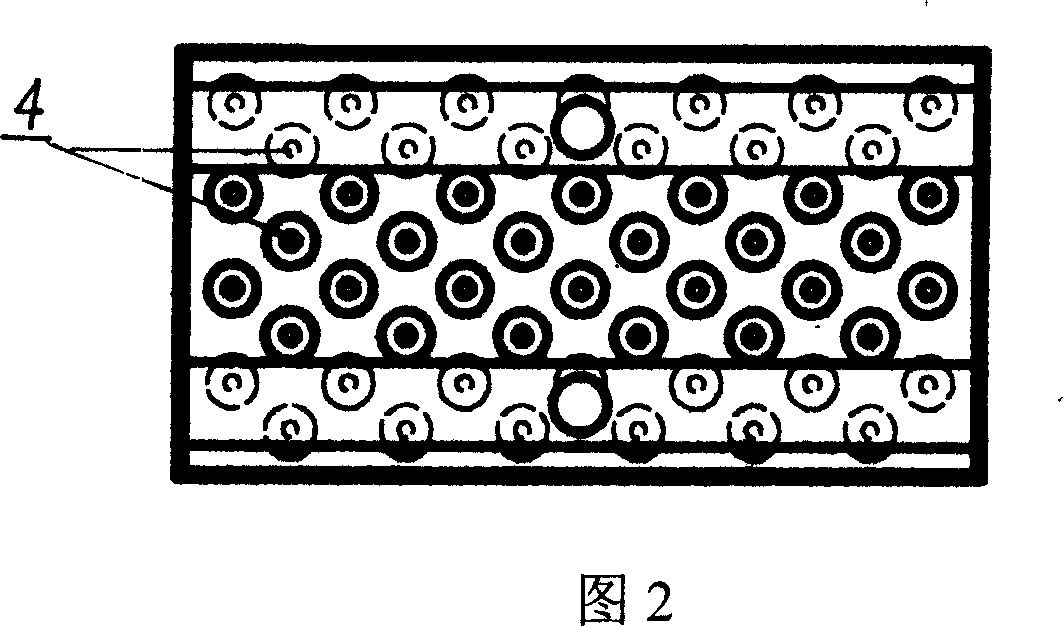

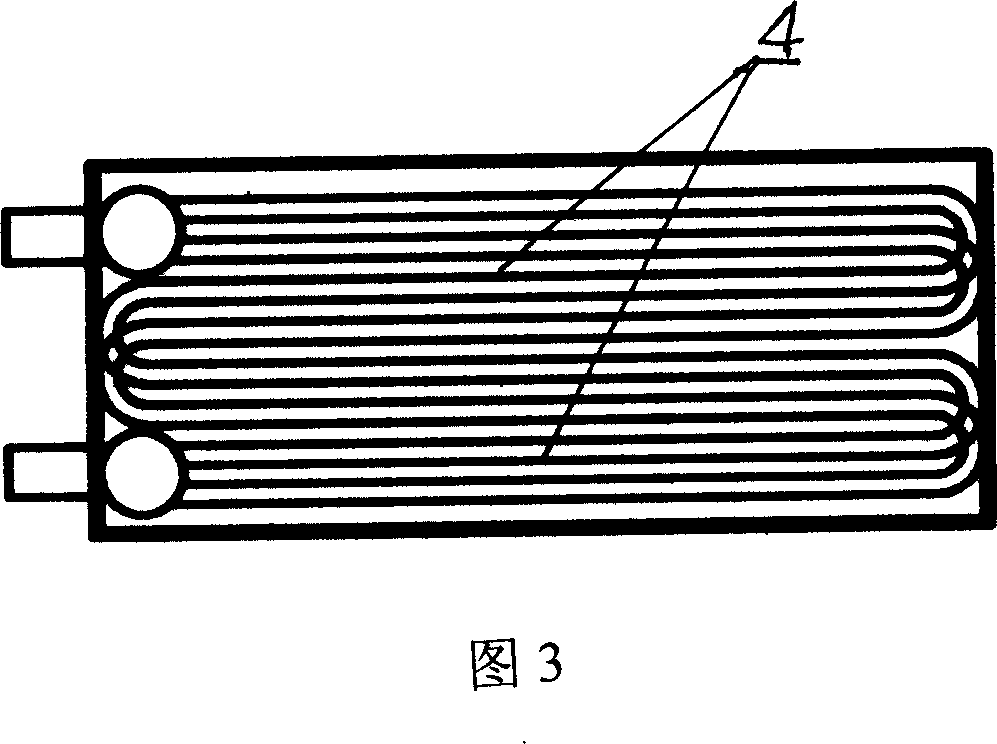

InactiveCN102654363AEasy maintenanceEasy to cleanCorrosion preventionStationary conduit assembliesHeat conductingMetallic materials

The invention discloses an anti-corrosive anti-scaling high-efficiency heat exchanger, mainly consisting of a support, descaling rings, a heat exchange coiled pipe, a heat exchanger inlet header and a heat exchanger outlet header, wherein the heat exchange coiled pipe is formed by stacking and alternatively arranging a plurality of heat exchange coiled pipe units, each heat exchange coiled pipe unit is manufactured through location of a location strip after two layers of snake-shaped coiled pipes are staggered, the heat exchange coiled pipe is made of a nonmetal material, and the nonmetal material includes but is not limited to polymer composite materials and modified heat-conducting composite materials. A plurality of descaling rings are suspended on each horizontal section of the heat exchange coiled pipe. The anti-corrosive anti-scaling high-efficiency heat exchanger has the advantages of effectively preventing corrosion of a heat exchanger used in different mediums, slowing down the time of scaling outside the heat exchange coiled pipe due to the arrangement of the descaling rings, and also improving the heat exchange effect of the heat exchanger, also has the advantages of compact structure, capability of mounting in a stacking manner, small overhaul space and the like, and can be widely applied to heat exchange occasions of different fluids.

Owner:陈建伟

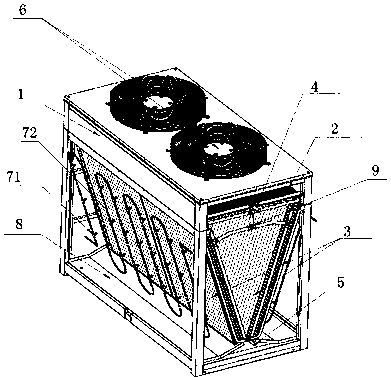

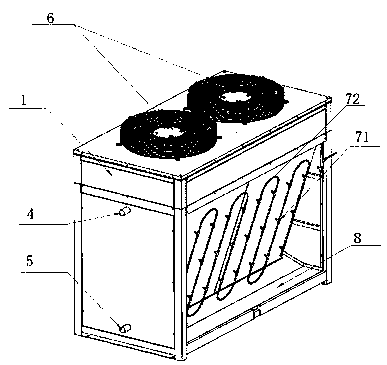

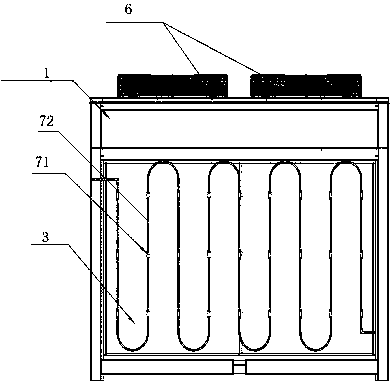

Pre-cooling spray evaporation type condenser

InactiveCN108709341AIncrease heat transfer contact areaSmall footprintEvaporators/condensersEvaporationEngineering

The invention discloses a pre-cooling spray evaporation type condenser. A pre-cooling heat exchange fin coil and two groups of condensation heat exchange fin coils are arranged in a condenser shell, and the two groups of condensation heat exchange fin coils are arranged in the condenser shell in a V shape; a refrigerant is circulated in a pipe of the pre-cooling heat exchange fin coil and pipes ofthe condensation heat exchange fin coils, water mist spray devices are located on the two sides of the two groups of condensation heat exchange fin coils, and an air outlet device is located at the top of the condenser shell. The condenser has the advantages that sprayed water mist is uniformly attached to and makes full contact with the surfaces of fins and the surfaces of the coils along with flowing of air for heat absorption and evaporation, the heat of the refrigerator in the condensation heat exchange fin coils is brought away, the heat exchange efficiency is high, and the size of equipment is small; the pre-cooling heat exchange fin coil pre-cools and cools the refrigerant entering the condensation heat exchange fin coils, the scaling efficiency of the condensation heat exchange fin coils is reduced, the later maintenance work is reduced, and meanwhile the production cost is reduced.

Owner:CHENGDU COMMON PIPE IND GRP CO LTD

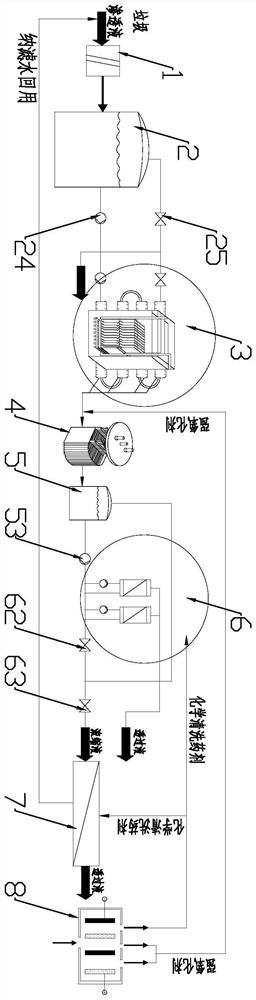

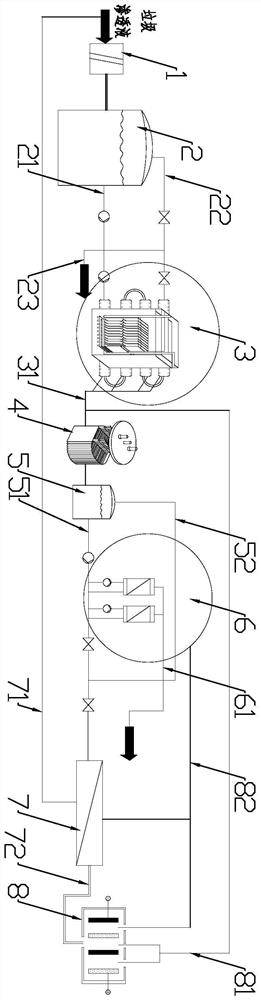

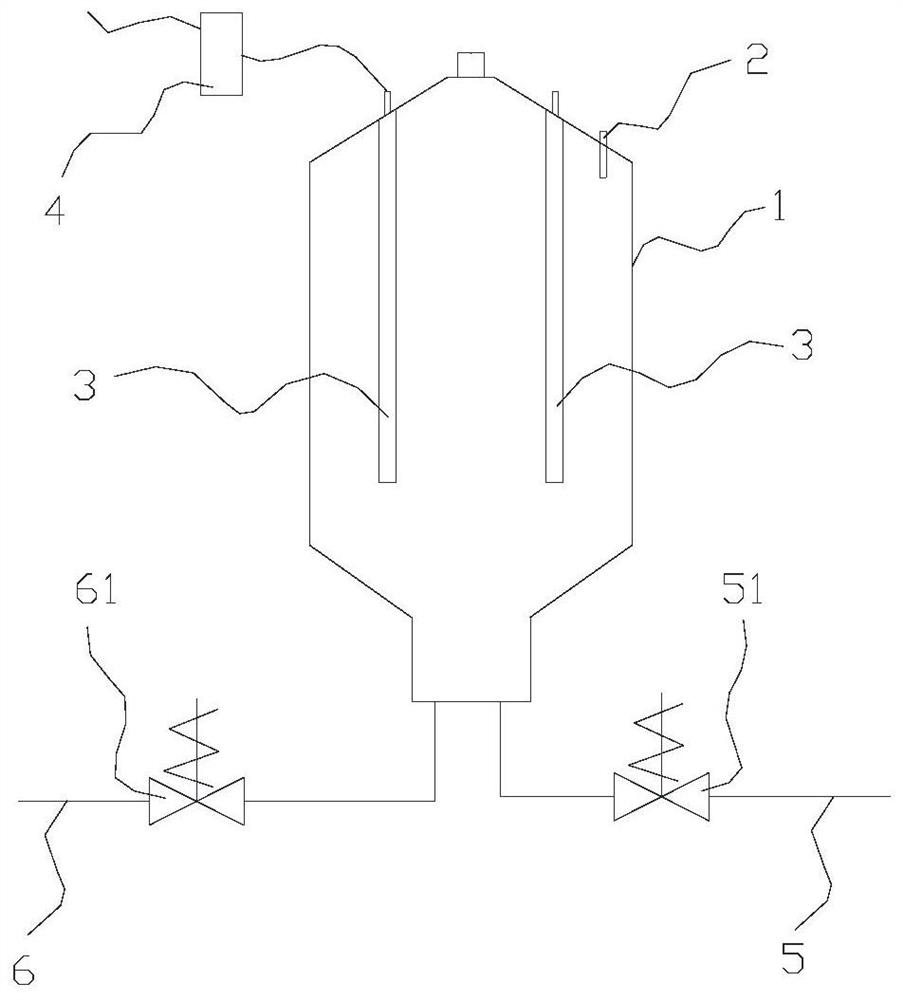

Comprehensive gasified grey water treatment and recovery device and method

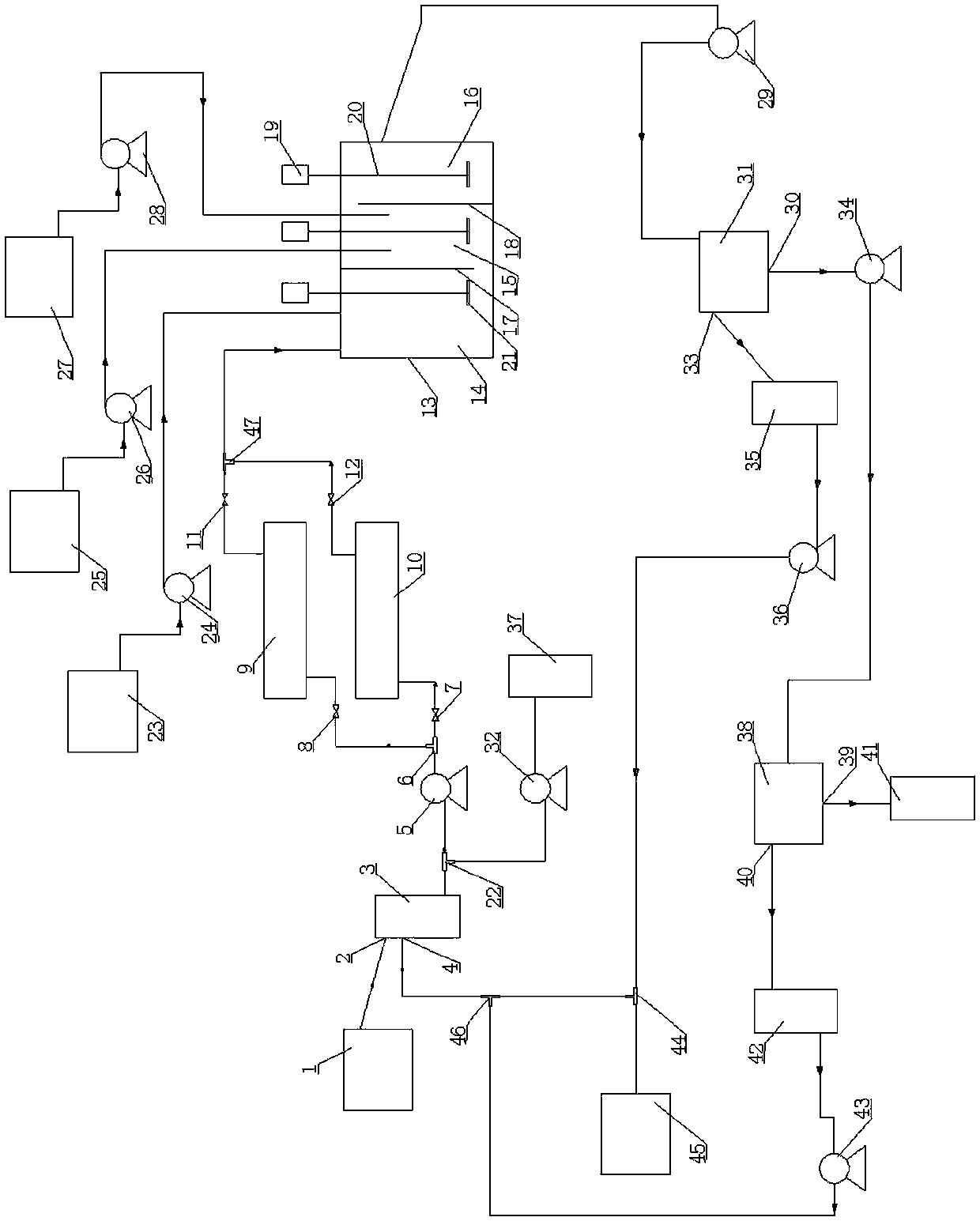

PendingCN110272151AReduce hardnessIncrease profitSludge treatment by de-watering/drying/thickeningWater contaminantsRecovery methodHardness

The invention belongs to a comprehensive gasified grey water treatment and recovery device and method. The device comprises a grey water clarifying tank connected with a gasification system, wherein a supernatant outlet of the grey water clarifying tank is connected with a grey water circulating system of the gasification system through a first inlet and fifth tee of the grey water tank and a 2# grey water pump; the third end of the fifth tee is connected with an inlet of one side of a dosing reaction tank through a 1# grey water pump and a 1# heat exchanger, an outlet of the other side of the dosing reaction tank is connected with the clarifying tank through a 1# lifting pump, an overflow port in the upper part of the clarifying tank is connected with a clear liquid tank, the clear liquid tank is connected with a sewage treatment system through a 2# lifting pump and a first tee, and the first tee is connected with a second inlet of the grey water tank through a second tee. The device has the advantages that ions Ca 2+, Mg 2+ and Si 2+ in grey water can be effectively removed on the premise of ensuring long-period stable running of a gasification device, the hardness of the grey water is reduced, the grey water is recycled, and the scaling rates of grey water equipment and pipelines are reduced.

