Patents

Literature

61results about How to "Effective control of emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

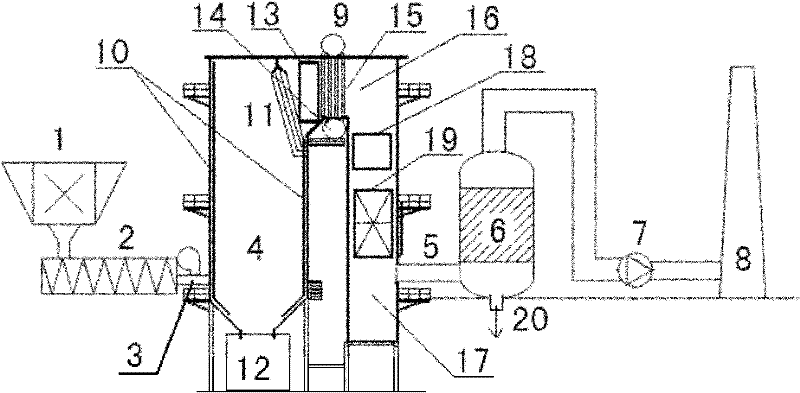

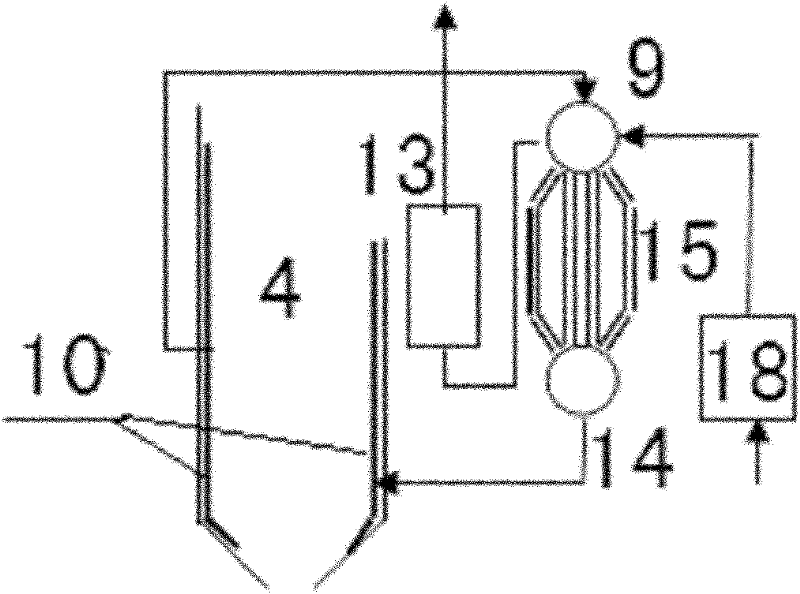

Coal-sludge co-combustion system based on high-temperature smoke drying and pneumatic conveying

ActiveCN105276603AIncrease speedEasy to handleSludge treatment by de-watering/drying/thickeningDispersed particle separationSludgeRotary feeder

The invention relates to a coal-sludge co-combustion system based on high-temperature smoke drying and pneumatic conveying. A sludge storage bin is connected with a spray drying pipe through a screw pump. An air inlet of the spray drying pipe is connected with a cyclone separator outlet flue of a circulating fluidized bed boiler. A first outlet of the spray drying pipe is connected with a first rotary feeder, and a second outlet of the spray drying pipe is connected with a cyclone separator. An exhaust opening of the cyclone separator is connected with the circulating fluidized bed boiler through a cooling condenser and an exhaust gas fan, and a discharging opening of the cyclone separator is connected with a second rotary feeder. A limestone bin is connected with a third rotary feeder. An outlet of the first rotary feeder, an outlet of the second rotary feeder and an outlet of the third rotary feeder are connected with a feeding opening of a jet feeding device, an air inlet of the jet feeding device is connected with a Roots fan, and an outlet of the jet feeding device is connected with the circulating fluidized bed boiler. The functions of sludge drying and conveying, dry tail gas waste heat utilization, sludge and coal co-combustion, pollutant control and the like can be achieved, bad smell and dust diffusion can be avoided, and the coal-sludge co-combustion system has the beneficial effects of being simple, environment-friendly and efficient.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

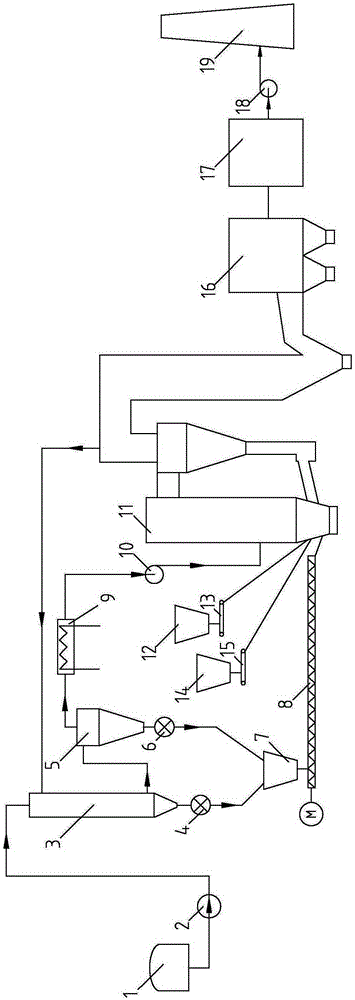

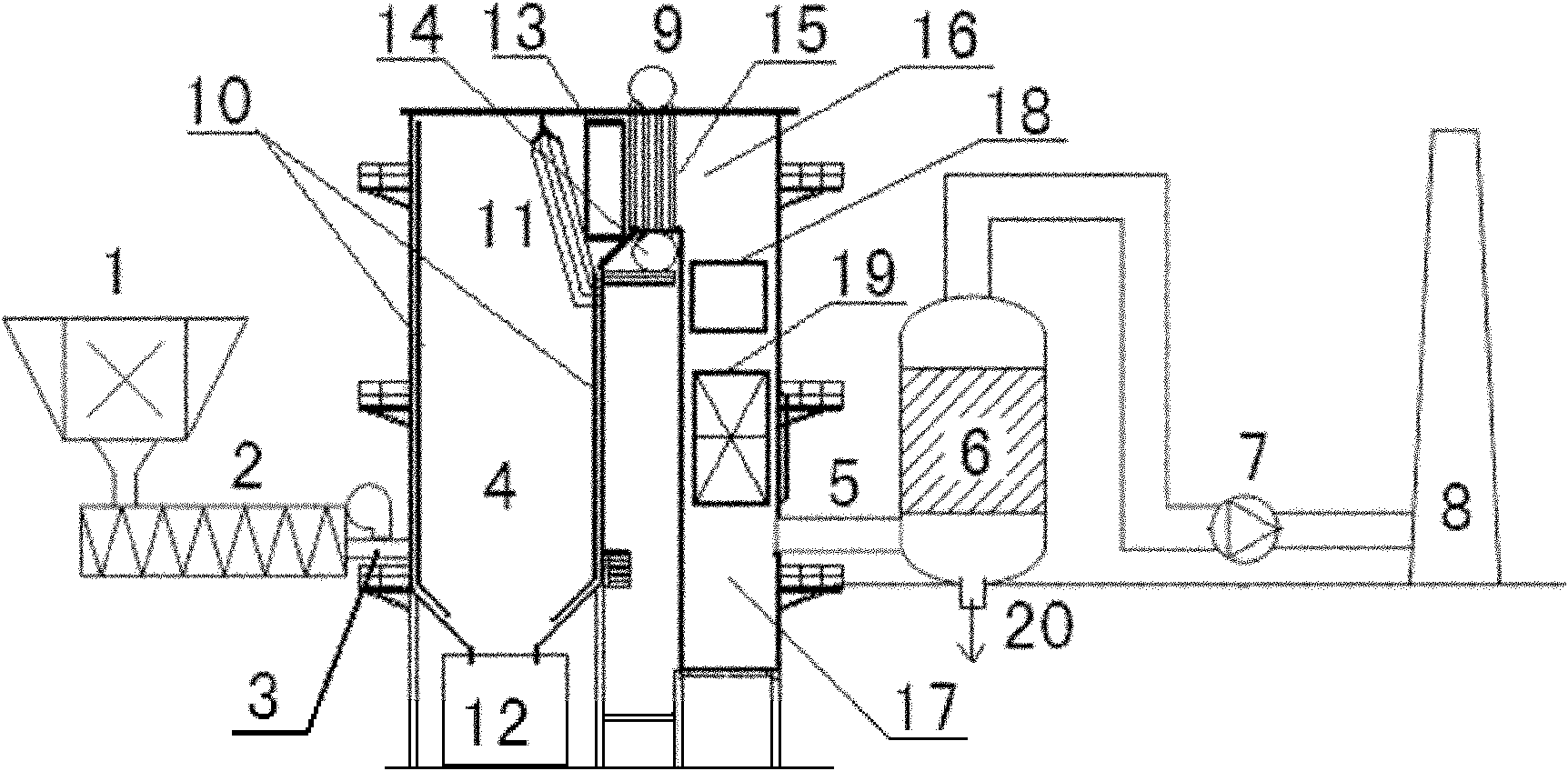

Coal-sludge co-combustion system based on high-temperature smoke drying and circulating fluidized bed boiler

