Patents

Literature

41results about How to "Ease of large-scale continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High impact high gloss bimodal polystyrene material and preparation method thereof

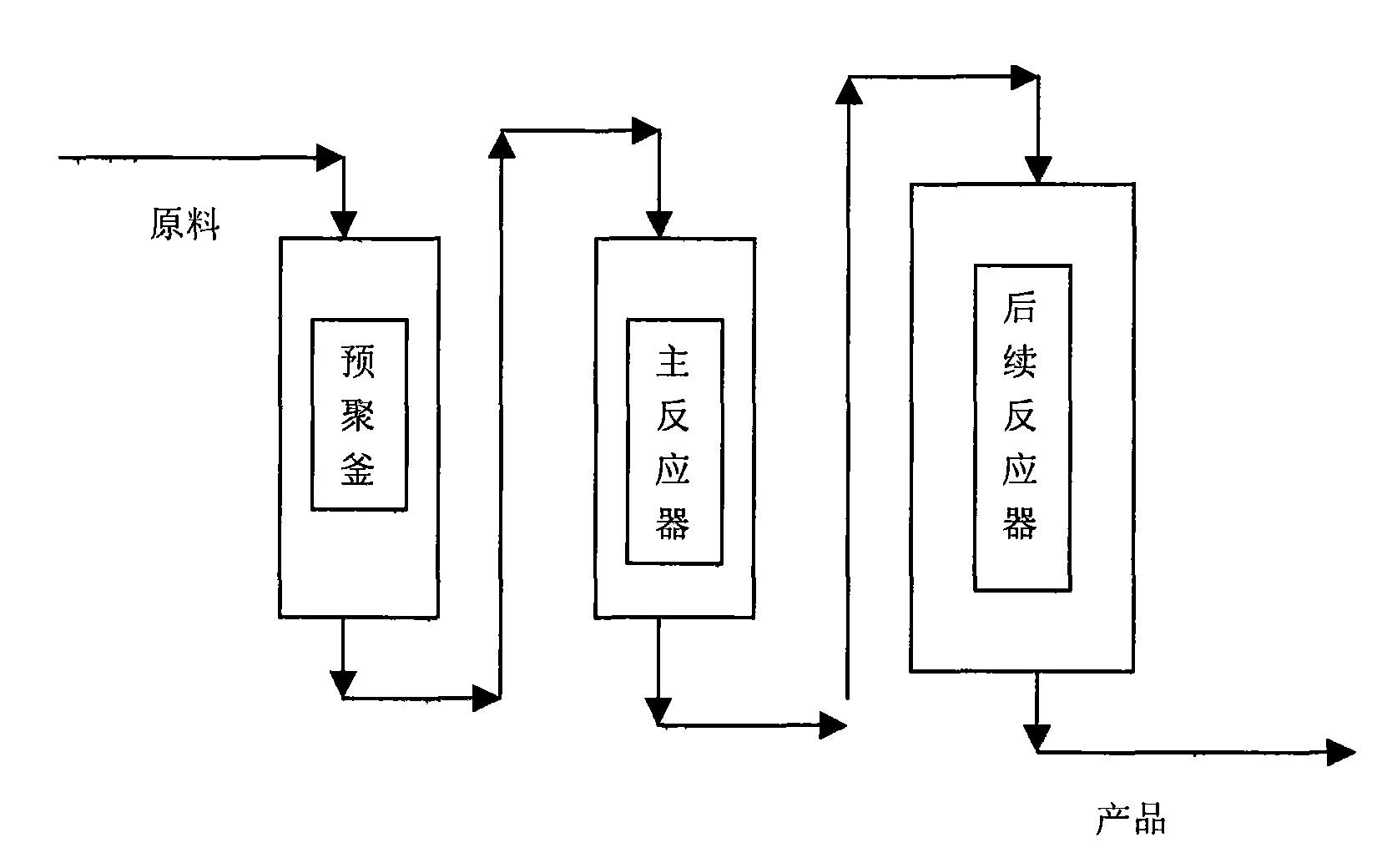

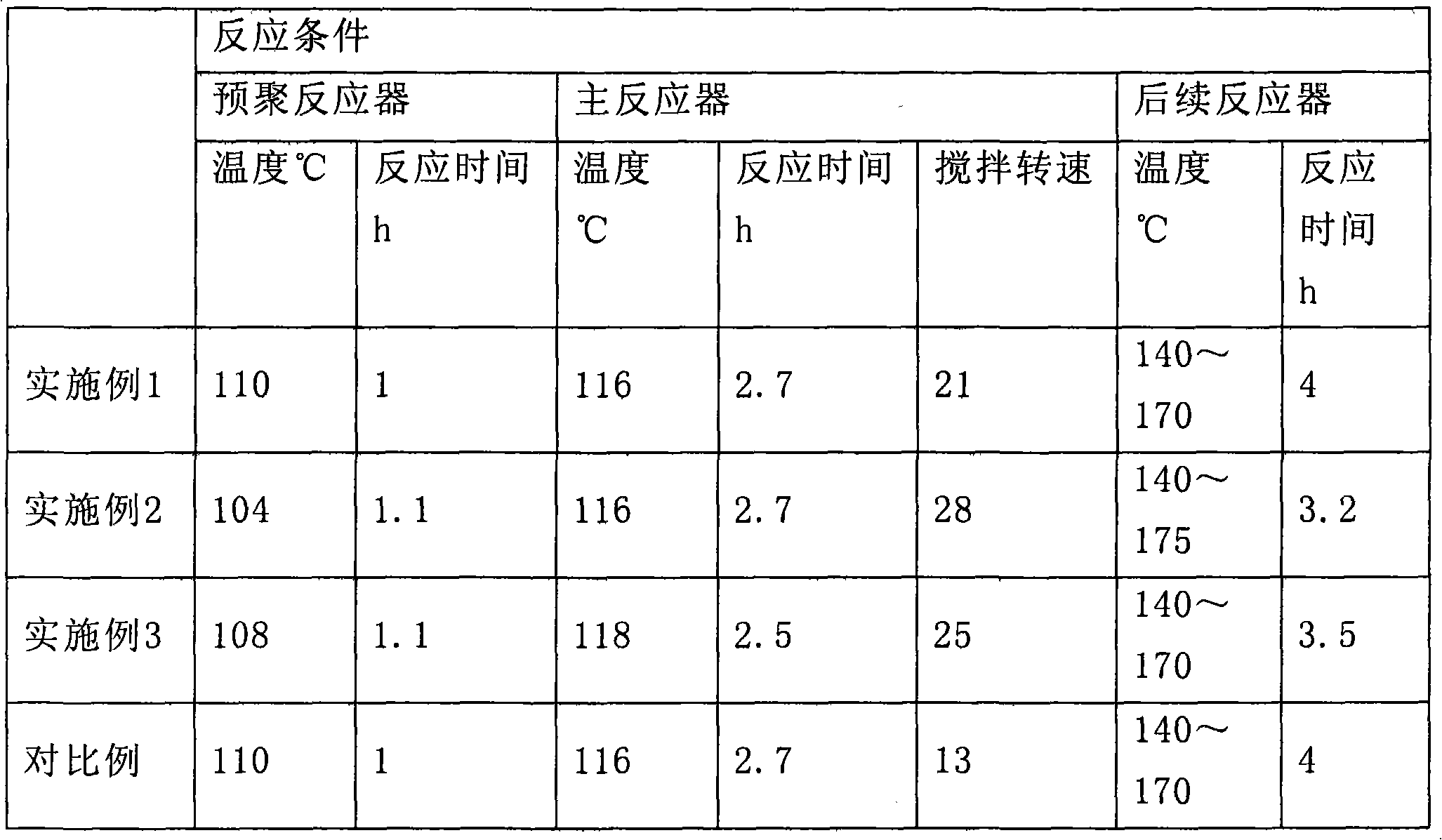

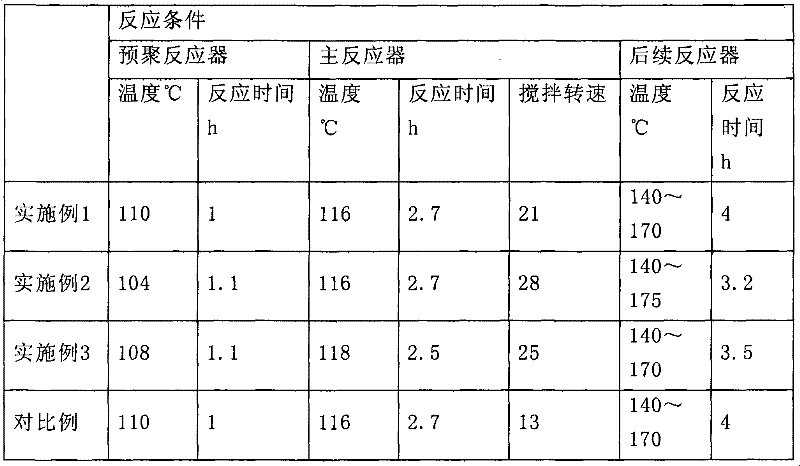

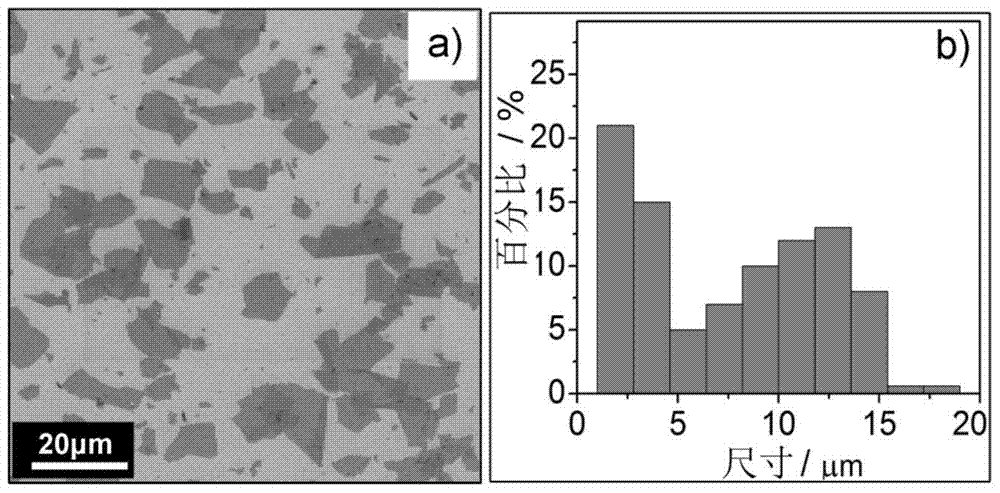

The invention provides a high impact high gloss bimodal polystyrene material and preparation method thereof, comprising the following steps: (a) the solution of polybutadiene rubber component mixed with polystyrene monomers is provided; wherein, the polybutadiene rubber component is selected from high cis-polybutadiene and / or low cis-polybutadiene, the cis-content of high cis-polybutadiene is not less than 94% by mole and the cis-content of low cis-polybutadiene is between 33% to 40% by mole ; (b) the solution obtained from the step (a) is used to perform prepolymerization reaction of styrene monomers to obtain a prepolymerization solution system which does not generate phase transition; (c) the prepolymerization solution system obtained from the step (b) is used to perform further prepolymerization reaction of styrene monomers in shearing force field until the system generates phase transition to obtain rubbery state material of which the particle size presents bimodal distribution; (d) the conversion rate of styrene monomers in the material obtained from the step (c) is further increased to obtain the high impact high gloss bimodal polystyrene material. The invention also provides a preparation method of the high impact high gloss bimodal polystyrene material.

Owner:SHANGHAI SECCO PETROCHEM

Method for extracting rose flavone from rose residue solution

ActiveCN103588742AEfficient separationOptimize process flowOrganic chemistryNatural dyesAlcoholFiltration

The invention relates to a method for extracting rose flavone from a rose residue solution. The method comprises the following steps: (1), filtering the rose residue solution, concentrating, adding ethyl alcohol to adjust the pH value of the solution, refrigerating and standing in the absence of light; (2), performing suction filtration on the solution in the step (1), and concentrating, so as to obtain rose flavone pigment coarse powder; (3), performing separation and purification on the rose flavone pigment coarse powder obtained in the step (2), so as to obtain eluant; (4), concentrating and drying the eluant, so as to obtain dry flavone. According to the invention, the flavone extraction ratio reaches above 8% to the maximum extent, and is greatly improved compared with the flavone extraction ratio being not higher than 5% in the prior art; the obtained flavone is bright red in color, and can be widely applied to the fields of medicine and food.

Owner:银谷芳香科技有限公司

Shape memory polymer composite and preparation method thereof

The invention relates to a shape memory polymer composite and a preparation method thereof. The composite is mainly prepared from random copolymer elastomer and small organic molecular crystal substances, and can also be prepared from other auxiliaries. Shape memory thin films, sheets, fiber and other products are directly obtained by sufficiently blending raw materials through a double-screw extruder. Random copolymer elastomer has good entropy elasticity and plays a role in restoring the original shape of the composite. Small organic molecule substances play a role in fixing and releasing the temporary shape of the composite through crystallization and fusion transformation. Random copolymer elastomer and small organic molecular crystal substances are used in cooperation for making the composite have excellent shape memory performance. Raw materials are common, easy to obtain and low in price. The double-screw extrusion method is a continuous preparation process, one-step preparation from raw materials to shape memory products is achieved, efficiency is high, the product stability is good, no solvent is used, and environment friendliness is achieved. Cost of shape memory polymer materials is powerfully reduced, and the preparation efficiency of shape memory polymer materials is remarkably improved.

Owner:TONGJI UNIV

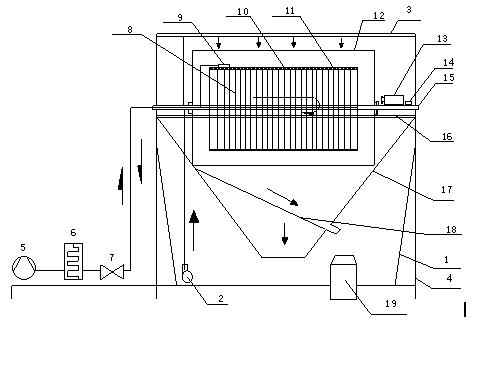

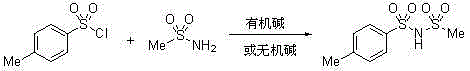

Method for desalting and purifying sewage through refrigeration and centrifugation and device thereof

InactiveCN102161516ALow fade effectReduce production energy consumptionGeneral water supply conservationWater/sewage treatment by freezingFrequency changerCollection system

The invention discloses a method for desalting and purifying sewage through refrigeration and centrifugation and a device thereof. The device consists of a water inlet system, an air-conditioning refrigeration system, a rotating cylinder ice production system, and an ice cube separation and collection system, wherein the water inlet system consists of a pre-cooling water tank, a submersible pump and a perforated spray pipe; the air-conditioning refrigeration system consists of a compressor, a condenser, a throttle valve and an evaporator; the rotating cylinder ice production system comprises an internal cylinder, an external rotating cylinder and a transmission system consisting of a variable-frequency adjustable-speed motor and a frequency converter; and the ice cube separation and collection system consists of a scraping knife, a square bucket, a screen and a centrifugal machine. The purification device can ensure that the removal rate of salinity in the sewage reaches between 80 and 96 percent and the removal rate of algae is kept between 35 and 70 percent. The method in which the sewage is desalted by adopting the device for desalting and purifying the sewage through refrigeration and centrifugation is suitable for large-scale continuous production; the production energy consumption is low; and the method and the device are widely applied to seawater desalination, strong water desalination and sewage purification in the future.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

Method for producing nutritional fine meal by utilizing edible fungus rinsing and scalding liquid

ActiveCN101822376AHigh value-added development and productionFull of nutritionFood preparationBiotechnologyMycoprotein

The invention provides a method for producing nutritional fine meal by utilizing an edible fungus rinsing and scalding liquid, and microcapsule functional nutritional fine meal is obtained by the method through the steps of filtering, wall material mixing, stirring, homogenizing and spray drying of the edible fungus rinsing and scalding liquid. The rinsing and scalding liquid disused in the edible fungus processing process is utilized by the method for producing the functional nutritional fine meal rich in granulose, edible fungus polyphenol and mycoprotein; consequently, not only the current problem of rinsing and scalding liquid processing is solved, pollution is reduced, and resources are reasonably used, but also the method is easy for continuous large-scale industrial production, and the produced microcapsule fine meal has the characteristics of abundant nutrition, good stability and long storage period.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

