Method for evaluating failure degree of ion exchange resin

An ion-exchange resin and ion-exchange column technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of accelerated electrolytic current corrosion, reduced work performance, chemical corrosion of aluminum radiators, etc., to reduce the scaling speed and eliminate production. Accident, Mitigation Effect of Chemical Corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0046] A kind of evaluation method of ion exchange resin failure degree of the present invention, its flow process is as follows figure 1 As shown, the specific steps are as follows:

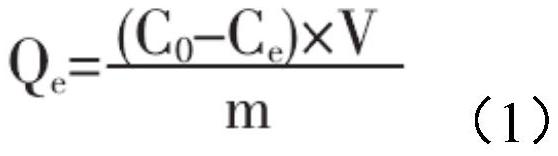

[0047] Step 1. Place the ion exchange resin in a constant temperature oscillator, set the oscillation frequency to 180-250rpm, and set the temperature to 25-35°C. Take out the quantitative solution from the ultra-high pressure converter valve internal cooling water system and mix it with the ion exchange resin. After 10-20 minutes, take out the quantitative solution from the cooling water system in the ultra-high pressure converter valve and mix it with the ion exchange resin, and so on, until the adsorption is balanced and the equilibrium adsorption amount is obtained. The equilibrium adsorption amount Q e Calculated according to formula (1), as follows:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com