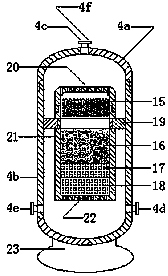

The invention relates to a coal-sludge co-combustion system based on high-temperature smoke drying and a circulating fluidized bed boiler. A discharging outlet of a sludge storage bin is connected with a feeding inlet of a spray drying pipe through a screw pump. An air inlet of the spray drying pipe is connected with an outlet flue of a cyclone separator of the circulating fluidized bed boiler. An outlet I of the spray drying pipe is connected with a dry sludge bin through a rotary feeder I, and an outlet of the dry sludge bin is connected with the circulating fluidized bed boiler through a spiral conveyer so that dry sludge in the dry sludge bin can be fed into a dense-phase zone of the circulating fluidized bed boiler through the spiral conveyer to be combusted; an outlet II of the spray drying pipe is connected with the cyclone separator, an unloading opening of the cyclone separator is connected with the dry sludge bin through a rotary feeder II, and an exhaust opening of the cyclone separator is connected with the circulating fluidized bed boiler through a cooling condenser and a vent fan. The coal-sludge co-combustion system integrates the functions of sludge drying, combustion and pollutant control, and has the characteristics of being concise, environmentally friendly and efficient.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Equipment for collecting and processing acidity mist

ActiveCN101130191AReduce total HCL (acid)Promote absorptionDispersed particle separationDirt cleaningWastewaterPollution

The invention discloses an acid mist collecting disposing device, which comprises the following parts: acid mist collecting mechanism, gas-liquid separated acid mist recycling mechanism, acid mist predisposing mechanism, acid mist disposing mechanism, fan, vent chimney and corresponding connecting duct line, wherein the duct line collecting mechanism, potcher and pickling bath are used to collect the acid mist generated from potcher and pickling bath; the gas-liquid separated acid liquid recycling mechanism connects acid mist collecting mechanism to separate and recycle acid liquid; the acid mist predisposing mechanism is set between the acid mist predisposed mechanism to predispose the acid mist in the acid mist disposing mechanism; the acid mist disposing mechanism washes and adsorbs the acid mist; the fan is connected between the acid mist disposing mechanism and smoke chimney generated by acid mist disposing mechanism to drain the waste gas out of drainage chimney. The invention can be applied in the waste disposing system in the steel surface disposing domain, which saves water and reduces the pollution of waste gas and waste water to improve economic and environmental benefit.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method for halogen-free flame-retardant rubber composite

ActiveCN102617936AStrong smoke suppression abilityHigh thermal decomposition temperaturePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsPolymer scienceVulcanization

The invention discloses a preparation method for a halogen-free flame-retardant rubber composite. The method comprises the following steps: A, forming Al(OH)3 nanoparticles; B, drying the Al(OH)3 nanoparticles obtained in the step A in an air dry oven, wherein a mixture of the Al(OH)3 nanoparticles and the solution of a silane coupling agent is pre-dried at a temperature of 150 DEG C for 50 min so as to realize said drying; C, adding the Al(OH)3 nanoparticles obtained in the step B into ethylene propylene diene monomer (EPDM) rubber which has undergone plastication / banburying, further adding rubber oil, a promoter and a vulcanizing agent, carrying out repeated mixing on a roller until a uniform mixture is obtained, and carrying out thin-passing and slice-making so as to obtain an EPDM rubber compound; and D, putting the mixed EPDM flame-retardant rubber into a mould, carrying out primary sulfuration after cold pressing and mould filling, and then putting the rubber in the air dry oven on glass cloth for secondary sulfuration so as to obtain a finished product of the halogen-free flame-retardant rubber composite. According to the invention, flame retardation of the EPDM rubber is substantially improved.

