Drying system and working method for washing and drying all-in-one machine, and washing and drying all-in-one machine

A technology of a drying system and a working method, applied in the field of clothes dryers, can solve problems such as poor heat dissipation effect, and achieve the effects of reduced cleaning, reduced water vapor content, and better heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

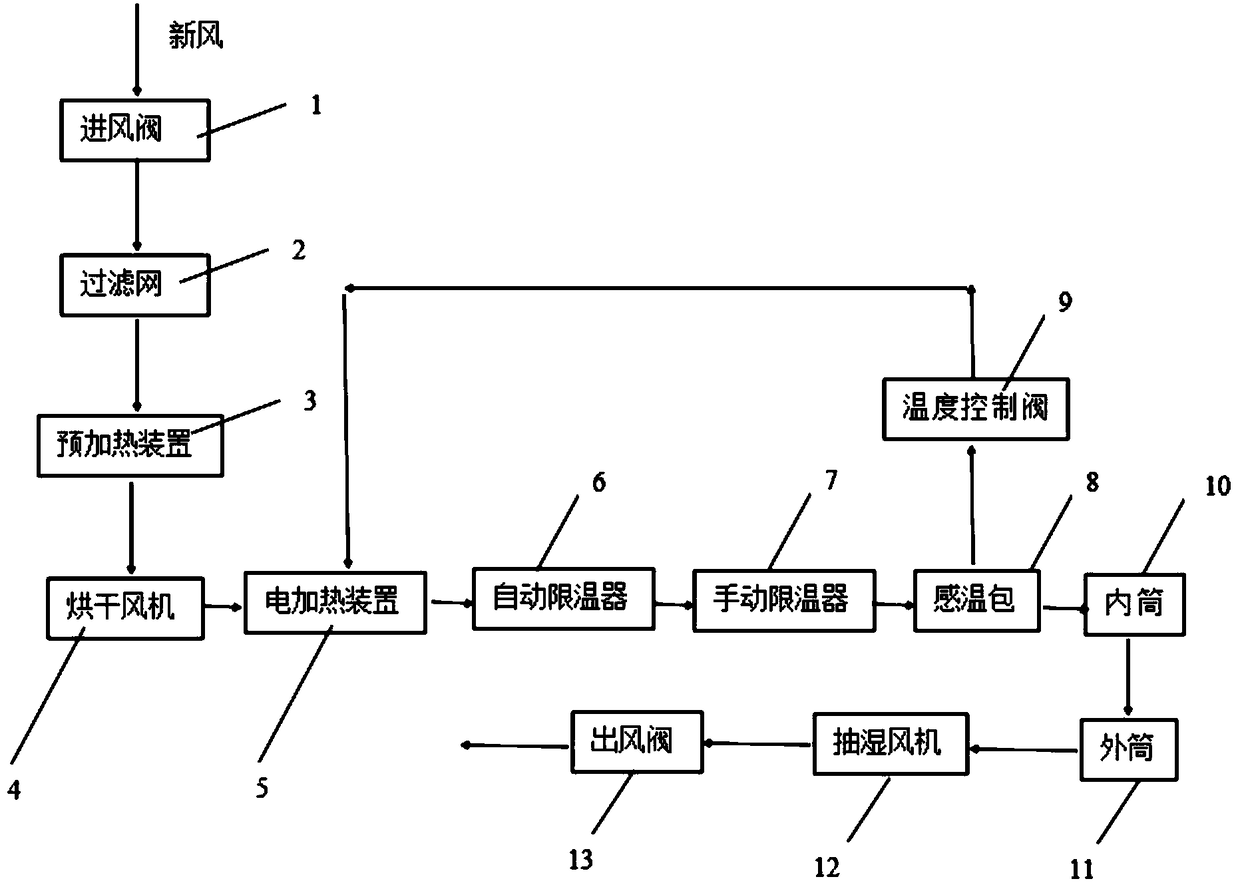

[0032] see figure 1 , the present invention provides a drying system for a washing and drying machine, including an air inlet structure and an air outlet structure, the air inlet structure and the air outlet structure are installed in the air duct of the washing and drying machine, wherein the air inlet structure and the washing and drying The inner cylinder 10 of the all-in-one machine is connected and the air outside the all-in-one washing and drying machine can enter the inner cylinder 10 through the air inlet structure, and the outer cylinder 11 of the all-in-one washing and drying machine is connected with an air outlet structure and the air in the inner cylinder 10 can be washed and dried in one. The outer cylinder 11 and the air outlet structure of the machine are discharged to the outside of the washing and drying machine. When it is necessary to dissipate heat from the inner cylinder 10 after the drying procedure, the air outside the washing and drying machine can ent...

Embodiment 2

[0039] The present invention also provides a working method of the drying system, which is applied to the drying system of the washing and drying integrated machine with the above-mentioned air inlet structure, wherein the working method of the drying system includes a drying method and a heat dissipation method. The drying method includes the following steps:

[0040] When the prototype runs in the drying mode, the air inlet valve 1 is opened, and new air (that is, fresh air) is introduced from the outside of the washing and drying machine. The temperature is raised, and then the pre-heated hot air is sent to the electric heating device 5 by the drying fan 4 for reheating treatment, and the wind temperature is detected by the manual temperature limiter 7, the automatic temperature limiter 6, and the temperature sensing package 8; if the temperature sensing package 8 When the detected air temperature heated by the electric heating device 5 is not greater than the preset value,...

Embodiment 3

[0048] The present invention also provides an integrated washing and drying machine, which includes an outer cylinder 11 , an inner cylinder 10 disposed in the outer cylinder 11 , and the drying system in Embodiment 1. The all-in-one washing and drying machine also includes a cleaning system. The cleaning system includes a water inlet valve and a drain pump. The water inlet valve is connected to the inner cylinder 10, and the outer cylinder 11 is connected to the drain pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com