Owner:HENAN XINLIANXIN FERTILIZER

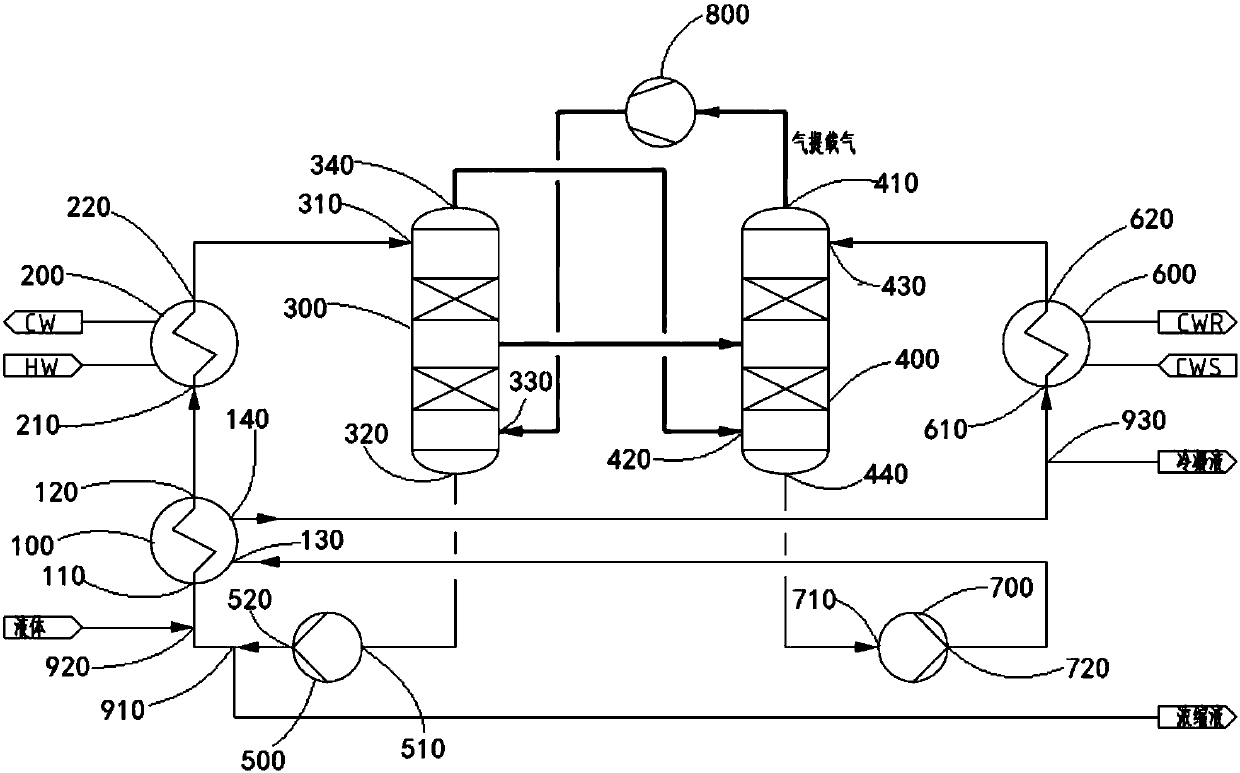

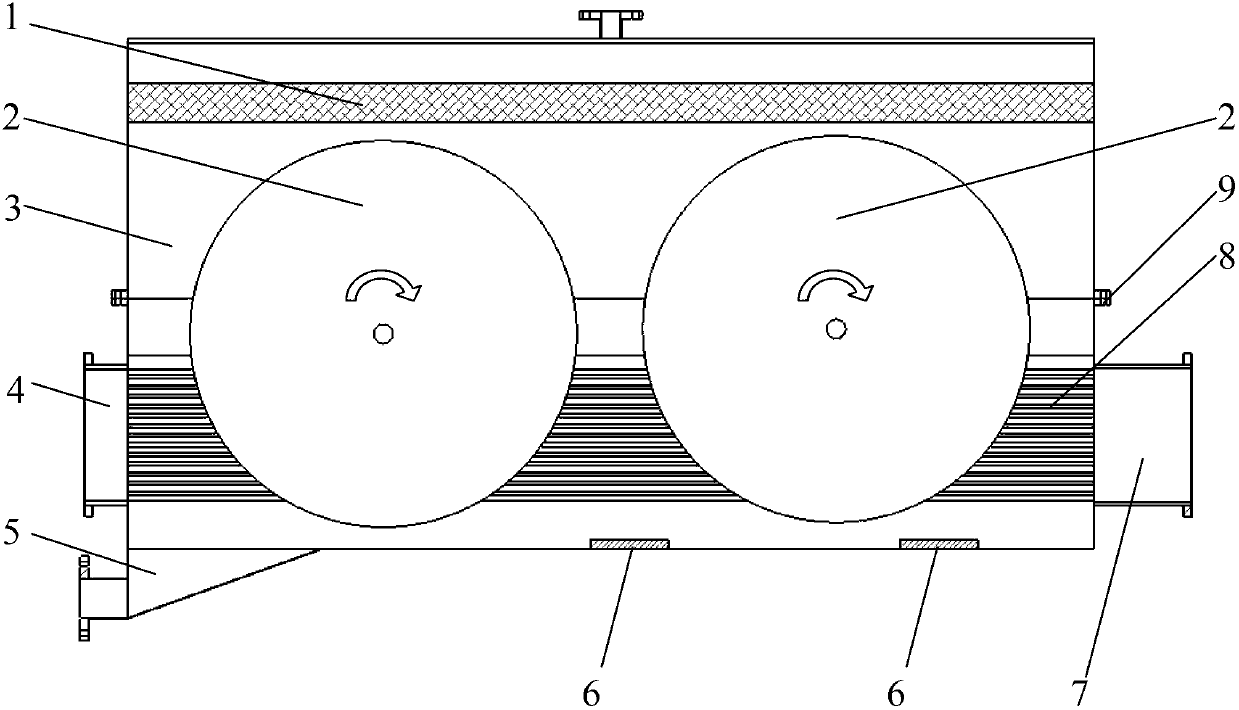

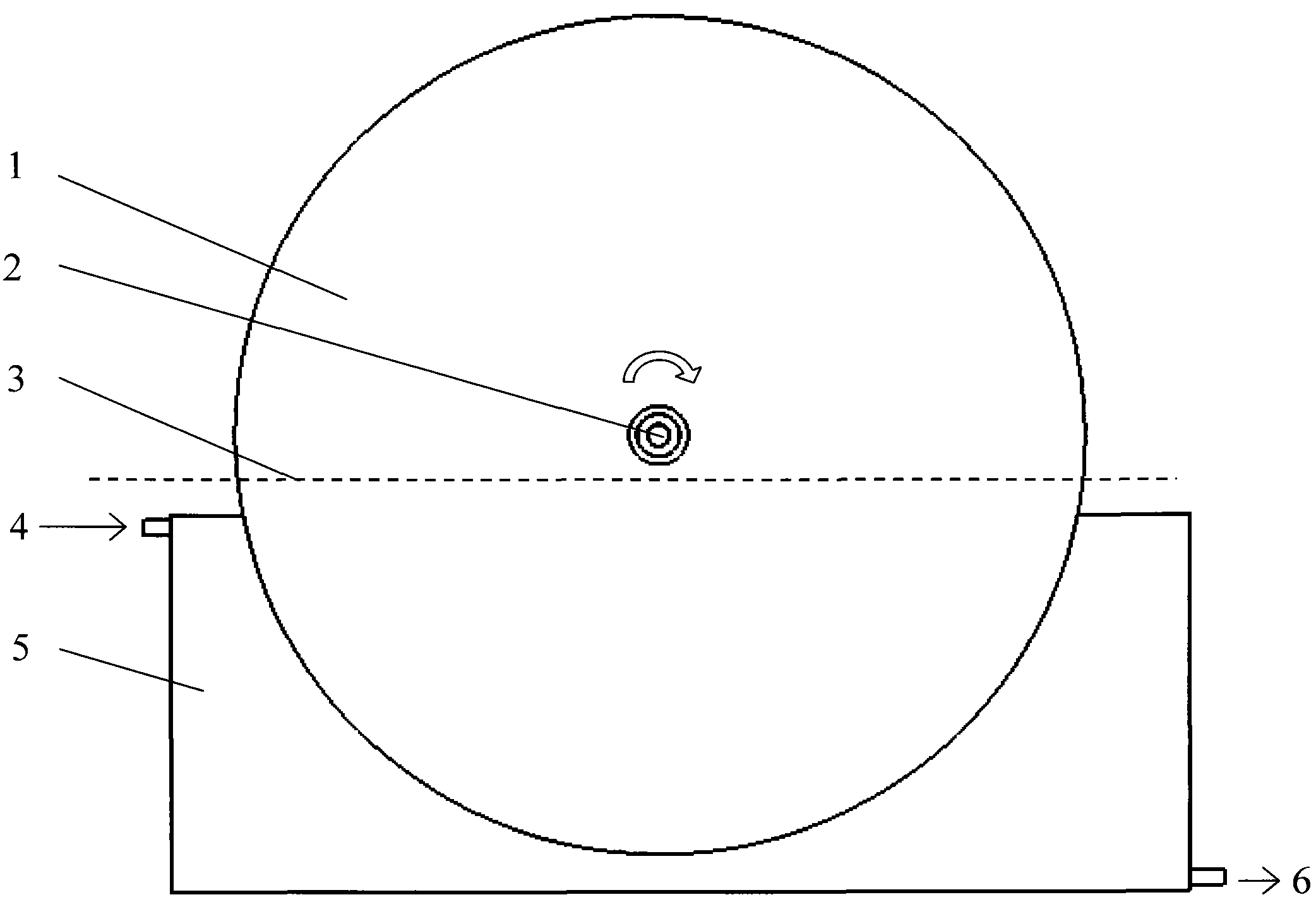

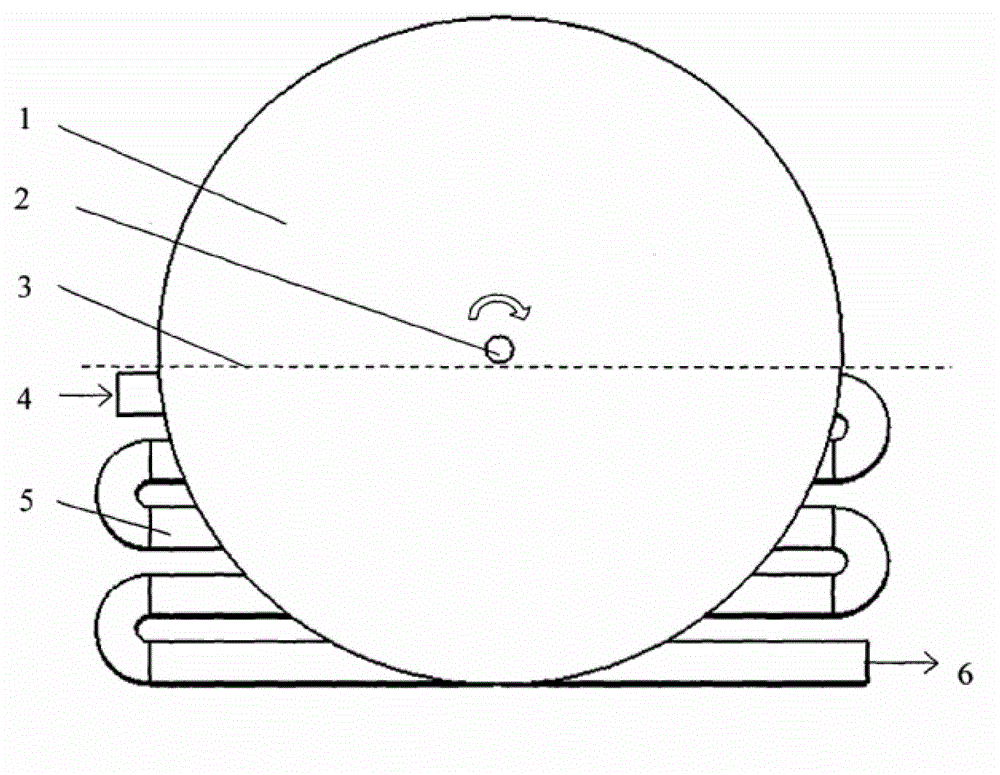

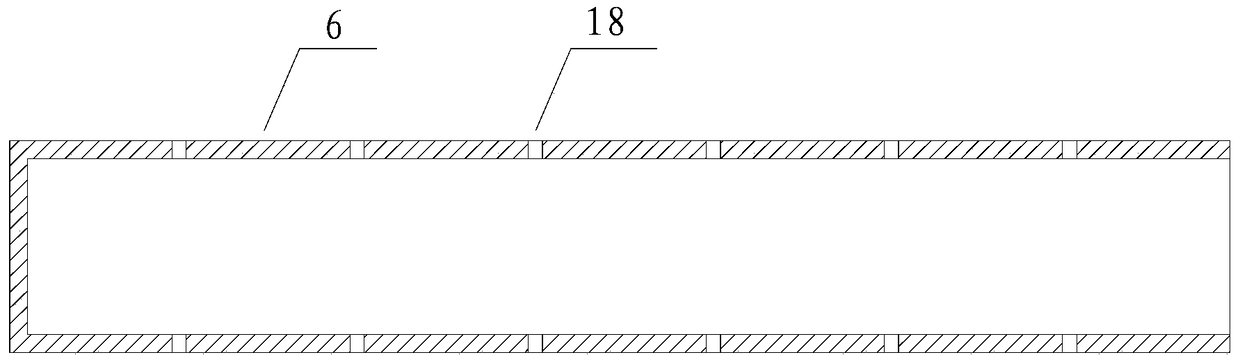

Novel combination type evaporation condenser

InactiveCN102849810AReduce lossesReduce fouling speedSteam/vapor condensersWater/sewage treatment by heatingEvaporationEngineering

The present invention discloses a novel combination type evaporation condenser, wherein the novel combination type evaporation condenser is suitable for simultaneous existence of an evaporation heat exchange process and a condensation heat exchange process. The novel combination type evaporation condenser comprises a container connected through flanges, rotation evaporation disks, and condensation pipes, wherein the rotation evaporation disk is driven by a rotation shaft, comprises a plurality of disk surfaces, and is provided for providing an evaporation effect, and the condensation pipes are arranged parallel to the disk surface of the rotation evaporation disk. The novel combination type evaporation condenser is characterized in that the condensation pipes are distributed in a straight line manner, the two sets of the rotation heat exchange disks and the condensation pipes are staggeredly arranged in a small interval. According to the novel combination type evaporation condenser of the present invention, the evaporator and the condenser are integrated, a structure is compact, and heat exchange efficiency is high.