Owner:GUANGDONG SUNLITE MATERIAL SCI & TECH

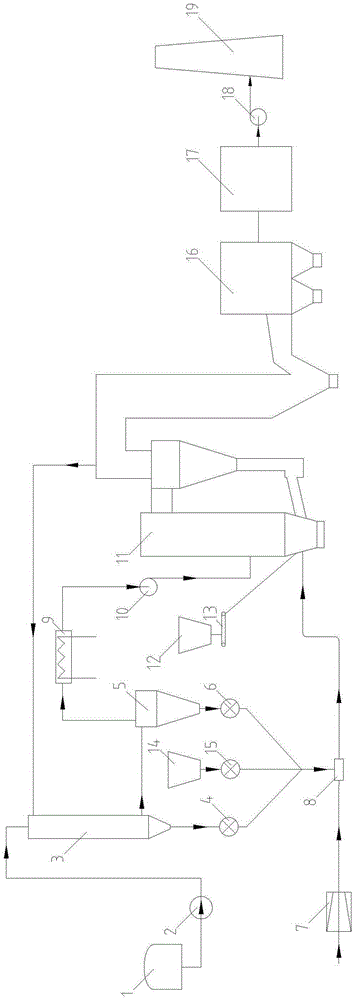

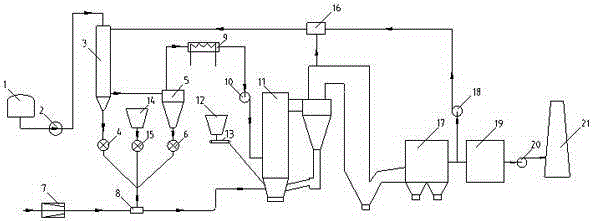

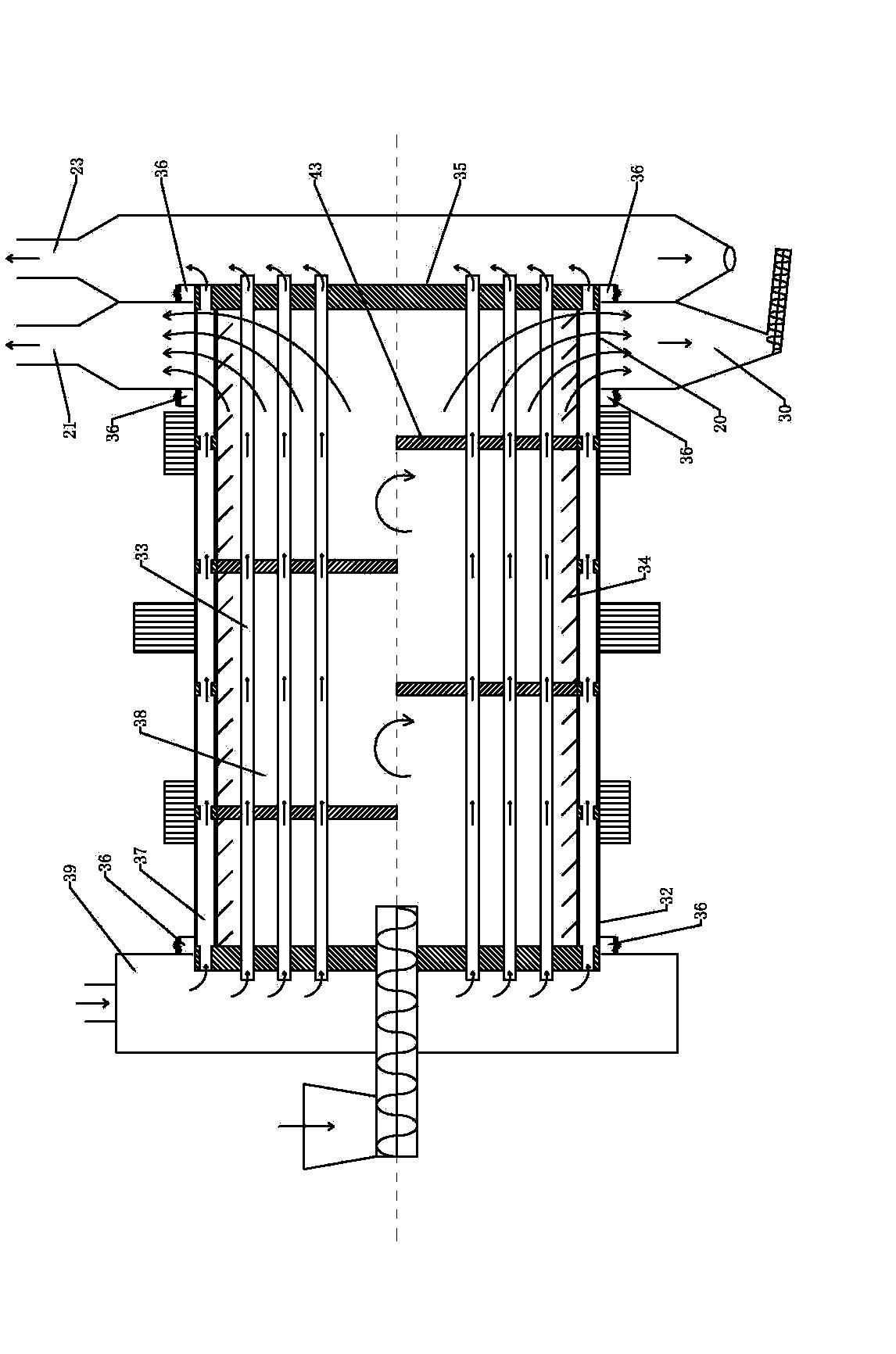

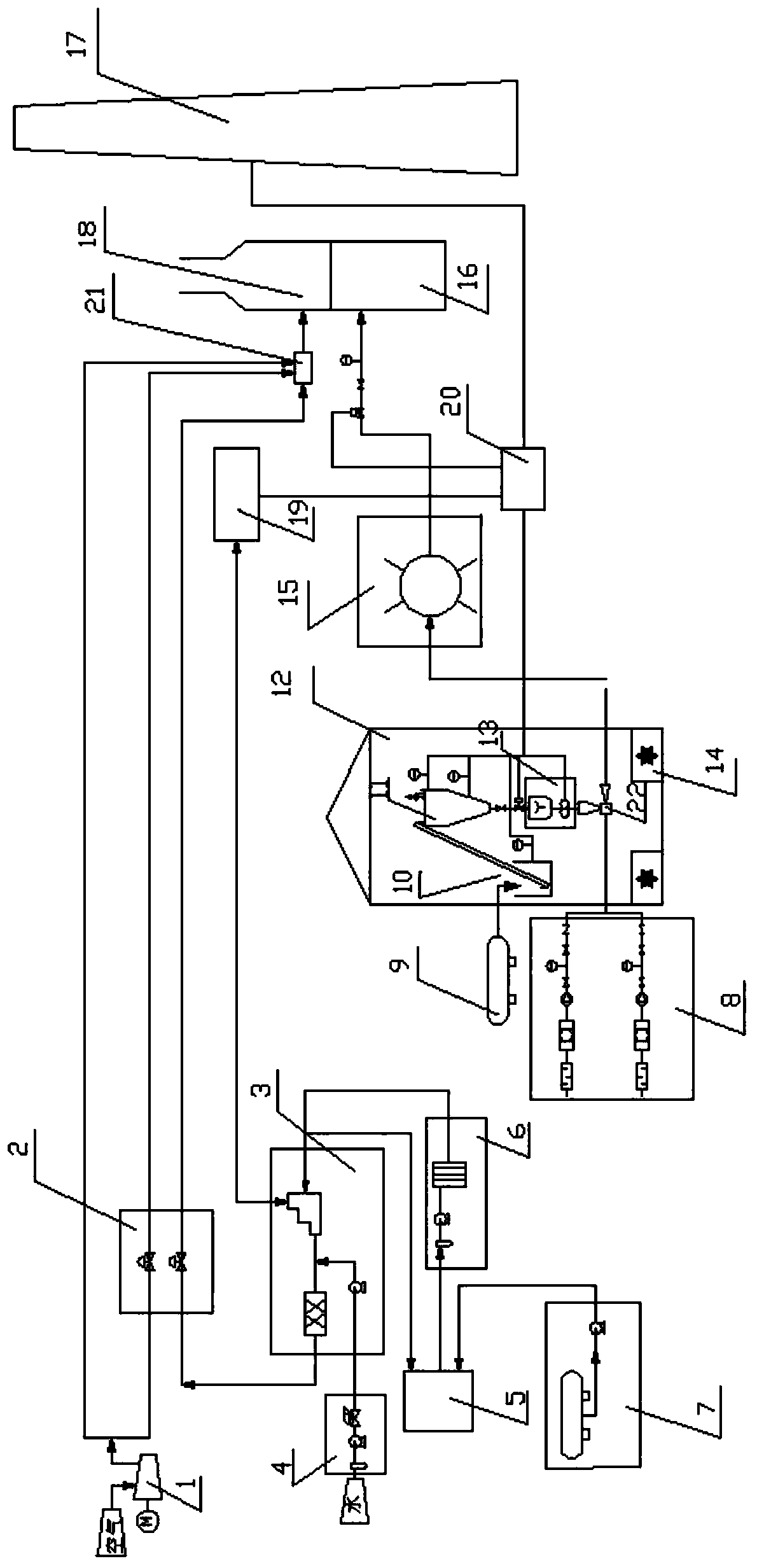

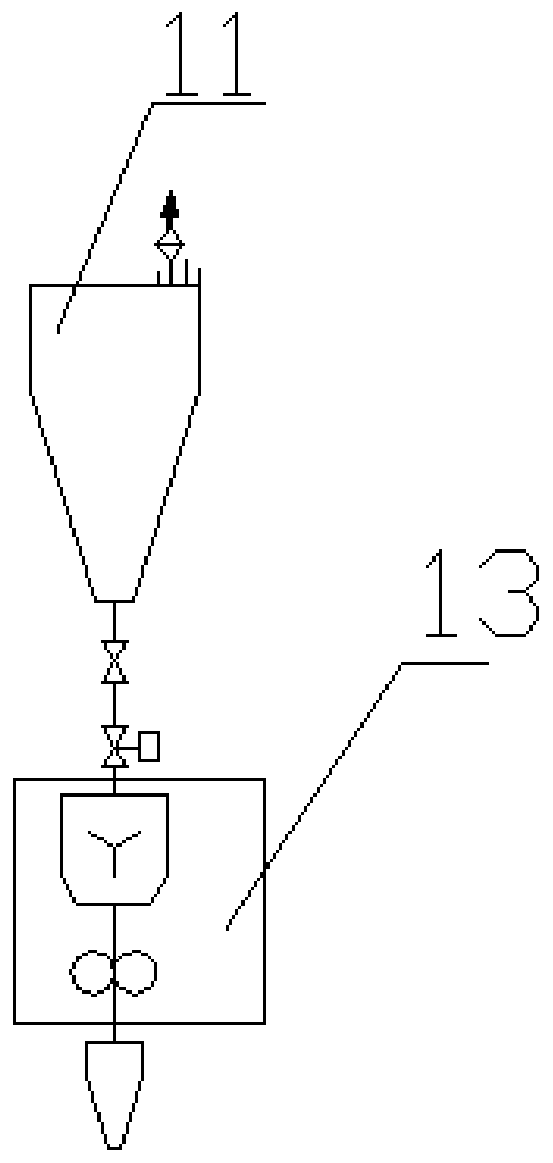

Coal-sludge multi-fuel combustion system based on two-medium flue gas drying and pneumatic transportation

The invention relates to a coal-sludge multi-fuel combustion system based on two-medium flue gas drying and pneumatic transportation. A sludge storage cabin is connected with a spraying drying pipe; the spraying drying pipe is connected with a mixing chamber; one path of an inlet of the mixing chamber is connected with an outlet flue of a cyclone separator, and the other path is connected with an outlet of a dust remover through a cold smoke draught fan; a spraying drying pipe outlet I is connected with a rotary feeder I; a spraying drying pipe outlet II is connected with the cyclone separator; an exhausting hole of the cyclone separator is connected with a circulating fluidized bed boiler through a cooling condenser and an exhausting steam draught fan; an unloading hole of the cyclone separator is connected with a rotary feeder II; a limestone cabin is connected with a rotary feeder III; the rotary feeder I, the rotary feeder II and the rotary feeder III are connected with the circulating fluidized bed boiler through a spraying feeder; and a gas inlet of the spraying feeder is connected with a Roots draught fan. With the adoption of the coal-sludge multi-fuel combustion system, functions of sludge desiccation and transportation, residual heat utilization of dry tail gas, multi-fuel combustion of sludge and coal, control of pollutants and the like can be realized, and the diffusion of stench and dust is facilitated; and the system has the characteristics of simplicity, environmental friendliness and high efficiency.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

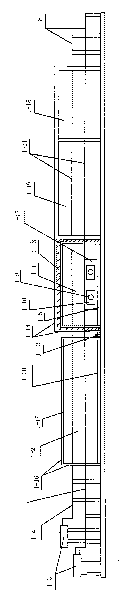

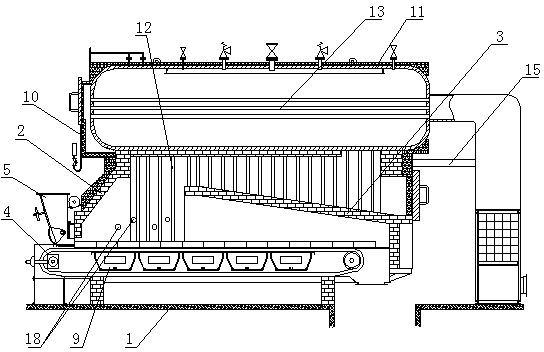

Vertical industrial pulverized coal boiler system

InactiveCN101929669AImprove air tightnessReduce air leakageCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir preheaterSlag

The invention discloses a vertical industrial pulverized coal boiler system, which comprises a stokehole pulverization device connected with a pulverized coal boiler body through a combustor, and the pulverized coal boiler body is connected with a chimney through a flue gas processing device. The vertical industrial pulverized coal boiler system is characterized in that: the pulverized coal boiler body comprises a horizontal flue, a hearth respectively communicated with two ends of the horizontal flue, and a vertical smoke well which are arranged in a vertical inverted U shape; the hearth consists of membrane water walls; a position of the hearth communicated with the outlet of the horizontal flue is provided with a slag condensing bank used for preventing high temperature flue gas from slagging; the horizontal flue behind the slag condensing pipe bundle is provided with a superheater and an convection bank inside in turn; the convection bank is connected to upper and lower boiler barrels positioned on upper and lower sides of the horizontal flue; the vertical smoke well is provided with an economizer and an air preheater inside from top to bottom; and the lower part of the vertical smoke well is connected with the flue gas processing device through a connecting flue. The vertical industrial pulverized coal boiler system has the advantages of high integration degree, small occupied area, high combustion efficiency, energy conservation, environmental protection, and wide market application prospect.

