Oil-making method of double-bed interactive and circling type for pyrolyzing sludge

A circulating sludge technology, applied in pyrolysis sludge treatment, dehydration/drying/thickened sludge treatment, petroleum industry, etc., to achieve low operating temperature, easy large-scale continuous production, and control emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

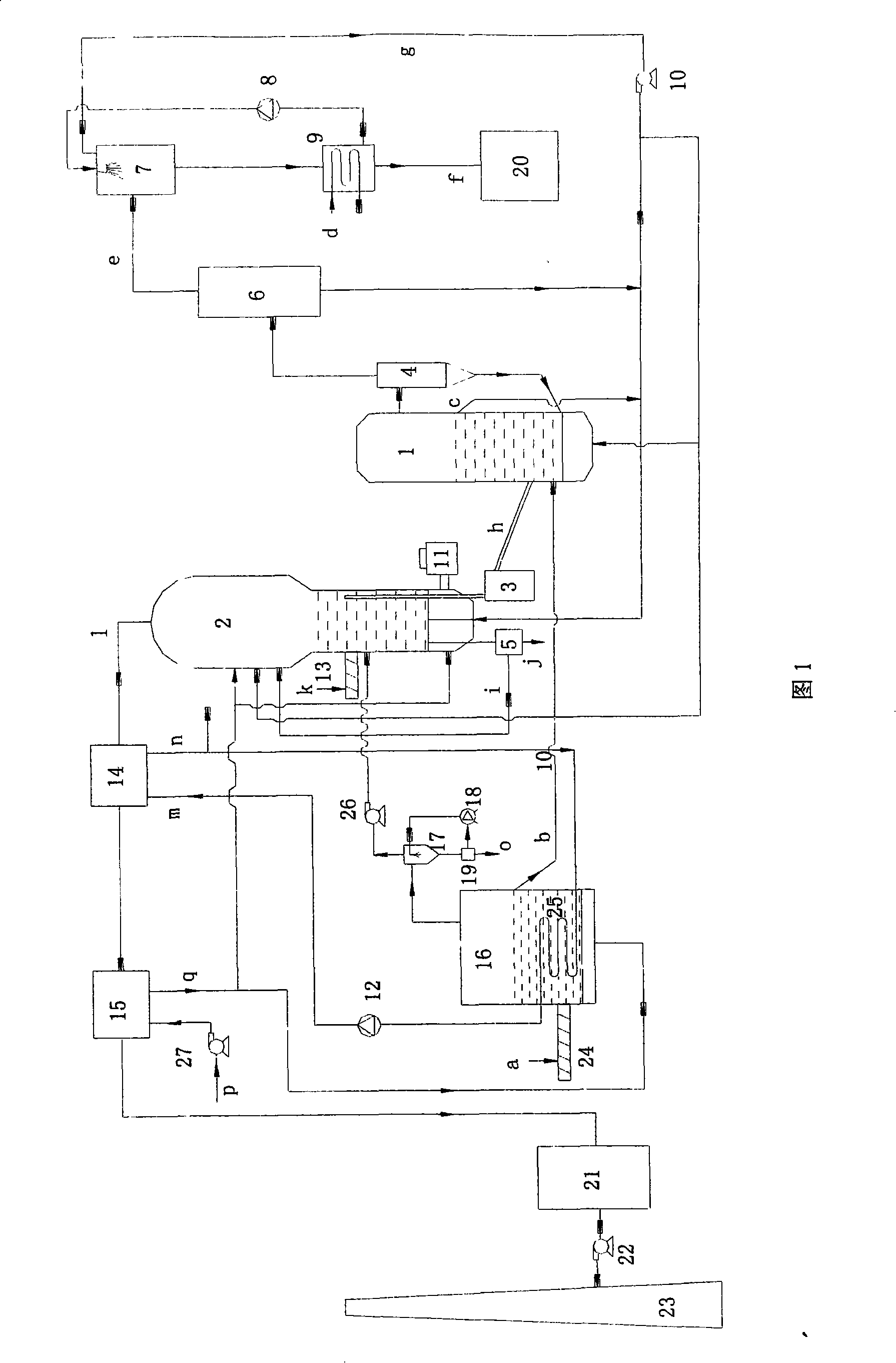

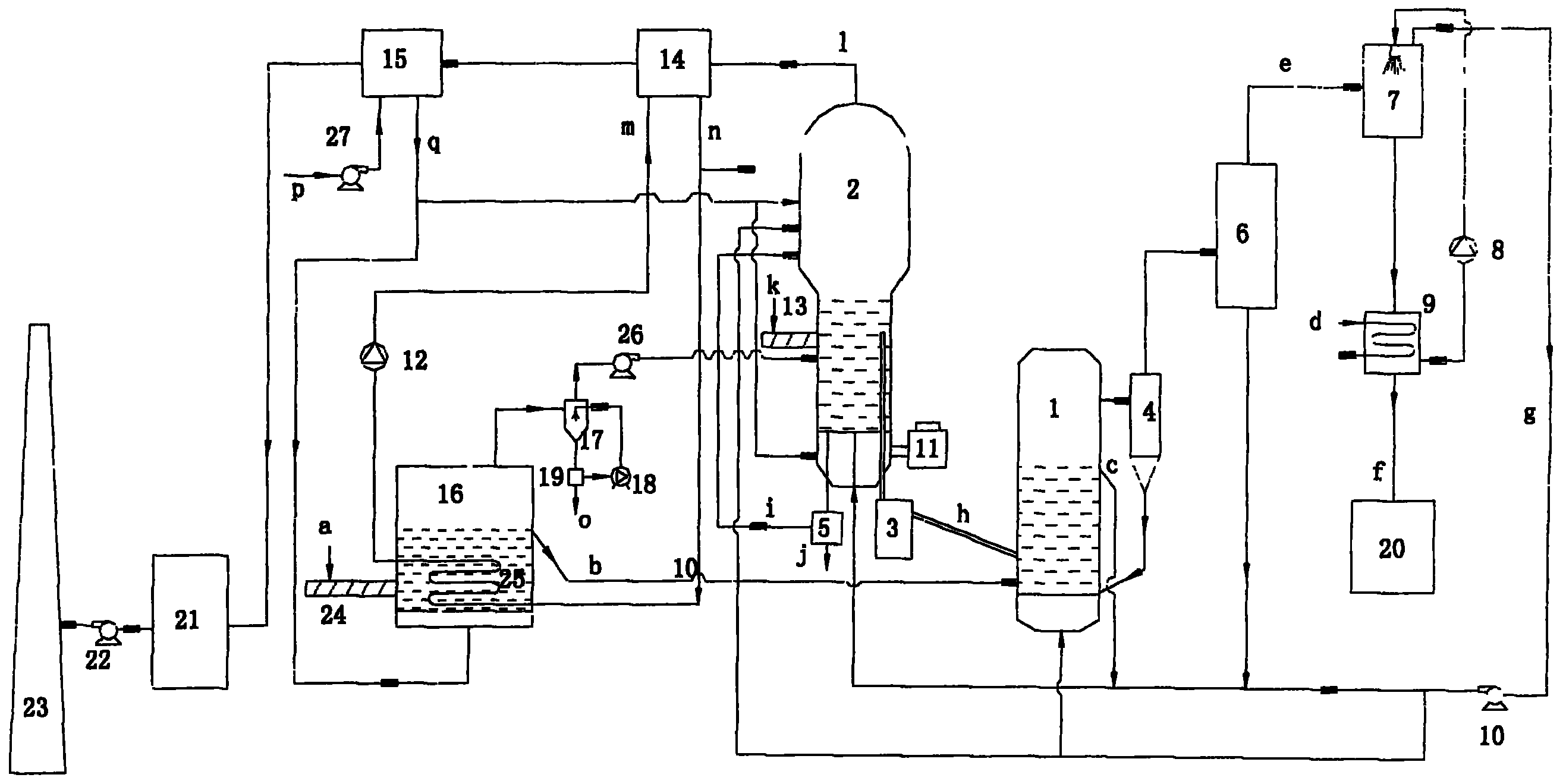

[0023] (1) The wet sludge dehydrated through mechanical pressure filtration is dried into dry sludge with a moisture content of 5-10% in the internal heating type fluidized bed drier 16, and then sent into the fluidized bed pyrolysis reactor 1, at 450- The pyrolysis reaction occurs at a temperature of 550°C and is transformed into pyrolysis gas and residual carbon. Fluidized bed pyrolysis reactor 1 has a large amount of inert bed material in it, which can quickly heat the sludge newly entering the reactor to reach the pyrolysis reaction temperature, and its heat storage function can also reduce and temperature fluctuations in the reactor caused by moisture changes. Since the operating temperature of the fluidized bed pyrolysis reactor 1 is low and the temperature in the bed is uniform, the synthesis reaction temperature of dioxins has not been reached, and the enrichment of heavy metals in the solid residue is relatively stable. The outlet of fluidized bed pyrolysis reactor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com