Owner:BEIHANG UNIV

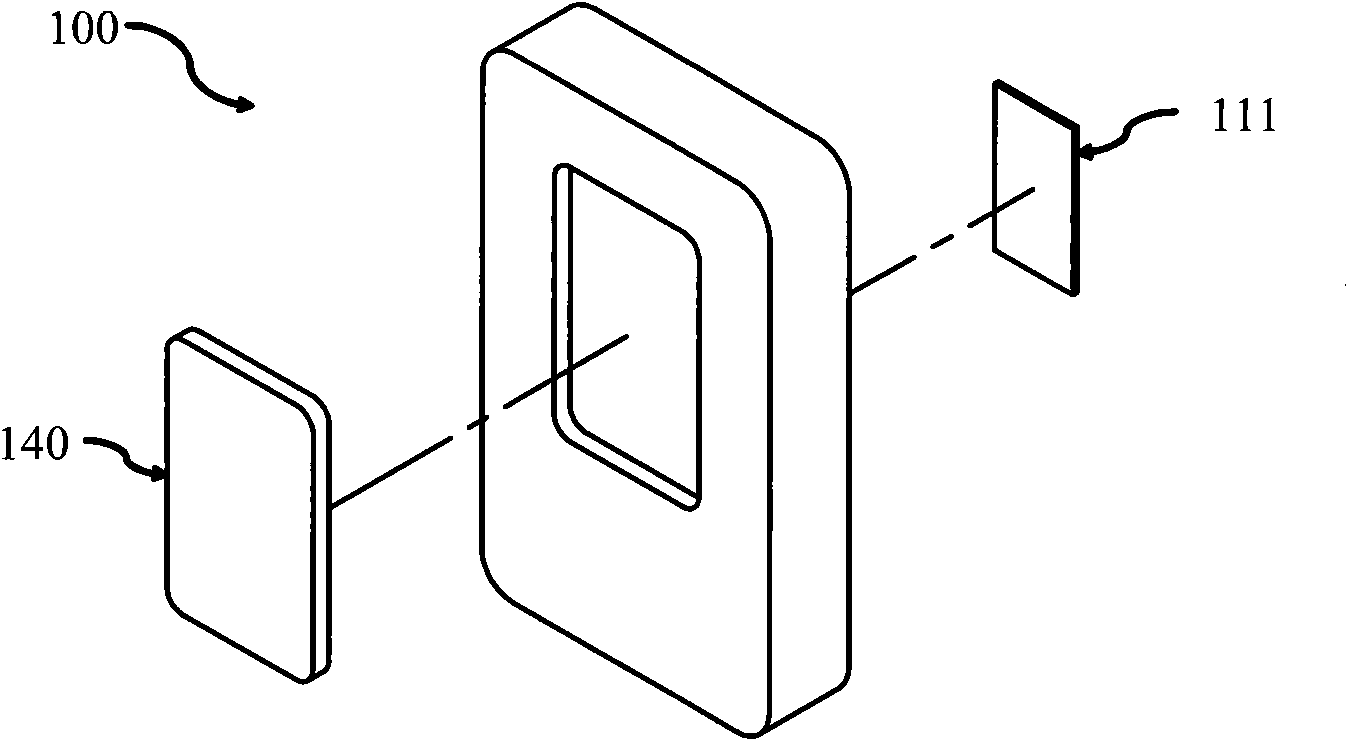

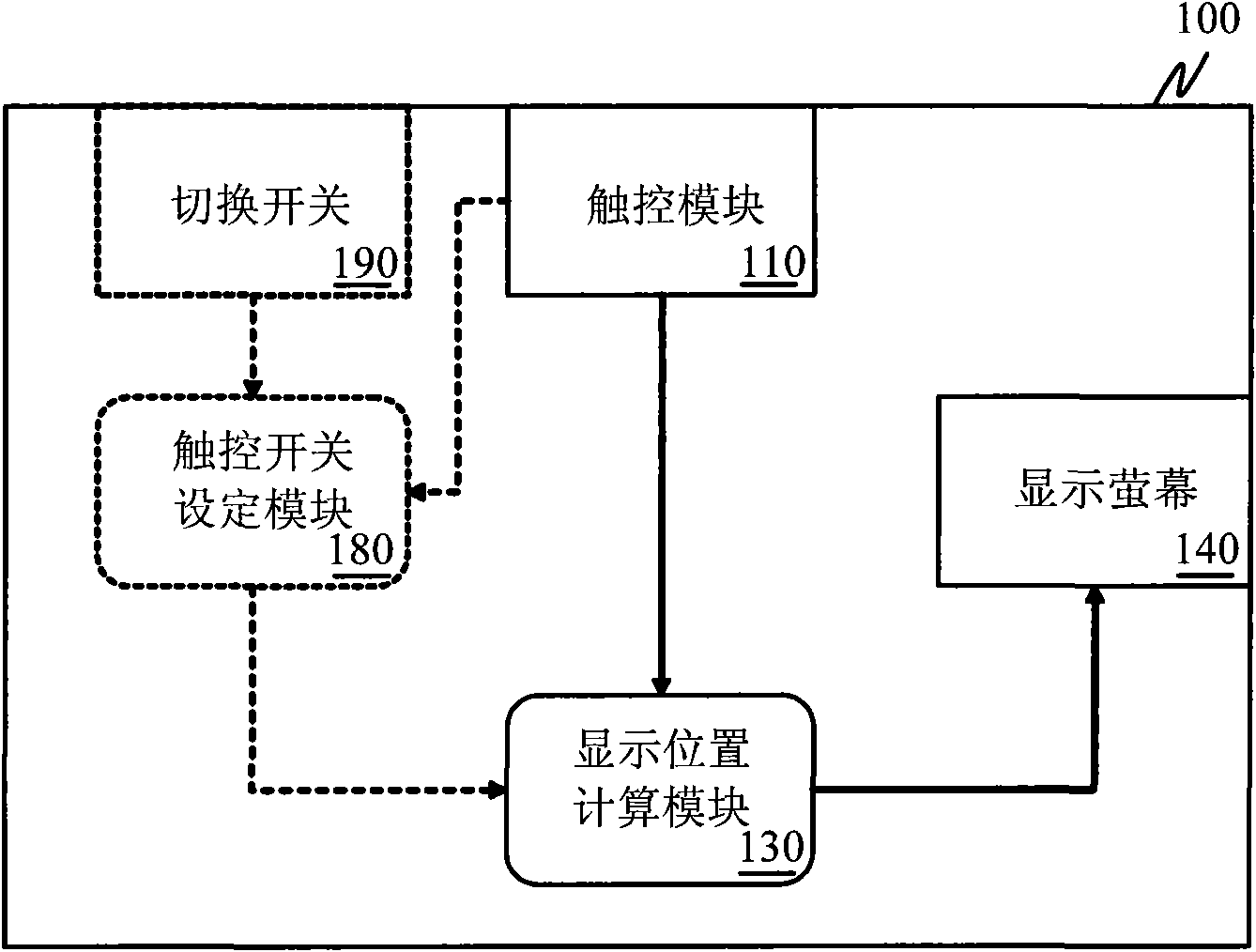

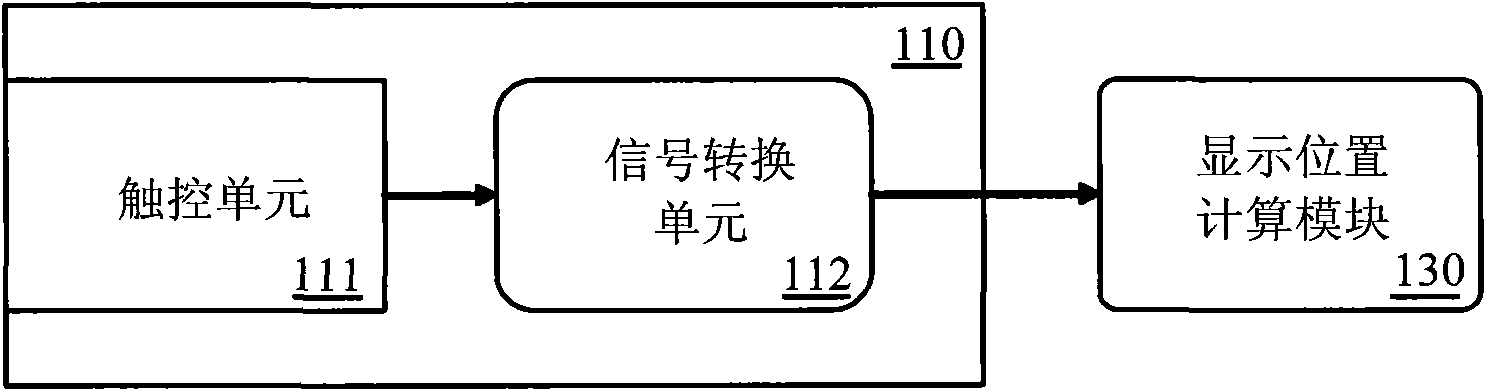

Portable device with input and display at two opposite sides and operation method thereof

InactiveCN101957631AReduce fouling speedDoes not affect viewing line of sightDigital data processing detailsSubstation equipmentEmbedded systemControl unit

The invention discloses a portable device with input and display at two opposite sides and an operation method thereof. A display screen is embedded in the front of the portable device, a touch control unit is embedded in the back of the portable device, and the display position of a target in the display screen can be calculated according to touch control activity input on the touch control unit so that the view is not influenced during carrying out touch control activity, and the technical efficacy of reducing the soiling speed of the display screen is achieved.

Owner:INVENTEC CORP

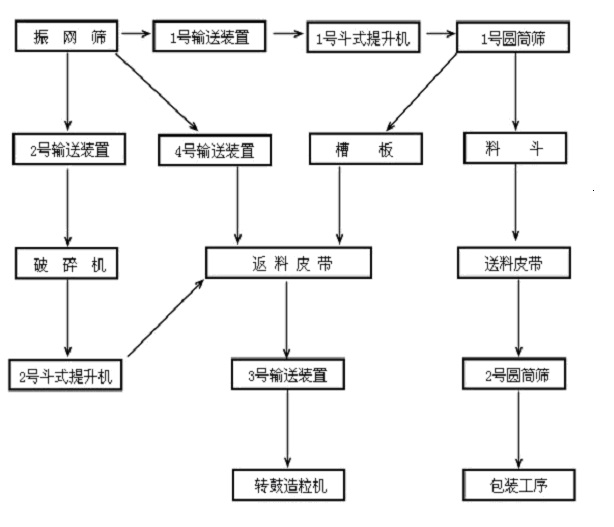

Monoammonium phosphate particle screening system

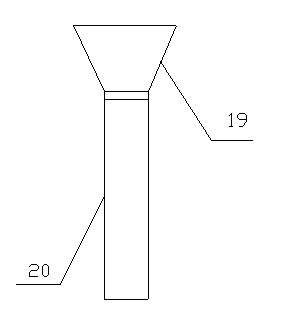

InactiveCN101863684AReduce fouling speedExtended service lifeAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateEngineering

The invention discloses a monoammonium phosphate particle screening system belonging to the field of corollary equipment of compound fertilizer production technology. The screening system is realized by the following devices and a connecting mode and is formed by successively connecting a meshwork vibrating screen, an transporter 1, an bucket elevator 1, an drum sieve 1, a hopper, a feeding belt and an drum sieve 2, wherein the large granulometric class returning port of the meshwork vibrating screen, an transporter 2, a crusher, an bucket elevator 2, a returning belt, an transporter 3 and a comminutor are successively connected; the small granulometric class returning port of the meshwork vibrating screen is connected with an transporter 4 and is arranged above the returning belt; and a trough plate is arranged below the small granulometric class returning port of the drum sieve 1, and one end of the trough plate downwards inclines and is arranged above the returning belt. The screening system overcomes the defects that the built-in screening system is easy to scale, frequently overhauls and has short use period, and the appearance of the screened product is poor; and the invention ensures the appearance quality of the particle while improving the yield of the monoammonium phosphate particle and adjusts the product particle grade to be produced as required.

Owner:SICHUAN YINGFENG IND

Electronic anticorrosion system of electric water heater

The invention discloses an electronic anticorrosion system of an electric water heater. The electronic anticorrosion system comprises a power source, an inner container, a heating bar, an anode and a titanium bar. The anode and the heating bar are fixed on the inner container, the lower end of the anode is connected with the titanium bar, the anode is connected with the positive electrode of the power source, the inner container is connected with the negative electrode of the power source, and the heating bar, the anode and the inner container are fixedly connected in an insulation mode. Compared with traditional magnesium bar anticorrosion, the electronic anticorrosion system is good in anticorrosion effect, no more dirty can be generated on the heating bar due to corrosion of magnesium, although the electronic anticorrosion system creates an electrode environment for the water environment in the inner container, the cathode and the anode of the heating bar are separated in an insulating mode, and therefore the heating bar can not be corroded, and the scaling speed of the heating bar is greatly relieved.

Owner:何刚

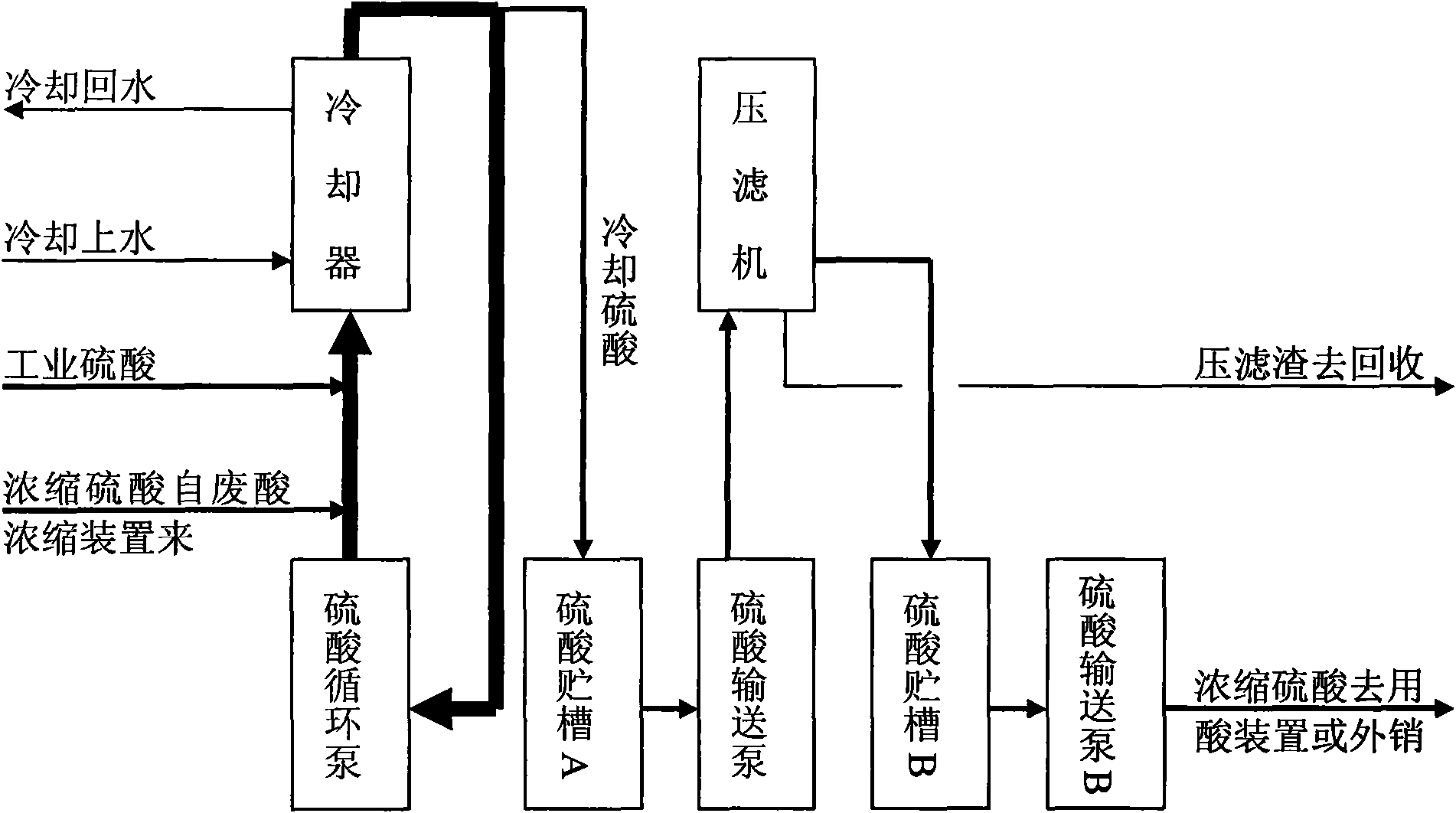

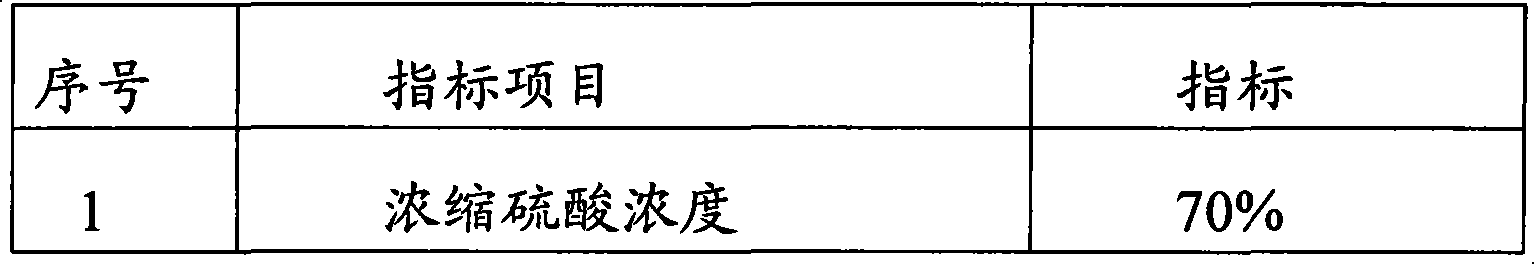

Method for recycling waste product and by-product in sulfuric acid method titanium dioxide production

ActiveCN101618864AEasy to produceLow investment costSulfur-trioxide/sulfuric-acidFiltrationEconomic benefits

The invention relates to a method for recycling the waste product and by-product in sulfuric acid method titanium dioxide production which adopts a forced circulation system which contains a sulfuric acid circulating pump, a cooler and recycle acid pipelines to cool and mix sulfuric acid, and combines the processes of refrigeration, purification and preparation of concentrated sulfuric acid in the sulfuric acid method titanium dioxide production to only one process through filtration, thus greatly simplifying the production process and reducing the production cost and investment. Because the invention adopts big flow forced circulation technology, the temperature of circulating sulfuric acid and the temperature difference are lower so that the demand to the material of the sulfuric acid circulating pump is reduced and the service life is prolonged; besides, the flow velocity on the sulfuric acid side of the cooler in the forced circulation technology is higher so that the scaling forming speed on the sulfuric acid side of the cooler is slower and the operation rate is higher. The invention solves the problems of the sulfuric acid method titanium dioxide production that the flows of refrigeration, purification and preparation of concentrated sulfuric acid are long, the investment is large, the operation rate is low, the production cost and the maintenance cost are high and the like, and the obtained economic benefit is remarkable.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