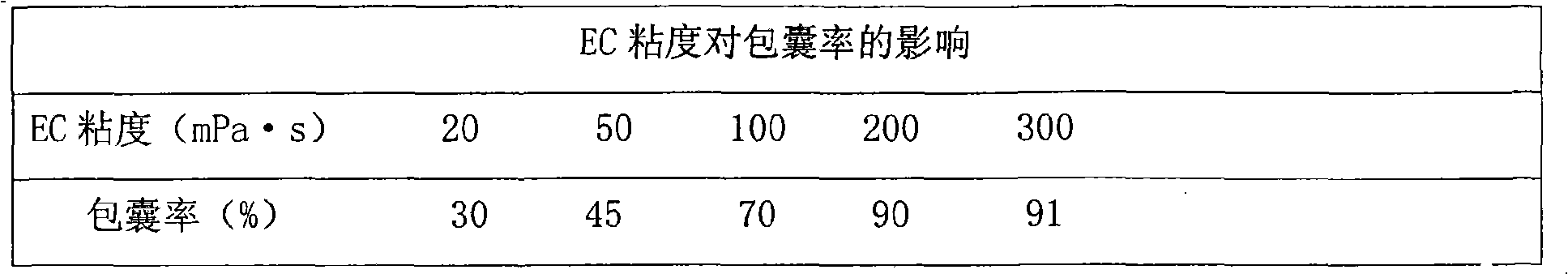

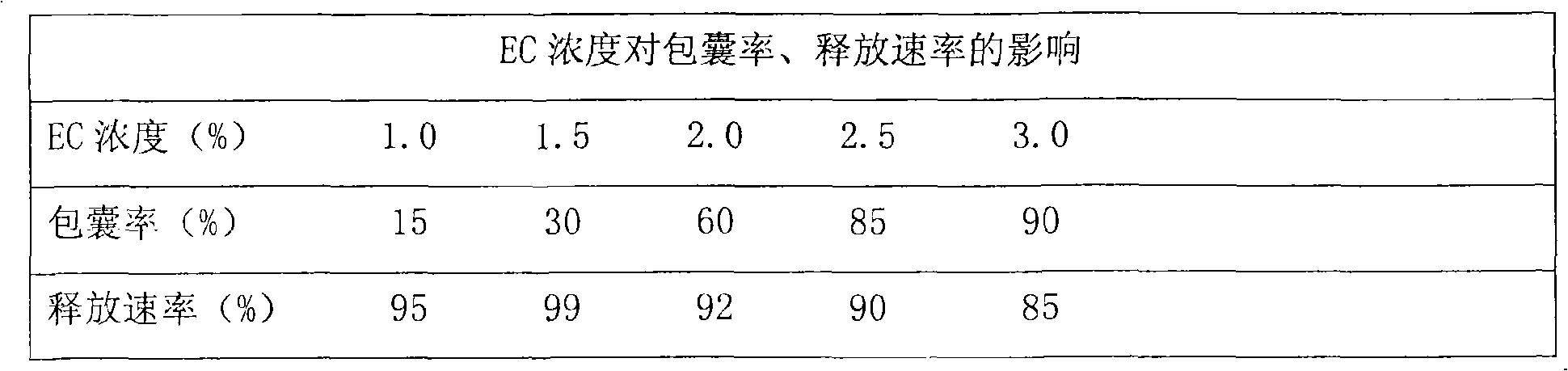

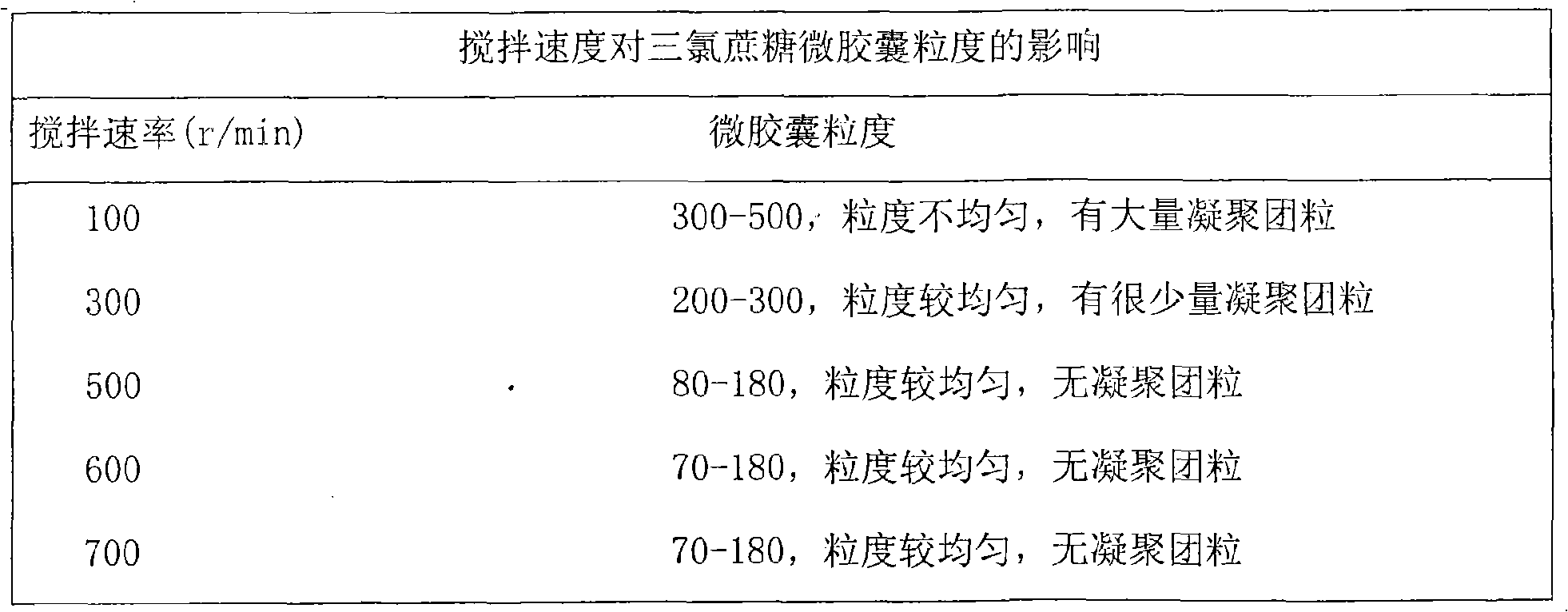

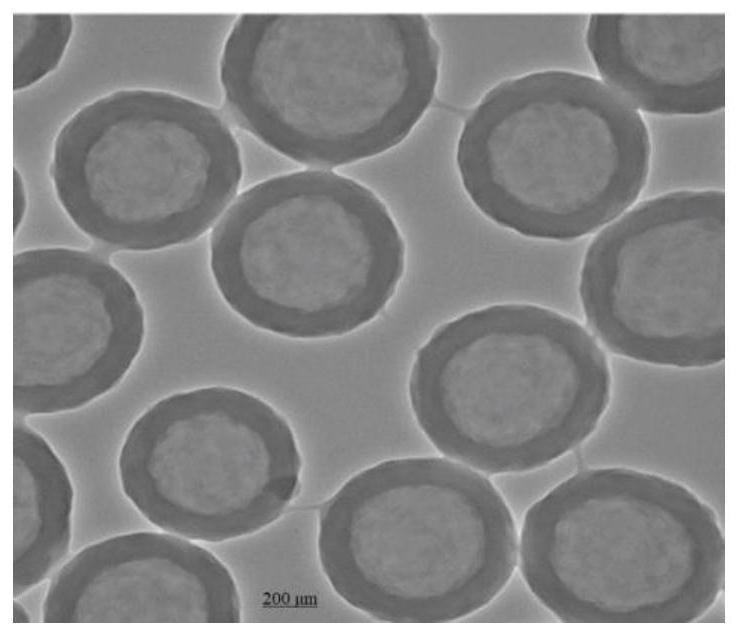

Sucralose microcapsule and preparation method thereof

The invention discloses a sucralose microcapsule and a preparation method thereof; the microcapsule comprises a capsule core and a capsule wall material, which is characterized in that the capsule core of the microcapsules uses sucralose as the main drug with the content being 2%-3%; a thinner is formed by combining any two of mannitol, sorbitol, erythritol, maltitol, xylitol, glucose, dextrine, aspartame, acesulfame potassium and fructose with the contents being respectively 40%-50%; and the dosage of a binder is 0.2%-0.6%; the capsule wall material mainly uses ethyl cellulose and polyethene, the dosage of ethyl cellulose is 2%-10%, and the dosage of polyethene is 0.4-5%.The sucralose microcapsules of the invention can prevent sucralose grain raw material from deliquescing, oxidizing and deteriorating, thus preventing the sweet taste from losing, and the sucralose microcapsules can be released at a slow and constant speed, thus ensuring the evenness of the sweet taste of the granule beverage; the preparation method of the microcapsule is simple with low cost, which is suitable for large scale continuous production, and the finished product has high encapsulation rate and high yield.

Owner:南京仕浪药业有限公司

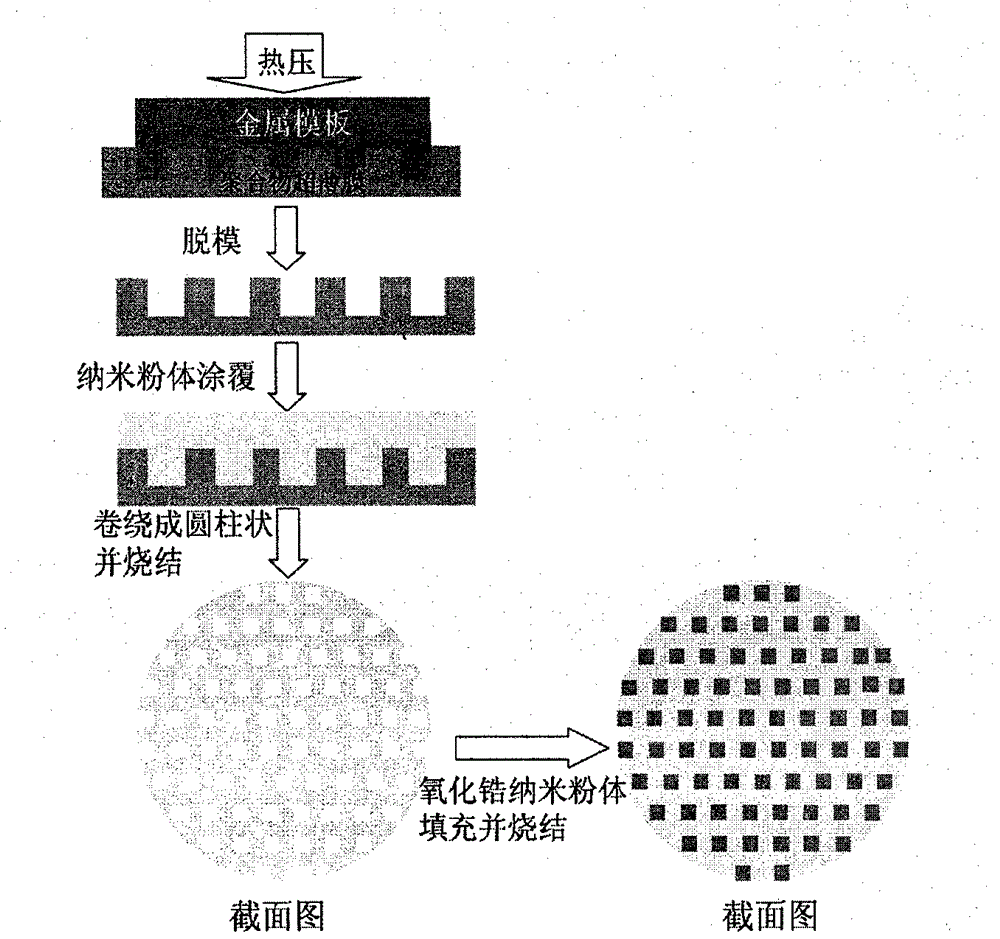

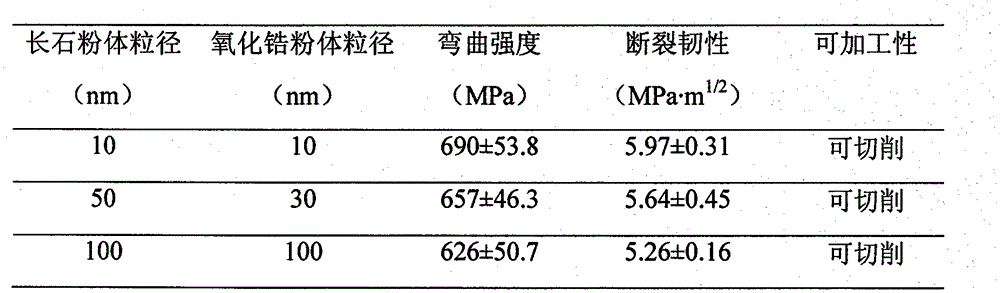

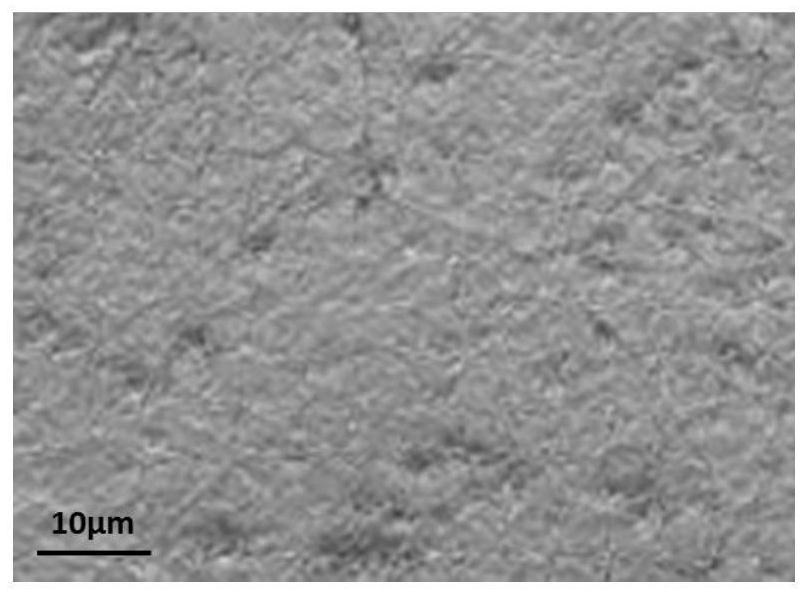

Preparation method of metal stable zirconia composite ceramics for dental restorations

InactiveCN103058653ASimple stepsHigh degree of automationImpression capsDentistry preparationsDental enamelComposite ceramic

The invention discloses a preparation method of metal stable zirconia composite ceramics for dental restorations, and a new template-sintering process is adopted in the preparation method. The preparation method comprises the following steps of: using a micromachining technology to process a metal template, and transferring a micro structure on the surface of the metal template on a polymer ultrathin membrane; and then coating nano feldspar powder on the polymer ultrathin membrane and sintering to obtain feldspathic porcelain with micron through hole structures; and finally filling metal stable zirconia nano powder into holes of the feldspathic porcelain and sintering to obtain the metal stable zirconia composite ceramics. The composite ceramics consist of the feldspathic porcelain and the metable stable zirconia, and have microstructures which are similar to dental enamel; and the zirconia ceramics serve as enamel prisms, and the feldspathic porcelain serves as an interprismatic substance. The composite ceramics have excellent mechanical properties and toughness; and a computer-aided design (CAD) / a computer-aided manufacturing (CAM) technology is utilized to process, and the surfaces of the composite ceramics are not veneered with ceramics, so that the ceramic fracture is avoided, and the composite ceramics can serve as materials for the dental restorations.

Owner:斯尔瑞(厦门)生物科技有限公司

Method for recycling waste artificial turf based on solid-phase mechanochemistry technology and material recycled by same

The invention discloses a method for recycling waste artificial turf based on solid-phase mechanochemistry technology and a material recycled by the same. The method comprises the following steps: directly putting the broken waste artificial turf or extruded aggregates into a high-speed pulverizer for circularly pulverizing for 1-5 times; putting the obtained primary powder into a solid-phase mechanochemical reactor for circularly grinding for 3-20 times; or continuously performing melt extrusion of the powder material to obtain a powder material containing 65-84wt% of polyolefin, 14-28wt% of polyester and 2-7wt% of silt and with the melt index of 0.9-1.8g / 10min and the average particle size of 52-283mu m or an aggregate material with the melt index of 1.2-1.8g / 10min, the tensile strength of 7.4-11.2Mpa and the breaking elongation of 237-336%. In the invention, the desire of no separation or classification or much washing can be truly realized in a process of recycling waste artificial turf, and the recycling technology is simple and efficient and is low in cost; and meanwhile, the high-performance high-value recycled waste artificial turf material enabling direct blending and melting processing and having good compatibility can be obtained.