Owner:XI AN JIAOTONG UNIV

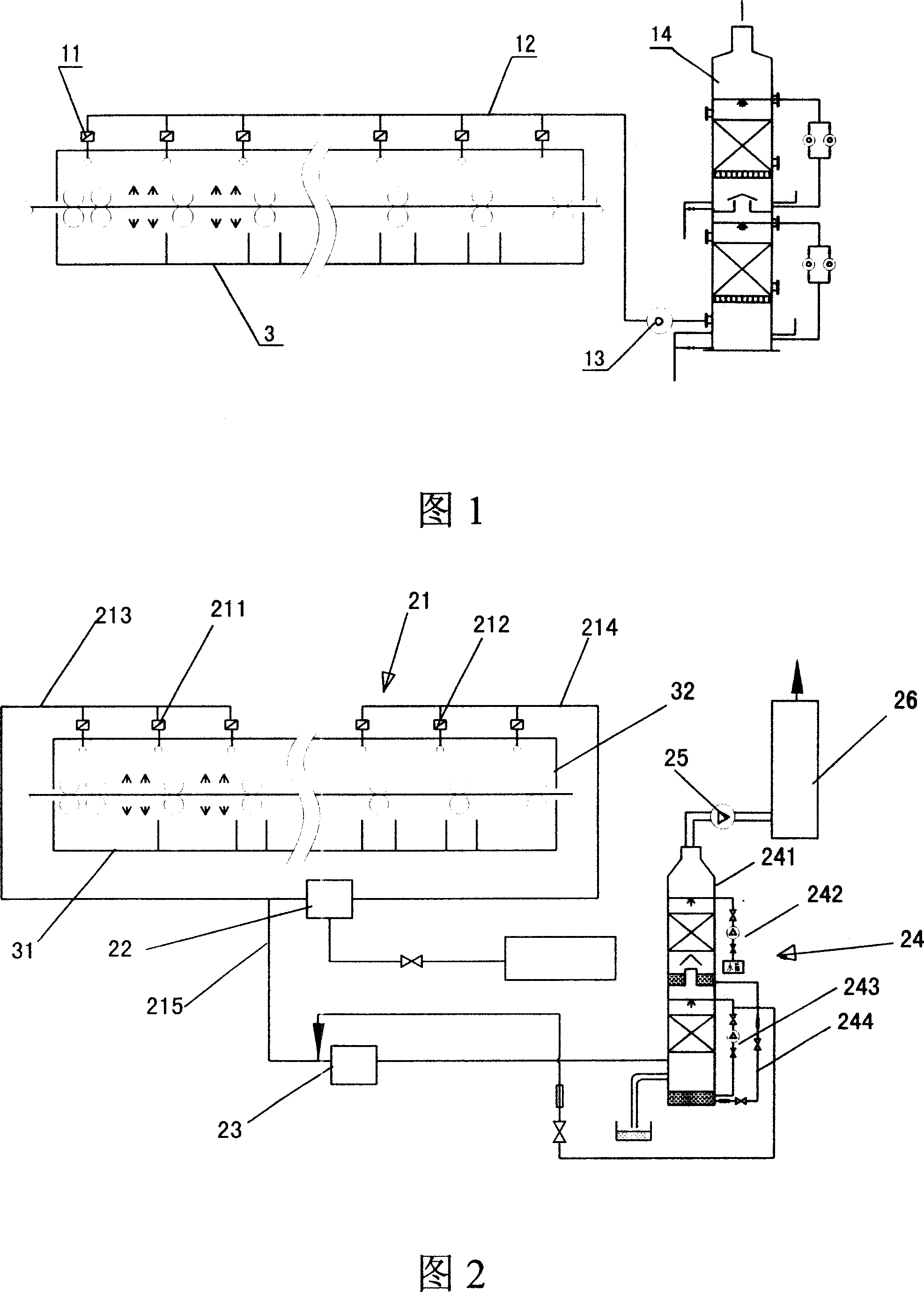

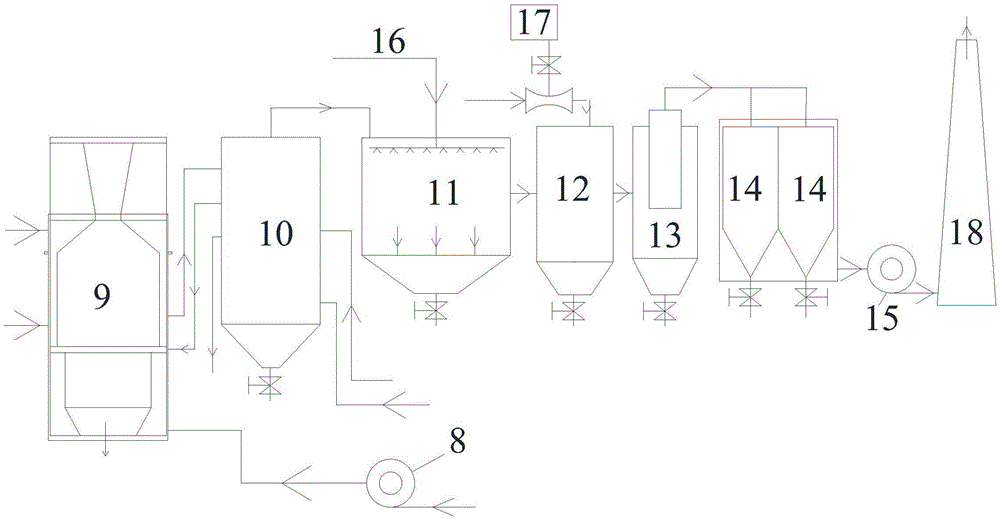

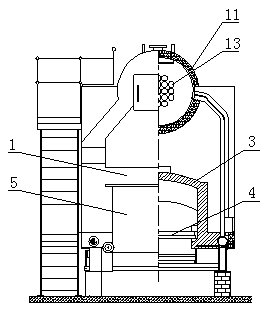

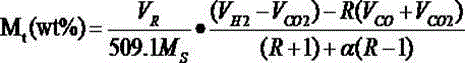

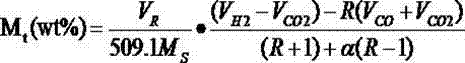

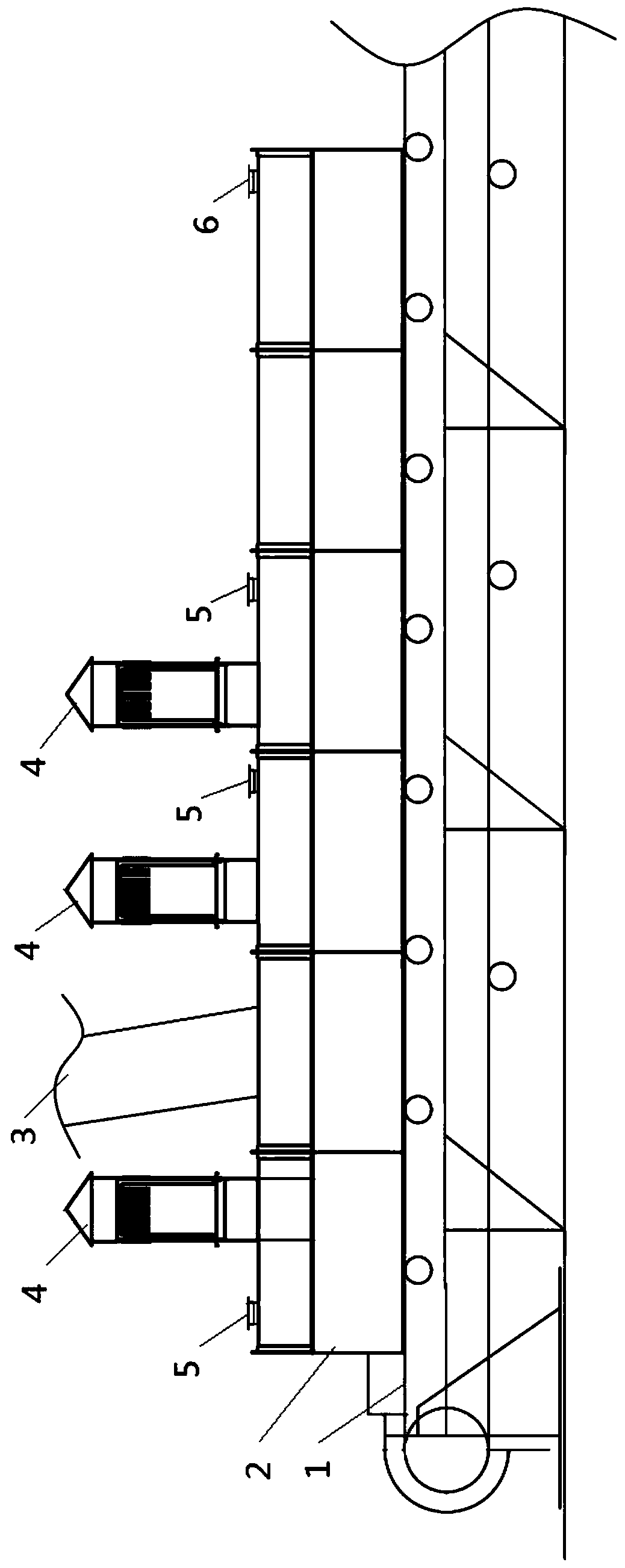

Waste incineration tail gas emission purification treatment process and special apparatus thereof

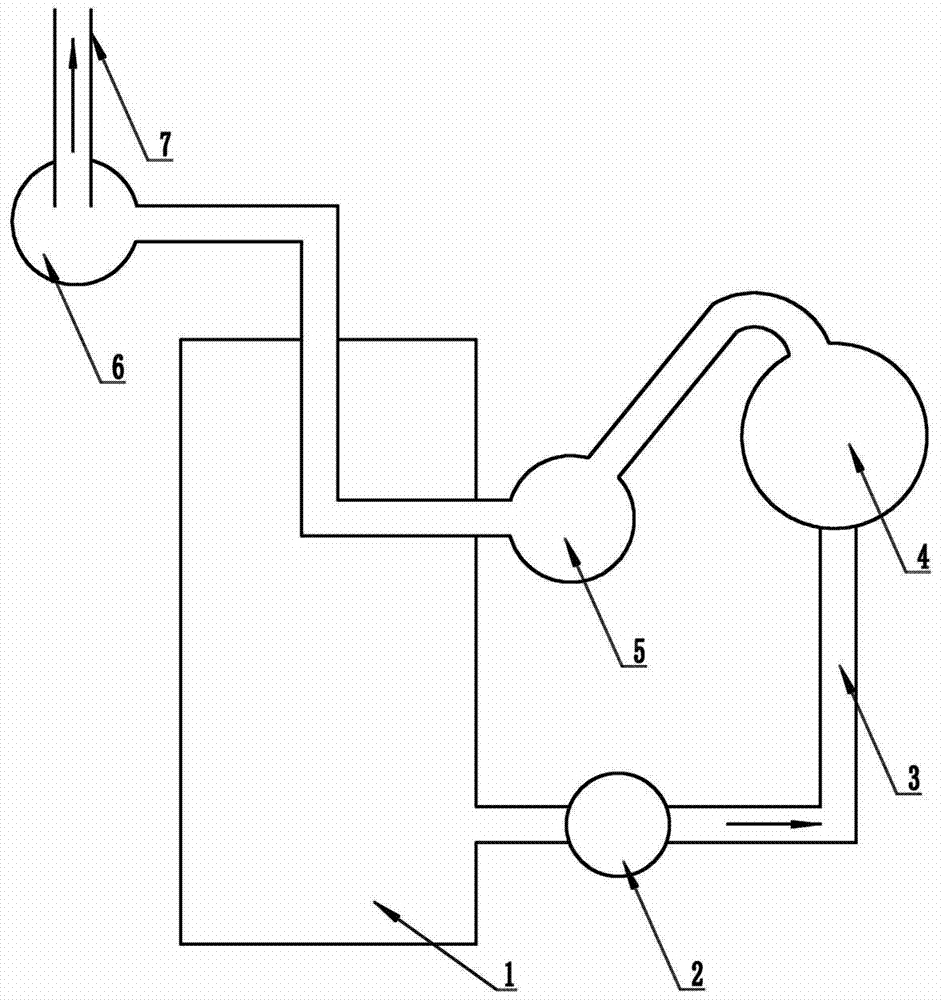

InactiveCN102949920AReduce generationEffective control of emissionsHuman health protectionUsing liquid separation agentToxic gasEmission channeling