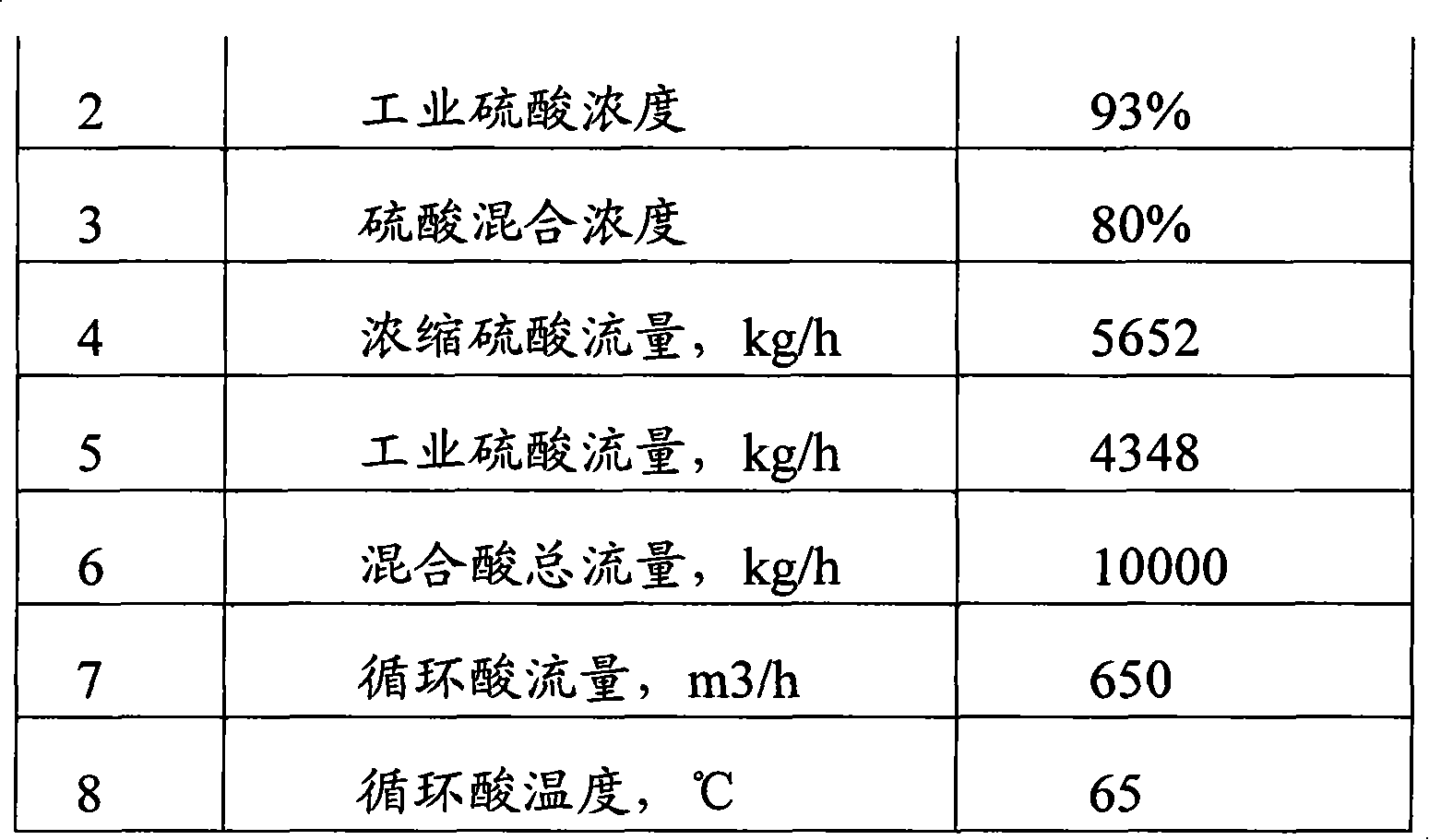

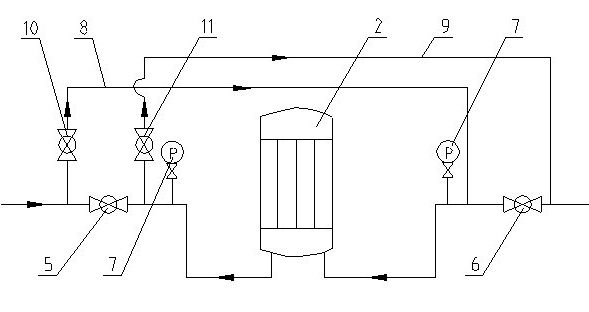

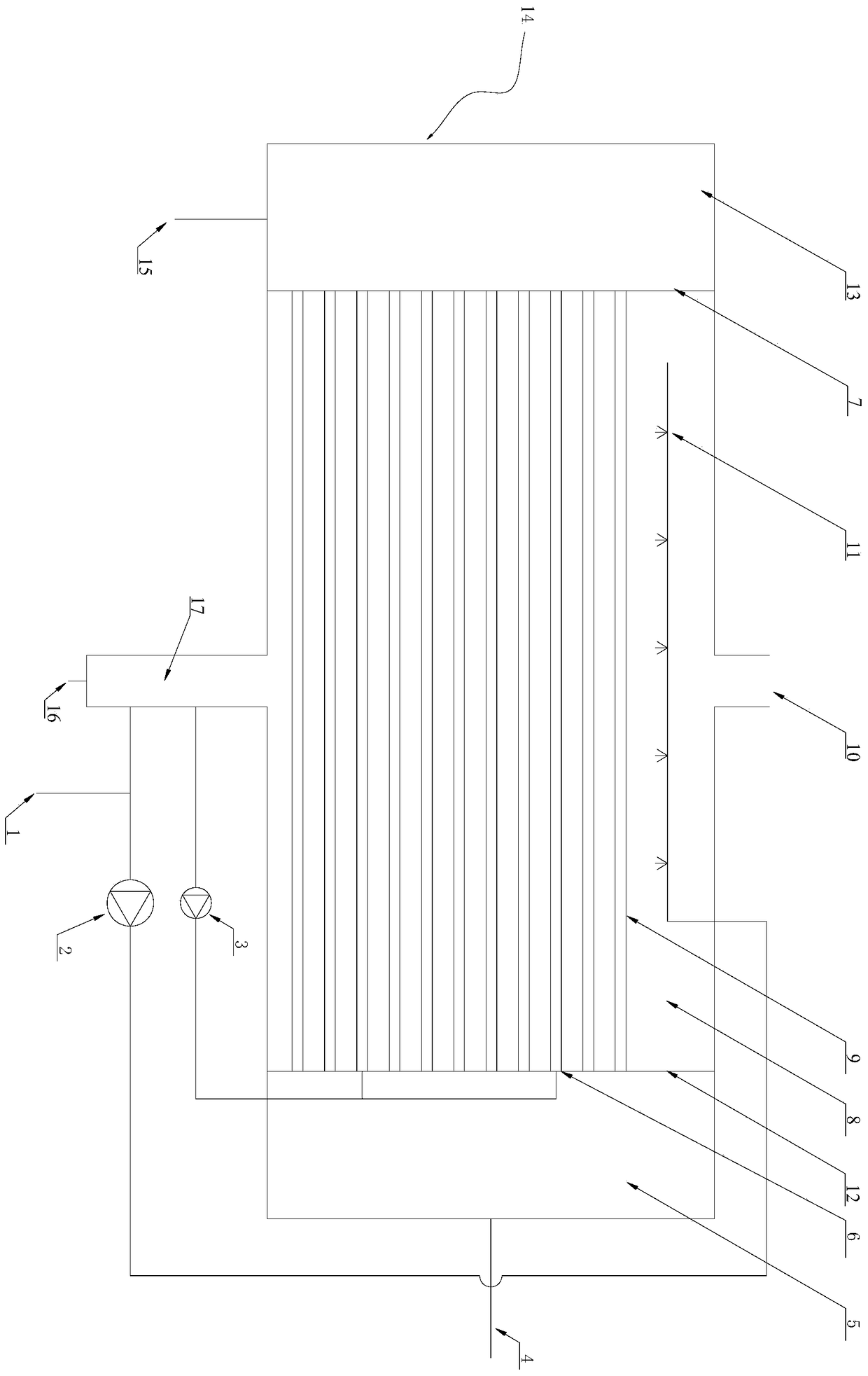

Cooling water system of refrigerating machine of ocean vessel

InactiveCN102564008AReduce dirty cloggingSolve the problem of prone to damageLighting and heating apparatusCooling fluid circulationFailure rateOperational reliability

The invention relates to a cooling water system of a refrigerating machine of an ocean vessel. The cooling water system comprises a cooling water circuit, a water pump (1) and a condenser (2) are arranged on the cooling water circuit, a filter (3) is disposed between the water pump (1) and the condenser (2), a valve I (5) is arranged on a water inlet pipe of the condenser (2), a valve II (6) is arranged on a water outlet pipe of the condenser (2), a backwash pipeline I (8) is arranged between the front end of the valve I (5) and the front end of the valve II (6) in a connection manner, a backwash pipeline II (9) is arranged between the rear end of the valve I (5) and the rear end of the valve II (6) in a connection manner, a valve III (10) is disposed on the backwash pipeline I (8), and a valve IV (11) is disposed on the backwash pipeline II (9). The cooling water system of the refrigerating machine of the ocean vessel has the advantages that failure rate of refrigerating machine equipment is reduced, maintenance expense of the equipment is saved, running reliability of the equipment is improved, and workload of maintenance staff is greatly reduced.

Owner:UNIT 63680 OF PLA

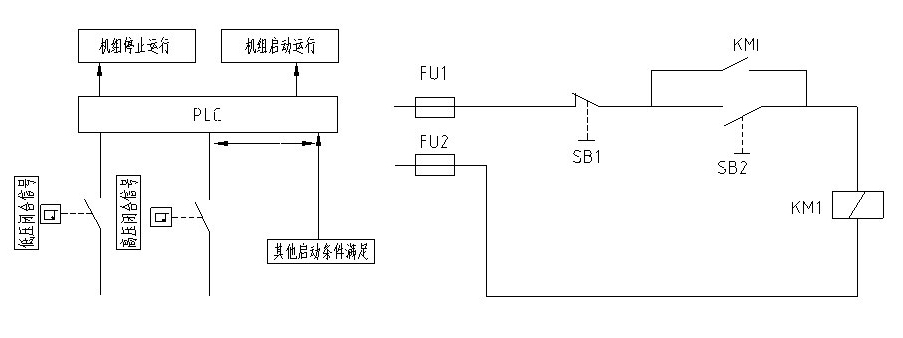

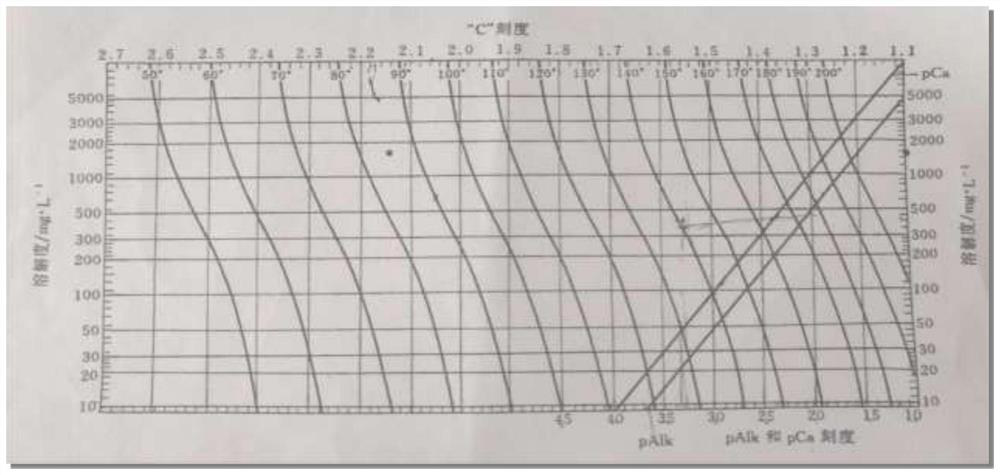

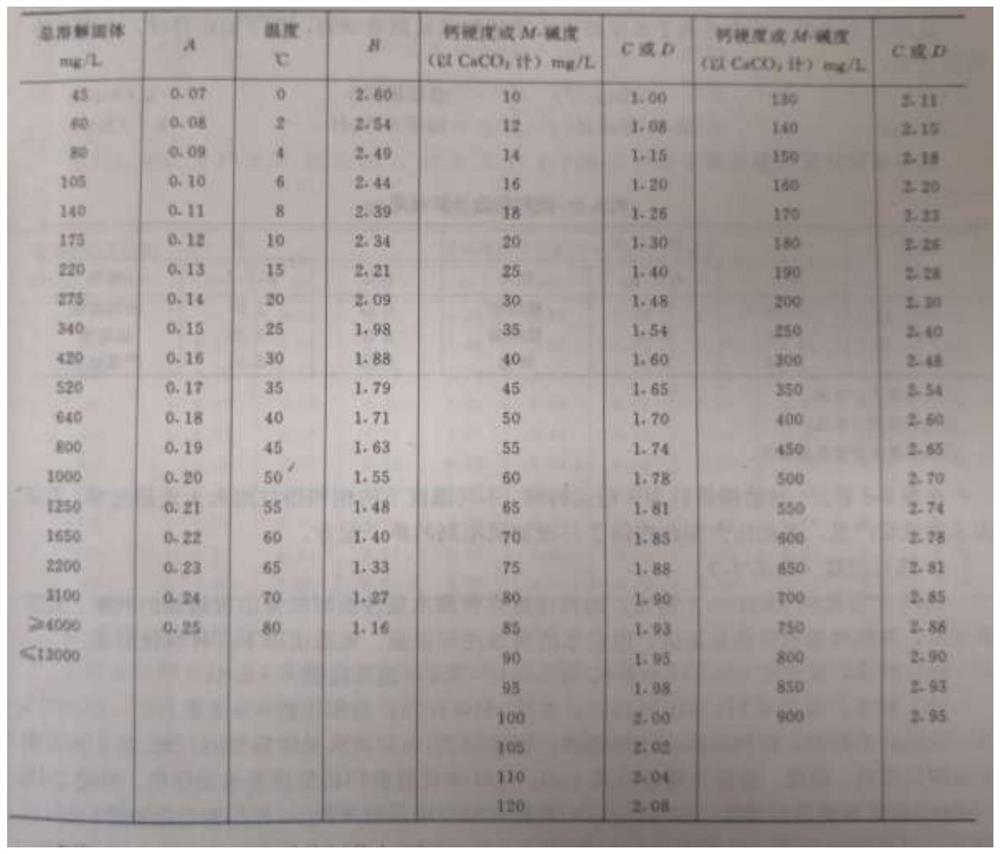

Central air conditioner cooling circulating water treatment comprehensive control treatment method

ActiveCN112010405AThe treatment process is scientific and reasonableEasy to handleWater treatment parameter controlWater contaminantsControl treatmentWater resources

The invention discloses a central air conditioner cooling circulating water treatment comprehensive control treatment method, and belongs to the field of water treatment of industrial circulating water cooling systems. The method comprises the following steps: analyzing calcium ion concentration, chloride ion concentration, pH value, alkalinity, conductivity and the like in make-up water and circulating cooling water, calculating a saturated pH value through a table look-up method and a graph look-up method, calculating the saturated pH value through a formula of pHs=9.7+A+B-C-D and a formulaof pHs=PCa+PMALK+C, then calculating a stability index through a formula that S=2pHs-pH, calculating the concentration multiple, the evaporation capacity, the water replenishing capacity and the sewage discharge capacity of the cooling circulating water according to the total alkalinity (mg / L) measured value and the like, formulating a comprehensive water treatment table, according to comparison of the calculated stability indexes, and carrying out comprehensive data processing in combination with control indexes such as calcium ions and hardness, so that the reasonable dosing amount and pollution discharge time are determined, blindness of dosing and pollution discharge of conventional central air conditioner water treatment is reduced, the accuracy of the dosing amount and the pollutiondischarge amount is improved, and waste of water treatment agents and water resources is reduced.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

Cooling tower control method and system used for central air-conditioner system

ActiveCN112665443ALower the water temperatureImprove cooling effectMechanical apparatusEfficient regulation technologiesCentral air conditioningCooling water temperature