Owner:SICHUAN UNIV

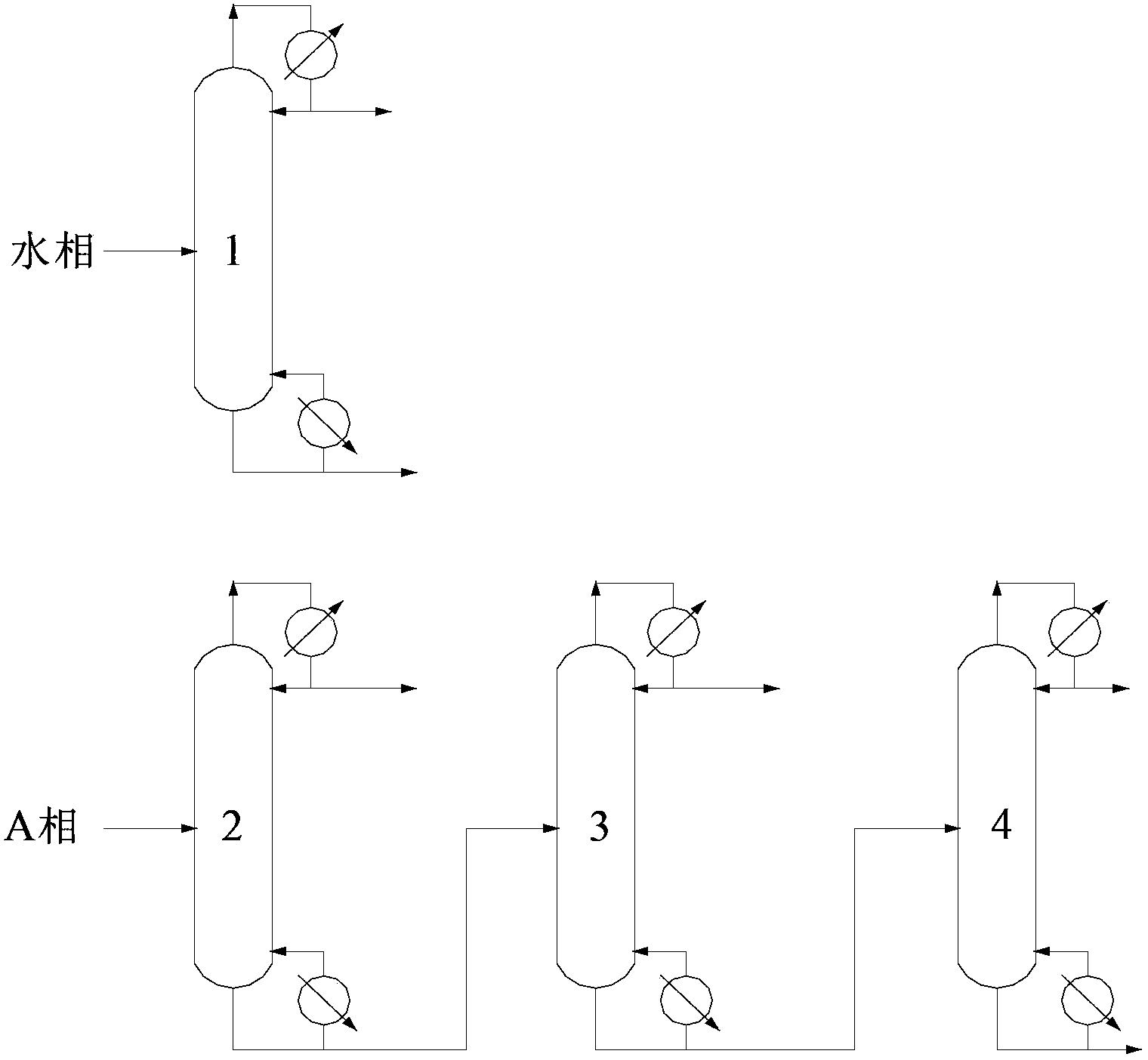

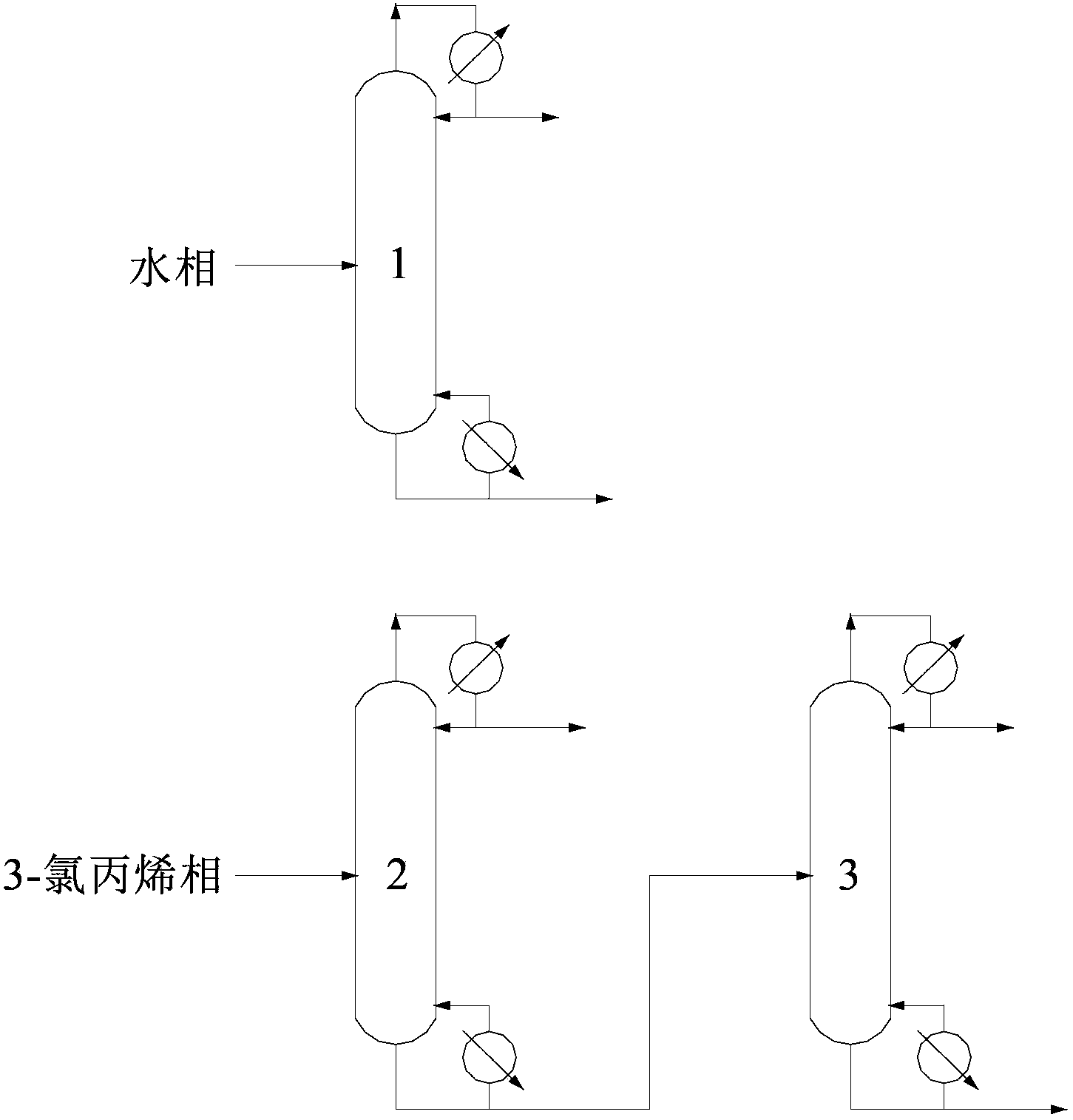

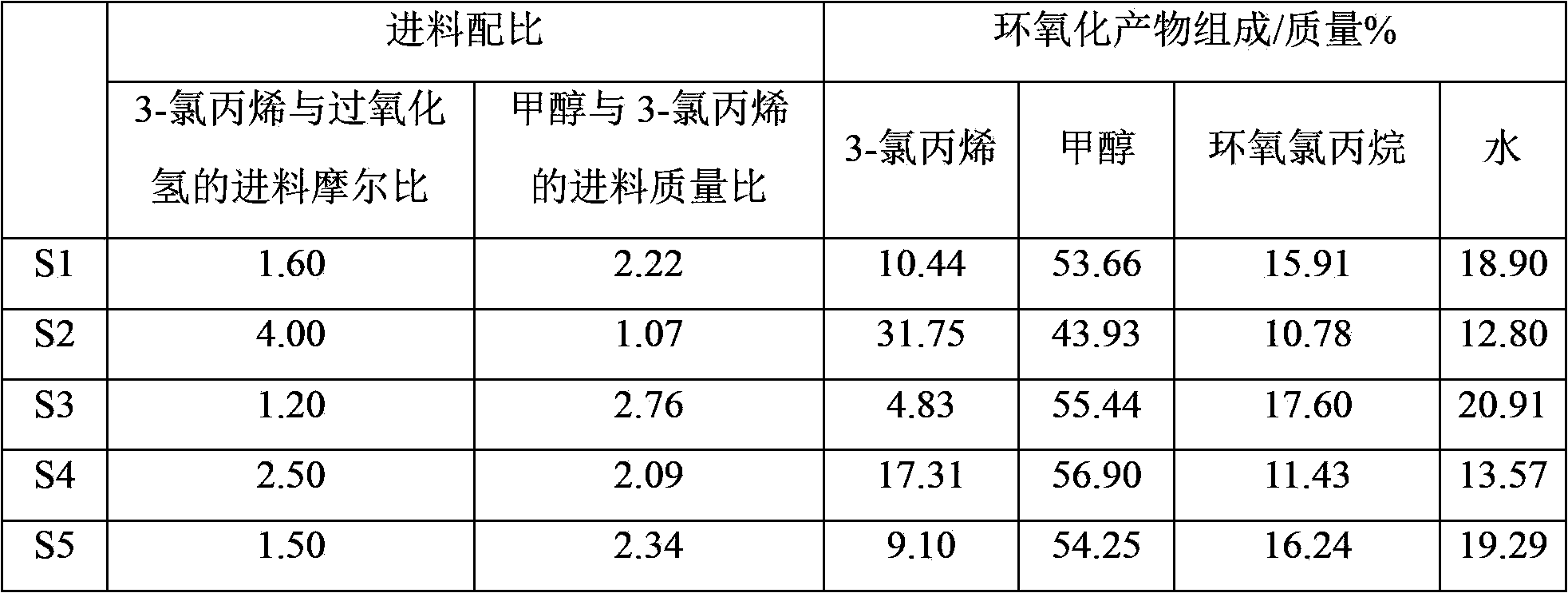

Separation method for epichlorohydrin

ActiveCN103420946ALower requirementReduce consumptionOrganic chemistryChemical industryOrganic solventBoiling point

A separation method for epichlorohydrin comprises: mixing a solution containing epichlorohydrin, methanol, 3-chloropropene and water and an extraction agent, separating to obtain a liquid phase rich in epichlorohydrin and a liquid phase rich in methanol, distilling the obtained the liquid phase rich in epichlorohydrin to obtain epichlorohydrin, wherein the extraction agent comprises water and an organic solvent immiscible with water, and the density difference between the organic solvent and water is at least 10 Kg / m<3>, the organic solvent is lower in methanol extraction capability and higher in epichlorohydrin extraction capability than water, and the organic solvent has a boiling point different with that of epichlorohydrin. The method has short separation time (less than 3 min) during extraction, so that the requirement on extractive separation equipment and the difficulty in extraction operation are reduced; also during distillation, only part of the extraction agent needs evaporative recovery, so that energy consumption is effectively reduced; and therefore, the method is quite suitable for large-scale continuous production.

Owner:CHINA PETROLEUM & CHEM CORP +1

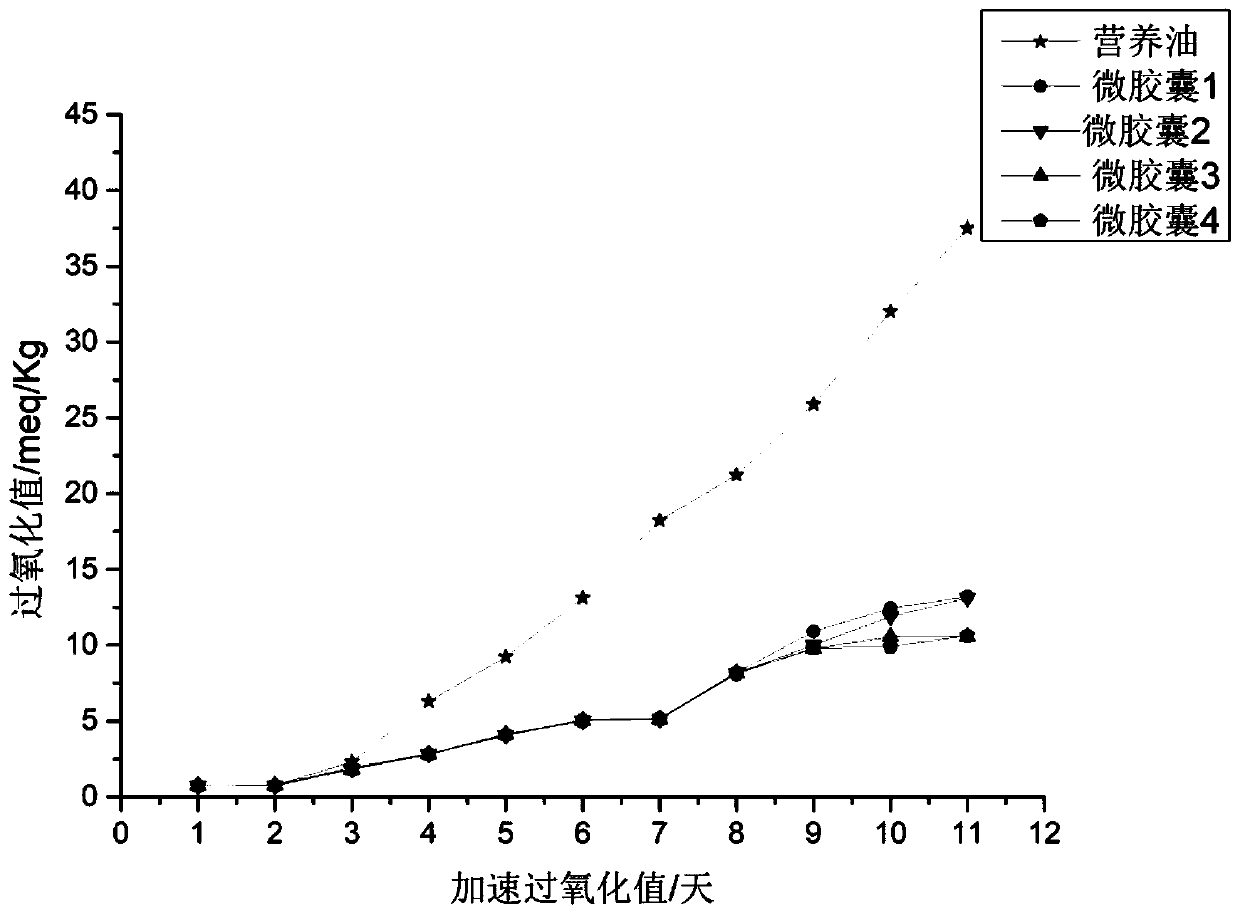

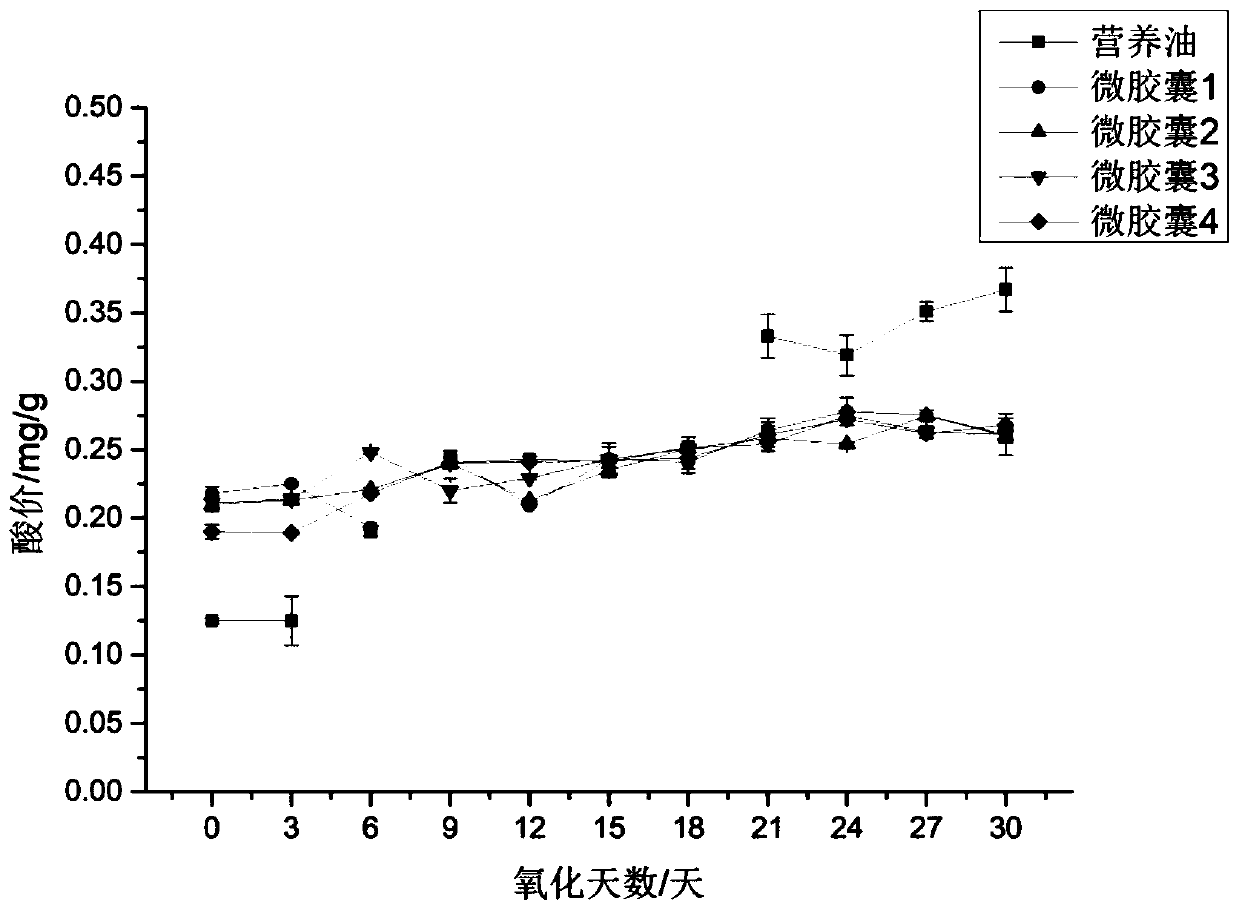

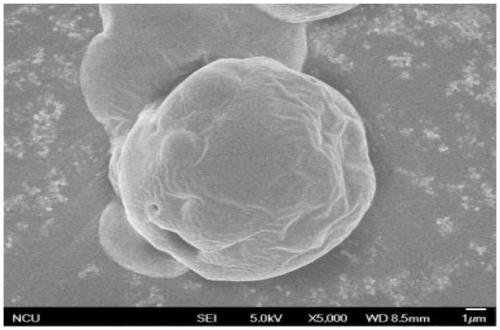

Method for producing fat microcapsules through low temperature electrostatic spray drying

The invention relates to the technical field of functional fat processing, in particular to a method for preparing fat microcapsules by a low temperature electrostatic spray drying method, and a method for producing fat microcapsules through nitrogen-charged low temperature electrostatic spray drying. The method comprises the steps of preparing materials, dissolving wall materials, preparing corematerials, pre-emulsifying the wall materials and the core materials, performing high-pressure homogenizing and performing spray drying. The fat microcapsules for infant formula milk powder, producedby the method disclosed by the invention, are high in oil content, can be stored at normal temperature for 2 years or above, and can be stored at 63 DEG C in a sealed light-away manner for 1 month, and the physical and chemical indexes of products conform to the national standard. The entrapping rate of the obtained perilla herb oil microcapsules disclosed by the invention is as high as 98% or above, compared with microcapsule products prepared by a traditional spray drying method, the fat microcapsules are lower in initial peroxide value and acid value, more stable in quality, simpler in technology and higher in operability, and large-scale continuous production is easy to realize.