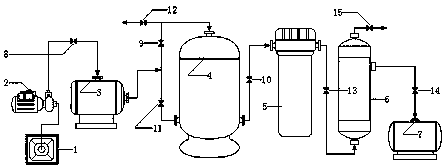

The invention relates to a waste incineration tail gas emission purification treatment process and a special apparatus thereof, wherein technical problems of difficult treatments on dioxin and heavy metals by the existing tail gas treatment apparatus and the like are mainly solved with the process and the special apparatus. Key points of the technical scheme comprise that: a fan (2) is arranged on a flue channel (3), one end of the flue channel (3) is communicated with a flue emission port of an incineration furnace (1), the other end of the flue channel (3) respectively forms a series connection with a processor (5) and a filter (6), and a flue emission channel (7) is arranged on the filter (6). According to the present invention, tail gas generated by incineration is subjected to five processes such as precipitation dust removing, desulfurization dechlorination, pharmaceutical agent treatment, adsorption purification and high temperature burn back so as to reduce tail gas harmful substance emission, particularly effectively control emissions of highly toxic gas dioxin, decompose heavy metals in tail gas precipitate, and effectively solve the problem of pollution on air and soil by tail gas after incineration.

Owner:钟伏桥

Internal-combustion high temperature furnace for ferro-coke pellets/lump ores

InactiveCN101726181AFast transmissionFast heatingFurnace typesPreheating chargesFurnace temperatureCombustion

The invention provides an internal-combustion high temperature furnace for ferro-coke pellets / lump ores, which is characterized in that: the high temperature furnace comprises a high temperature furnace body; the front end and the rear end of the high temperature furnace body are provided with a pre-heating furnace and a cooling system respectively; the rear end of the cooling system is provided with a discharging platform; the front end of the pre-heating furnace is provided with an upper loading platform and a lower loading platform positioned below the upper loading platform; the ends of the upper loading platform and the lower loading platform are provided with a vehicle pusher respectively; and the upper loading platform and the lower loading platform are connected with the discharging platform by running through the pre-heating furnace, the high temperature furnace body and a sliding guide rail for a charging carriage of the cooling system respectively. The internal-combustion high temperature furnace has the advantages of simple structure, rational heating, uniform furnace temperature, high heat efficiency and capability of effectively controlling the emission of harmful gas, low labour intensity and production cost reduction.

Owner:上海得旺力实业有限公司

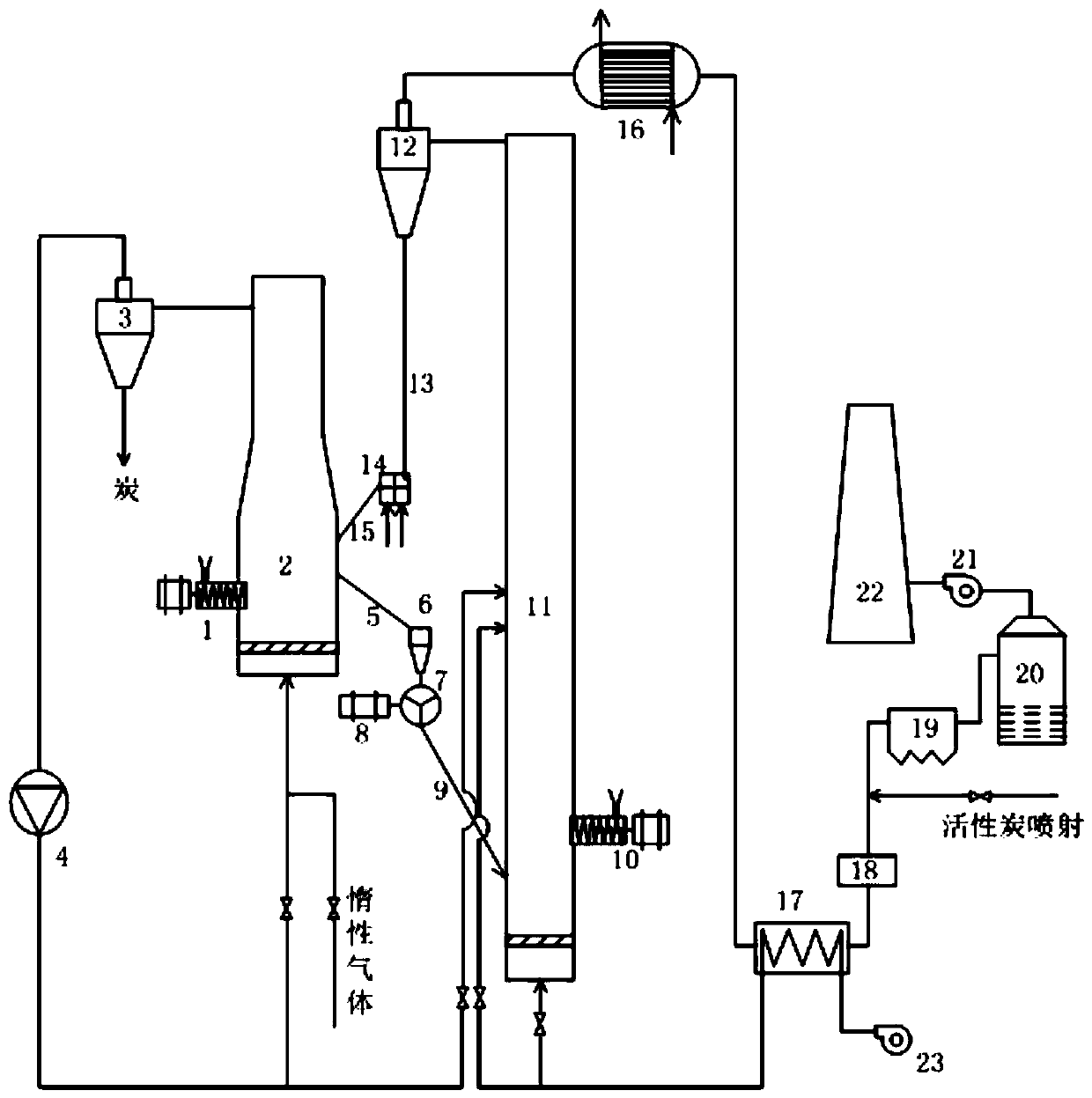

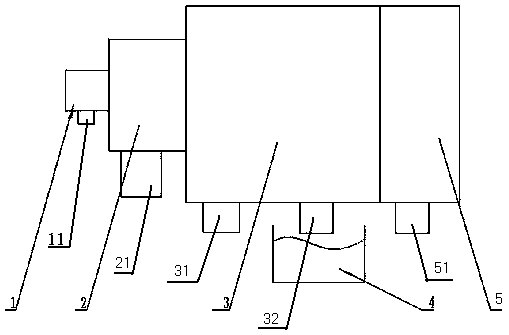

Low dioxin emission system and method for high-temperature carbonization pyrolysis and high-temperature gasification incineration of medical waste

InactiveCN106468441AControlling Hazardous Waste and Medical Waste DischargeProtect human health and ecological environmentIncinerator apparatusTarScrap

The invention relates to a low dioxin emission system and method for high-temperature carbonization pyrolysis and high-temperature gasification incineration of medical waste. The system comprises a dry distillation bar making system and a high-temperature gasification purifying system. The dry distillation bar making system comprises a storage warehouse, a carbonization furnace, a bar making machine, a warehouse, a purifying device, a waste heat boiler and a combustion chamber. Solid waste is brought out of the storage warehouse and then thrown into the carbonization furnace, and after carbonization, solids and oil tar are removed out and conveyed to the bar making machine to serve as raw materials. The carbonization furnace is connected with the combustion chamber and the purifying device. The purifying device is connected with the waste heat boiler. The high-temperature gasification purifying system comprises a draught fan, a gasification furnace, a waste heat boiler, a quenching tower, a dioxin removing tower, a cyclone mixing adsorption device, dust collecting bags, an induced draught fan and the like, wherein the draught fan, the gasification furnace, the waste heat boiler, the quenching tower, the dioxin removing tower, the cyclone mixing adsorption device, the dust collecting bags, the induced draught fan and a chimney are sequentially connected. By means of the system and method, emission of dangerous waste and medical waste can be effectively controlled, and harmlessness, reduction and reclamation are achieved.

