Method for controlling precipitation of crystal alkali in evaporator

A technology to control evaporator and internal crystallization, which is applied in multi-effect evaporation, solution crystallization, alkali metal aluminate/aluminum oxide/aluminum hydroxide preparation, etc. It can solve the problems of increasing steam consumption, fouling of evaporator heating surface, and affecting Evaporation efficiency and other issues, to achieve the effect of reducing steam consumption, slowing down scaling speed and improving evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

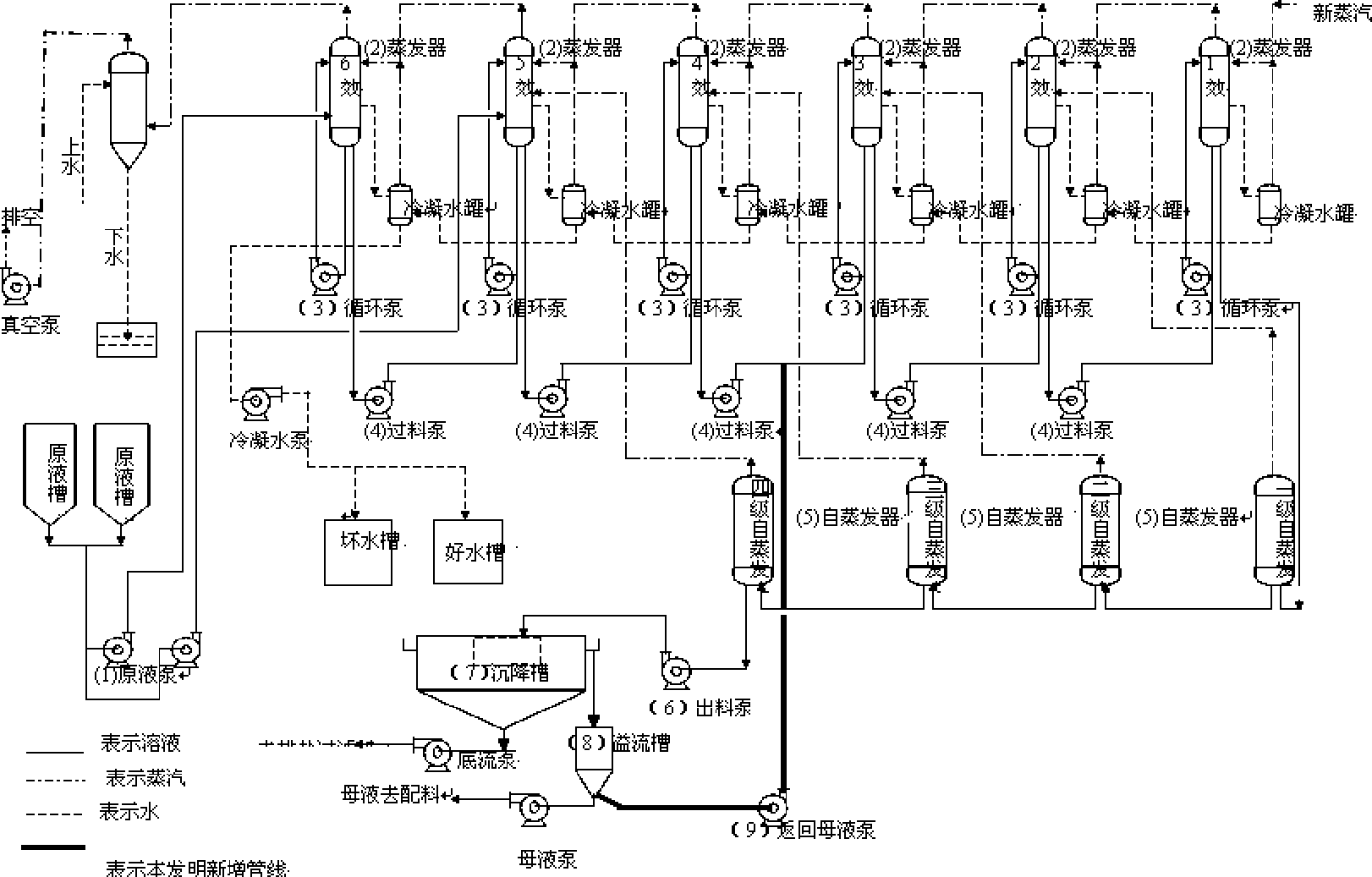

[0018] Take the plate falling film evaporator with 6-effect operation and 4-stage self-evaporation in countercurrent flow as an example.

[0019] as attached figure 1 As shown: the evaporated raw liquid (seeding mother liquid) is sent to the 6th effect and 5th effect of the evaporator 2 by the raw liquid pump 1 to evaporate, and the circulation pump 3 is continuously pumped to circulate the cloth film to evaporate, and then passed through the feeding pump 4 The solution evaporated in this stage is transported to the next-stage evaporator for evaporation. In this way, after the 6-stage evaporation, the solution enters the 1st to 4th-stage self-evaporator 5 through self-pressure in the 1-effect evaporator for further evaporating. Self-evaporation concentration, after 4 stages of self-evaporation, the solution is sent into the mother liquor settling tank 7 through the discharge pump 6 to separate carbonate and sulfate, and the overflow after separation (evaporation mother liquor)...