Owner:NANCHANG UNIV +1

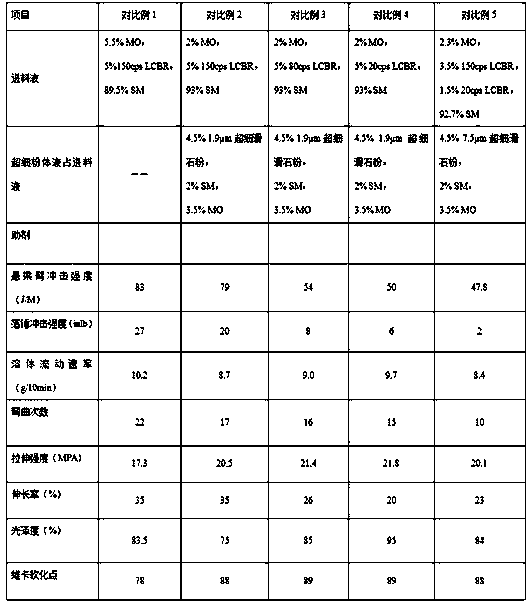

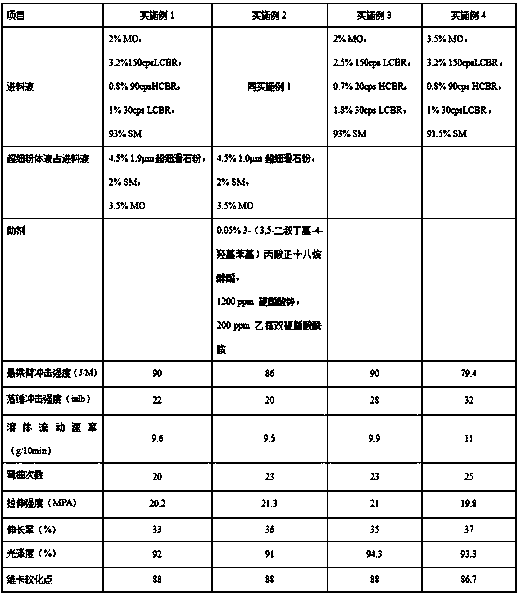

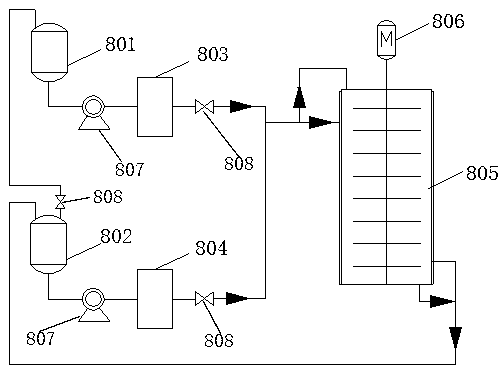

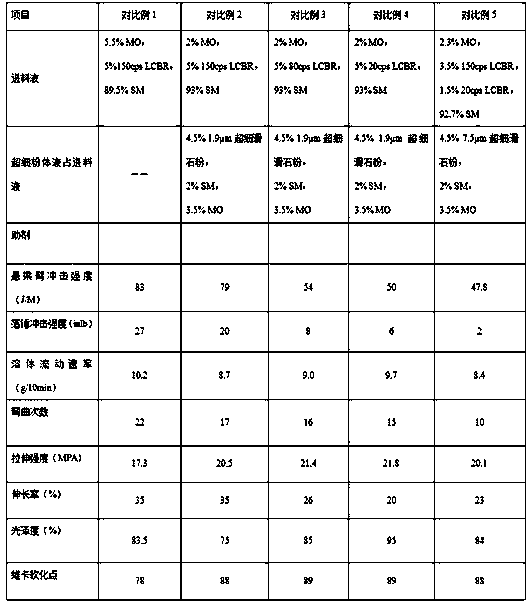

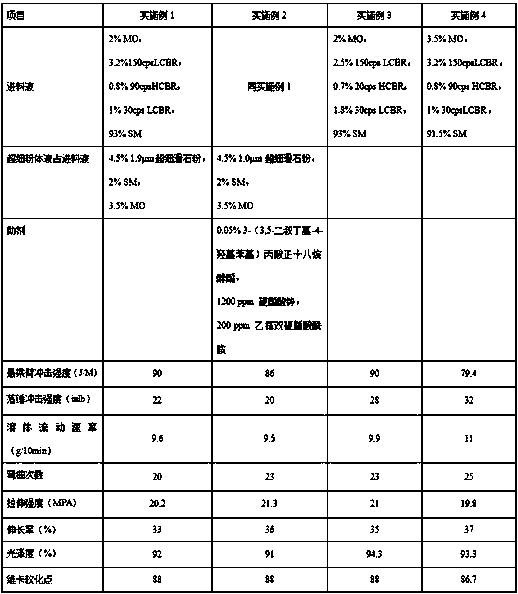

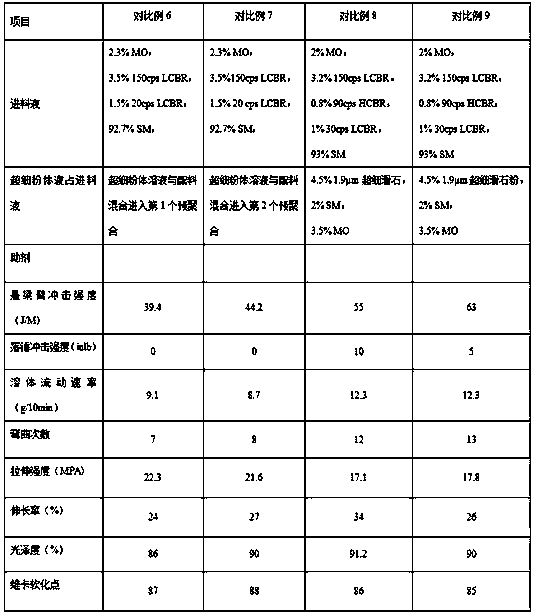

Medium-anti-impact polystyrene resin and preparation method thereof

The invention discloses medium-anti-impact polystyrene resin and a preparation method thereof. The resin is prepared from the following raw material ingredients in percentage by weight: 85 to 96 percent of styrene monomers, 1 to 6.5 percent of mixed rubber, 1 to 8 percent of flowing modifying agents and 1.5 to 7 percent of superfine powder, wherein the mixed rubber is prepared from two or three kinds of rubber in rubber with the solution viscosity being 140 to 190 cps, rubber with the solution viscosity being 70 to 100 cps and rubber with the solution viscosity being 20 to 50 cps. A polymerization method is used for replacing a mixing method to obtain the medium-anti-impact polystyrene resin; the cooperated effect of a PS body, rubber and ultrafine powder body is sufficiently achieved; onthe premise of ensuring the intensity, the consumption of the toughening agent rubber is possibly reduced, so that the intensity, the rigidity, the flowing performance and the luster degree of the product can be properly improved; the requirements of users on the medium-anti-impact product can be met; the mass production is easy.

Owner:GUANGDONG RASTAR SYNTHETIC MATERIAL COMPANY

Method for continuously preparing ordered membrane electrode catalyst layer on large scale

InactiveCN109888302AGood effectAchieve orderMaterial nanotechnologyCell electrodesFiberNano catalyst

The invention relates to the technical field of new energy batteries, in particular to a method for continuously preparing an ordered membrane electrode catalyst layer on a large scale. The catalyst layer is prepared by modifying polytetrafluoroethylene fibers with nano-catalysts, then carrying out mixing melting extrusion on the modified polytetrafluoroethylene fibers, perfluorinated sulfonic acid resin and carbon fibers, carrying out calendering to prepare a catalyst membrane blank, and finally carrying out heating and longitudinal stretching. According to the membrane electrode catalyst layer prepared with the method provided by the invention, the toughness and the strength are excellent, the carbon fibers and the catalysts are orderly arranged in a fiber shape; channels are provided for electron and proton transmission; micro-channels beneficial to gas and water transmission are reserved after being attached to a proton exchange membrane, so that the catalytic activity and the durability are improved; and moreover, the preparation method is simple and easy to control, and is easy for large-scale continuous production.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

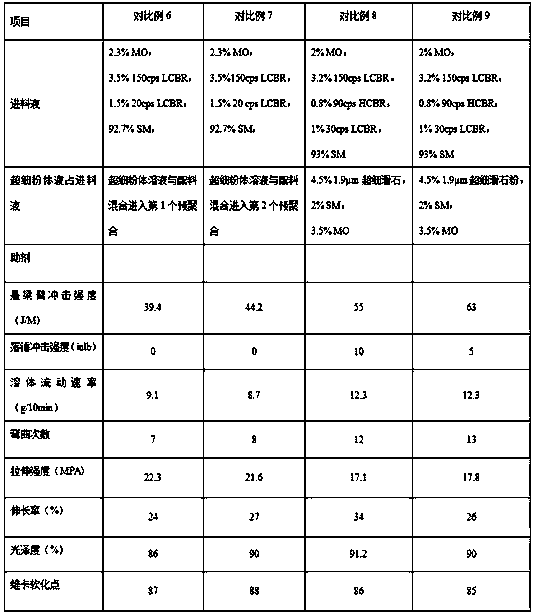

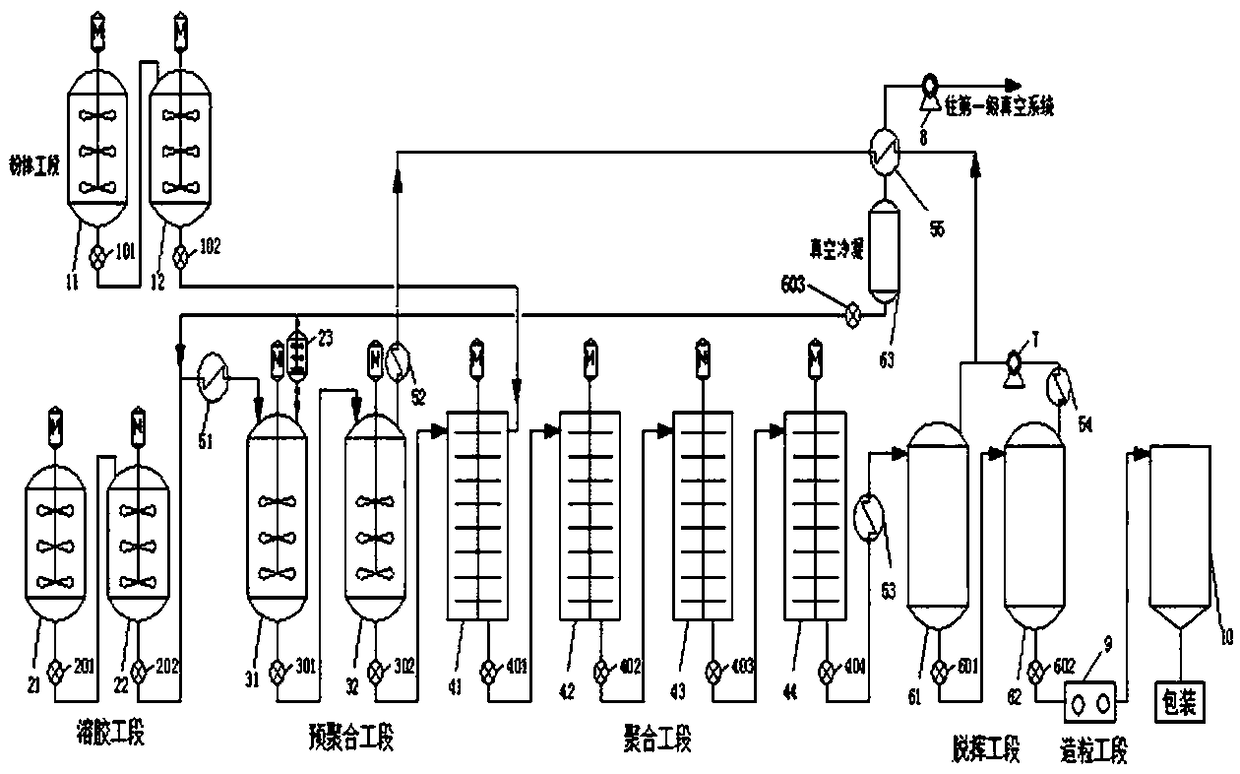

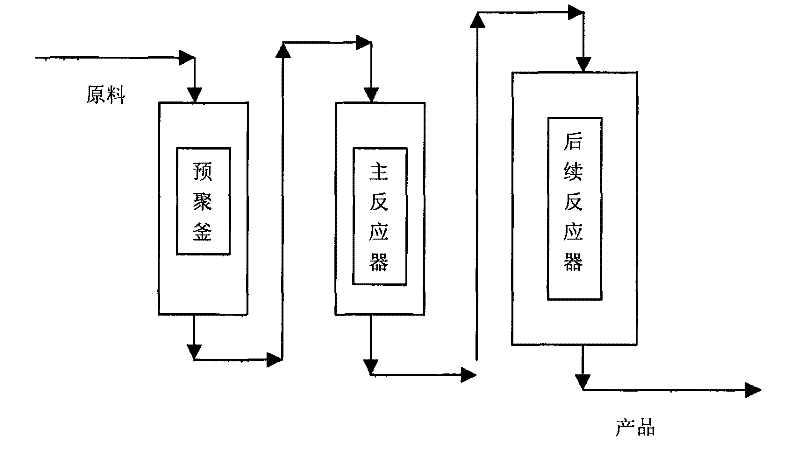

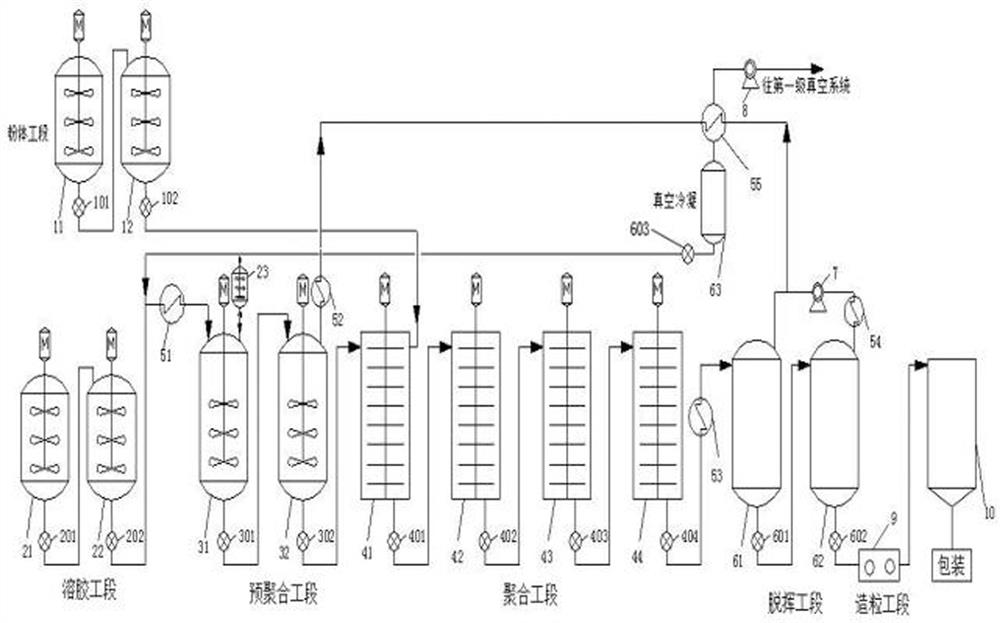

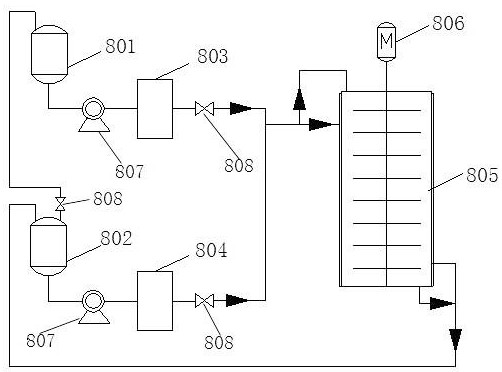

Medium-anti-impact polystyrene resin production system

The invention discloses a medium-anti-impact polystyrene resin production system, which comprises a system collosol tank, a mixed feeding tank, a two-stage prepolymerization reactor, a multistage polymerization reactor, a two-stage devolatilization device and a pelleting machine in sequential and series connection, wherein a superfine powder material preparation tank and a superfine powder feedingtank are connected in series and are then connected with an inlet of a first-stage polymerization reactor of the multistage polymerization reactor; a prepolymerization preheater is arranged on a pipeline between the mixed feeding tank and the first-stage polymerization reactor; a devolatilization preheater is arranged on a pipeline between the last-stage polymerization reactor of the multistage polymerization reactor and a first-stage devolatilization device; the upper parts of the end parts of the first-stage and second-stage devolatilization devices are connected in series and are then connected with a cycle condenser through a conveying pipeline; a connecting tank is connected with the bottom of the cycle condenser; a bottom outlet of the collecting tank is connected with an inlet of the prepolymerization preheater. A multistage prepolymerization-multistage polymerization-multistage devolatilization combination system is used; the requirements of users on medium-anti-impact products can be met; the large-scale production is easy.

