High-performance graphene film and fiber and its gel conversion preparation method

A graphene fiber and graphene film technology, applied in the field of materials, can solve the problems of reducing the electrical conductivity and heat transfer of the film, hindering the electron transmission of the graphene sheet, increasing the contact resistance, etc., achieving excellent toughness and facilitating industrial continuous production Effect with promotion, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

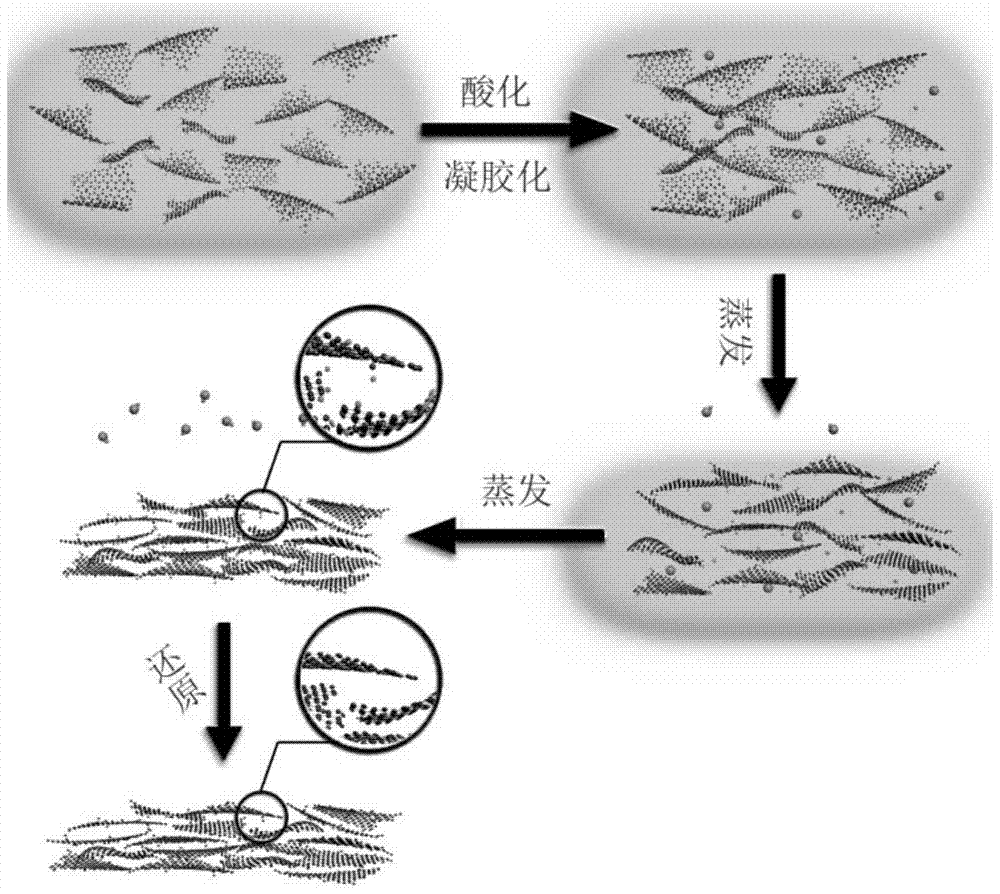

[0082] Embodiment 1, by acidification induction graphene oxide gelation, prepare graphene film:

[0083] Preparation of graphene oxide dispersion:

[0084] 1) Add 3.0g of 325 mesh natural graphite powder into the reaction bottle, then slowly add 72mL of 98wt% concentrated sulfuric acid, stir evenly, and control the temperature of the reaction system below 5°C. Under low temperature conditions, stir evenly and slowly add 9.0g of potassium permanganate powder, control the temperature of the system at 0-40°C for 1 hour of constant temperature reaction, slowly add 300mL of cold dilute sulfuric acid with a concentration of 7.4% by mass, and then carry out the reaction at constant temperature 8h;

[0085] 2) Pour the reaction mixed system obtained in step 1) into an ice-water mixing bath to terminate the reaction, continue stirring for 15 minutes, and add 3 wt% hydrogen peroxide aqueous solution until no more bubbles are generated. The reaction solution turned from brown to khaki,...

Embodiment 2

[0092] Embodiment 2, the graphene film is prepared by inducing the gelation of graphene oxide by thermal annealing.