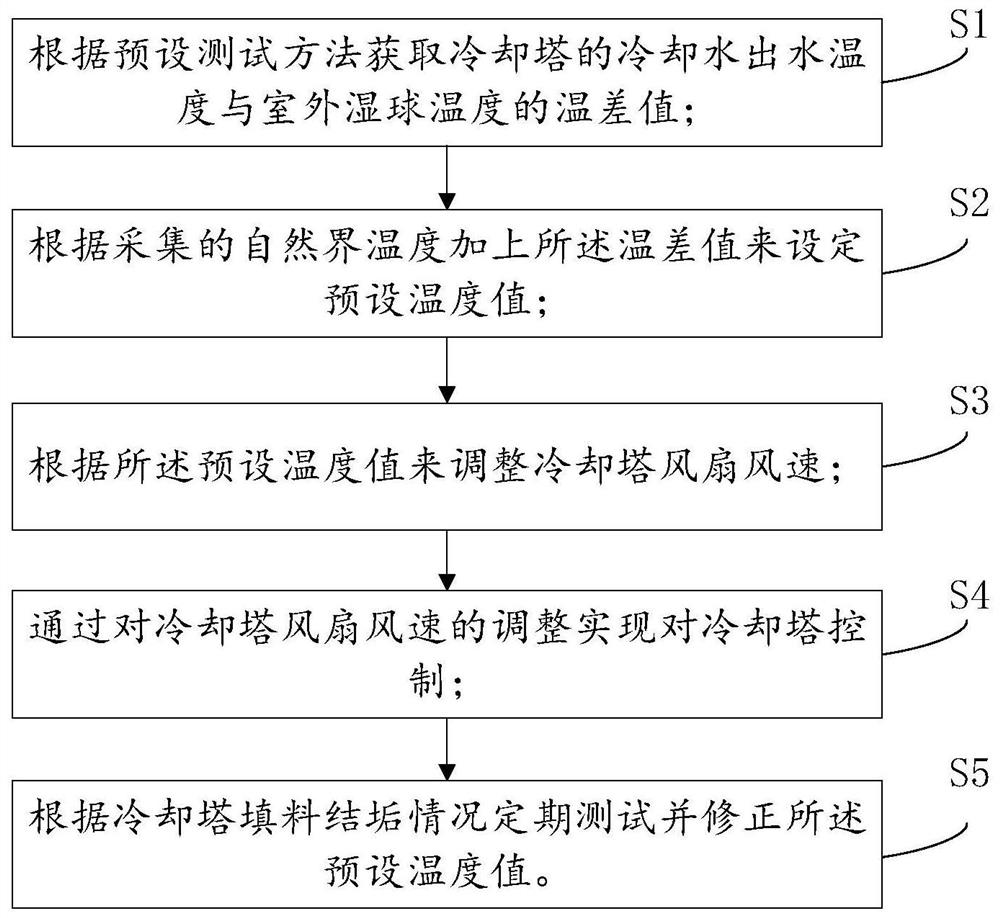

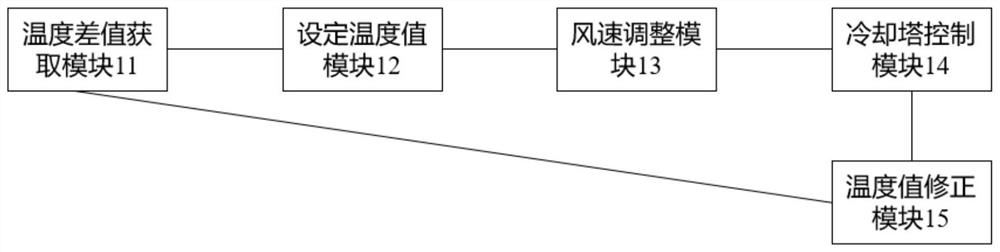

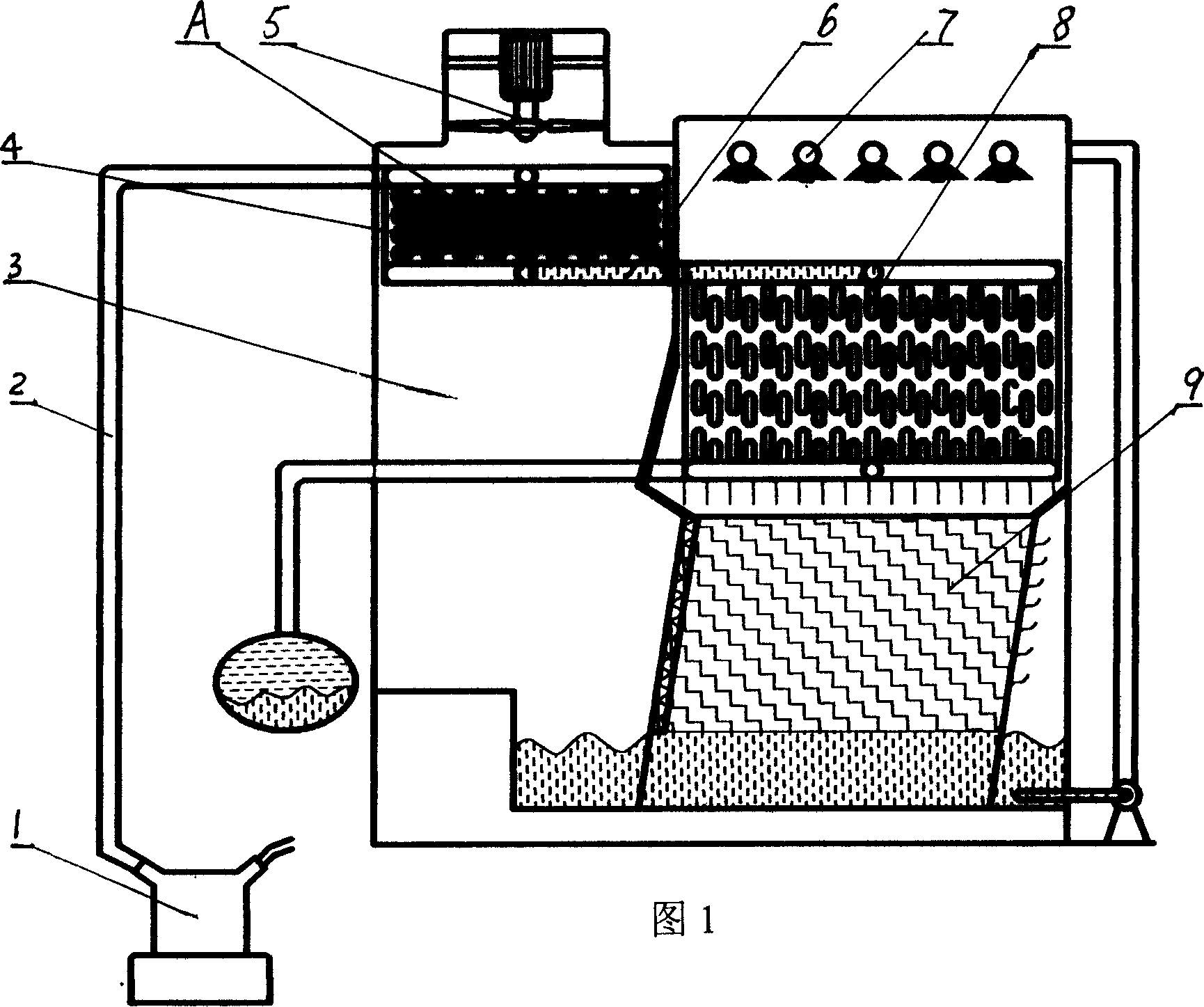

The invention discloses a cooling tower control method and system used for a central air-conditioner system, and relates to the field of refrigerating unit cooling water temperature control. The method comprises the following step: according to a preset testing method, acquiring a temperature difference value of a cooling water outlet temperature of cooling towers and an outdoor wet bulb temperature, according to a collected nature temperature and the temperature difference value, setting a preset temperature value, according to the preset temperature value, adjusting the wind speed of fans of the cooling towers, and controlling the cooling towers by adjusting the wind speed of the fans of the cooling towers. Refrigerating units give play to the maximum refrigerating capacity, the water outlet temperature of the cooling towers is reduced furthest, the efficiency of the refrigerating units is greatly improved, overall energy conservation and consumption reduction of a refrigerating station are achieved, and the overall refrigerating efficiency of the refrigerating station is improved.

Owner:BEIJING CAPITAL AIRPORT POWER & ENERGY

Evaporation type condenser

InactiveCN1967096AImprove heat transfer coefficientNot easy to damageEvaporators/condensersEvaporative coolerRefrigerant

An evaporative condenser comprises a compressor, evaporating condenser, precooling disk channel inside the negative pressure cavity of the evaporative condenser, precooling disk channel at the lower part of the axial fan. When strong humid warm air exhaust from the major coiler of the condenser and heat exchanging layer into the negative pressure cavity going through the gap between the pre cooling coilers with quick evaporation, reducing the temperature of the coolant inside the pre cooling coiler, greatly reducing the scaling speed at the surface of the condenser coiler of the coolant, with endurable quality and long durability.

Owner:河南中轴集团有限公司

Cleaning synergist for heating supply system

The invention discloses a cleaning synergist for a heating supply system. The cleaning synergist specifically comprises thiourea, 5-chloro-2-methyl-4-isothiazolin-3-one, sodium nitrite, mercaptobenzothiazole, polyoxyethylene lauryl ether, zinc sulfate, diethylene triamine pentamethylene phosphonic acid, potassium chromate, sodium alginate, and the balance water. The invention further discloses a preparation method of the cleaning synergist. By the adoption of the strong cleaning synergist, a cleaning agent can be assisted in effectively and thoroughly cleaning away various rust spots, dirt and cured products attached to the inside of a boiler and the inside of a pipeline, and the scale formation speed of the boiler and the pipeline is decreased. The cleaning synergist for the heating supply system is high in acidity and good in water solubility, has no toxicity to human bodies, has no corrosiveness to the boiler and the pipeline, can remarkably improve the heat efficiency of the boiler and the pipeline, and is simple in preparation process, convenient to operate and safe and reliable to use.

Owner:科谱研发技术中心(青岛)有限公司

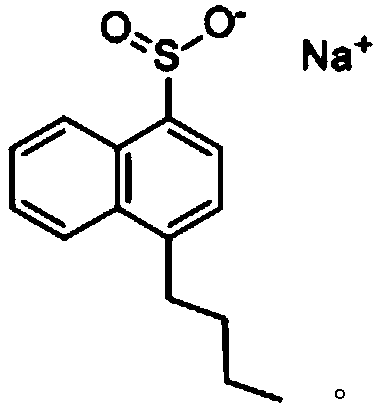

Cleaning solution for removing calcium carbonate scale and preparation method and application of cleaning solution

The invention discloses a cleaning solution for removing calcium carbonate scale and a preparation method and application of the cleaning solution, and belongs to the field of chemical descaling. Thecleaning solution comprises, by mass, 3%-8% of phosphorus-free organic acid complexing agent, 10%-25% of phosphorus-free chelating agent, 2%-6% of penetration cosolvent, 0.05%-0.15% of corrosion inhibitor, and the balance water. The corrosion inhibitor is oleic acid imidazoline corrosion inhibitor and / or thiazole corrosion inhibitor. The penetration cosolvent is prepared by the following steps that anionic surfactant, polyols and clean water are added into a reaction still and heated to 30-50 DEG C, stirring is conducted for 20-40 minutes, sodium hexametaphosphate, sodium but and the clean water are added, the temperature is reduced to 15-25 DEG C, stirring is conducted for 30-50 minutes under the constant temperature conditions, and the penetration cosolvent is obtained; and the mass ratio of the anionic surfactant, the polyols to the clean water added for the first time is 1:10-20:20-30, the mass ratio of the sodium but, the sodium hexametaphosphate to the clean water added for the second time is 1:40-50:80-200, and the mass percent of the sodium but accounted for the penetration cosolvent is 0.16-0.3%. The cleaning solution is high in scale dissolving rate, good in scale inhibition effect, safe and environmentally friendly, and good in biodegradability.