Owner:SHANGHAI QINZE ENVIRONMENTAL PROTECTION TECH CO LTD

Sludge drying/pyrolysis/gasification/incineration integrated treatment system

InactiveCN103666504AGood energy saving effectSimple equipment structureSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisGas generatorPyrolysis

The invention discloses a sludge drying / pyrolysis / gasification / incineration integrated treatment system which comprises a burning system, a drying system, a pyrolysis and gasification system and a fume cleaning system, wherein the burning system comprises a gas generator and an incinerator; the drying system comprises a blower and Stage 1-5 drying machines; the pyrolysis and gasification system comprises a pyrolysis gasifier and a separator; and the fume cleaning system comprises a dedusting devulcanizer, a draught fan and a chimney which are respectively connected with each other through pipelines. The integrated treatment system disclosed by the invention has the characteristics of high safety and reliability, energy saving, emission reduction, low carbon, environment friendliness, low operating cost and the like, and realizes reduced, stabilized, harmless and recycling treatment.

Owner:浙江绍兴鸿杰节能环保科技有限公司

Method for preparing arsenic trioxide by utilizing arsenious waste water

ActiveCN102602994ASimple processLow equipment requirementsMultistage water/sewage treatmentWater/sewage treatment by heatingFatty aldehydeArsenate

The invention discloses a method for preparing arsenic trioxide by utilizing arsenious waste water. The method comprises the following steps of: adopting the arsenious waste water as a raw material, adding a water-soluble organic reducing agent such as low-grade fatty aldehyde and urea, reacting for 0.5-8 hours under the temperature of 15-150 DEG C and the pressure of 0.1-10MPa, reducing arsenateinto arsenite, then adding sulfuric acid for adjusting pH to be acid, enabling the arsenite to be converted into the arsenic trioxide which is precipitated, then evaporating and concentrating solution, filtering, drying, then carrying out heating sublimation or recrystallizing purification on the obtained arsenic trioxide, and then obtaining a high-purity arsenic trioxide product. The method disclosed by the invention has the advantages of simple process, easiness in implementation, lower cost, and high recovery rate and product purity.

Owner:HUNAN ZHANTAI NON FERROUS METALS

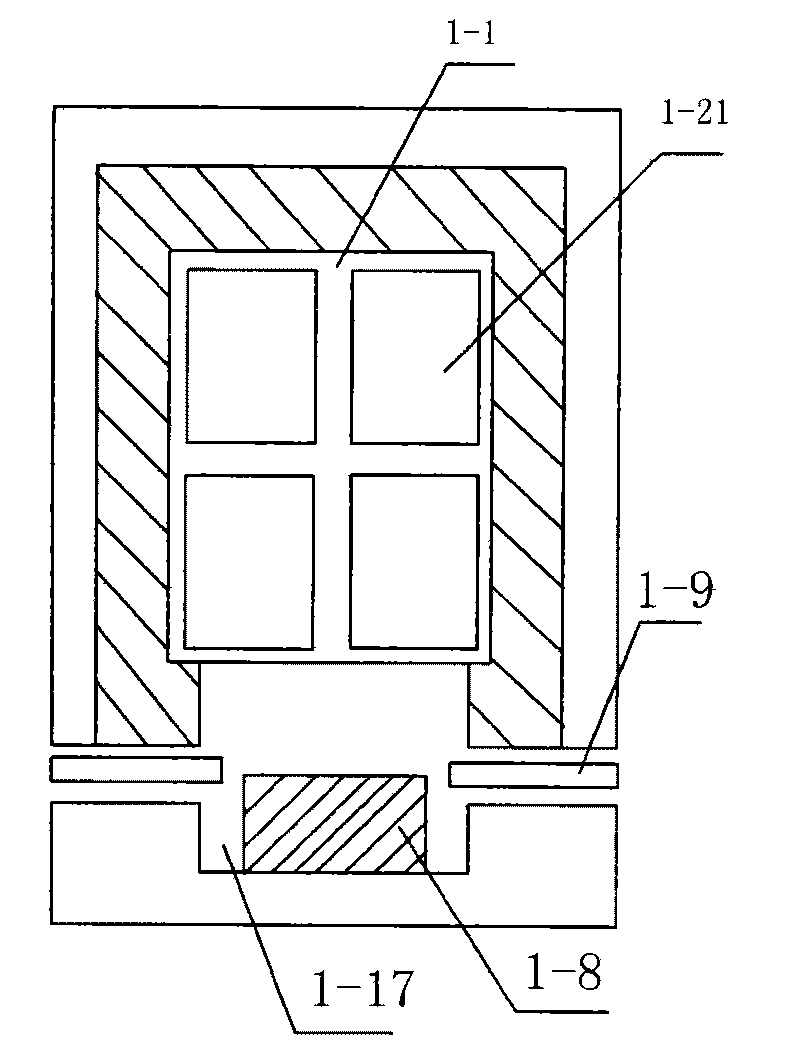

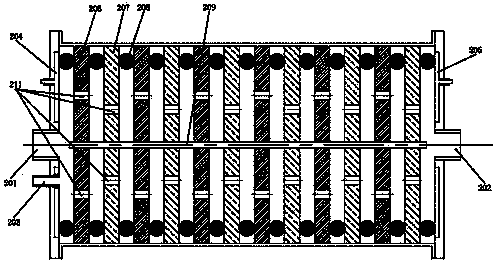

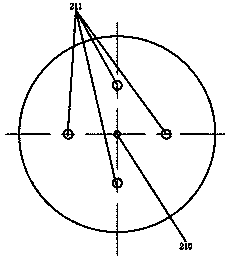

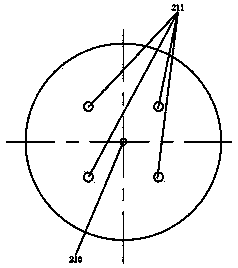

Chain coal-fired boiler capable of reducing nitrogen oxide emission

InactiveCN104214764ABurn fullyBurn completelyDamper arrangementSolid fuel combustionNitrogen oxidesEngineering

The invention discloses a chain coal-fired boiler capable of reducing nitrogen oxide emission. The chain coal-fired boiler capable of reducing nitrogen oxide emission comprises a furnace body internally provided with a furnace hearth, wherein the furnace hearth is jointly defined by a furnace wall, a boiler cylinder and a water cooling wall pipe; a front furnace arch and a rear furnace arch are arranged in the furnace hearth; a chain plate type grate driven by a power mechanism is arranged under the furnace hearth; an air supply device is arranged on the furnace body; a coal supply hopper is arranged in front of the furnace body; an exhaust gas passing pipe penetrating through the boiler cylinder is arranged on the furnace body; the chain plate type grate comprises two oppositely arranged transmission chains; a support rod is arranged between the two transmission chains; a grate plate is hinged to the support rod; the coal supply hopper comprises a coal supply hopper type box; a coal inlet is arranged on the top part of the coal supply hopper type box, and a coal outlet located above the front part of the chain plate type grate is arranged on the bottom part of the coal supply hopper type box; a material distributing roller driven by a power device is rotatably connected to the upper part in the coal supply hopper type box; a plurality of material distributing dialing plates are circularly distributed on the material distributing roller; an adjustable guide funnel located under the material distributing roller is arranged in the coal supply hopper type box. The chain coal-fired boiler capable of reducing nitrogen oxide emission has the advantage and effect that the nitrogen oxide emission can be effectively controlled.

Owner:山东百川集大环境工程有限公司

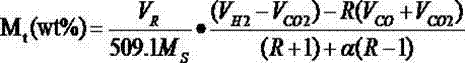

Fuel gas with high calorific value, preparation method thereof and equipment for carrying out the preparation method

