Cooling water system of refrigerating machine of ocean vessel

A technology for cooling water systems and ocean-going ships, applied in cooling fluid circulation devices, household refrigeration devices, lighting and heating equipment, etc. Damage, increase the work intensity of maintenance personnel, etc., to achieve the effect of reducing the speed of dirt blocking, reducing workload and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

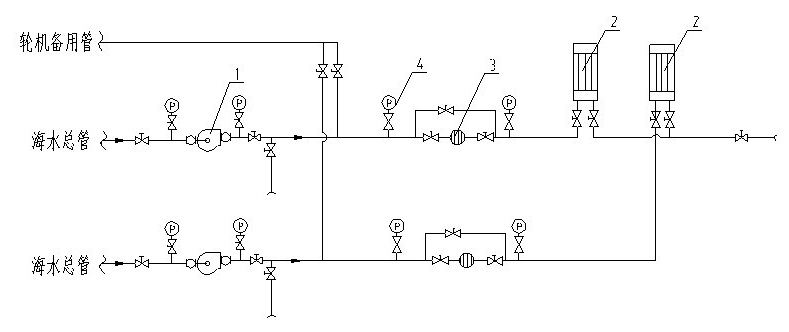

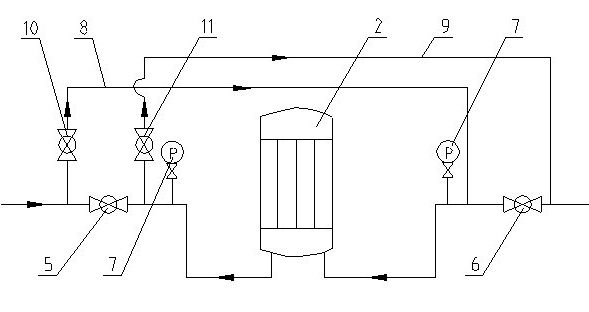

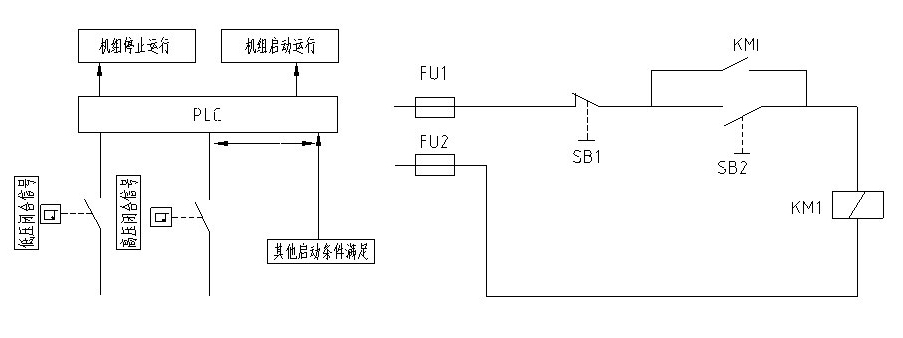

[0036] see figure 1 , figure 2 , the present invention relates to an ocean-going ship ice machine cooling water system, which includes a cooling water circuit, on which a water pump 1 and a condenser 2 are sequentially arranged from front to back, and a water pump 1 and a condenser 2 are arranged between the water pump 1 and the condenser 2 There is a filter 3, and a pressure gauge I4 is installed before and after the filter 3, the aperture of the filter 3 is 3mm, the water inlet pipe of the condenser 2 is provided with a valve I5, and the water outlet pipe of the condenser 2 is provided with a valve II6, a pressure gauge II7 is arranged between the condenser 2 and the valve I5 and the valve II6, a backwash pipeline I8 is connected between the front end of the valve I5 and the front end of the valve II6, and the rear end of the valve II5 is connected to the valve II6 A backwash pipeline II9 is connected between the rear ends of the II6, the backwash pipeline I8 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com