Owner:PETROCHINA CO LTD

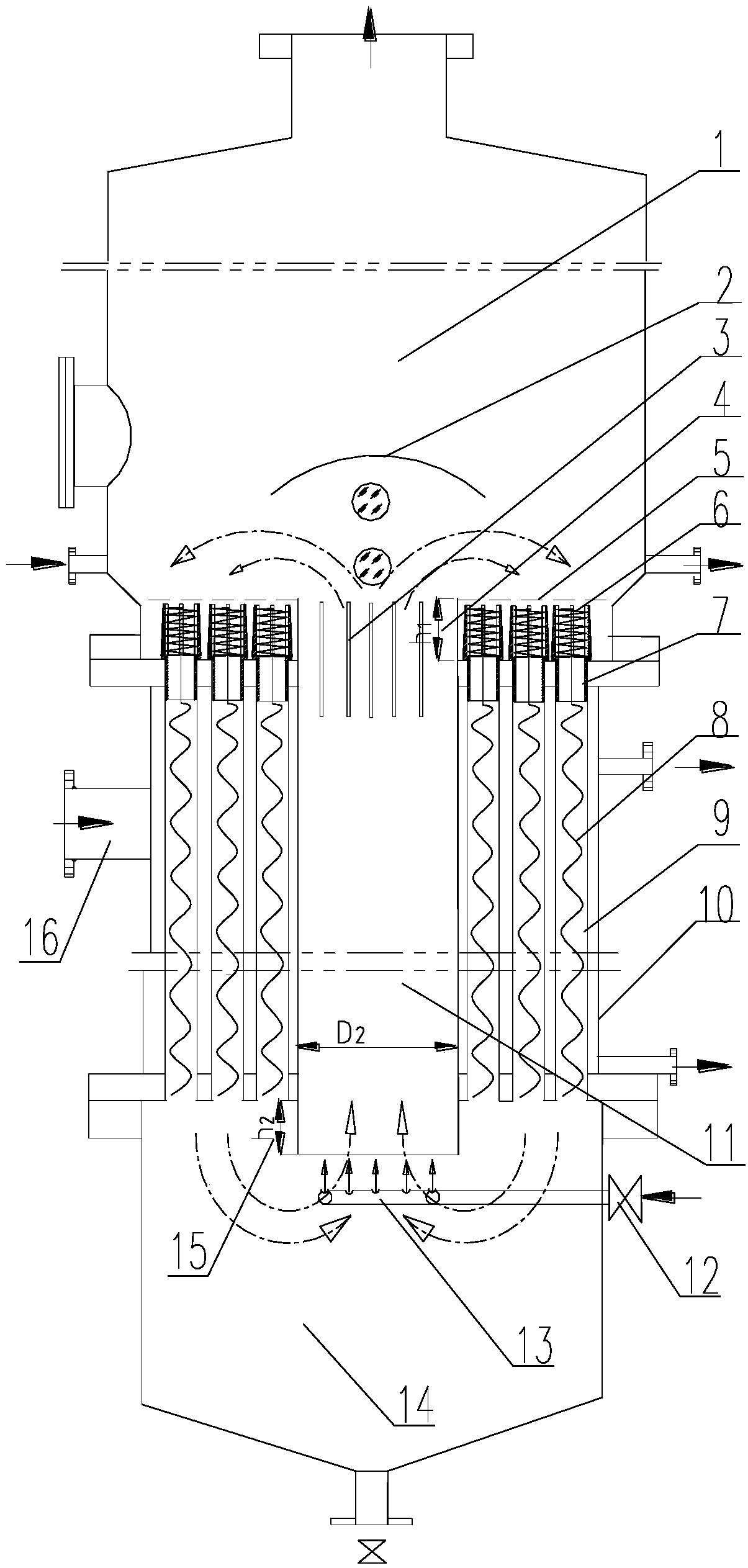

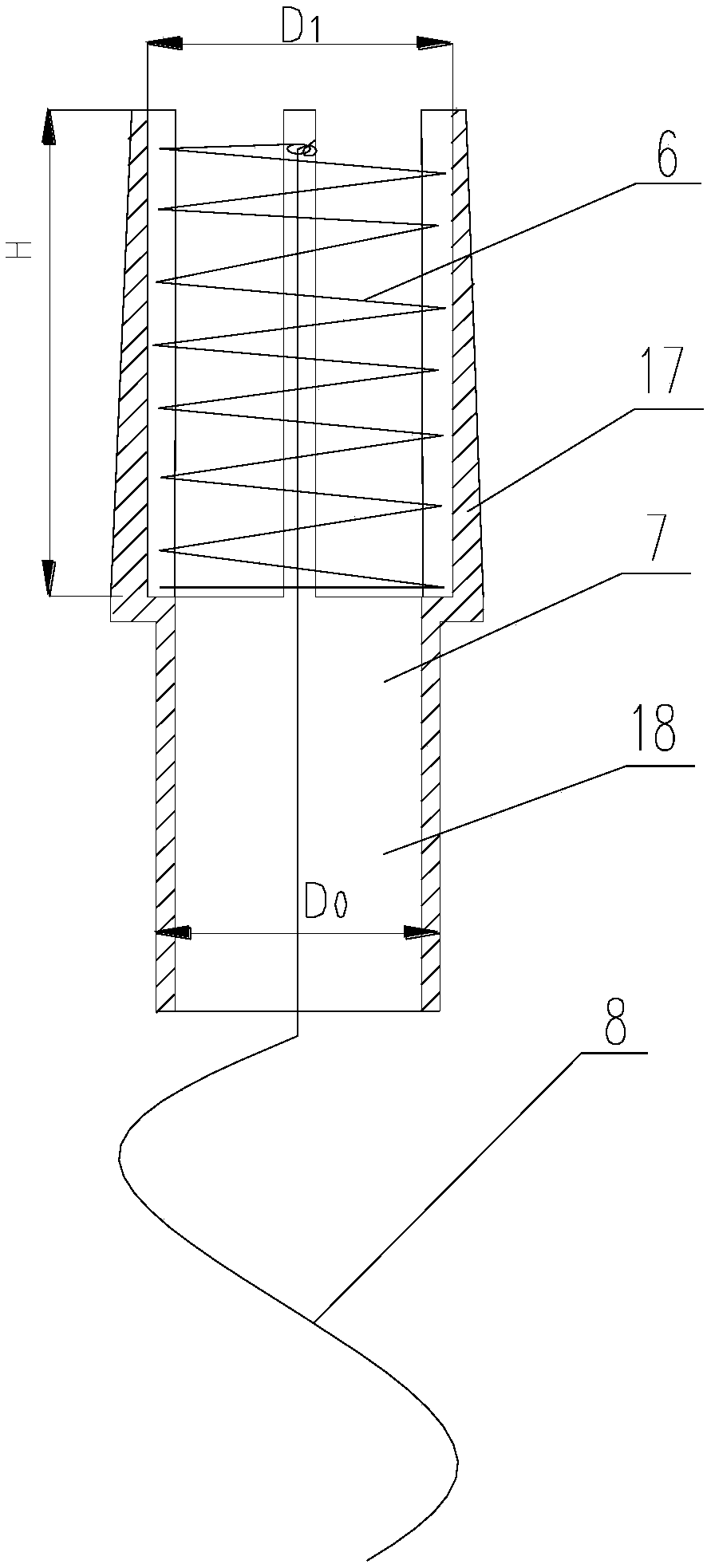

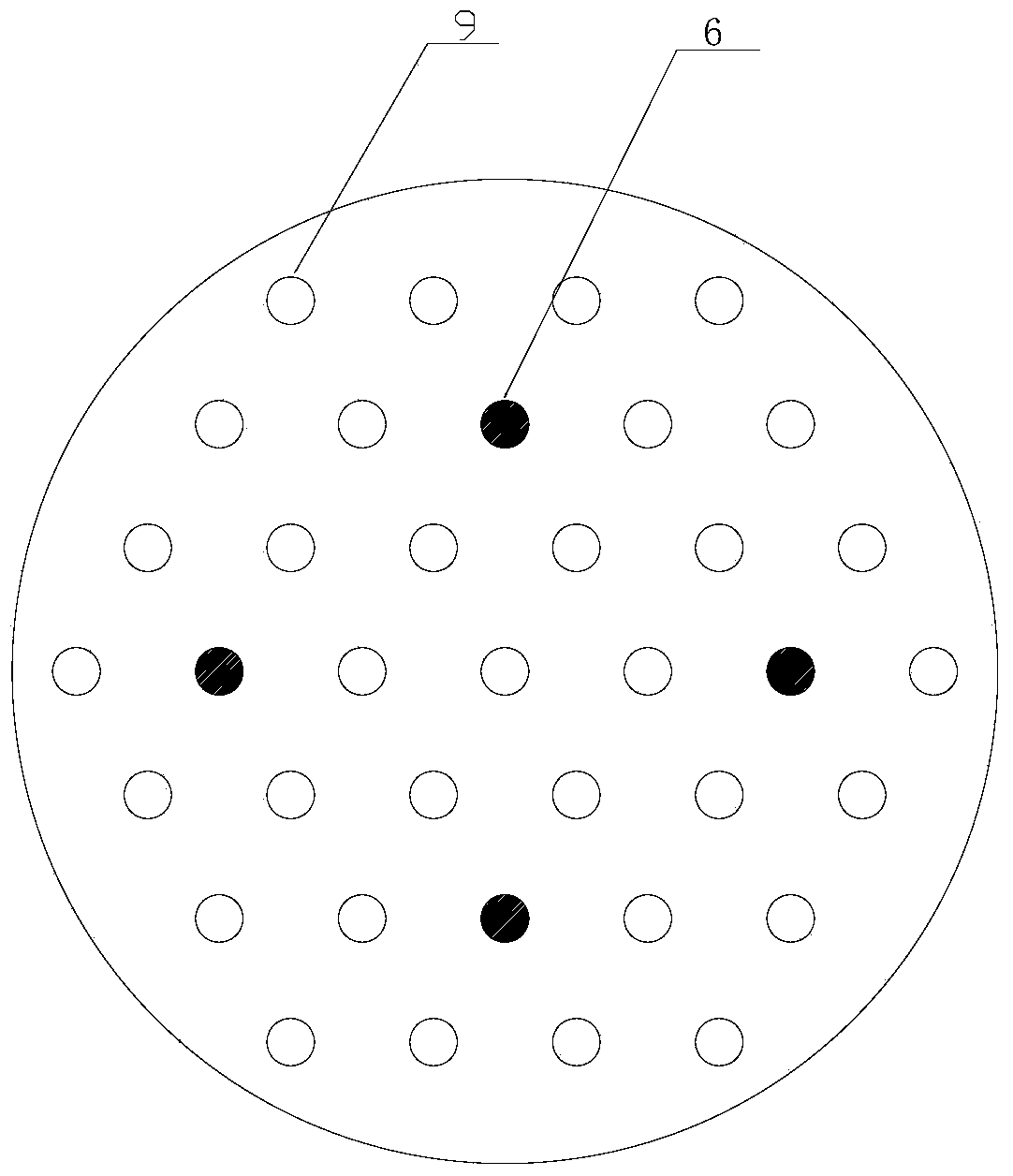

Self-cleaning type reverse natural circulation evaporator

ActiveCN108211386AAvoid boilingAvoid periodic parking for cleaningEvaporator accessoriesEvaporator regulation/controlEngineeringConvective heat transfer

The invention discloses a self-cleaning type reverse natural circulation evaporator. The evaporator comprises a self-cleaning mechanism which at least consists of a steel wire spiral, a cylindrical spring and a limiting frame. During production and operation, the steel wire spiral not only is a convective heat transfer augmentation element, but also triggers up-down floating and sinking movementsfor 10 times each minute and an intermittent vibrated type of slow self-rotating movement under the action of fluctuated flow velocity of two-phase flow at a reverse natural circulation outlet, and uniform and effective cleaning is realized through knocking crystallized salt crust on an inner wall of a heating pipe. Therefore, the purpose of long-term, stable, efficient and continuous production can be achieved, and the energy-saving and yield-increasing benefits are remarkable.

Owner:HUNAN UNIV OF TECH

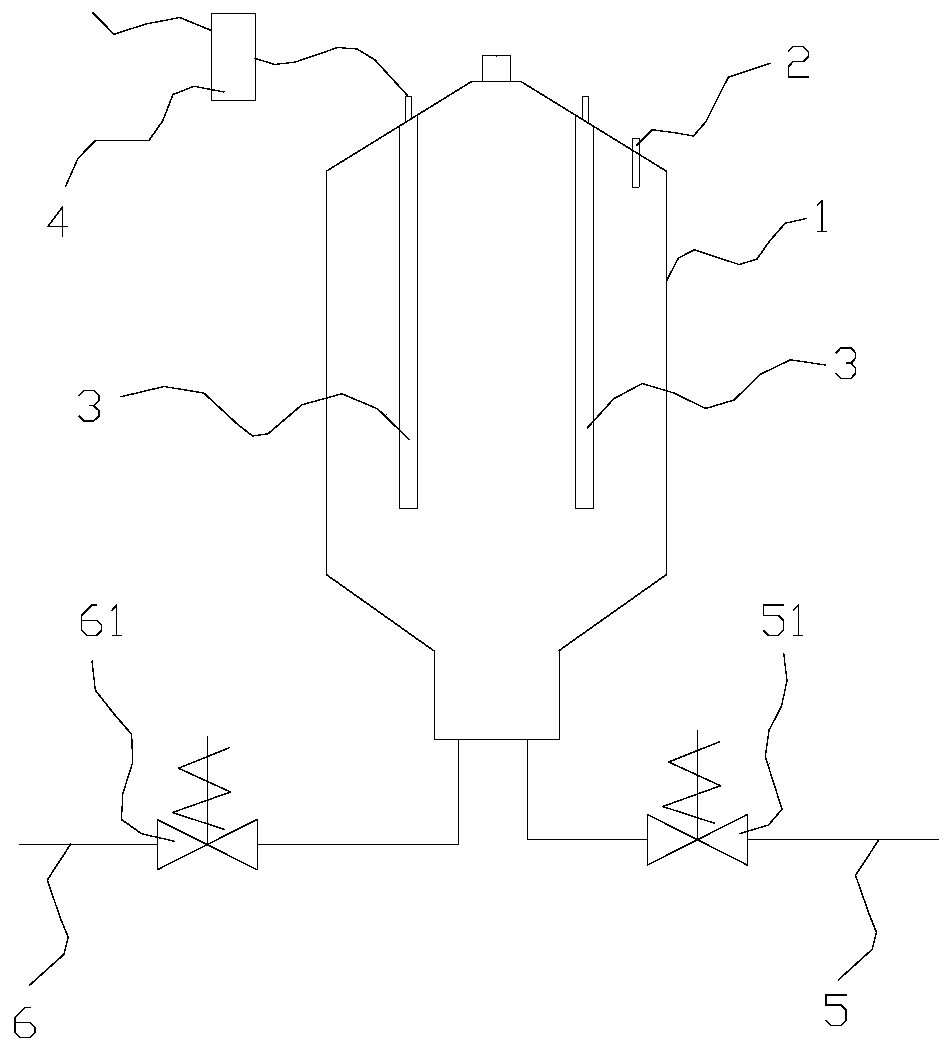

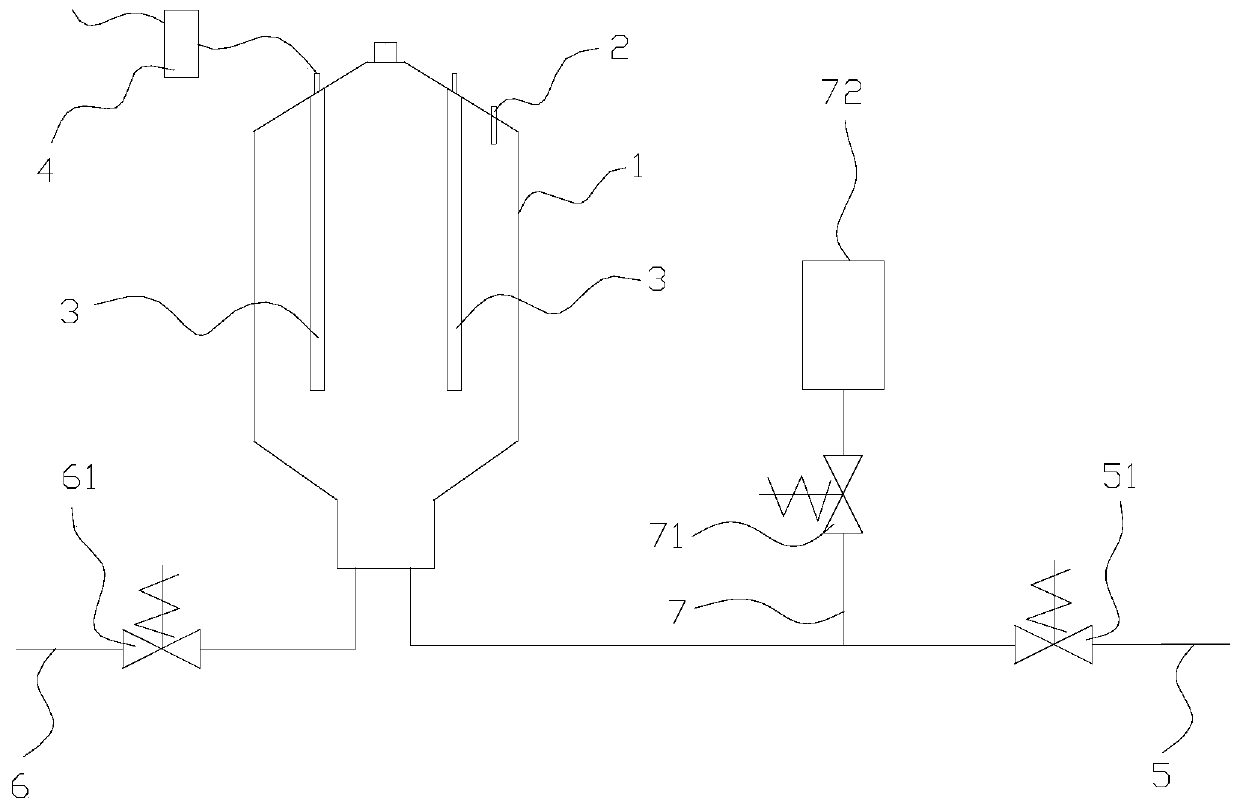

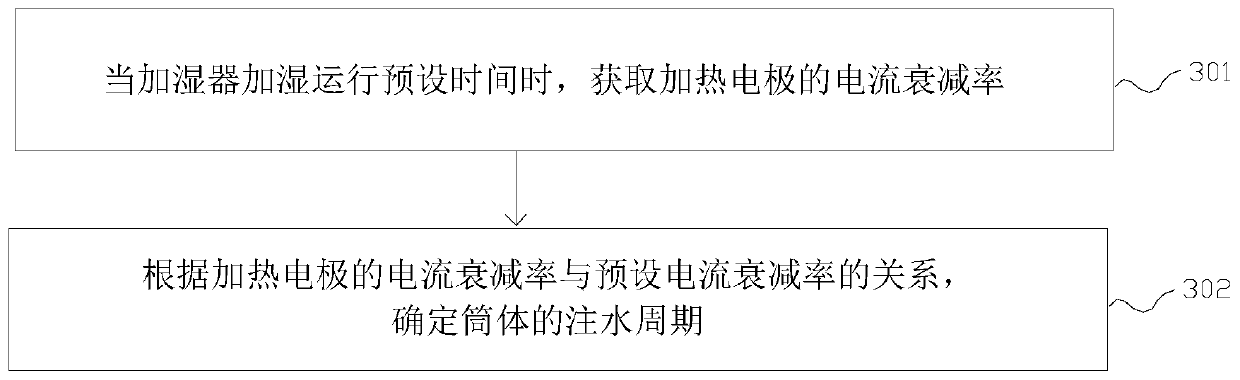

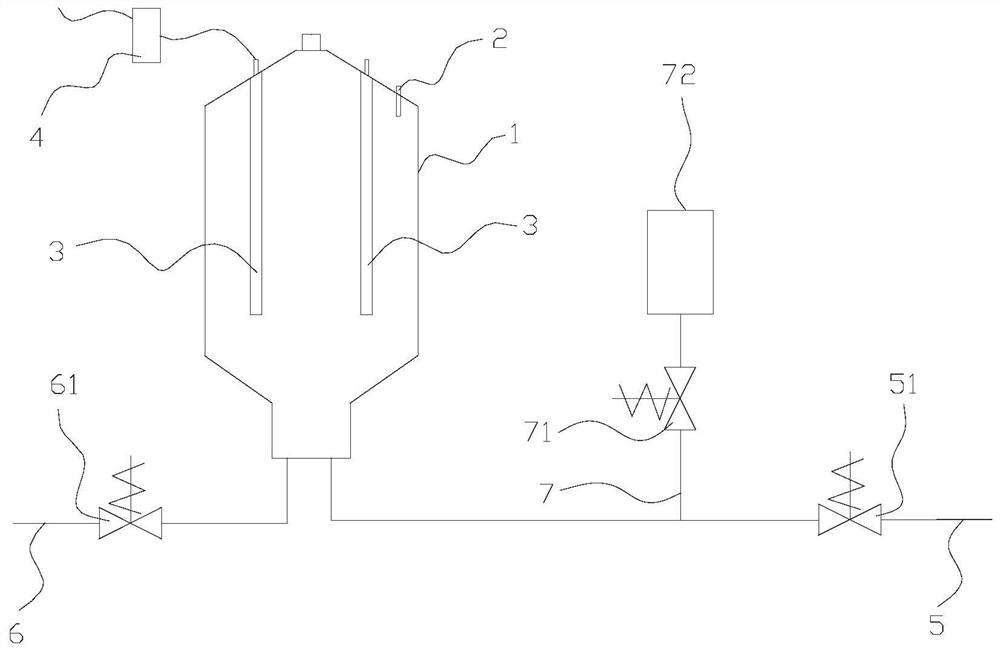

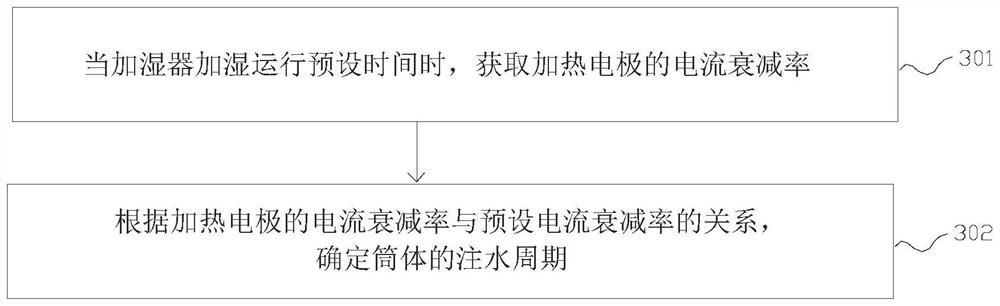

Humidifier, control method thereof, air conditioner and memory medium

ActiveCN109882979AImprove the humidification effectReduce fouling speedMechanical apparatusLighting and heating apparatusUltrasound attenuationWater quality