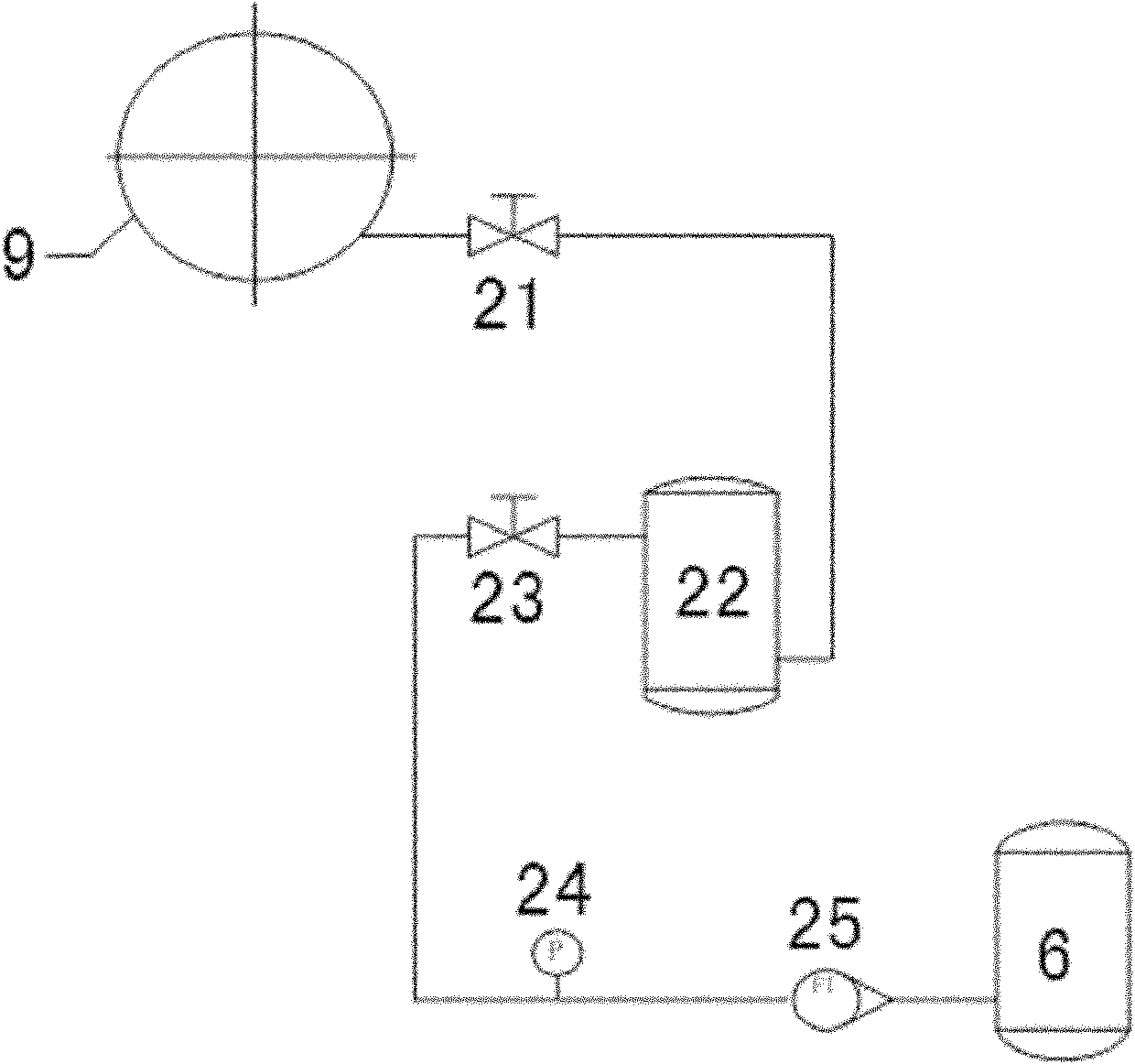

ActiveCN104312648AGood energy saving and emission reduction effectEffective control of emissionsGaseous fuelsElectrolysisControl system

The invention relates to a fuel gas with a high calorific value, a preparation method thereof, and equipment for carrying out the preparation method. The equipment comprises a control system, a water ion electrolysis system, and a hydrocarbon compound reforming system. The control system collects the data of time, pressure, temperature, and material feeding and automatically carries out management. The equipment has the advantages of safety, reliability, easiness in application, and convenience in control. The prepared fuel gas has a high calorific value, which can reach 11000 to 51000 Kcal / cm3, and does not contain any sulfur or nitrogen element. Compared to the conventional fuels, the energy and cost can be saved by 50% or more, and the fuel gas has the characteristics of cleanness, environment-friendliness, and high calorific value.