Owner:GUANGDONG RASTAR SYNTHETIC MATERIAL COMPANY

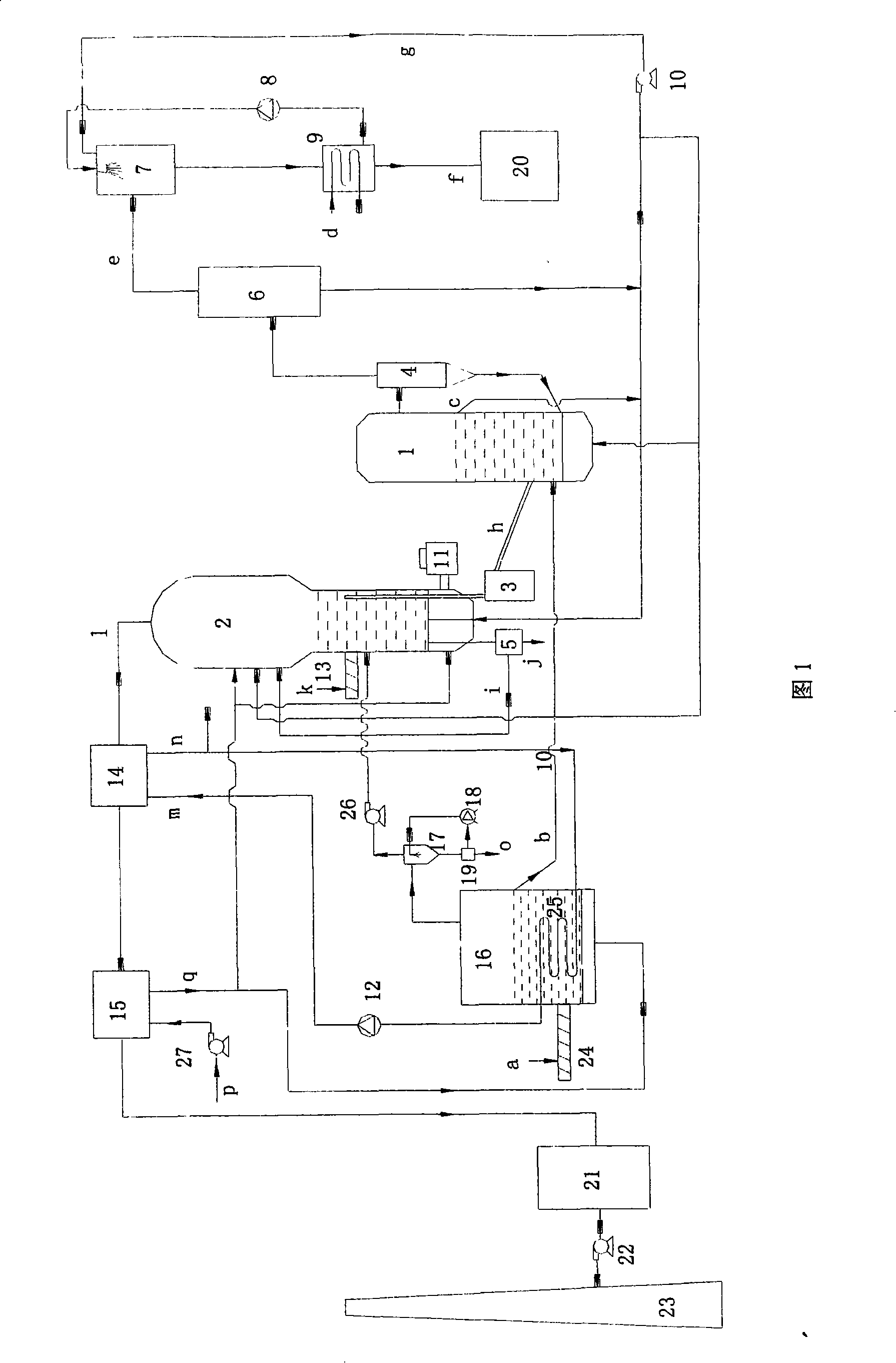

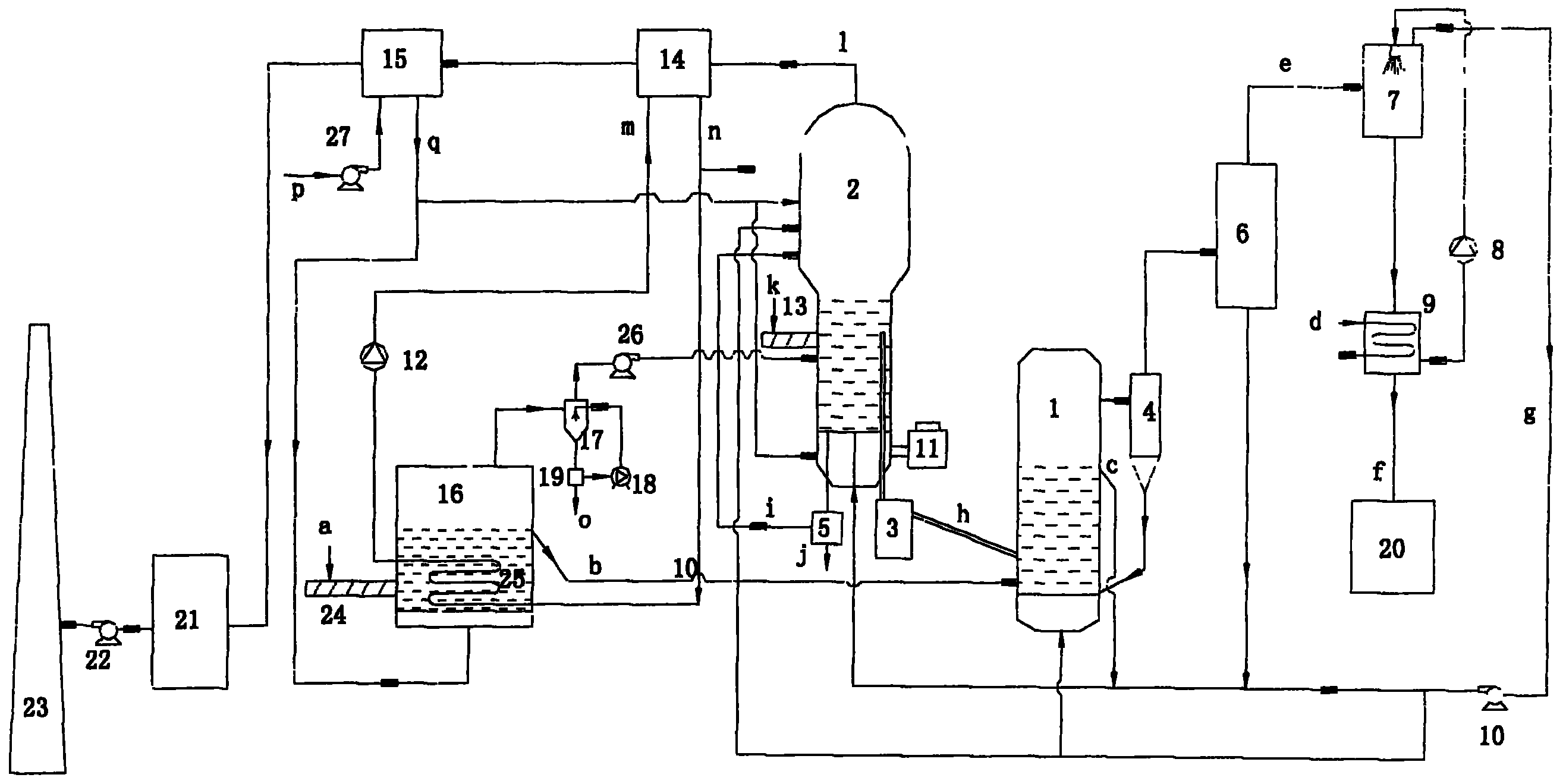

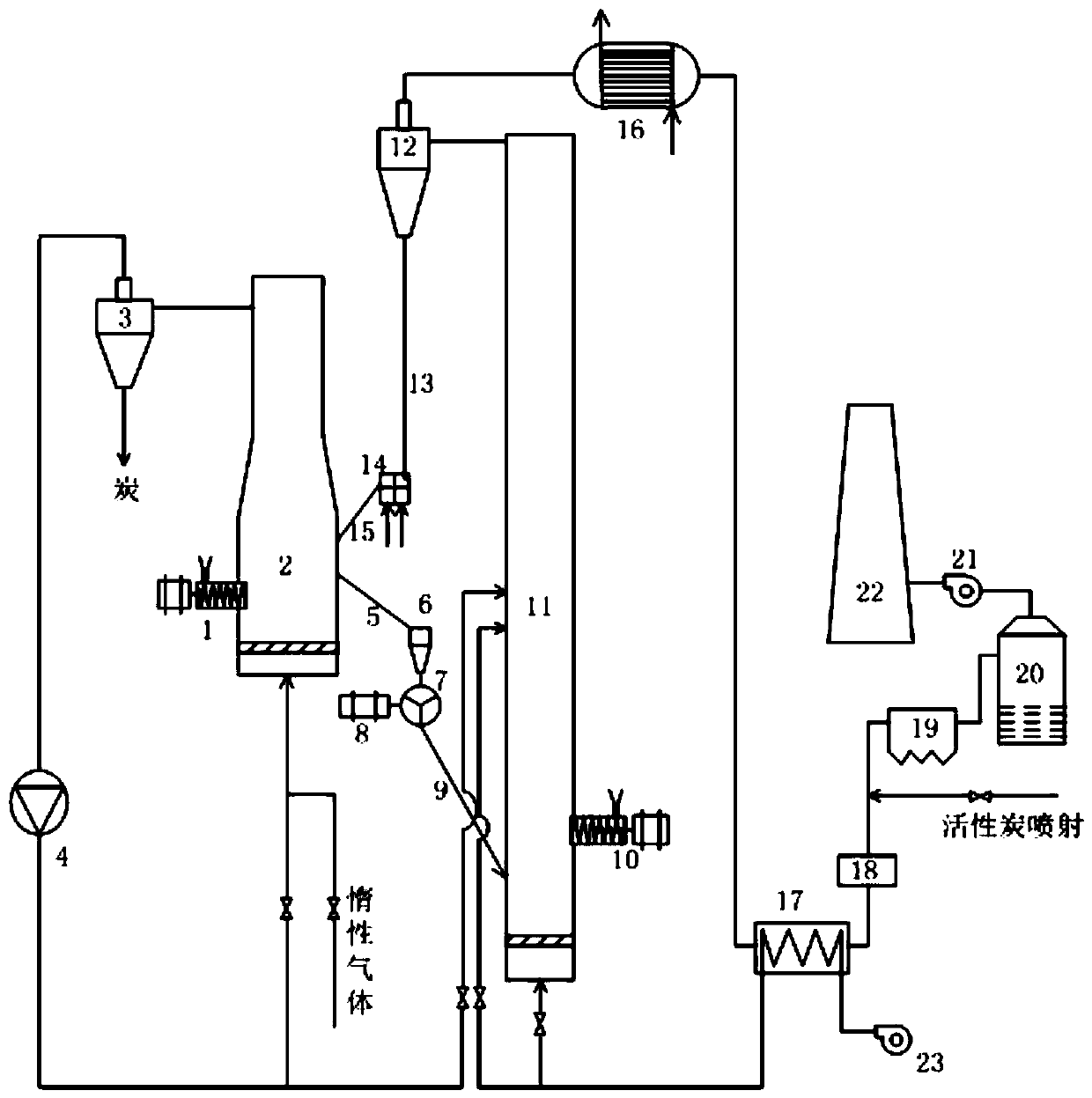

Oil-making method of double-bed interactive and circling type for pyrolyzing sludge

ActiveCN101307244BHigh yieldSimple structureSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisFluidized bed dryingHeat carrier

The invention provides a method for making oil by double bed cross circulation type pyrolysis of sludge, belonging to the energy environmental protection technical field. Between double beds of a fluidized bed pyrolysis reactor(1) and a fluidized bed combustion reactor(2), inert solid particle bed materials are used as heat carriers for the cross circulation, and the heat generated by pyrolysis carbon residues and incondensable gases burning in the fluidized bed combustion reactor(2) is transferred to sludge in the pyrolysis reactor as the heat source for the pyrolysis of sludge; a high temperature non-mechanical valve (3) is used to control the flow rate of the high temperature inert solid particle bed materials entering the pyrolysis reactor from the combustion reactor and further control the temperature of the pyrolysis reactor; the fluidized bed pyrolysis reactor(1) discharges excessive solid particle materials in the overflow mode, and the inert solid particle bed materials, the pyrolysis carbon residues and incondensable gases are transferred to the combustion reactor in the pneumatic transport mode; the wet sludge is dried by an internal heating type fluidized bed(16); and pyrolysis gases are condensed into oil-water mixture and incondensable gases in a spray tower(7).

Owner:SOUTHEAST UNIV

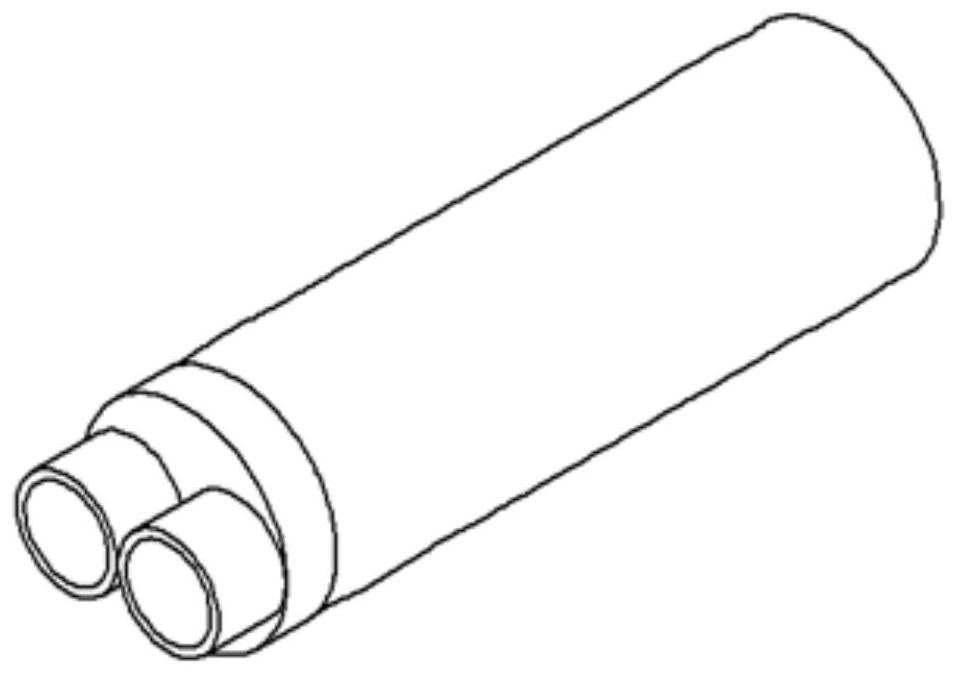

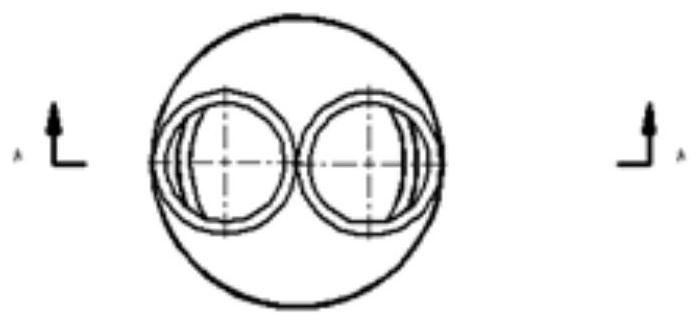

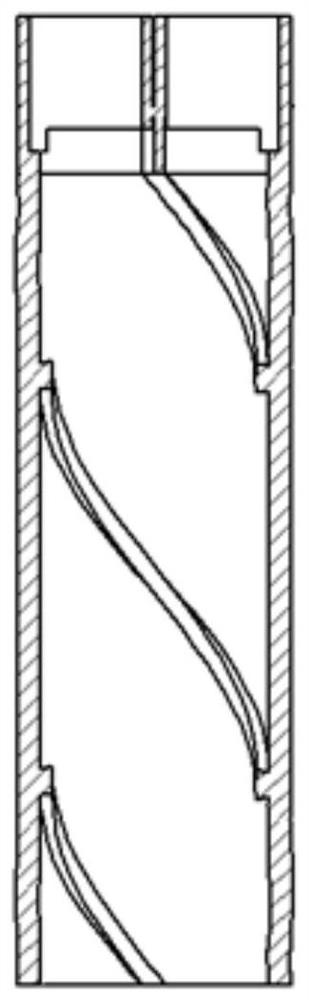

Bacterial cellulose composite fiber and preparation method thereof

ActiveCN113802215AImprove mechanical propertiesImprove performanceConjugated cellulose/protein artificial filamentsWet spinning methodsFiberPolymer science

The invention discloses bacterial cellulose composite fiber and a preparation method thereof. The preparation method comprises the following steps of carrying out alkali treatment on a grown bacterial cellulose membrane, washing thebacterial cellulose membrane to be neutral, cutting thebacterial cellulose membrane into small blocks, crushing thesmall blocks into slurry by a machine, drying the slurry, dissolving the slurry in a calcium chloride / acid dissolution system, extruding a bacterial cellulose solution and a second-phase solution into a coagulating bath through a special composite spinning nozzle, making the two solutions form spiral heterogeneous nascent fibers under the action of rifles in the spinning nozzle, and performing drying and water bath stretching on the fibers to prepare the bacterial cellulose composite fiber. The process is simple, the cost is low, large-scale production is easy, and the prepared bacterial cellulose composite fiber is excellent in mechanical property.