The invention discloses a humidifier, a control method thereof, an air conditioner and a memory medium and belongs to the technical field of humidifiers. The humidifier comprises a barrel body, heating electrodes and a controller. The heating electrodes are used for emitting heat with water inside the barrel body as a conducting medium. The controller is used for obtaining the current attenuationrate of the heating electrodes when the humidifier operates for a preset time for humidification and determining the water injection cycle of the barrel body according to the relation between the current attenuation rate of the heating electrodes and the preset current attenuation rate. The invention further provides the control method based on the humidifier, the air conditioner and the memory medium. The humidifier has the beneficial effects that the water injection cycle of the barrel body can be automatically adjusted according to different water quality conditions in different areas so that deceleration of scale formation of the electrodes can be balanced with guaranteeing of the humidification operation time and the humidification performance of the humidifier can be improved.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

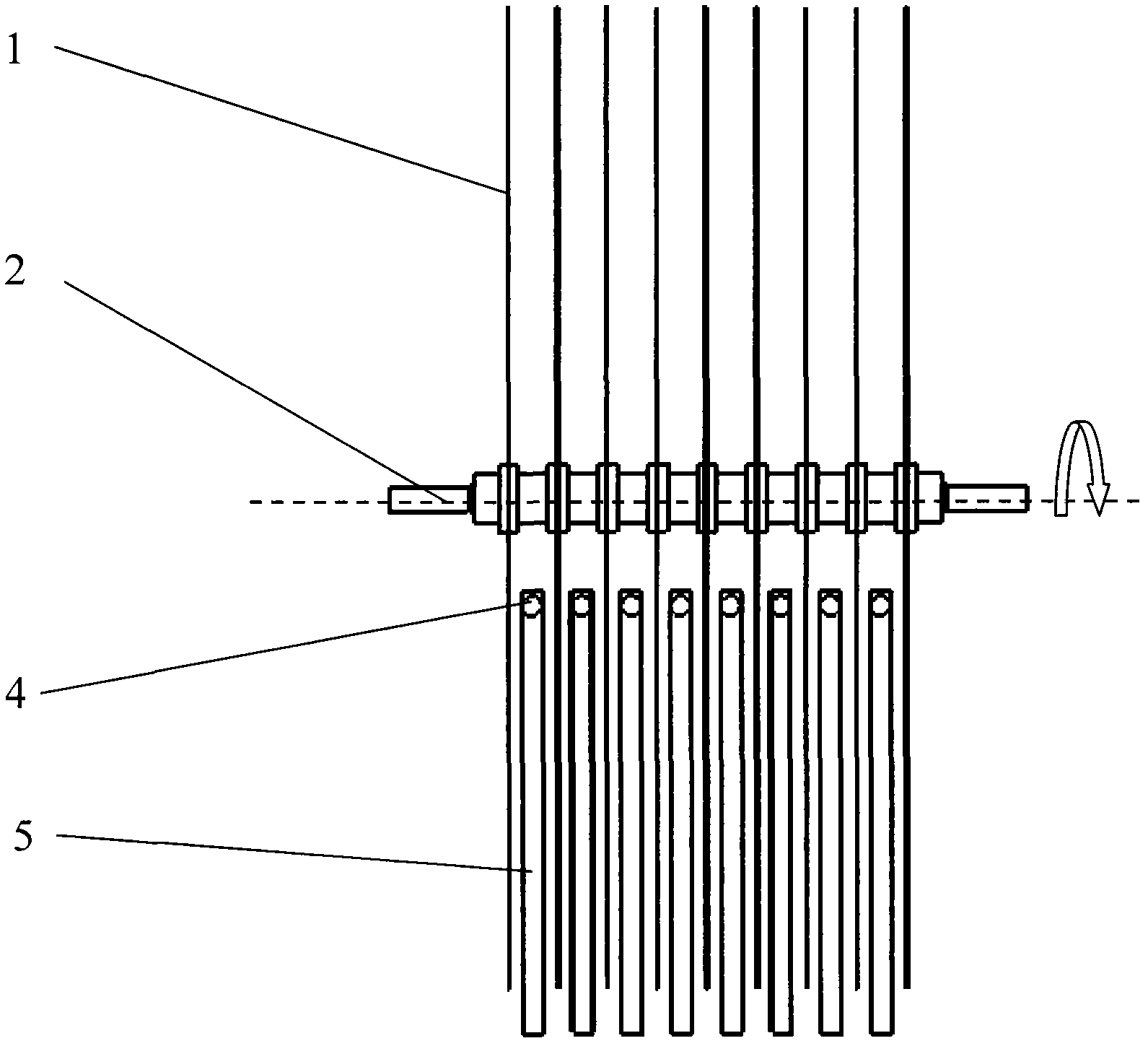

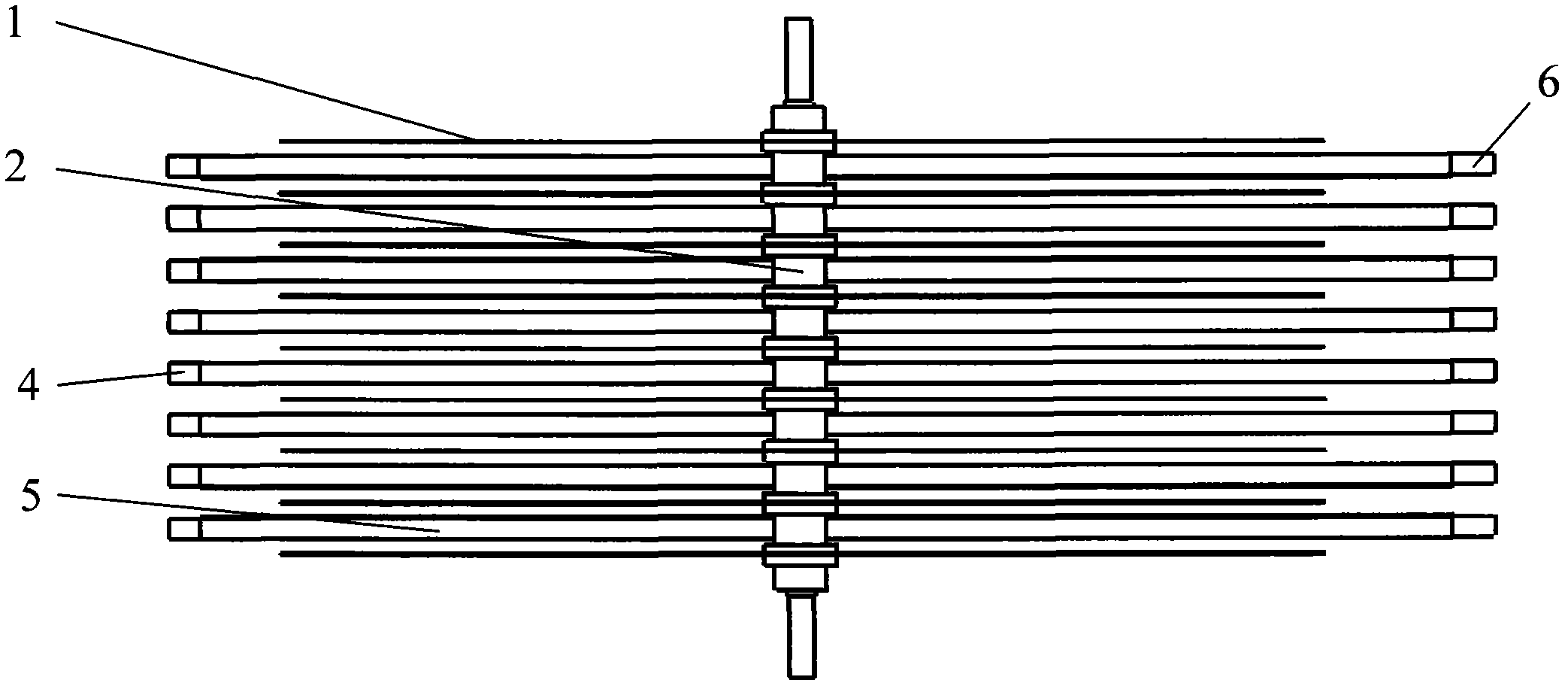

Combined wheel plate type evaporator condenser

InactiveCN102589199ASpeed up the flowImprove heat transfer effectEvaporators/condensersWater/sewage treatment by heatingVapor liquidEngineering

The invention discloses an evaporation-condensation structure used in water treatment field and chemical and refrigeration industry technological process, which comprises a set of rotary disc evaporators, and plate type condensers arranged in parallel to the disc surfaces of the rotary disc evaporators. The evaporation-condensation structure is characterized in that the plate surfaces of the plate type condensers and the disc surfaces of the rotary disc evaporators are staggered, a space between the disc surface and pipe wall is 0-50mm, and the plate type condensers are arranged below the rotary disc evaporators. The combined wheel plate type evaporator condenser can realize 100% evaporation of liquid on the evaporation surface and condensation vapor-liquid tank heat exchange of small temperature difference lower than 3 DEG C in the condenser, and has very high heat exchange efficiency.

Owner:吴思

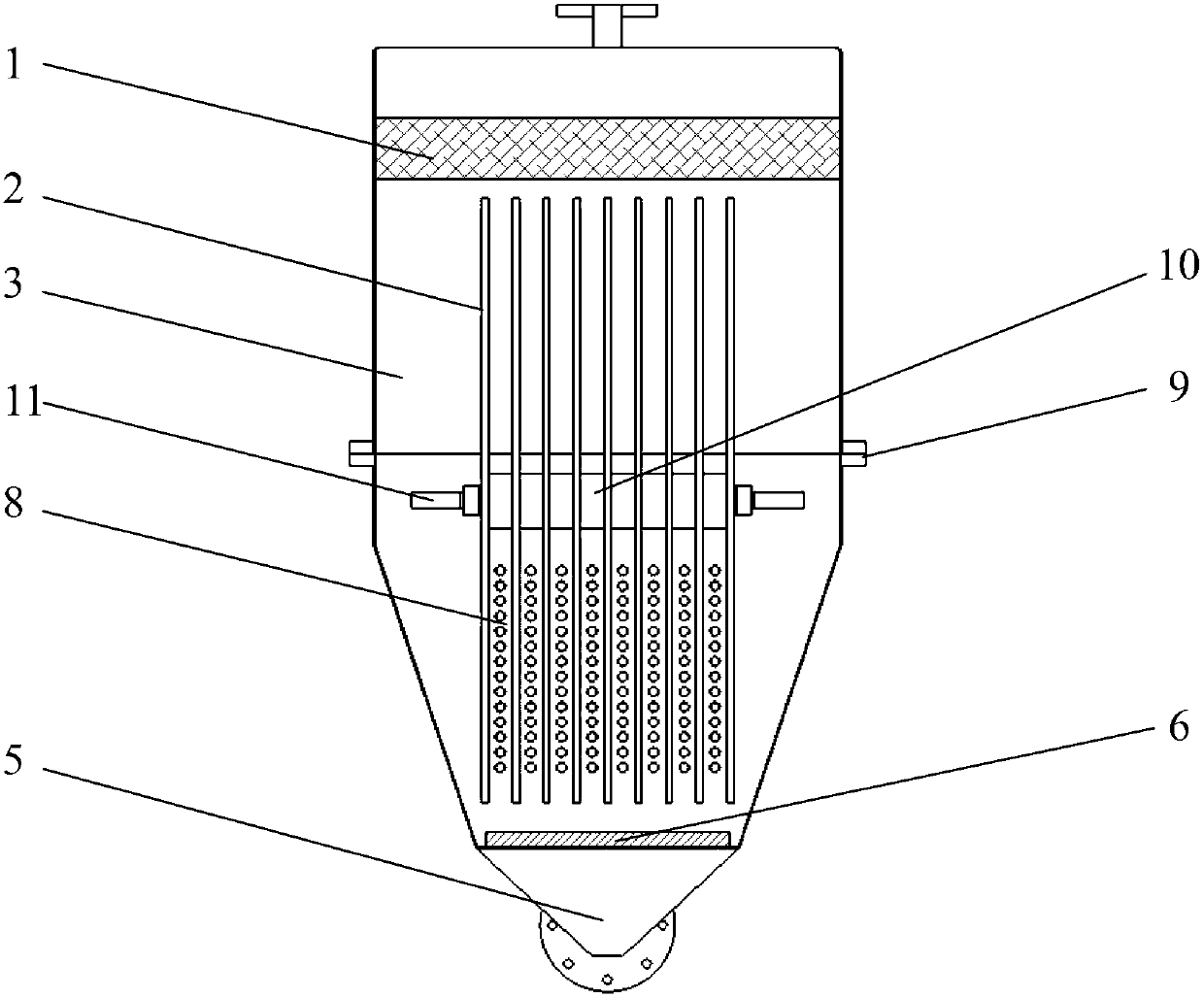

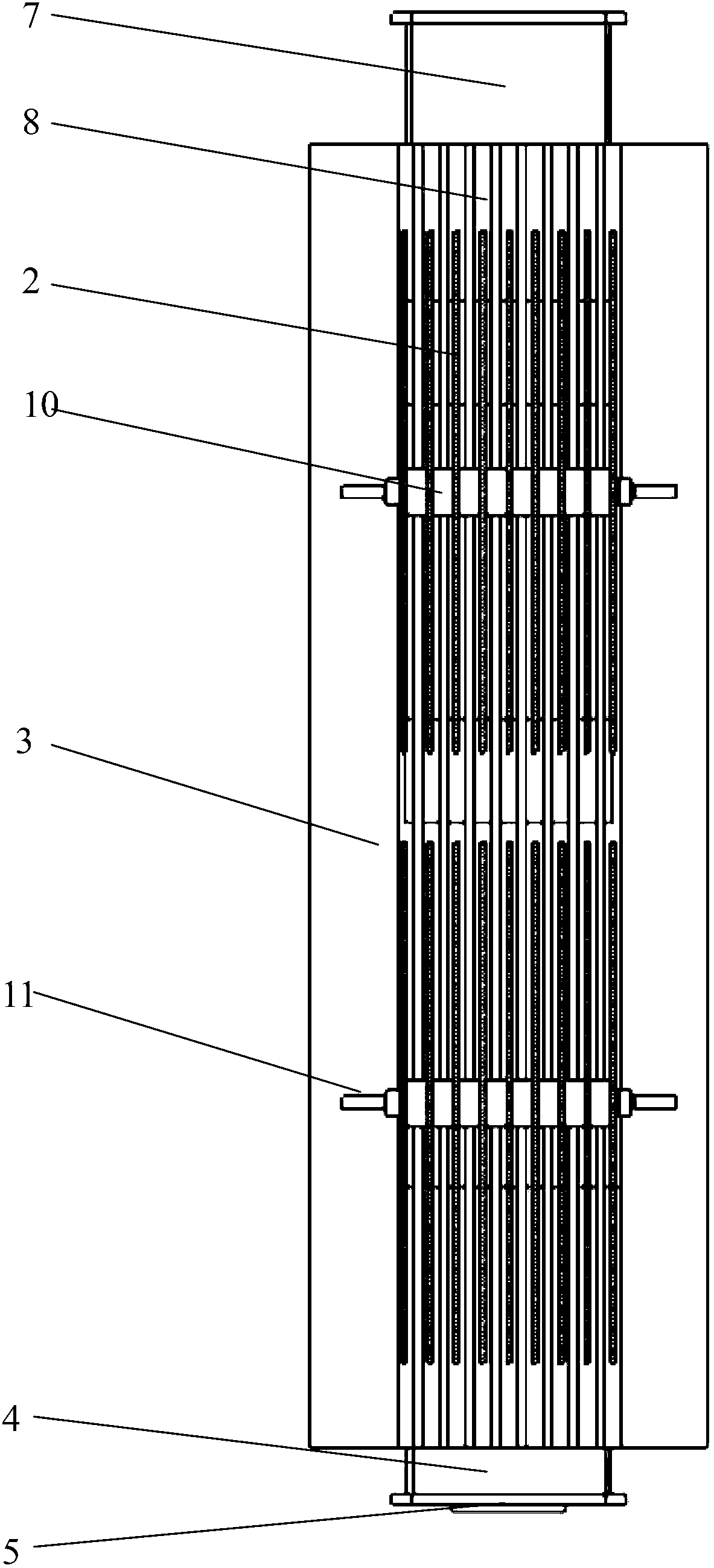

Combined evaporator and condenser and control method thereof

InactiveCN102944132AImprove heat transfer efficiencyIncrease contact surfaceIndirect heat exchangersHeat exchange apparatusRotational axisEngineering

The invention provides a combined evaporator and condenser and a control method thereof. The combined evaporator and condenser comprises a rotary table evaporator which consists of rotary tables arranged in parallel at intervals on a rotary shaft to evaporate and a bundle condenser. The bundle of the bundle condenser is circuitously arranged in intervals of the rotary tables, and a plurality of annular bumps are arranged in parallel on the outer surface of the bundle. The combined evaporator and condenser provided by the invention has the prominent advantage of intensifying the heat exchange efficiency of the bundle of the condenser and a liquid by maintaining the flow velocity of the liquid on the surface of the bundle of the condenser at a high speed.

