Method and system for anti-scaling and descaling of membrane evaporator

A film evaporator and anti-scaling technology, which is applied in the direction of cleaning heat transfer devices, flushing, lighting and heating equipment, etc., can solve the problems of slow material flow, scaling, and affecting production efficiency, so as to slow down the speed of scaling , Strengthen heat transfer efficiency, improve the effect of descaling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

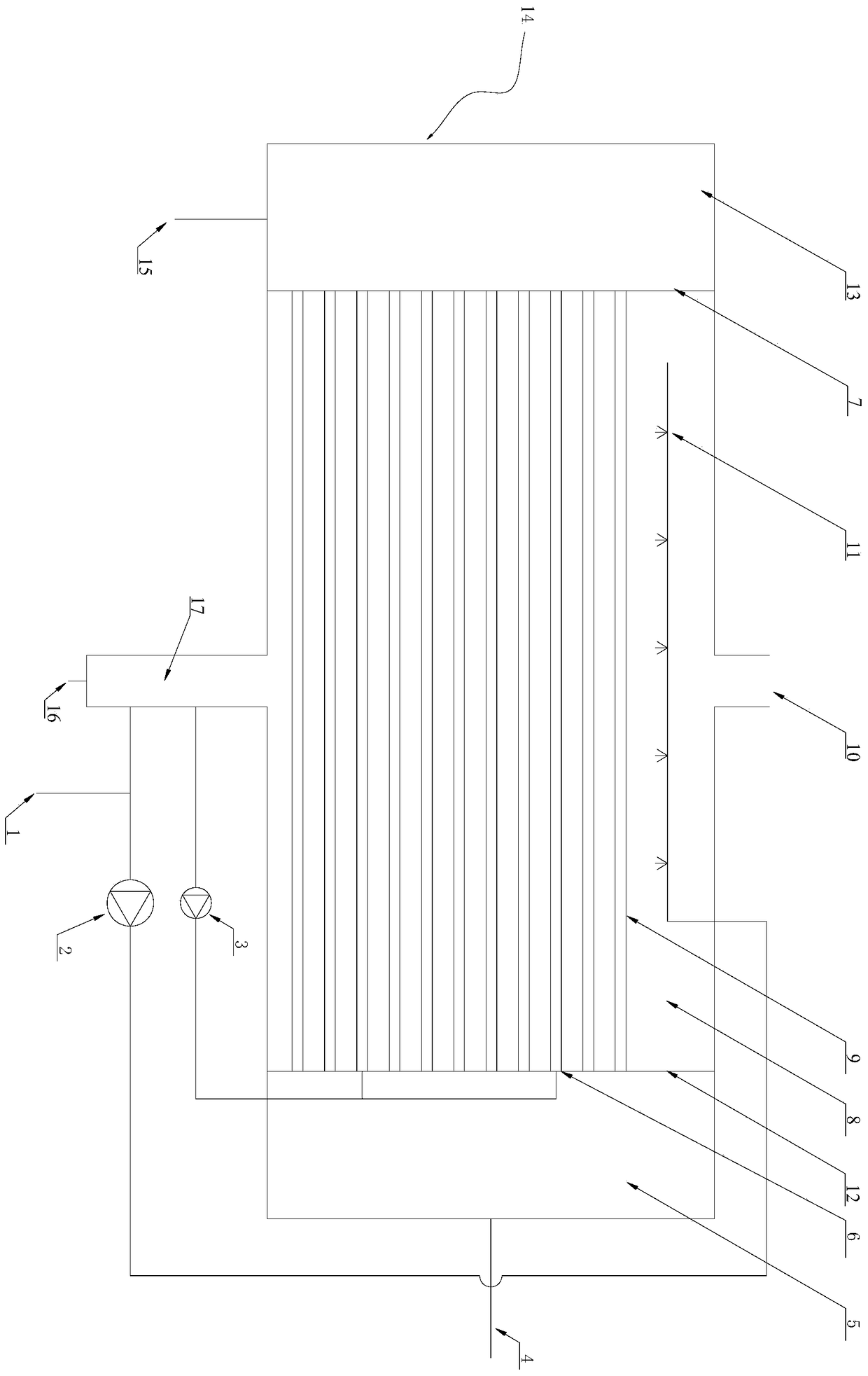

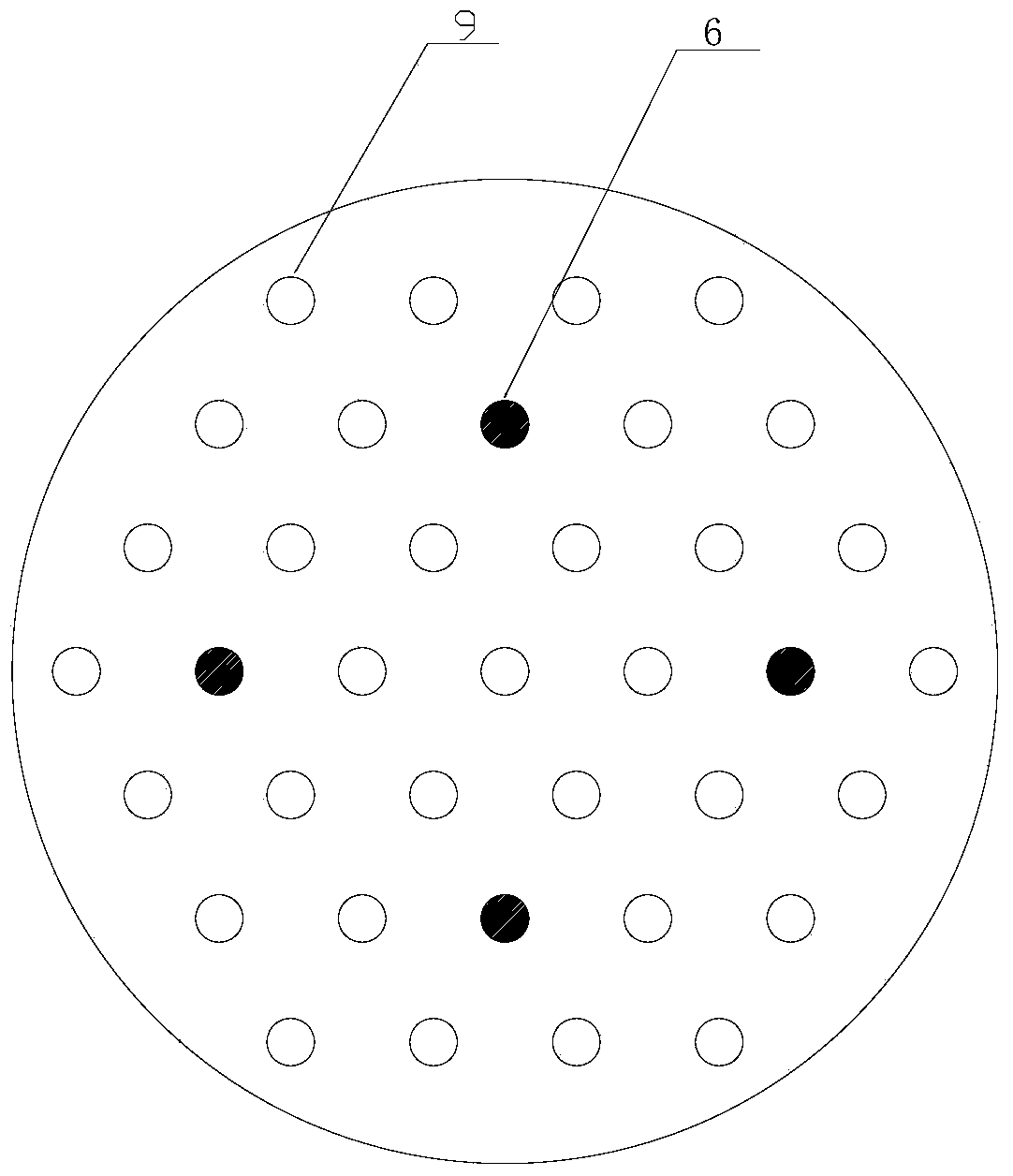

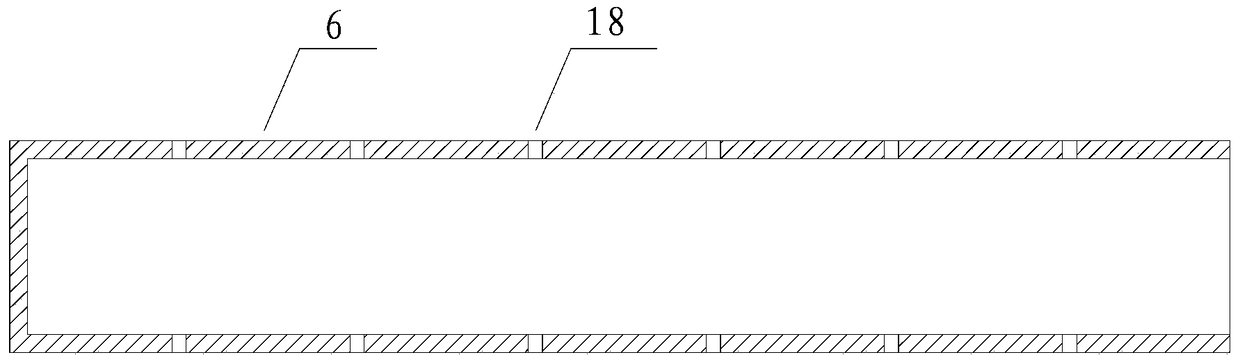

[0037] refer to figure 1 , the present invention adopts two kinds of flow rate fluids to pass through the heat exchange surface. One is the main fluid pumped by the second circulation pump 2, which is the same as the existing film evaporator, with large flow rate and low flow rate; the other is the secondary fluid pumped by the first circulation pump 3, with small flow rate and low flow rate. The flow rate is high, and the high-speed fluid sprays the surface of the heat exchange tube to wash away the scale that has just formed on the heat exchange surface. The auxiliary fluid is sprayed out after being pressurized by the first circulation pump 3. The power consumption per unit mass of the fluid is higher than that of the main fluid, but the flow of the auxiliary fluid is less, generally only accounting for 2-4% of the main fluid, so the overall energy consumption increases little.

[0038] The auxiliary fluid is pressurized by the first circulation pump 3 and enters the injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com