Sodium sulfide MVR plate-type evaporation process

A plate evaporation and sodium sulfide technology, applied in the field of sodium sulfide MVR plate evaporation process, can solve the problems of increasing the operating cost of the enterprise, reducing the system capacity, increasing the burden on the enterprise, etc., achieving high dissolution and descaling efficiency, reducing operating costs and reducing burdens Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

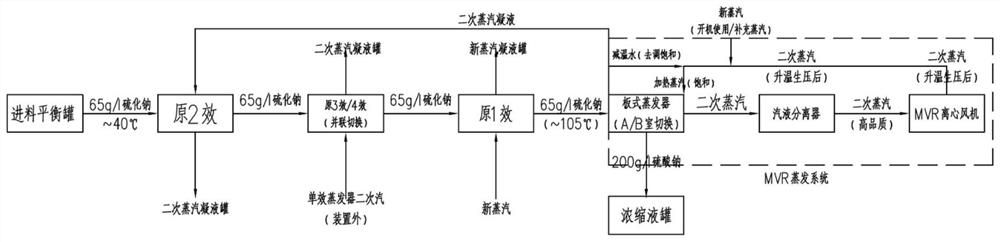

[0021] see figure 1 , the present invention provides a technical solution: a sodium sulfide MVR plate evaporation process, comprising the following process:

[0022] S1. Send the sodium sulfide feed liquid in the feed balance tank with a concentration of 65g / l and a temperature of 40°C to the original second effect for preheating, then to the original third effect for preheating, and finally to the original first effect for preheating. Heat to 105°C;

[0023] S2. Inject the sodium sulfide feed liquid preheated to 105°C in S1 into room A of the plate evaporator, and then into room B, and the concentrated solution will be effective. The sodium sulfide feed liquid with a concentration of 200g / l and a temperature of 98°C will enter the concentrated liquid Tank, after buffering, enter the next stage of concentration, and generate secondary steam at the same time;

[0024] S3. The secondary steam generated by the plate evaporator in S2 enters the vapor-liquid separator for process...

Embodiment 2

[0031] see figure 1 , the present invention provides a technical solution: a sodium sulfide MVR plate evaporation process, comprising the following process:

[0032] S1. Send the sodium sulfide feed liquid in the feed balance tank with a concentration of 65g / l and a temperature of 40°C to the original second effect for preheating, then to the original fourth effect for preheating, and finally to the original first effect for preheating. heat up to 100°C;

[0033] S2. Inject the sodium sulfide feed liquid preheated to 105°C in S1 into room A of the plate evaporator, and then into room B, and the concentrated solution will be effective. The sodium sulfide feed liquid with a concentration of 200g / l and a temperature of 98°C will enter the concentrated liquid Tank, after buffering, enter the next stage of concentration, and generate secondary steam at the same time;

[0034] S3. The secondary steam generated by the plate evaporator in S2 enters the vapor-liquid separator for pro...

Embodiment 3

[0041] see figure 1 , the present invention provides a technical solution: a sodium sulfide MVR plate evaporation process, comprising the following process:

[0042] S1. Send the sodium sulfide feed liquid in the feed balance tank with a concentration of 65g / l and a temperature of 40°C to the original second effect for preheating, then to the original fourth effect for preheating, and finally to the original first effect for preheating. Heat to 105°C;

[0043] S2. Inject the sodium sulfide feed solution preheated to 105°C in S1 into room A of the plate evaporator, and then into room B, and the concentrated solution will be effective. The sodium sulfide feed solution with a concentration of 200g / l and a temperature of 95°C will enter the concentrated solution Tank, after buffering, enter the next stage of concentration, and generate secondary steam at the same time;

[0044] S3. The secondary steam generated by the plate evaporator in S2 enters the vapor-liquid separator for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com