Owner:FANGDA CARBON NEW MATERIAL CO LTD +1

Combustible solid waste pyrolysis device and pyrolysis method

InactiveCN110484284ASimple structureEase of large-scale continuous productionDirect heating destructive distillationSpecial form destructive distillationHeat carrierProcess engineering

The invention discloses a combustible solid waste pyrolysis device and a pyrolysis method. The pyrolysis device comprises a fluidized bed pyrolysis reactor and a fluidized bed combustion reactor whichadopt heat carrier bed material interactive circulation. Combustible solid waste fuel is pyrolyzed in the fluidized bed pyrolysis reactor, and a heat carrier bed material overflows and is sent to thecombustion reactor through a star-shaped return feeder; the heat carrier bed material is heated again by utilizing heat released by pyrolysis oil gas combustion in the combustion reactor; and the heated heat carrier bed material enters the pyrolysis reactor again through a fluidized bed return feeder. Heat generated by combustion is transmitted to a pyrolysis process by utilizing interactive circulation of the heat carrier bed material between the two reactors, so that the problem of non-uniform temperature in reactors caused by heat transfer of conventional reactors is solved; the star-shaped return feeder for pyrolysis material returning achieves a good sealing effect, the fluidized bed material return feeder for combustion material returning avoids high oxidation and deformation of mechanical moving parts, and meanwhile the solid circulation flux can be controlled.

Owner:SOUTHEAST UNIV

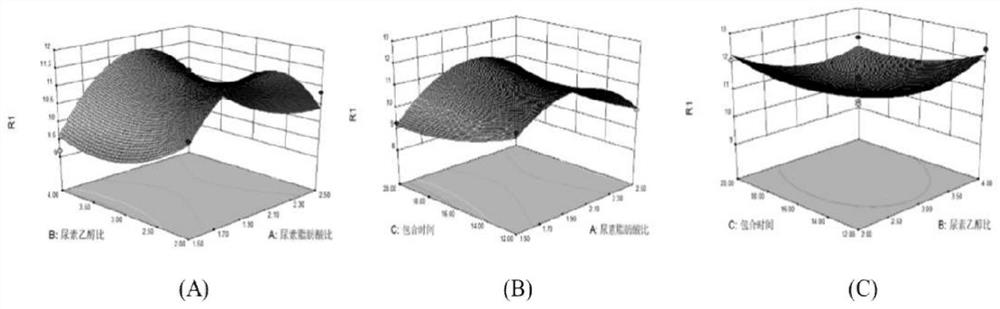

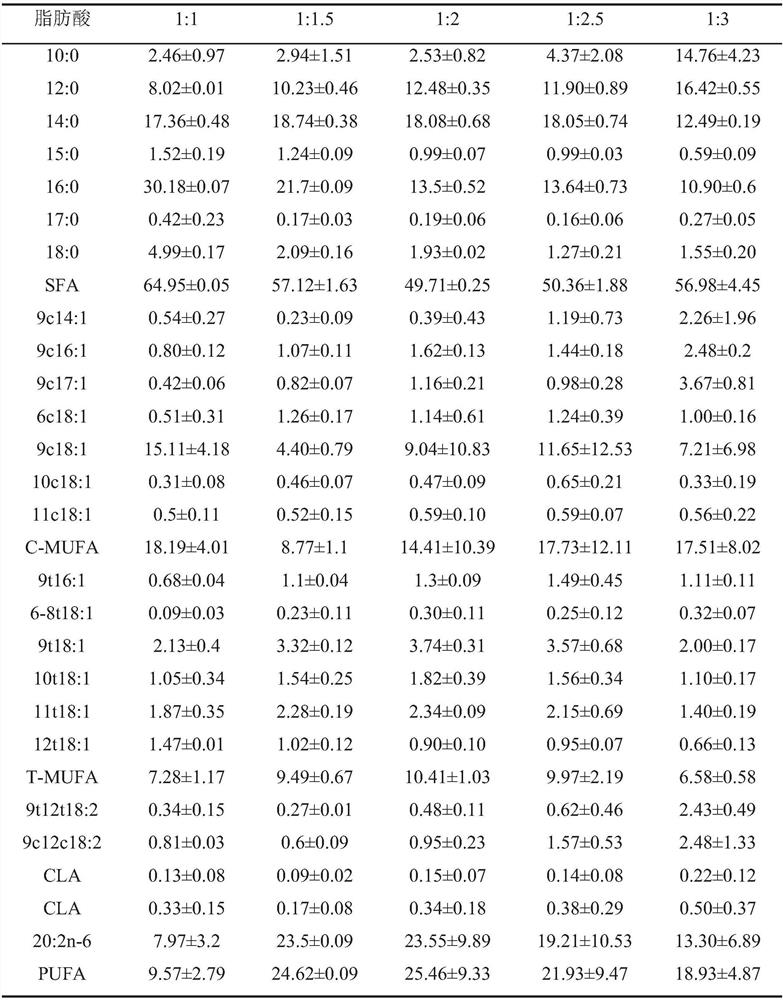

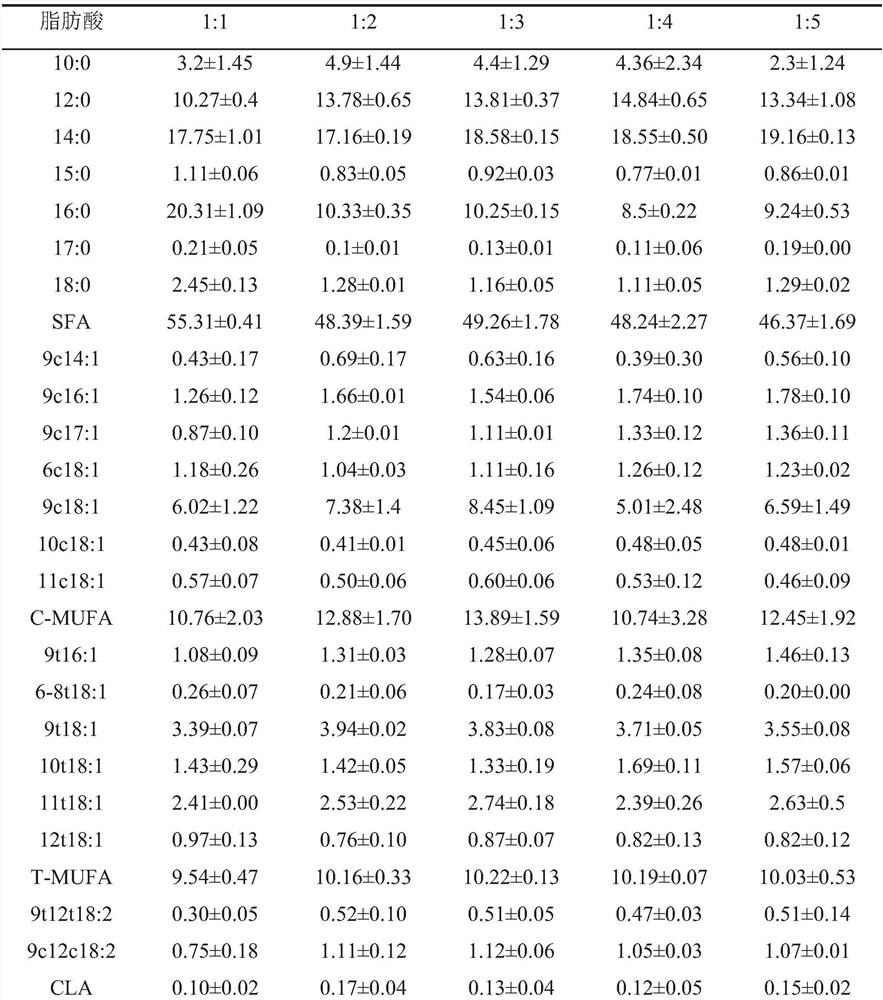

Preparation method of ruminant trans-fatty acid

PendingCN114181778ASimple processEasy to operateFatty acids production/refiningAccessory food factorsBiotechnologyAlcohol ethyl

The invention discloses a ruminant trans-fatty acid preparation method, which comprises: (1) carrying out a saponification reaction on butter and a sodium hydroxide ethanol solution under a 85-90 DEG C water bath condition, adding a sulfuric acid solution, stirring under a 45-50 DEG C water bath condition for 20-30 min, dissolving, standing, and taking the upper layer oily matter to obtain butter free fatty acid; (2) adding urea into absolute ethyl alcohol according to a certain proportion, carrying out rotary reflux at 70-85 DEG C, then adding a certain amount of butter free fatty acid, carrying out reflux at 77 DEG C, and carrying out inclusion at-5 DEG C; performing vacuum suction filtration to obtain filtrate, performing rotary evaporation on the filtrate at 65 DEG C, removing ethanol, dissolving with deionized water at 60 DEG C, extracting upper oily matter, drying with anhydrous sodium sulfate, and filtering to obtain the ruminant trans-fatty acid product. The preparation method of the ruminant trans-fatty acid is simple in process, high in operability, low in production cost and energy consumption and easy to realize large-scale continuous production.

Owner:NANCHANG UNIV

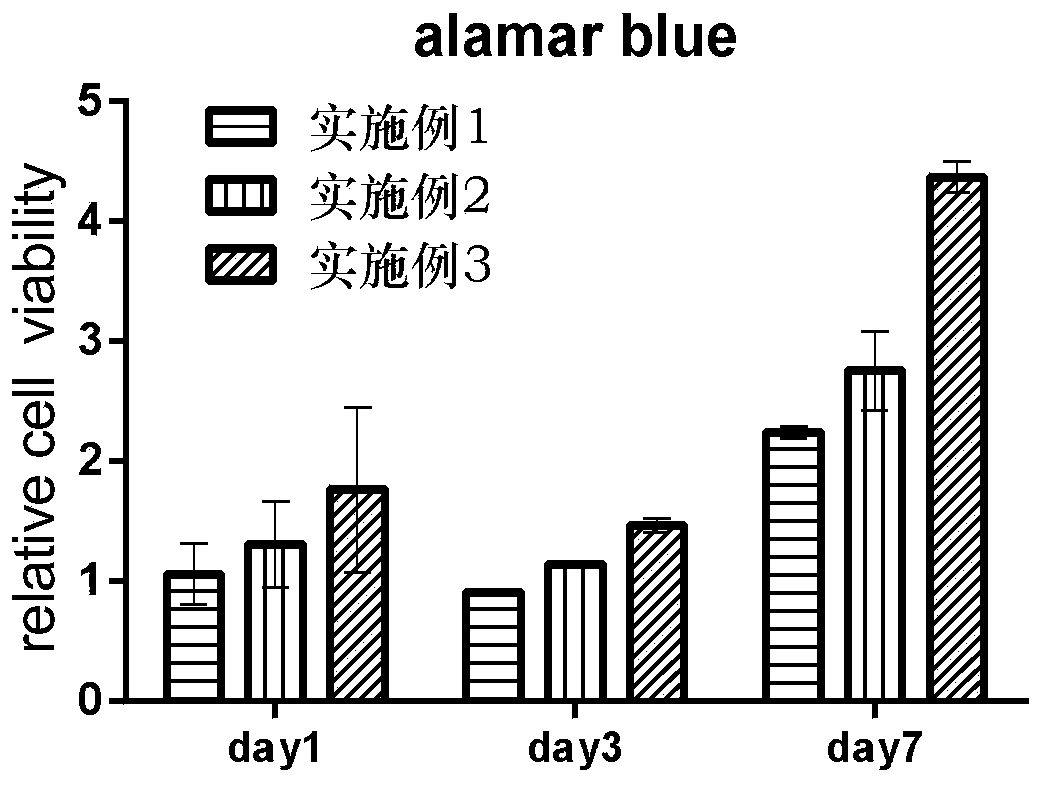

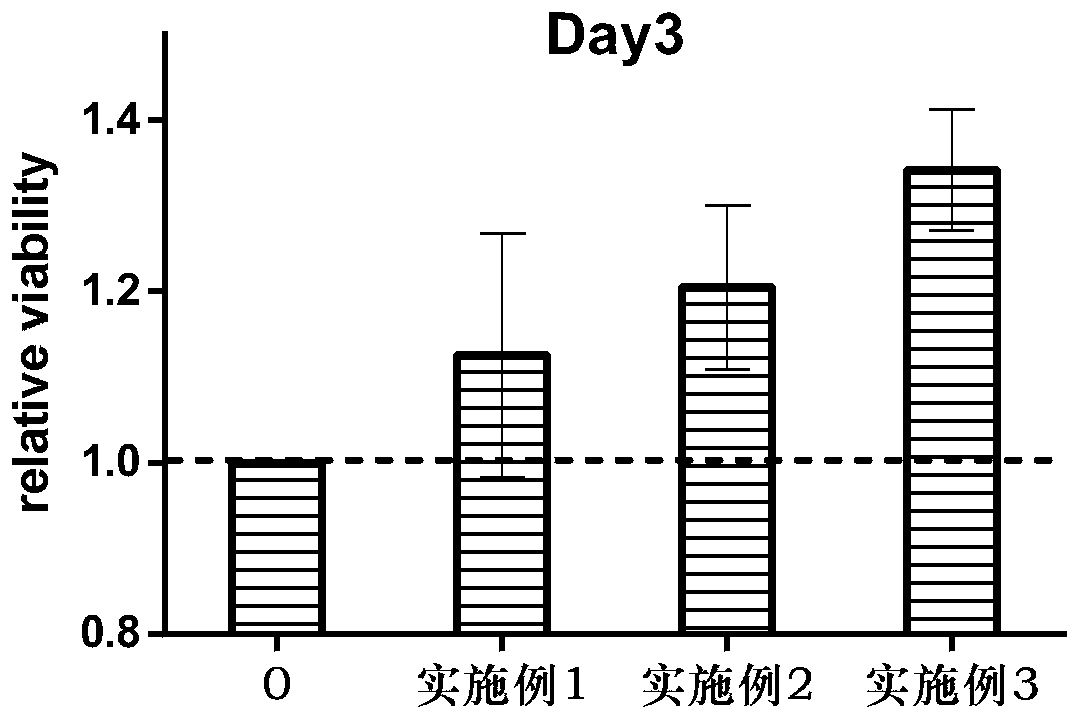

Preparation method of sub-totipotent mesenchymal stem cell secretin

PendingCN110551204APromote rapid proliferationHigh in active ingredientsSecretinsPeptide preparation methodsMesenchymal stem cellSkin cell

The invention provides a preparation method of sub-totipotent mesenchymal stem cell secretin. The preparation method comprises steps including preculture of mesenchymal stem cells, large-scale cultureof the mesenchymal stem cells, preparation of a mesenchymal stem cell secretin stock solution and preparation of mesenchymal stem cell secretin lyophilized powder. The preparation method of the sub-totipotent mesenchymal stem cell secretin is simple and easy to implement, rapid, convenient and favorable for large-scale continuous production. According to the method, rapid proliferation of the mesenchymal stem cells can be realized without adding biological factors, the mesenchymal stem cell secretin can be efficiently and continuously produced only through a cell culture solution replacementmanner, and the production cost is greatly reduced; and the mesenchymal stem cell secretin has higher content of active ingredients and has remarkably improved skin cell and bone cell proliferation capability.

Owner:深圳刚华健医疗有限公司

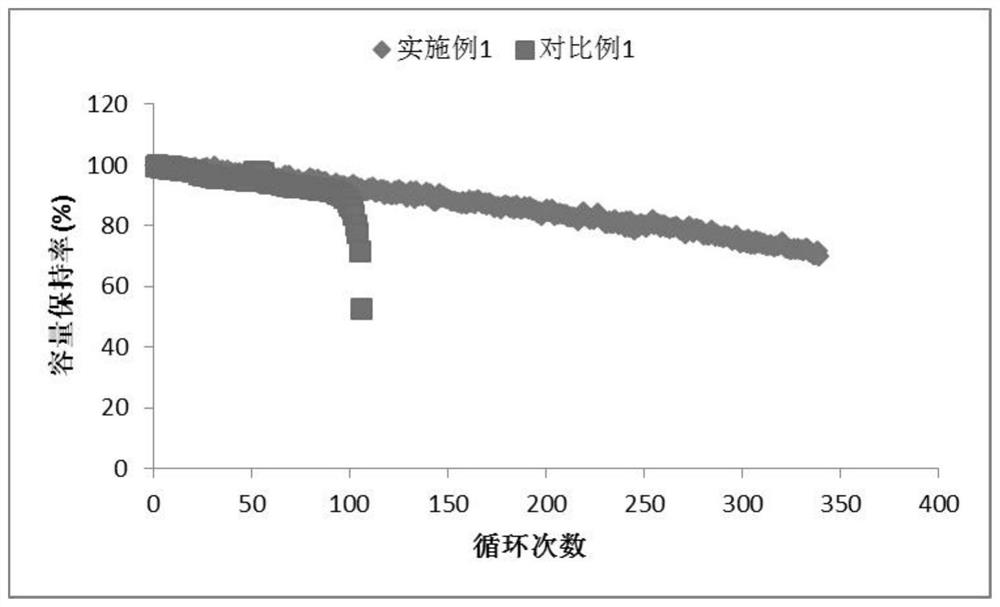

High impact high gloss bimodal polystyrene material and preparation method thereof

The invention provides a high impact high gloss bimodal polystyrene material and preparation method thereof, comprising the following steps: (a) the solution of polybutadiene rubber component mixed with polystyrene monomers is provided; wherein, the polybutadiene rubber component is selected from high cis-polybutadiene and / or low cis-polybutadiene, the cis-content of high cis-polybutadiene is notless than 94% by mole and the cis-content of low cis-polybutadiene is between 33% to 40% by mole ; (b) the solution obtained from the step (a) is used to perform prepolymerization reaction of styrenemonomers to obtain a prepolymerization solution system which does not generate phase transition; (c) the prepolymerization solution system obtained from the step (b) is used to perform further prepolymerization reaction of styrene monomers in shearing force field until the system generates phase transition to obtain rubbery state material of which the particle size presents bimodal distribution; (d) the conversion rate of styrene monomers in the material obtained from the step (c) is further increased to obtain the high impact high gloss bimodal polystyrene material. The invention also provides a preparation method of the high impact high gloss bimodal polystyrene material.

