An Airborne Flame Suppressor with Adjustable Pore

A technology of flame suppression and porosity, which is applied in the field of airborne flame suppressors, can solve problems such as ice blockage, ice blockage, and difficulty in cleaning, reduce cleaning and maintenance frequency, reduce ice blockage and dirty blockage, and facilitate cleaning and maintenance. The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

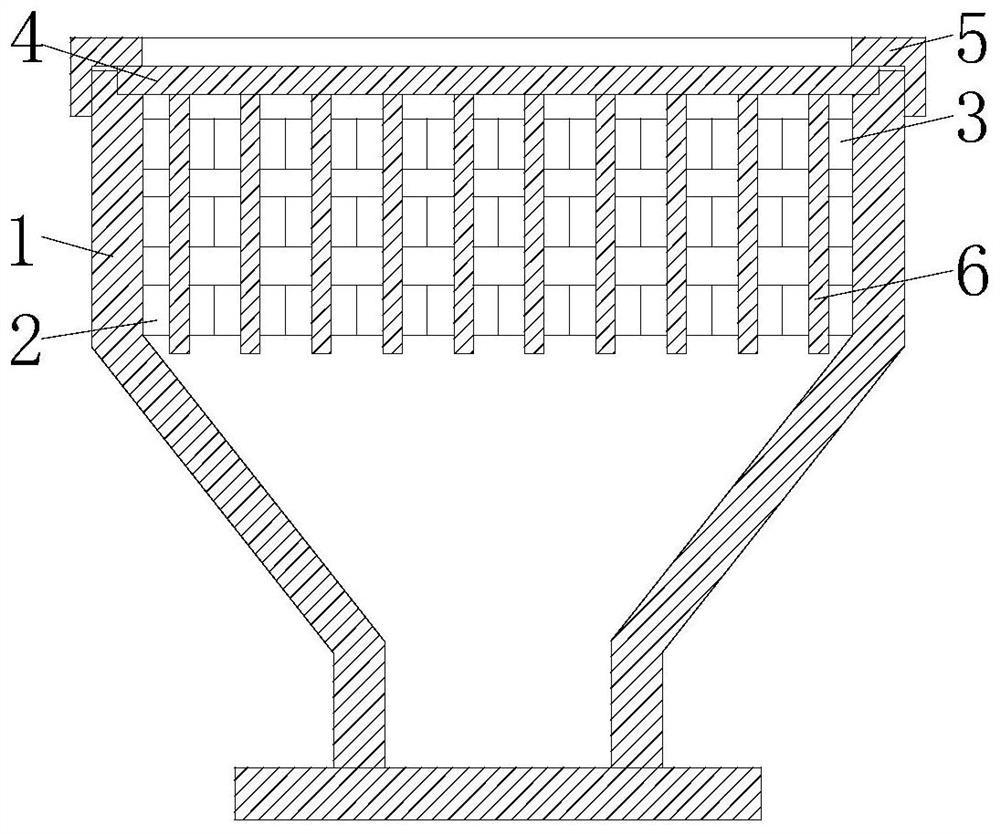

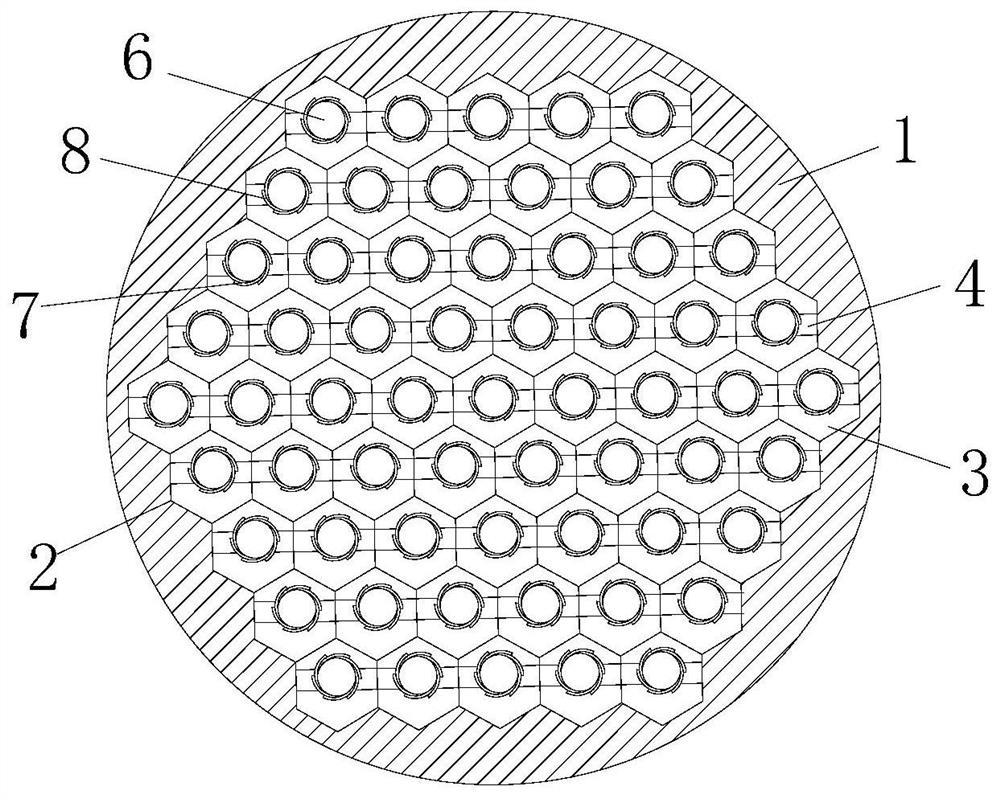

[0025] With other conditions unchanged, the difference in Embodiment 2 is that each side of the fire-stop channel 3 is fixedly connected with a shape memory alloy segment 7, and the shape memory alloy segment 7 is fixedly connected with a partition plate 8, and the partition plate 8 is far away from the shape memory. One end of the alloy section 7 is provided with soft colloid, and the shape of the shape memory alloy section 7 changes at high temperature, which drives the partition plate 8 to unfold, and the partition plate 8 presses against the adjustment rod 6, and the soft colloid ensures the airtightness of the formed small channel. Medium heat deformable materials are used less and are correspondingly faster.

[0026] Working principle of the present invention:

[0027] Fire arresting process

[0028] When the gas near the shell 1 is ignited by an external fire source, the gas deflagrates, the temperature rises, and the shape of the shape memory alloy segment 7 changes d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com