Owner:王益

Advanced treatment method of garbage permeate fluid

PendingCN111908718AHigh mechanical strengthExtended service lifeSpecific water treatment objectivesWater contaminantsWastewaterProcess engineering

The invention provides an advanced treatment method of garbage permeate fluid, and belongs to the technical field of multi-stage treatment of water, wastewater or sewage. To-be-treated garbage permeate fluid is sequentially subjected to external ceramic MBR membrane filtration, electrolytic flocculation precipitation, single-stage DTRO, nanofiltration and bipolar electrolytic treatment; NaOH, HClOand NaClO solutions are formed at a bipolar electrolytic cell; NaOH is fed into a nanofiltration mechanism and the single-stage DTRO through an external circulating pipe to be used as chemical cleaning agents, and the HClO and NaClO solutions are fed into an electrolytic flocculation mechanism to be used as strong oxidants. The method is applied to treatment of garbage permeate fluid or sewage with the same property, and has the advantages of being stable in degradation, low in cost, capable of recycling effective components for multiple times and the like.

Owner:ZHEJIANG TIANXINGJIAN WATER SERVICE CO LTD

A kind of cleaning solution for removing calcium carbonate scale and its preparation method and application

Owner:PETROCHINA CO LTD

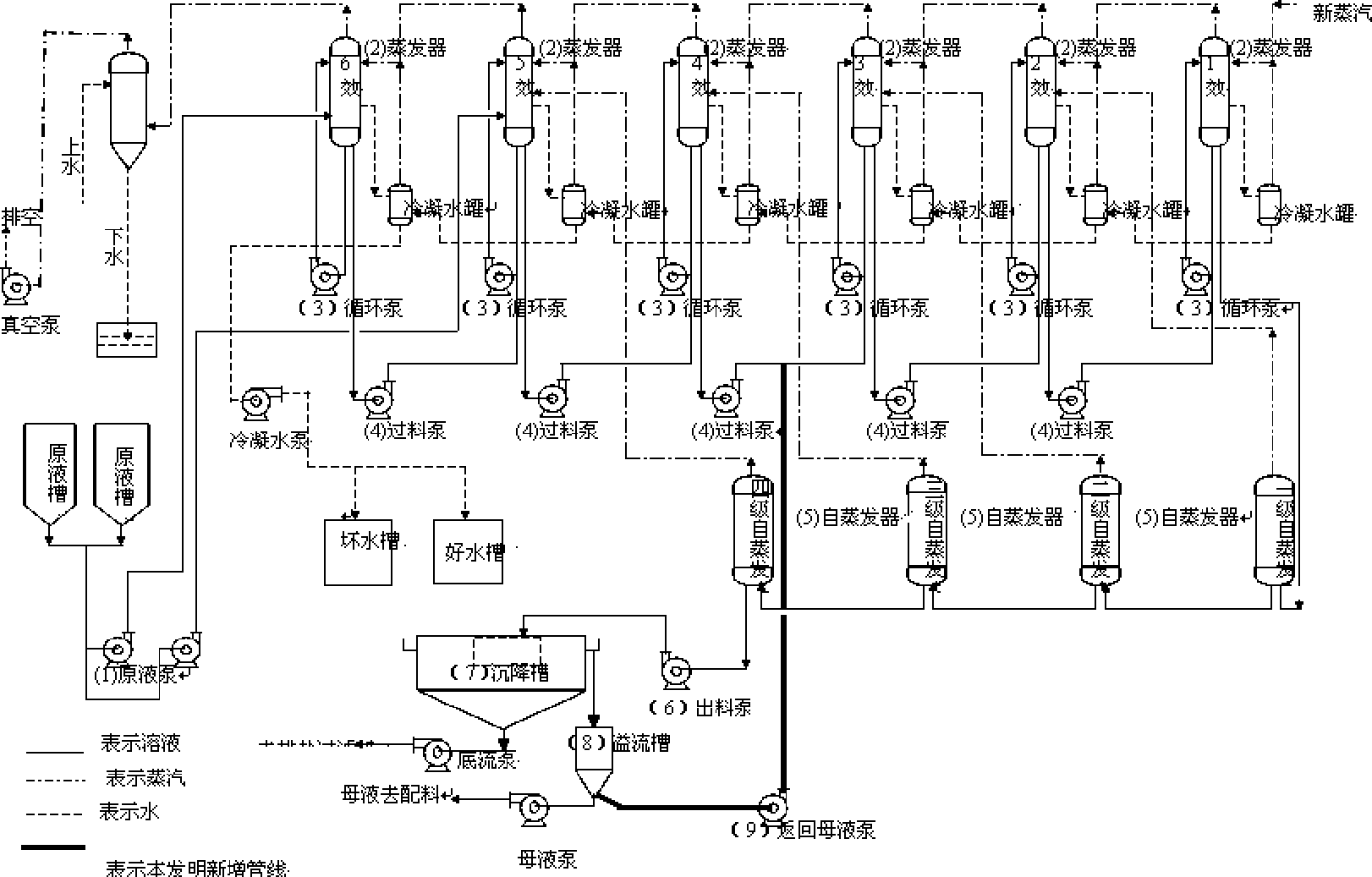

Method for controlling precipitation of crystal alkali in evaporator

ActiveCN102107897BThe amount of crystallization is reducedReduce consumptionSolution crystallizationMultiple-effect evaporationSulfateSodium sulfate

The invention discloses a method for controlling precipitation of crystal alkali in an evaporator. The evaporation mother solution after carbonate and sulfate are precipitated and separated is partially returned to one of final three-effect evaporators in the evaporation process to reduce the crystal precipitation amount of the carbonate and the sulfate in the final three effects. The method can be used for the countercurrent flow operation of the evaporation process. The evaporation mother solution is partially returned into the three-effect evaporators in the evaporation process to reduce the crystal precipitation amount of the carbonate and the sulfate in the final three effects. The ratio of the part of the evaporation mother solution returned to the evaporation process to the total amount of the evaporation mother solution is 0.5-1.5: 3. The method is suitable for a plate type falling film evaporator, and also suitable for an external heating type natural circulating evaporator. After the method is adopted, compared with the prior art, the precipitation amount of the crystal alkali on the heating surface of the evaporator is remarkably reduced, the scaling speed of sodium carbonate and sodium sulfate on the high temperature effect heating surface is slowed down, and the period of washing a boiling tank is prolonged so that washing water entering the production flow is reduced and the consumption of steam is reduced. Because the scales of the sodium carbonate and the sodium sulfate on the heating surface of the evaporator are reduced, the evaporation efficiency is greatly improved, and the average productivity of the evaporator is improved by 10 to 15 percent compared with the prior art.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

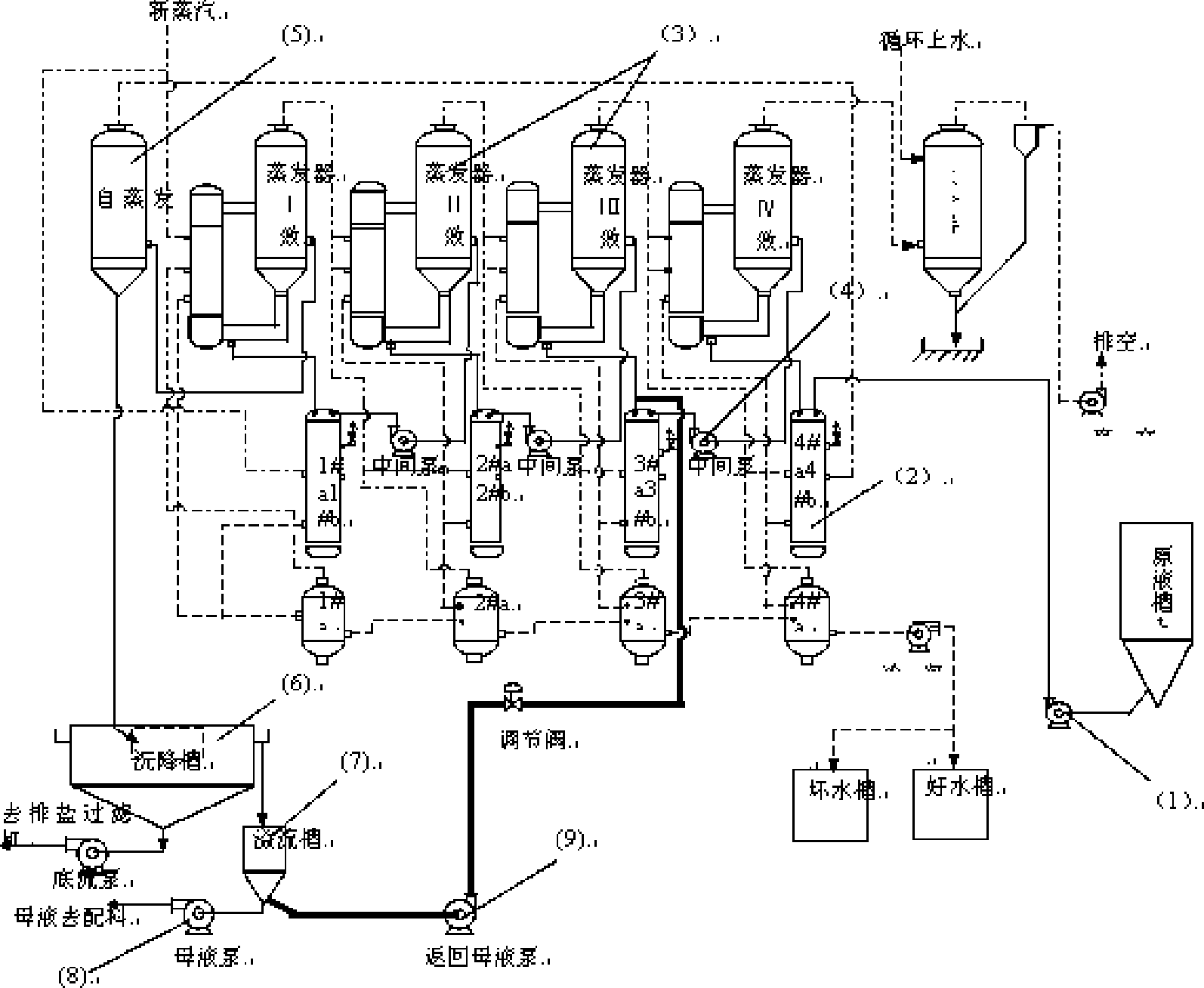

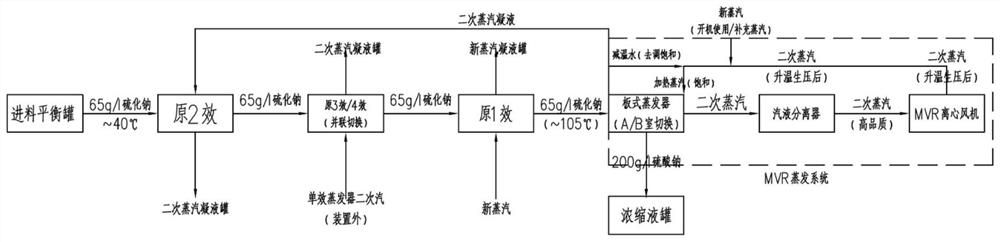

Sodium sulfide MVR plate-type evaporation process

InactiveCN112090096ALow running costImprove heat transfer performanceEvaporation with vapour compressionEvaporator accessoriesProcess engineeringVaporizer

The invention discloses a sodium sulfide MVR plate-type evaporation process which comprises the following steps: S1, feeding sodium sulfide feed liquid with the concentration of 65g / l and the temperature of 40 DEG C in a feeding balance tank into an original second-effect preheater, then feeding into an original third-effect preheater or an original fourth-effect preheater, finally feeding into anoriginal first-effect preheater, and preheating to 105 DEG C; S2, injecting the sodium sulfide feed liquid preheated to 105 DEG C in the step S1 into a chamber A of a plate-type evaporator, then feeding the sodium sulfide feed liquid into a chamber B, enabling a concentrated solution to take effect, feeding the sodium sulfide feed liquid with the concentration of 200g / l and the temperature of 98DEG C into a concentrated solution tank, buffering, then feeding the sodium sulfide feed liquid into the next section for concentration, and simultaneously generating secondary steam; switching an integrated two-chamber belt, enabling a thinner to enter the chamber A to be evaporated and then enter the chamber B to be evaporated and then to be discharged in the first eight hours, enabling the thinner to enter the chamber B to be evaporated and then enter the chamber A to be evaporated and then to be discharged in the later eight hours, so that the dissolving and descaling efficiency is higher,the system has a self-cleaning function, the operation period of the system is further prolonged, and the operation cost of enterprises is reduced.

Owner:上海巨道环保科技有限公司

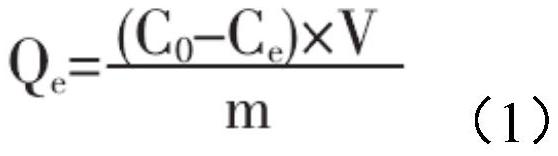

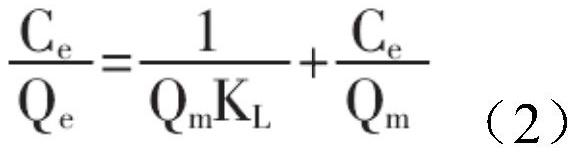

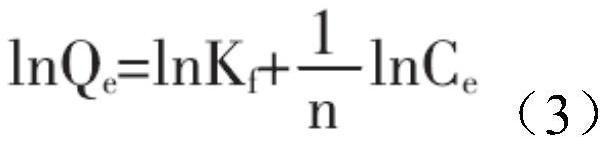

Method for evaluating failure degree of ion exchange resin

PendingCN113791043AChemical Corrosion MitigationReduce fouling speedColor/spectral properties measurementsChemical physicsPhysical chemistry

The invention discloses a method for evaluating the failure degree of ion exchange resin. The method specifically comprises the following steps of 1, obtaining the equilibrium adsorption quantity of the ion exchange resin; 2, obtaining the adsorption characteristics of ion exchange resin on the degradation products in a cold water system in an ultra-high voltage converter valve; 3, establishing a Langmuir adsorption isothermal model and a Freundlich adsorption isothermal model, and fitting data to obtain a saturation adsorption capacity characteristic constant and an adsorption strength characteristic constant; 4, fitting the data by using quasi-first-level dynamics, quasi-second-level dynamics and a particle internal diffusion model to obtain an adsorption rate constant and an internal diffusion rate constant; and 5, calculating the failure degree of the ion exchange resin according to the obtained equilibrium adsorption capacity, adsorption mass, saturated adsorption capacity, adsorption strength, adsorption rate constant and internal diffusion rate constant. According to the evaluation method for the failure degree of the ion exchange resin, the quantitative and accurate evaluation on the failure degree of the ion exchange resin is realized.

Owner:XIAN UNIV OF TECH

Oriented heat-absorbing film material and method for applying the same

ActiveCN108192393BImprove absorption efficiencyImprove transmission efficiencyAntifouling/underwater paintsChemical industryHafniumManganese oxide

The invention relates to an oriented heat absorption film material and a spreading method thereof. The oriented heat absorption film material is prepared through a method including the steps of S1, grinding, by weight, 20-55% of crystalline manganese oxide, 5-25% of tantalum carbide, 5-10% of hafnium carbide, 2-20% of fluorphlogopite mica and 5-30% of crystalline iron oxide into a powder materialwith granularity of 100-250 mesh, wherein the total weight percentage of all the components is 100%; S2, heating the powder material obtained through grinding in the step S1 in a resistance furnace at950-1200 DEG C for 6-8 hours to obtain a solid material of the oriented heat absorption and energy conservation film material, and adding pure water accounting for 10-30% of the total weight of the solid material and inorganic high-temperature-resistant liquid gel accounting for 10-20% of the total weight of the solid material to be evenly mixed in a mixer for 7-10 h so as to obtain the orientedheat absorption film material. The film material is high in radiation intensity, generates a radiation magnetic field perpendicular to the tangential direction of the surface of a heated body under the effect of a high-temperature heat source, and enhances the heat energy absorption efficiency of a heated medium and greatly improves the heat energy transmission efficiency when directly acting on the heated medium.

Owner:JILIN GUANGDA ENERGY SAVING TECH

Method and system for anti-scaling and descaling of membrane evaporator

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

A humidifier and its control method, air conditioner, and storage medium

ActiveCN109882979BReduce fouling speedAutomatic adjustment of water injection cycleMechanical apparatusLighting and heating apparatusProcess engineeringMechanical engineering

The invention discloses a humidifier, a control method thereof, an air conditioner and a storage medium, and belongs to the technical field of humidifiers. The humidifier includes a cylinder, a heating electrode, and a controller, wherein the heating electrode is used to generate heat using water in the cylinder as a conductive medium, and the controller is used to obtain the current of the heating electrode when the humidifier operates for a preset time. Attenuation rate, according to the relationship between the current attenuation rate of the heating electrode and the preset current attenuation rate, determine the water injection period of the cylinder. Also provided are a control method based on the humidifier, an air conditioner, and a storage medium. Beneficial effects of the present invention: the humidifier can automatically adjust the water injection cycle of the cylinder according to the different water quality conditions in different regions, so as to achieve the balance between delaying the fouling speed of the electrode and ensuring the humidification operation time, so as to improve the humidification performance of the humidifier .

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com