Owner:SHANGHAI SECCO PETROCHEM

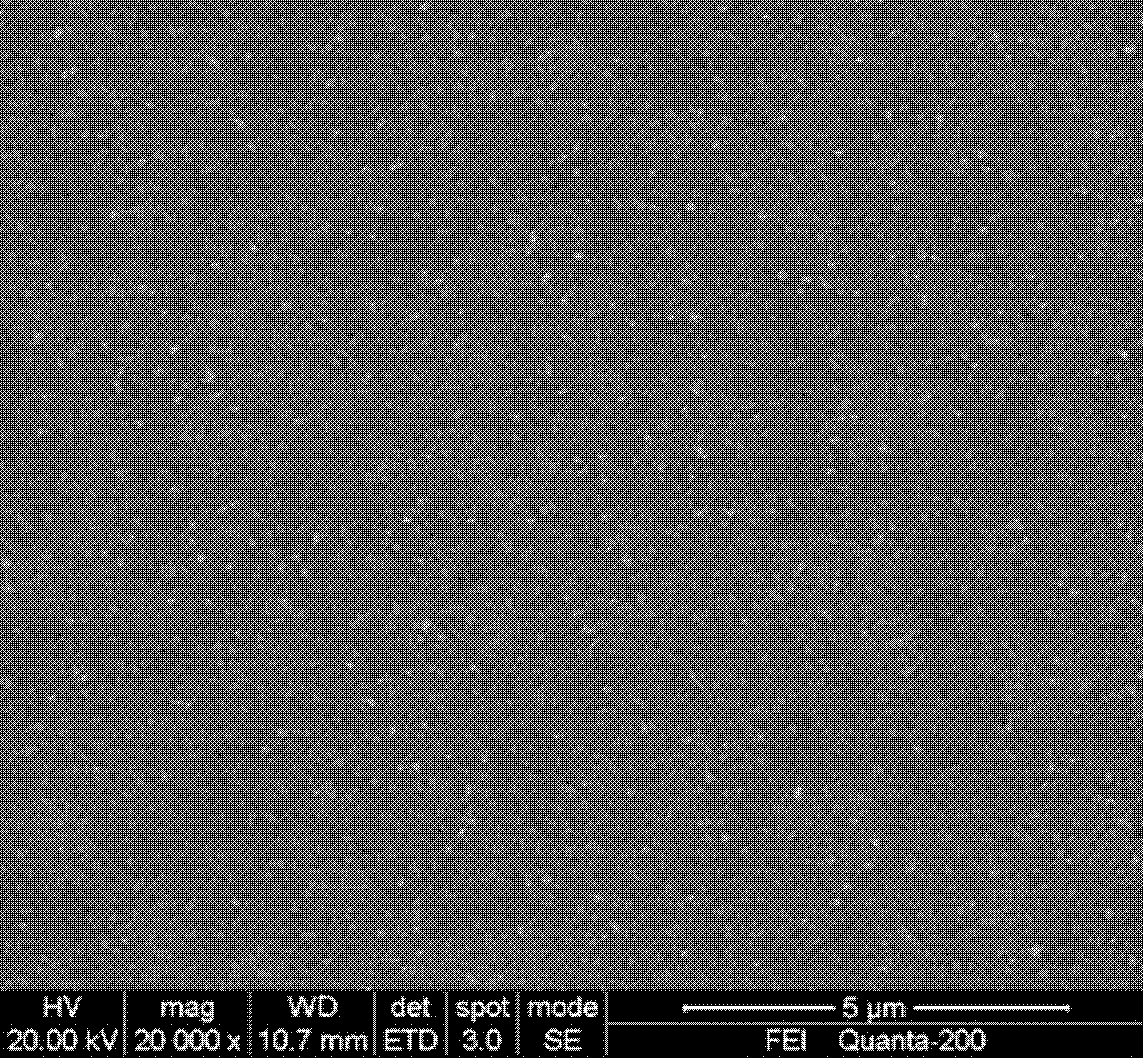

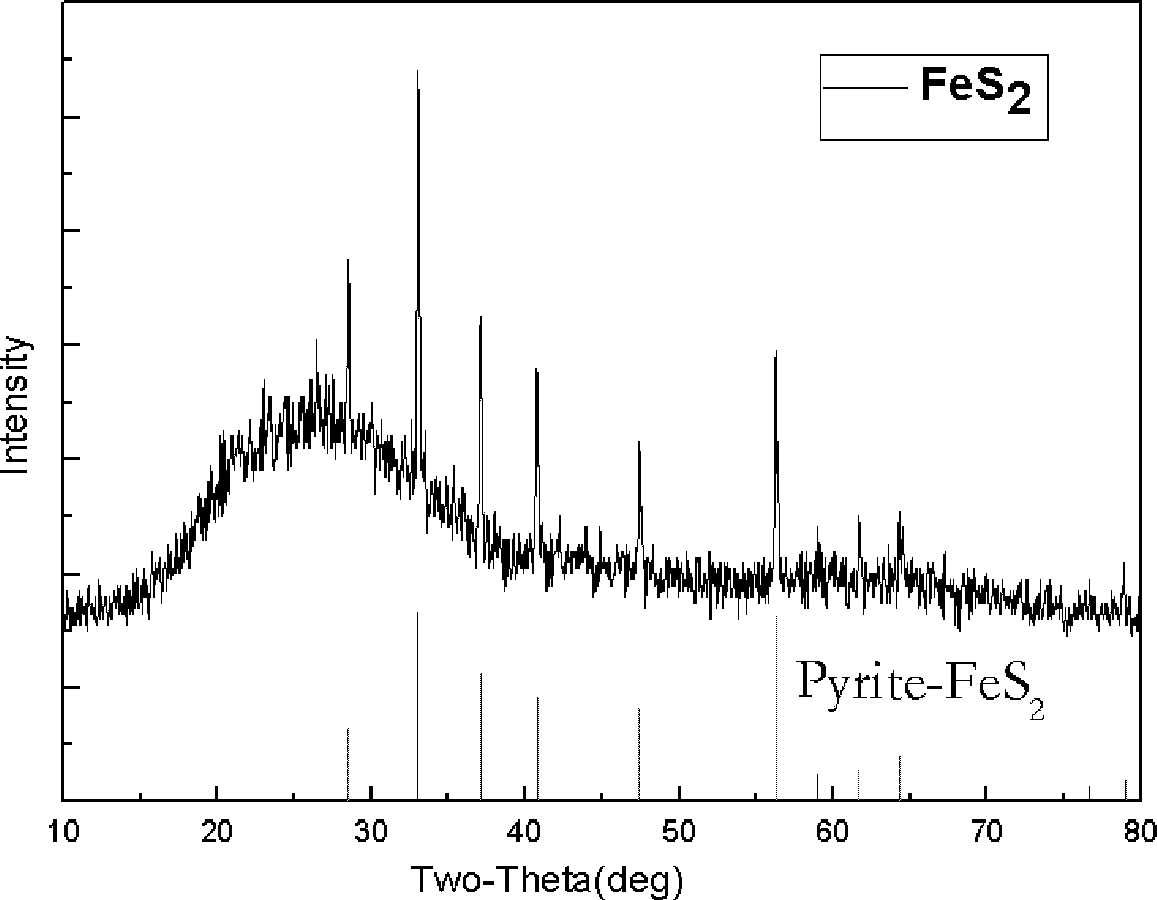

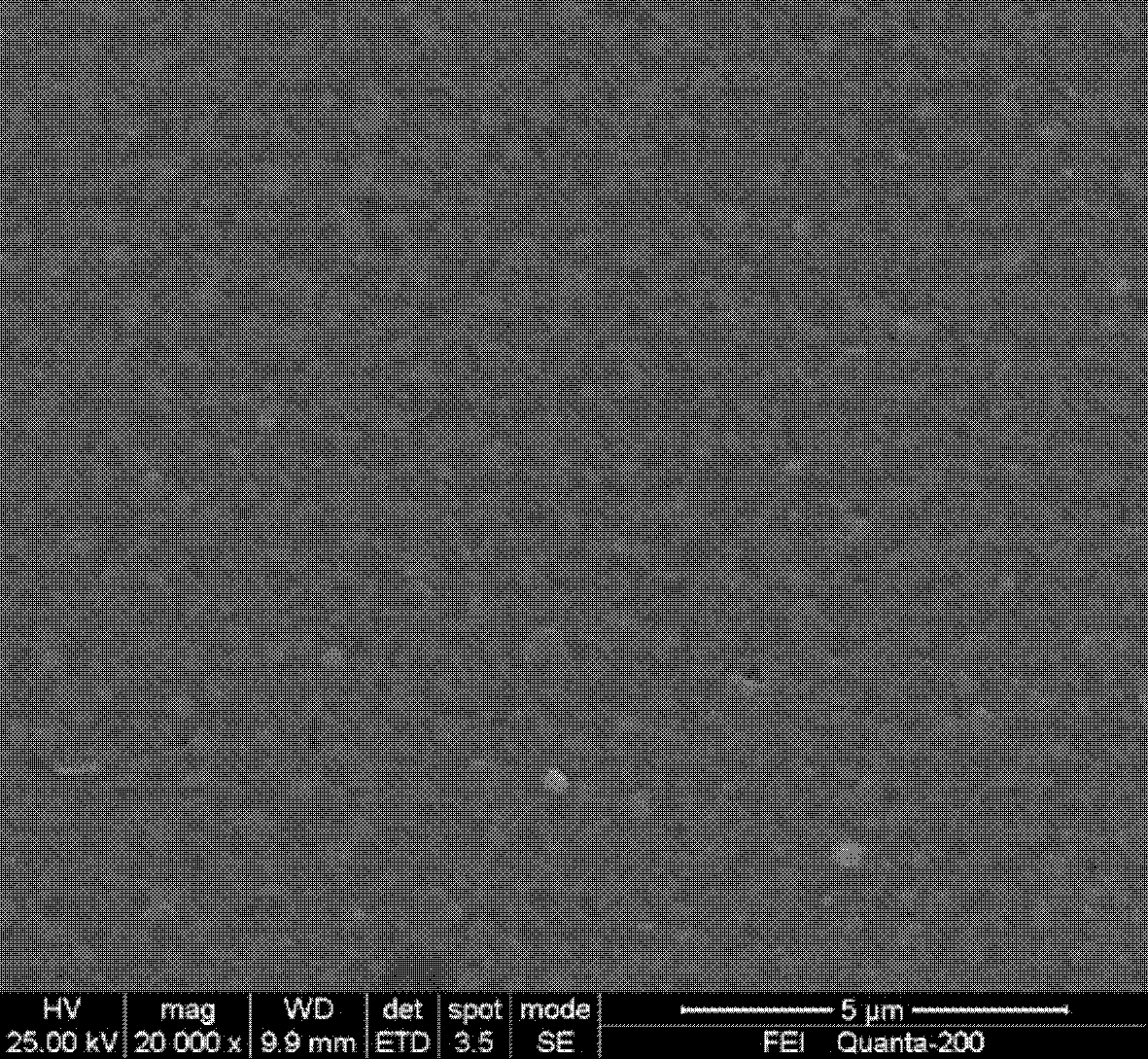

Ferrous disulfide semiconductor film preparation method

The invention discloses a ferrous disulfide semiconductor film preparation method, which relates to the field of preparation of compound semiconductor films for solar cells and the like. The method includes: by an aqueous solution deposition method, using ferrous sulfate or ferrous chloride aqueous solution as cation precursor solution, and using sodium polysulfide aqueous solution as anion precursor solution; controlling immersion time of a substrate in the precursor solution and circulation times to deposit a ferrous disulfide film premade layer; and subjecting the premade layer to vulcanization heat treatment at the high temperature to obtain a ferrous disulfide film. The ferrous disulfide semiconductor film preparation method is short in procedure, low in cost, high in reproducibilityand easy in massive continuous production, and the film is controllable in component and suitable for large-area growth. The deposition substrate can be normal soda lime glass, conductive glass, flexible stainless steel plates, titanium plates, molybdenum plates or plastic plates. The film prepared by the method is controllable in thickness and component, compact and uniform in appearance, high in crystallizing performance and photoelectric property and applicable to thin film solar cells.

Owner:CENT SOUTH UNIV

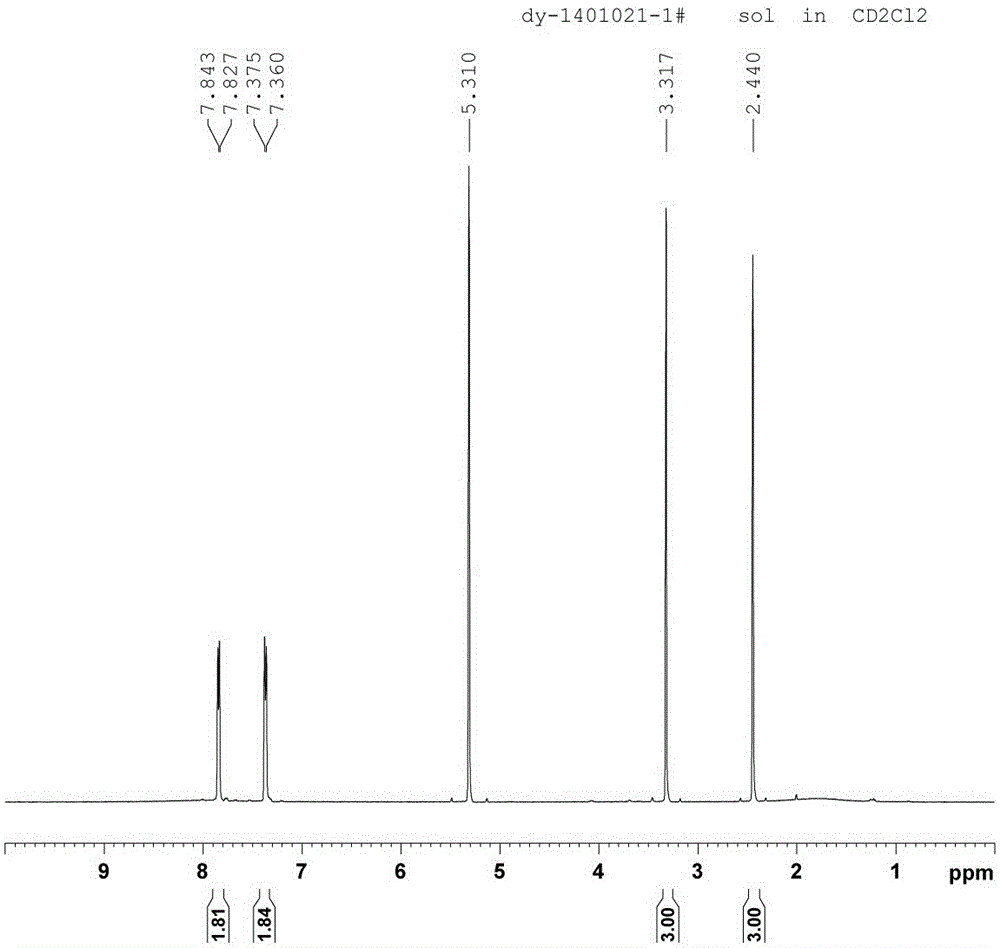

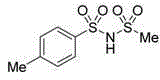

N-(methyl sulphonyl)-p-methylphenyl sulphonylamine and preparation method thereof

InactiveCN105001125ARaw materials are cheap and easy to getSimple and fast operationOrganic-compounds/hydrides/coordination-complexes catalystsSulfonic acid amide preparationPolyesterGlycoluril

The invention relates to N-(methyl sulphonyl)-p-methylphenyl sulphonylamine shown in the formula (I) and a preparation method thereof. The preparation method includes the steps that p-toluenesulfonyl chloride, methyl sulfonamide and a phase transfer catalyst are dissolved in an organic solvent, the mixture is heated to 60 DEG C-120 DEG C, an acid-binding agent is added, the organic solvent is distilled out after complete reaction, a generated solid is dissolved in water, the pH value is adjusted to be smaller than 1 through hydrochloric acid, the temperature is decreased to 20 DEG C-24 DEG C, crystals are separated out, filtration and drying are performed, and then the N-(methyl sulphonyl)-p-methylphenyl sulphonylamine is obtained. According to the method, the raw materials are easy to obtain, operation is easy and convenient, productivity is high, and large-scale continuous production is easy; the N-(methyl sulphonyl)-p-methylphenyl sulphonylamine has a good catalytic effect on polyester-system products of TMMGU, is a brand-new high-gloss powder coating curing agent or catalyst and can used for preparing environment-friendly high-gloss high-performance paint films.

Owner:ANSHAN RUNDE FINE CHEM

Method for using device for desalting and purifying sewage through refrigeration and centrifugation

InactiveCN102161516BLow fade effectReduce production energy consumptionGeneral water supply conservationWater/sewage treatment by freezingCollection systemAir conditioning

The invention discloses a method for desalting and purifying sewage through refrigeration and centrifugation and a device thereof. The device consists of a water inlet system, an air-conditioning refrigeration system, a rotating cylinder ice production system, and an ice cube separation and collection system, wherein the water inlet system consists of a pre-cooling water tank, a submersible pump and a perforated spray pipe; the air-conditioning refrigeration system consists of a compressor, a condenser, a throttle valve and an evaporator; the rotating cylinder ice production system comprises an internal cylinder, an external rotating cylinder and a transmission system consisting of a variable-frequency adjustable-speed motor and a frequency converter; and the ice cube separation and collection system consists of a scraping knife, a square bucket, a screen and a centrifugal machine. The purification device can ensure that the removal rate of salinity in the sewage reaches between 80 and 96 percent and the removal rate of algae is kept between 35 and 70 percent. The method in which the sewage is desalted by adopting the device for desalting and purifying the sewage through refrigeration and centrifugation is suitable for large-scale continuous production; the production energy consumption is low; and the method and the device are widely applied to seawater desalination, strong water desalination and sewage purification in the future.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

A production system for medium-impact polystyrene resin

The invention discloses a medium-anti-impact polystyrene resin production system, which comprises a system collosol tank, a mixed feeding tank, a two-stage prepolymerization reactor, a multistage polymerization reactor, a two-stage devolatilization device and a pelleting machine in sequential and series connection, wherein a superfine powder material preparation tank and a superfine powder feedingtank are connected in series and are then connected with an inlet of a first-stage polymerization reactor of the multistage polymerization reactor; a prepolymerization preheater is arranged on a pipeline between the mixed feeding tank and the first-stage polymerization reactor; a devolatilization preheater is arranged on a pipeline between the last-stage polymerization reactor of the multistage polymerization reactor and a first-stage devolatilization device; the upper parts of the end parts of the first-stage and second-stage devolatilization devices are connected in series and are then connected with a cycle condenser through a conveying pipeline; a connecting tank is connected with the bottom of the cycle condenser; a bottom outlet of the collecting tank is connected with an inlet of the prepolymerization preheater. A multistage prepolymerization-multistage polymerization-multistage devolatilization combination system is used; the requirements of users on medium-anti-impact products can be met; the large-scale production is easy.