Embodiment 2

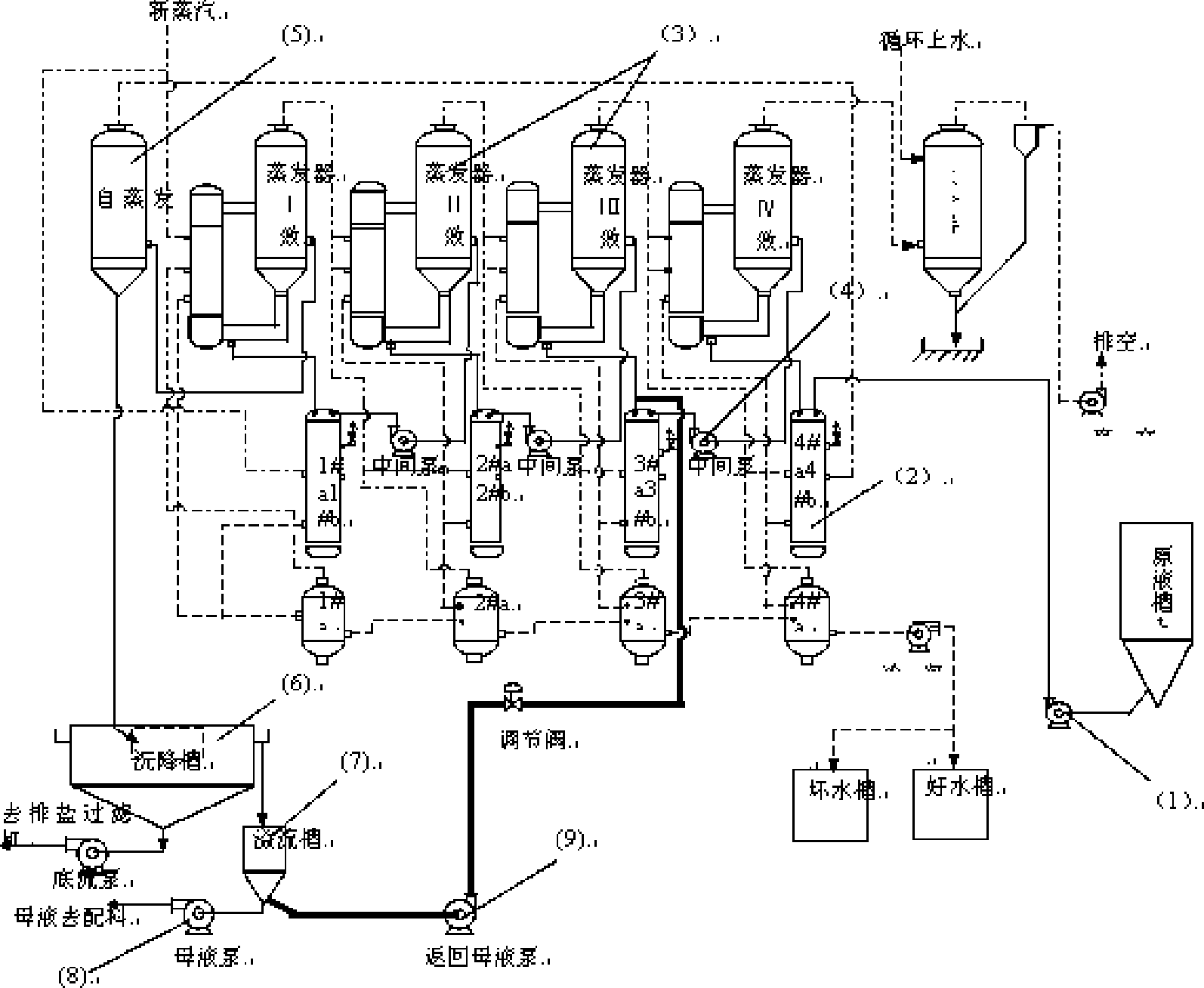

[0021] Take the externally heated natural circulation evaporator with 4-effect operation and 1-stage self-evaporation in countercurrent flow as an example to illustrate.

[0022] As shown in the attached figure: the evaporated raw liquid (seeding mother liquor) is transported to the fourth effect preheater 2 by the raw liquid pump 1, and then enters the fourth effect evaporator 3 to evaporate after being preheated by the preheater, and then passes through the middle pump 4. Transport the evaporated solution of this stage to the 3-effect preheater, and then enter the 3-effect evaporator for evaporation after being preheated by the preheater, and then transport the evaporated solution of this stage to the 2-effect preheater through the intermediate pump After being preheated by the preheater, it enters the 2-effect evaporator for evaporation, and then transports the evaporated solution of this stage to the 1-effect preheater through the intermediate pump, and then enters the 1-ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com