Combustible solid waste pyrolysis device and pyrolysis method

A solid waste and pyrolysis technology, which is applied in the direction of direct heating dry distillation, special form dry distillation, petroleum industry, etc., can solve the difficulty of pyrolysis control of combustible solid waste, large fluctuation range of solid waste composition, composition ratio changes, etc. problems, to achieve the effects of easy large-scale continuous production, accurate control of solid circulation flux, and avoiding high oxidation and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

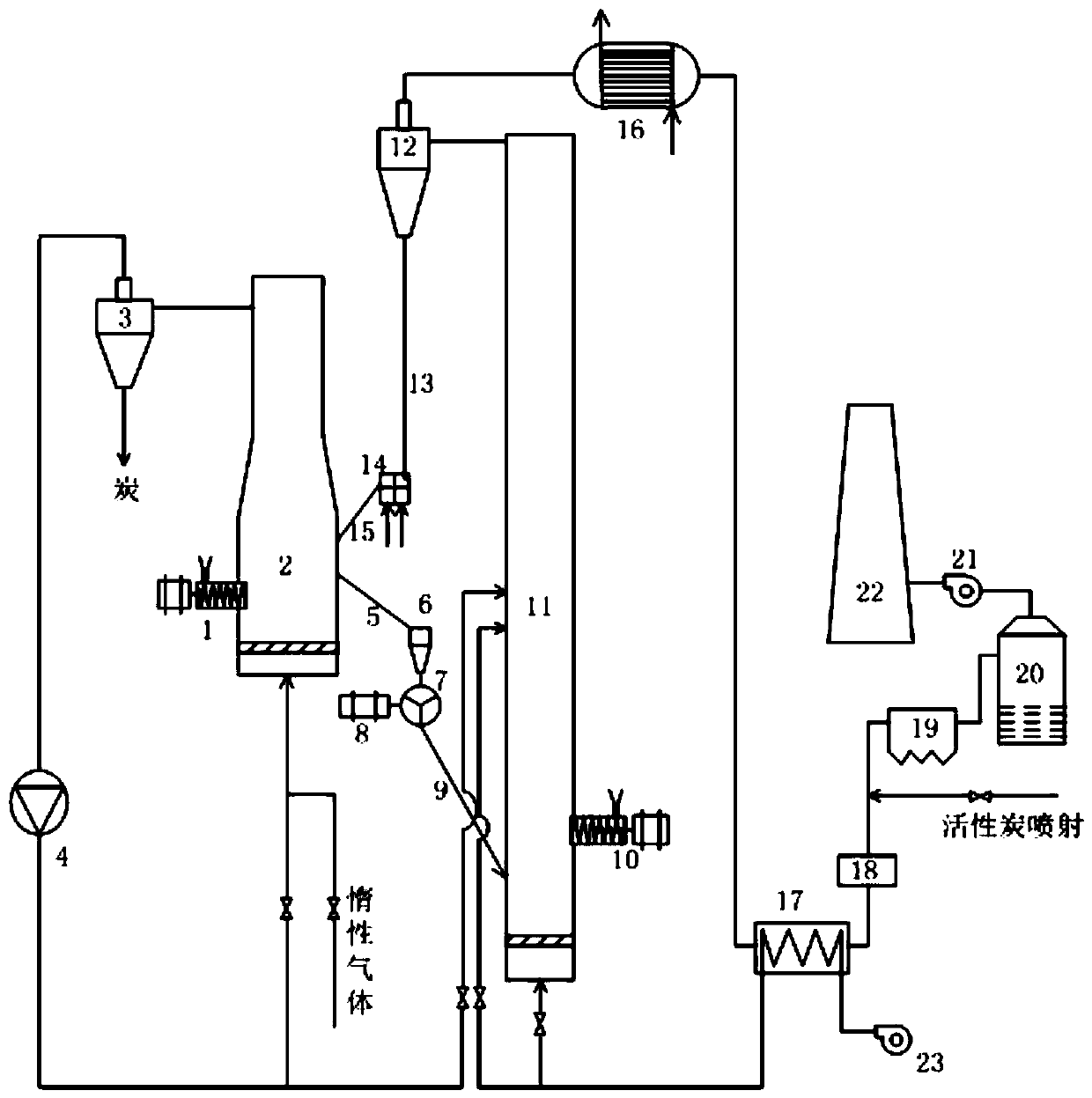

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] A combustible solid waste pyrolysis device of the present invention, such as figure 1 , the device uses alternating circulation double fluidized bed, including fluidized bed combustion reactor and fluidized bed pyrolysis reactor.

[0028] The upper outlet of the fluidized bed pyrolysis reactor 2 is connected to the pyrolysis reactor cyclone separator 3, and the solid carbon is directly collected by the pyrolysis reactor cyclone separator 3, and the gas is connected to the circulating fan 4; the fluidized bed pyrolysis reactor The middle part is provided with a pyrolysis reactor overflow inclined pipe 5 connected to the pyrolysis reactor buffer bin 6, and then sent to the pyrolysis reactor star-shaped feeder 7; the star-shaped feeder 7 passes through the combustion reactor to return the inclined pipe 9 is connected to the fluidized bed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com