Owner:GUANGDONG RASTAR SYNTHETIC MATERIAL COMPANY

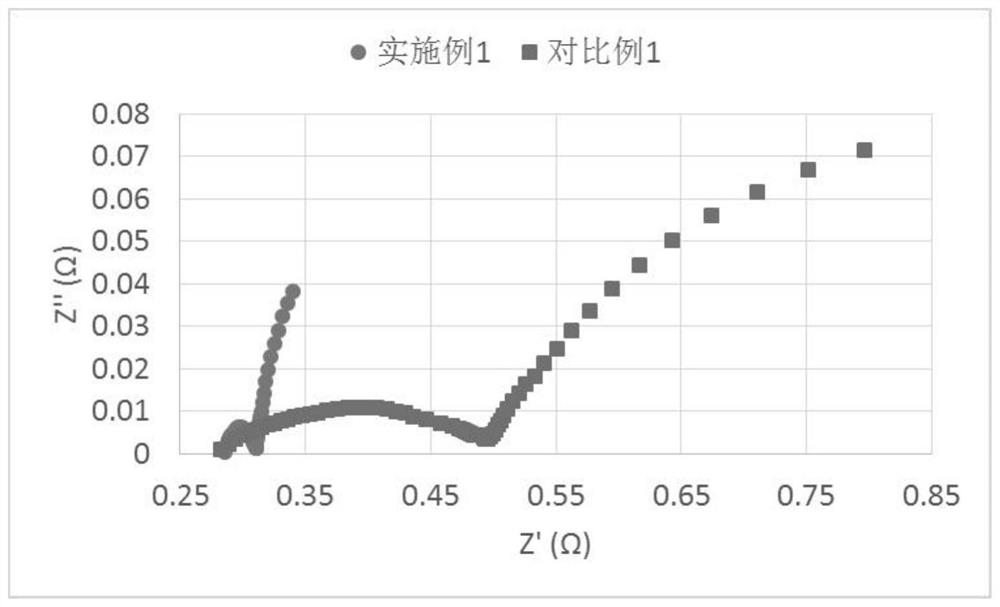

A kind of electrolyte used in lithium, sodium and potassium batteries

ActiveCN109830747BImprove cycle performanceImprove securityFinal product manufactureGroup 5/15 element organic compoundsMetallic lithiumElectrolytic agent

The invention provides an electrolyte additive, an electrolyte and an application of the electrolyte, belonging to the technical field of lithium metal batteries, and the specific technical scheme is as follows: an electrolyte additive, the additive is an organic compound salt containing phosphorus and boron, Its cation part is a phosphorus-containing cation with four benzene rings, and its anion part is a boron-containing anion with four benzene rings. The additive is used in the electrolyte, and the effect of inhibiting dendrites is outstanding, which can improve the lithium metal. (or sodium or potassium) cycle performance and safety performance of the battery, while ensuring that it brings into play the high energy density advantage of the metal lithium (or sodium or potassium) negative electrode; the general structural formula of the additive is as follows:

Owner:ZHUHAI COSMX BATTERY CO LTD

Method for producing nutritional fine meal by utilizing edible fungus rinsing and scalding liquid

ActiveCN101822376BHigh value-added development and productionFull of nutritionFood preparationBiotechnologyMycoprotein

The invention provides a method for producing nutritional fine meal by utilizing an edible fungus rinsing and scalding liquid, and microcapsule functional nutritional fine meal is obtained by the method through the steps of filtering, wall material mixing, stirring, homogenizing and spray drying of the edible fungus rinsing and scalding liquid. The rinsing and scalding liquid disused in the edible fungus processing process is utilized by the method for producing the functional nutritional fine meal rich in granulose, edible fungus polyphenol and mycoprotein; consequently, not only the currentproblem of rinsing and scalding liquid processing is solved, pollution is reduced, and resources are reasonably used, but also the method is easy for continuous large-scale industrial production, andthe produced microcapsule fine meal has the characteristics of abundant nutrition, good stability and long storage period.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Preparation method of konjac fermented soybean milk powder

ActiveCN111758788ALow drying temperatureDry fastMilk preservationOther dairy technologyBiotechnologyLactic acid bacterium

The invention discloses a preparation method of konjac fermented soybean milk powder. The preparation method comprises the following steps: firstly, preparing enzymolysis konjac liquid and soybean milk separately, then adding the enzymolysis konjac liquid into the soybean milk, adding soybean protein isolate, then performing mixed fermentation through various lactic acid bacteria, and finally performing low-temperature spray drying, thereby obtaining the konjac fermented soybean milk powder. By adding the soy isolate protein and the konjac enzymatic hydrolysate and then fermenting with the mixed lactic acid bacteria, the soy milk can have a good health-care effect, and the product is high in protein content, rich in nutrition, unique in flavor and good in palatability; and low-temperaturespray drying is adopted, the viable count of lactic acid bacteria in fermented soybean milk powder can be preserved to the maximum extent, and the prepared powdery product has the advantages of beinghigh in lactic acid bacteria activity, small in storage space, convenient to eat and the like.

Owner:南昌泰康食品科技有限公司

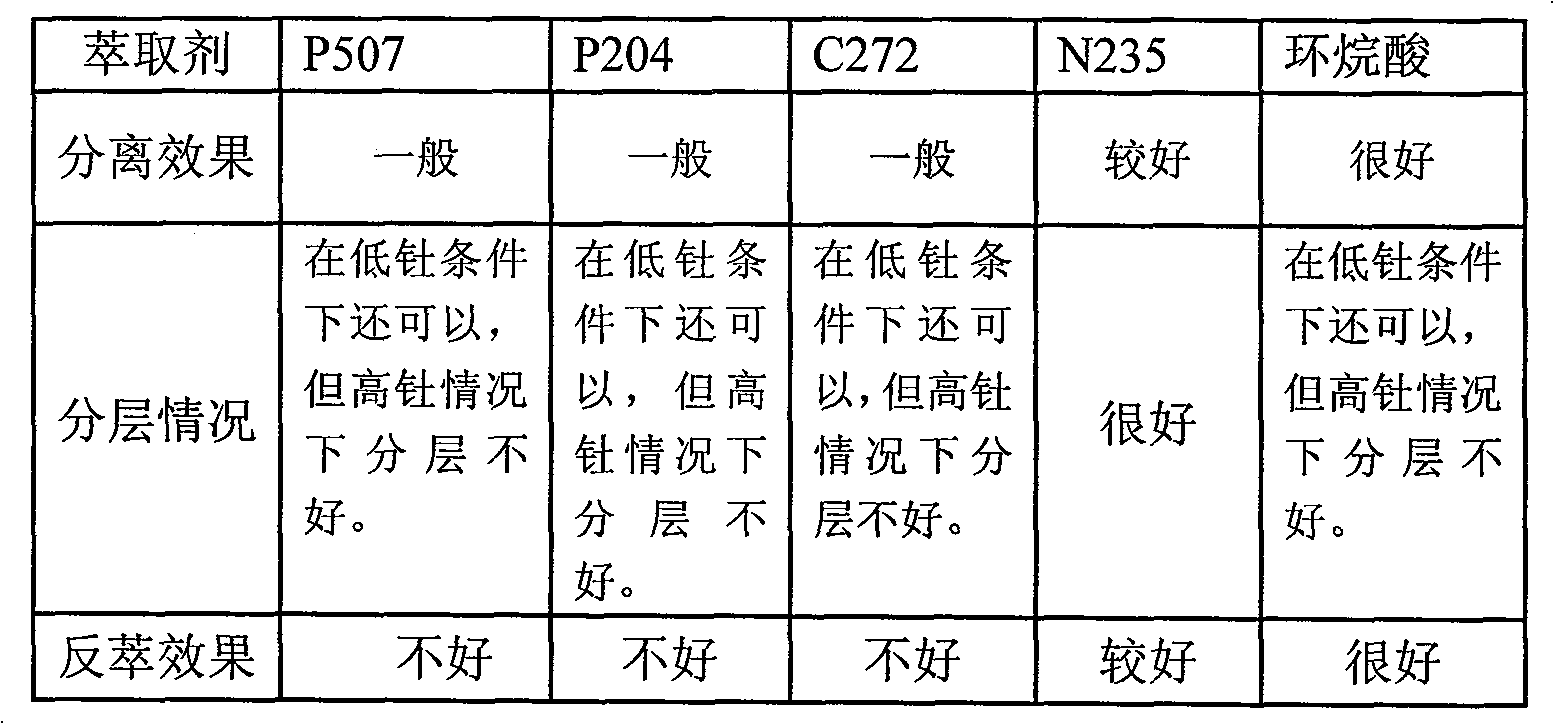

Preparation method of low-thorium lutetium oxide

ActiveCN101748275BEasy to separateThe separation effect is achievedRare earth metal compoundsProcess efficiency improvementLutetiumKerosene

The invention relates to a preparation method of low-thorium lutetium oxide, comprising the following steps of: firstly carrying out 3-10 level of primary countercurrent extraction on lutetium oxide extracted from a solvent as a raw material by adopting an isooctanol or kerosene solution of 0.5-2.0mol / L of N235 extracting agent, and then carrying out 3-10 level of countercurrent washing selectivebackextraction on organic phases of extracted thorium by adopting 0.1-2mol / L of alkali abluent solution; then separating the low-thorium lutetium oxide by a kerosene solution of 0.1-1.0mol / L of another extracting agent, carrying out 3-10 level of countercurrent washing selective backextraction on the organic phases of the extracted thorium by adopting 0.5-2mol / L of acidic abluent solution, carrying out oxalic precipitation, washing and dehydration on aqueous-phase lutetium oxide after thorium removal, and burning at the condition of 750-1000 DEG C to obtain a product, namely, the low-thorium lutetium oxide. In the method, rare earth and thorium are thoroughly separated, and the organic extracting agent is low in price.

Owner:江阴加华新材料资源有限公司

A kind of medium impact polystyrene resin and preparation method thereof

The invention discloses medium-anti-impact polystyrene resin and a preparation method thereof. The resin is prepared from the following raw material ingredients in percentage by weight: 85 to 96 percent of styrene monomers, 1 to 6.5 percent of mixed rubber, 1 to 8 percent of flowing modifying agents and 1.5 to 7 percent of superfine powder, wherein the mixed rubber is prepared from two or three kinds of rubber in rubber with the solution viscosity being 140 to 190 cps, rubber with the solution viscosity being 70 to 100 cps and rubber with the solution viscosity being 20 to 50 cps. A polymerization method is used for replacing a mixing method to obtain the medium-anti-impact polystyrene resin; the cooperated effect of a PS body, rubber and ultrafine powder body is sufficiently achieved; onthe premise of ensuring the intensity, the consumption of the toughening agent rubber is possibly reduced, so that the intensity, the rigidity, the flowing performance and the luster degree of the product can be properly improved; the requirements of users on the medium-anti-impact product can be met; the mass production is easy.

Owner:GUANGDONG RASTAR SYNTHETIC MATERIAL COMPANY

Method for preparing sucralose microcapsules

PendingCN113331388ASmall sizeLittle agglomerationFood shapingFood ingredient as emulsifierSucroseAdhesive

The invention is applicable to the related field of sucralose production, and provides a method for preparing sucralose microcapsules. The method comprises the following steps: dissolving sucralose crystals in water, adding an emulsifier, uniformly mixing, and stirring to obtain an emulsion A; dissolving an adhesive in an alcoholic solution at 50-70 DEG C, dropwise adding into the emulsion A, and conducting stirring and emulsifying to obtain an emulsion B; and drying and screening the emulsion B to obtain sucralose microcapsule powder. The sucralose microcapsule is obtained by emulsifying sucralose in a multi-emulsification mode and performing spray drying, the prepared microcapsule powder has excellent fluidity and excellent dispersibility, the size of the microcapsule is small, the agglomeration effect is small, spots cannot appear on the surface of prepared food, the capsule shell is more completely sealed, and the encapsulation rate is high, so that the possibility of rupture or damage is prevented and reduced, the food taste is ensured. The preparation method has the advantages of simplicity in operation, low cost and easiness in large-scale continuous production.

Owner:NEWTREND TECHNOLOGY CO LTD

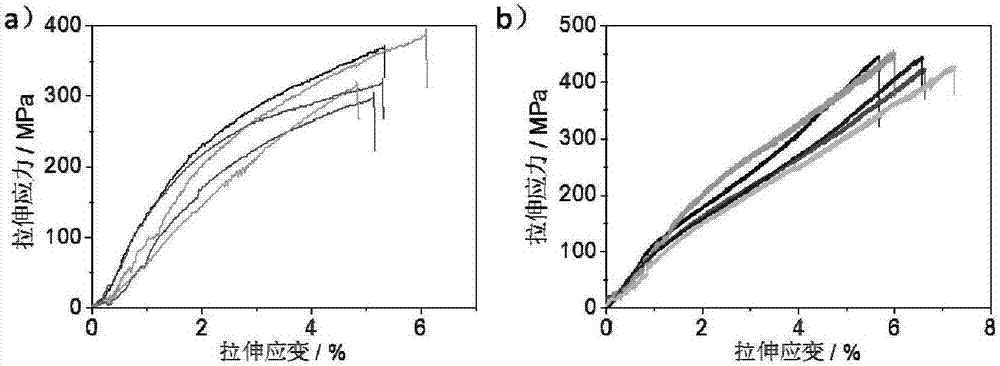

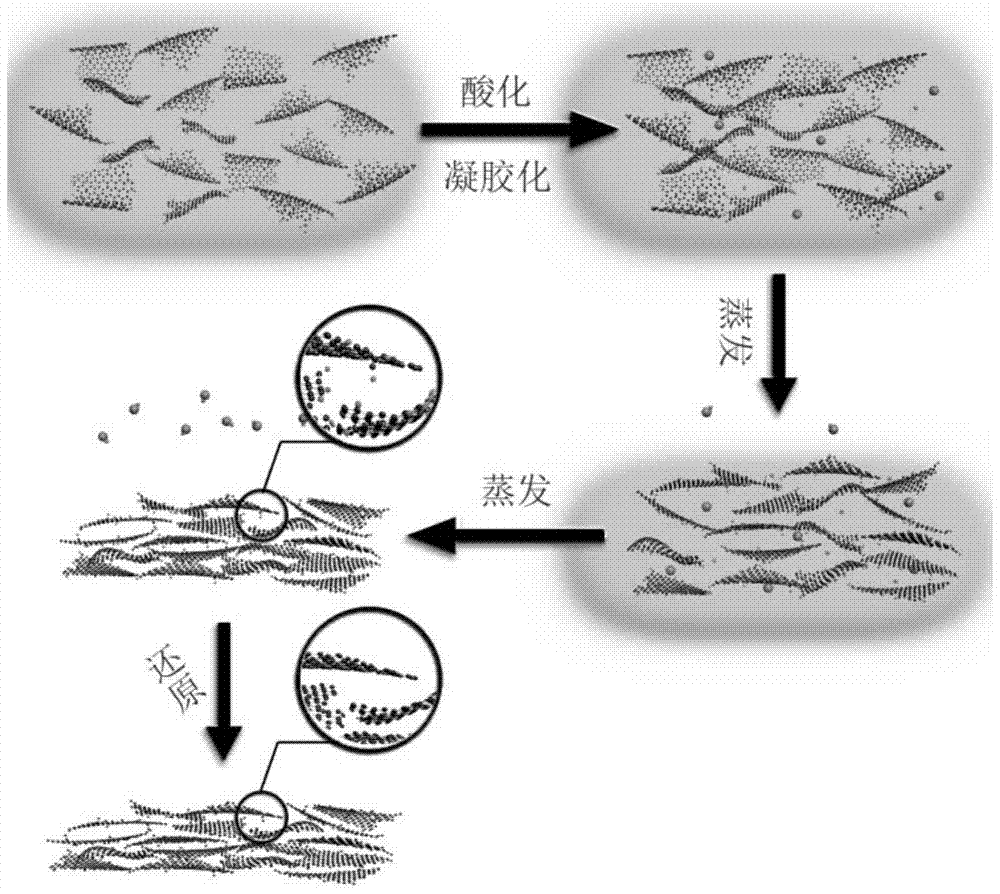

High-performance graphene film and fiber and its gel conversion preparation method

ActiveCN105174249BReduce defect densityGood dispersionGrapheneArtificial filament chemical after-treatmentFiberPresent method

The invention discloses a high-performance graphene film and fiber and a gel conversion preparation method thereof. Natural graphite powder was oxidized by the improved Hummers method to obtain graphene oxide colloidal solutions with different oxidation degrees and different defect densities. Based on the method of sol-gel chemistry, acidification or mild thermal annealing are used to transform the flowing sol state of graphene oxide dispersion into viscous gel state. And further obtain graphene oxide film and graphene fiber with good mechanical strength. The preparation process of the method is simple, efficient and cheap, and can be produced and applied continuously on a large scale. At the same time, this method does not use an additional crosslinking agent, and does not use a coagulation bath. The preparation process is environmentally friendly, simple and time-saving, and the prepared graphene film and fiber have excellent mechanical properties, high electrical conductivity, and good thermal conductivity. Excellent toughness, with good application prospects.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com