[0093] Preparation of graphene oxide dispersion:

[0094] 1) Add 3.0g of 325 mesh natural graphite powder into the reaction bottle, then slowly add 100mL of 98wt% concentrated sulfuric acid, stir evenly, and control the temperature of the reaction system below 5°C. Under low temperature conditions, stir evenly and slowly add 12.0g of potassium permanganate powder, control the temperature of the system at 0-40°C for constant temperature reaction for 16h, slowly add 300mL of cold dilute sulfuric acid with a mass percentage concentration of 9.8% for 12h;

[0095]2) Pour the reaction mixed system obtained in step 1) into an ice-water mixing bath to terminate the reaction, continue stirring for 15 minutes, and add 3 wt% hydrogen peroxide aqueous solution until no more bubbles are generated. The reaction solution turned from brown to brown, and the suspension was fi...

Embodiment 3

[0102] Embodiment 3, by acidification induction graphene oxide gelation, prepares graphene fiber:

[0103] With the graphene oxide hydrogel prepared in Example 1 as the processing precursor, the extrusion speed of 18mL / h is passed through a capillary with a diameter of 260 μm through a spinning device, and a flat substrate is carried by a slide table moving at a constant speed below to match the Velocity receives extruded graphene oxide gel fibers. The fiber was dried at room temperature to obtain graphene oxide ribbon fiber.

[0104] The ribbon-shaped fiber obtained in step 1) was placed in a mixed solvent of hydroiodic acid / methanol with a volume ratio of 1:3 for room temperature reduction for 12 hours, washed and dried with ethanol to obtain pure graphene fibers with high conductivity.

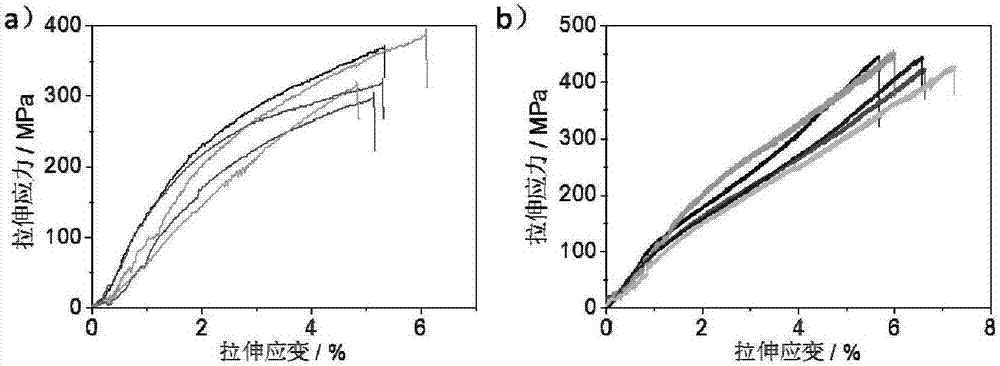

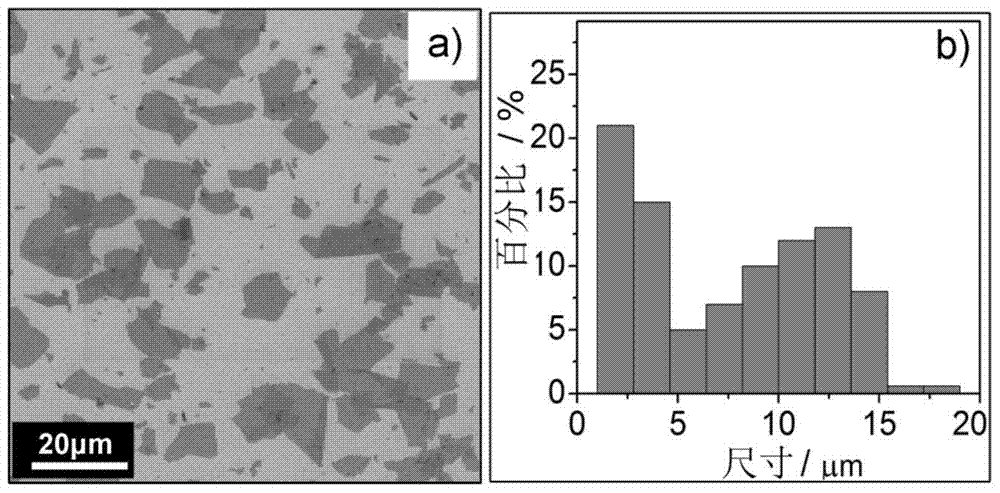

[0105] The graphene fiber prepared through the above steps has good toughness, can be woven and knotted, and the graphene sheets are arranged along the axial direction of the fiber. Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

| toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com