Owner:北京三昌宇恒科技发展有限公司

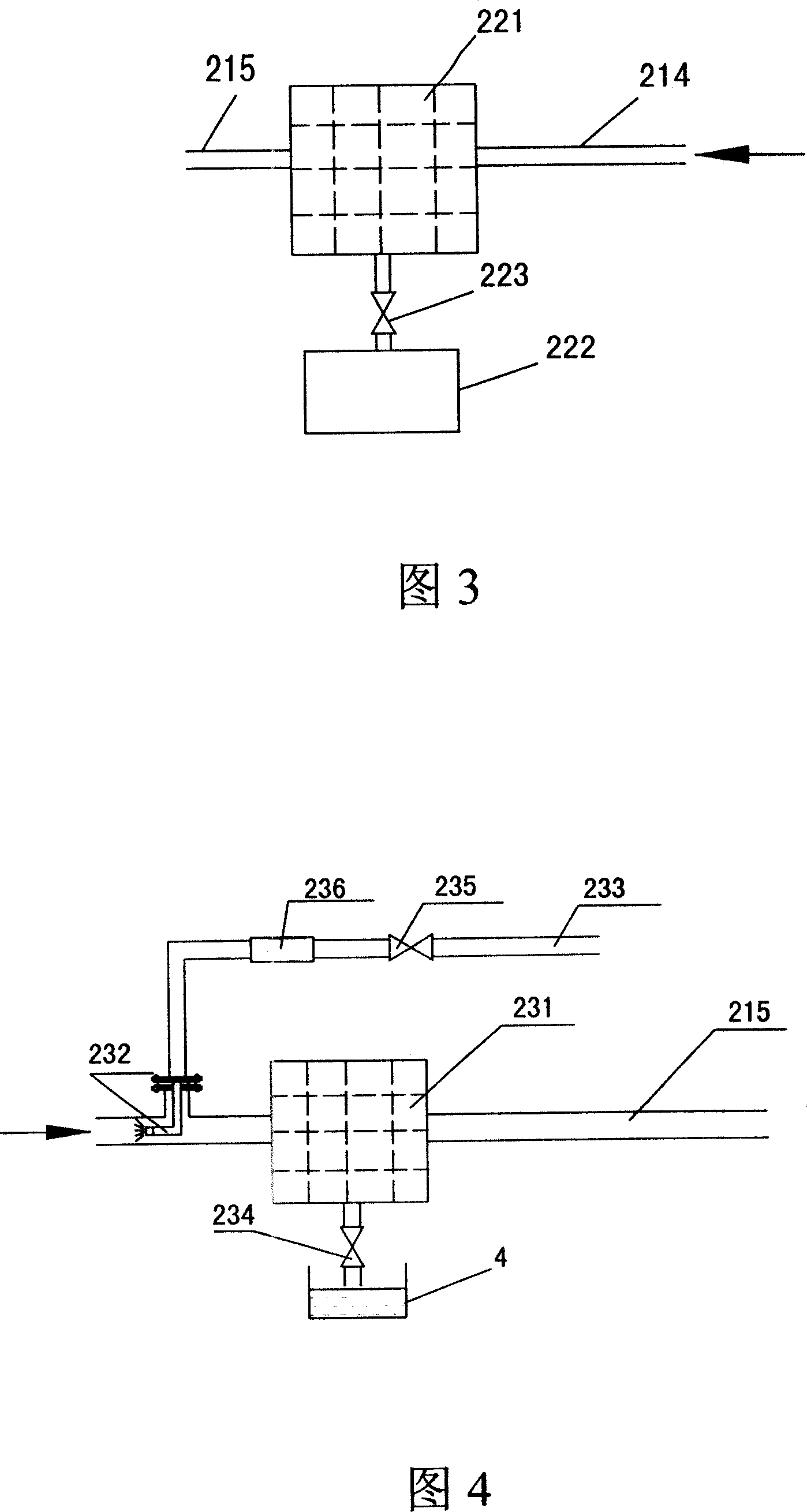

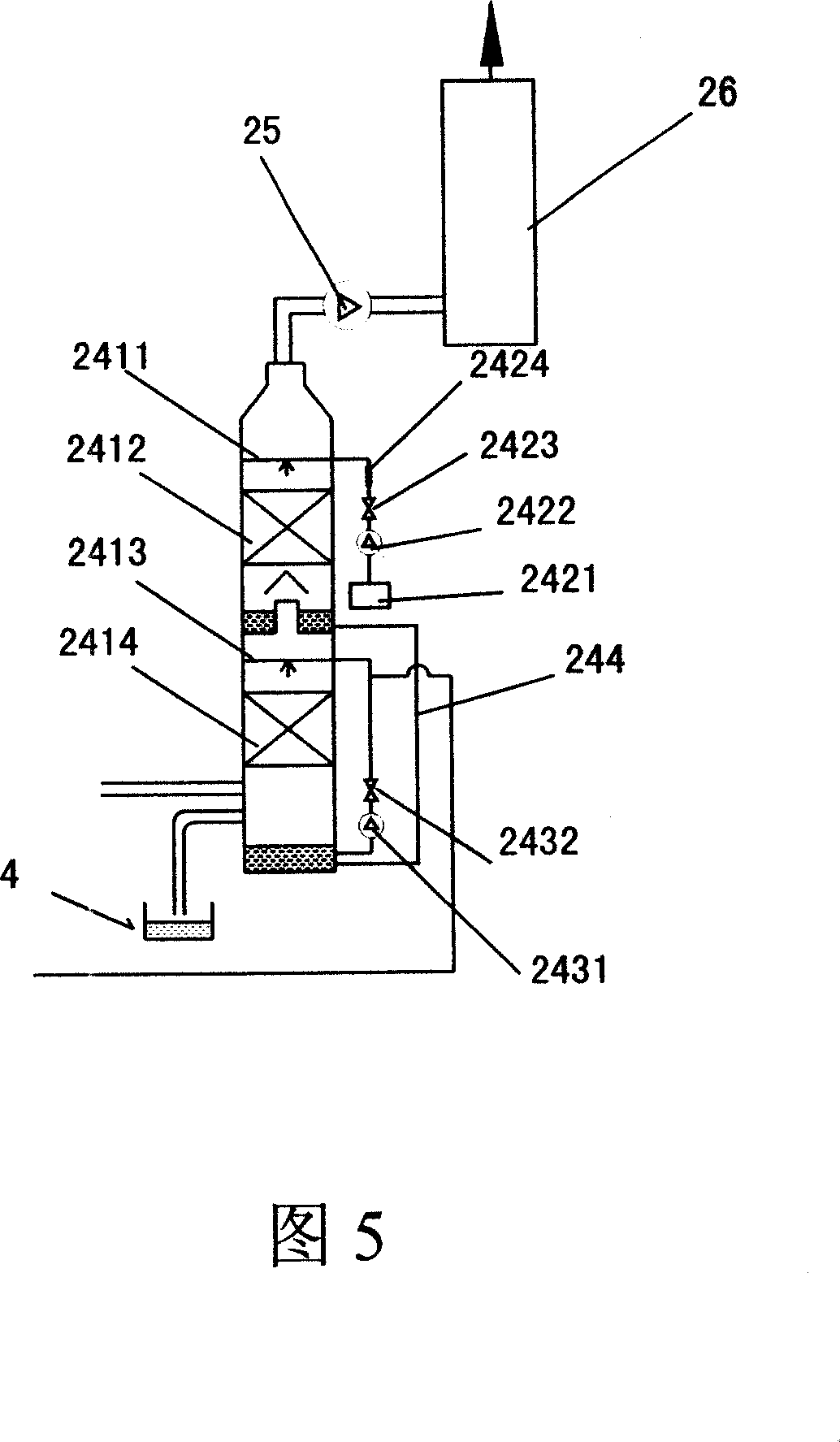

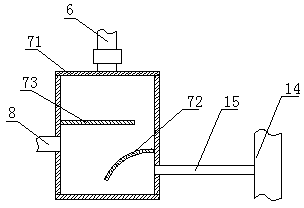

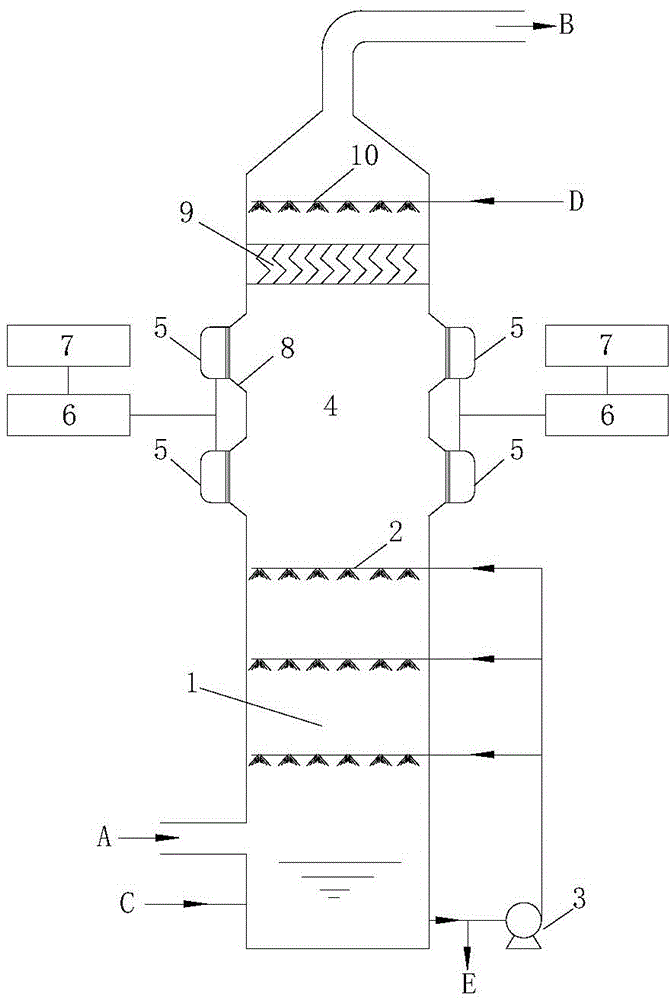

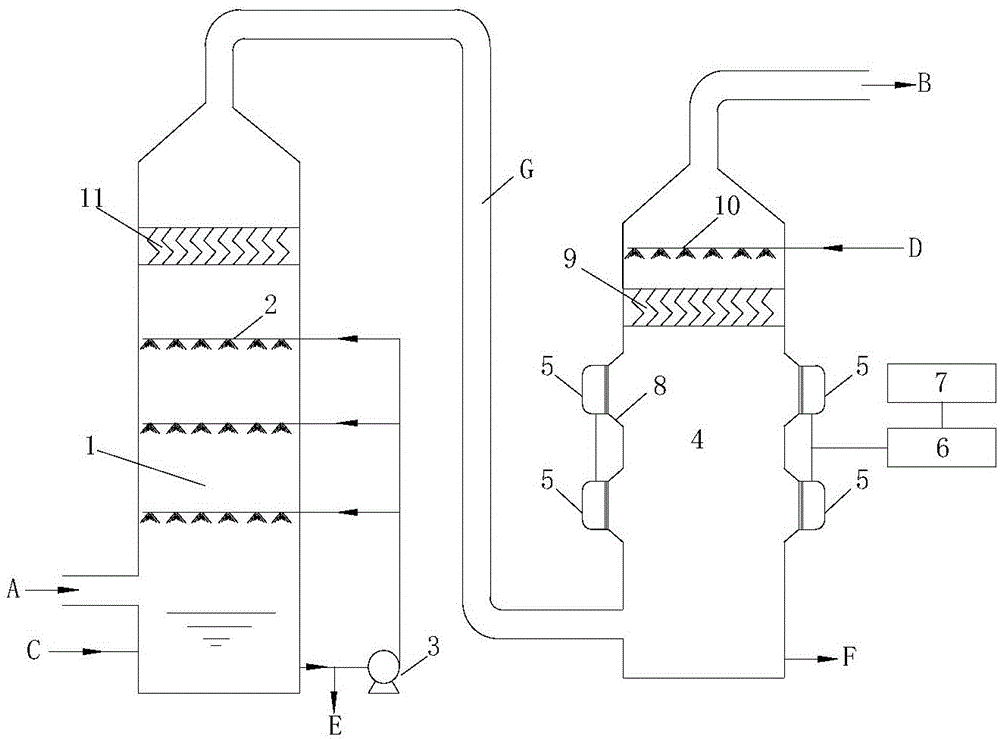

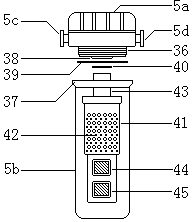

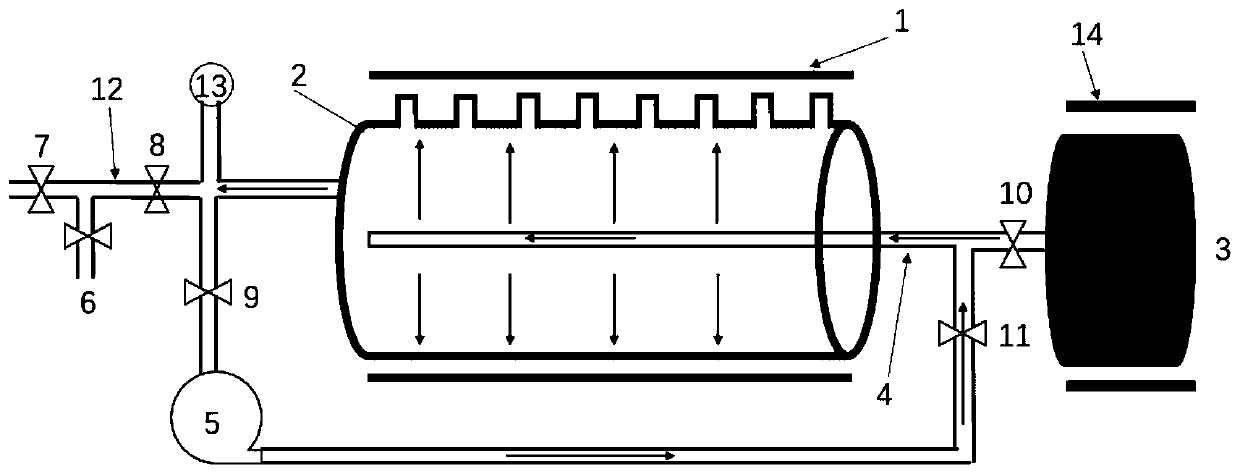

A device and method for wet flue gas desulfurization combined with fine particle removal

ActiveCN104307282BImprove the efficiency of collision agglomerationImprove the capture effectCombination devicesSound sourcesFlue gas

The invention discloses a device and a method for synergic wet method flue gas desulphurization and fine grain removal, and relates to flue gas treatment. The device is provided with a flue gas desulfurization washing device, a desulfurization liquid washing system, a desulfurization liquid circulating pump, an acoustic agglomeration device, a droplet trapping device and a flushing nozzle; the flue gas desulfurization washing device, the acoustic agglomeration device and the droplet trapping device are from top to bottom connected in series to form a whole, the lower part of the flue gas desulfurization washing device is provided with a desulfurization flue gas inlet, a desulfurization liquid inlet and a desulfurization liquid outlet, the desulfurization liquid outlet is connected, through the desulfurization liquid circulating pump, with the desulfurization liquid washing system arranged in the flue gas desulfurization washing device, a desulfurization liquid storage area, a desulfurization washing area, an acoustic agglomeration growth area and a droplet trapping area are successively formed from bottom to top in the direction of flow of flue gas; the opposite side position of the acoustic agglomeration device is provided with a sound source, the sound source is connected with a signal generator by a power amplifier, the top of the droplet trapping device is connected with a purified flue gas outlet, the flushing nozzle is arranged above the droplet trapping device, and the flushing nozzle is connected with a flushing water inlet.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

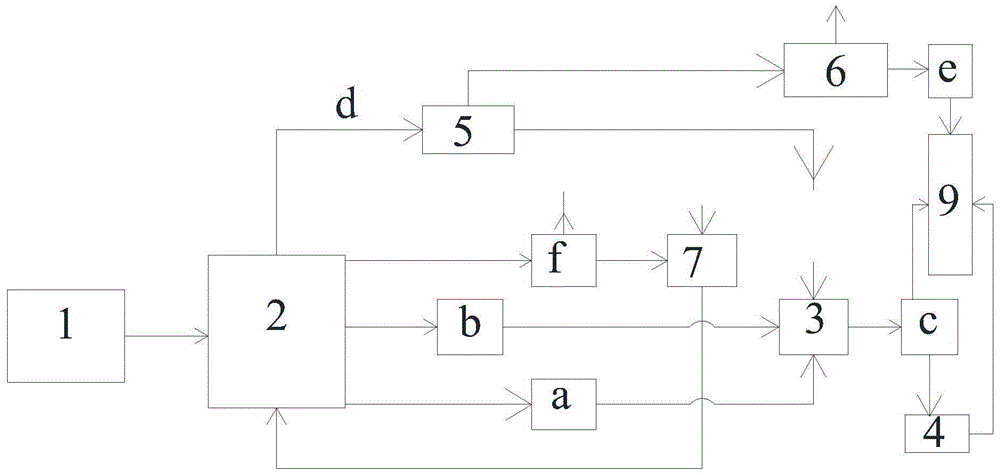

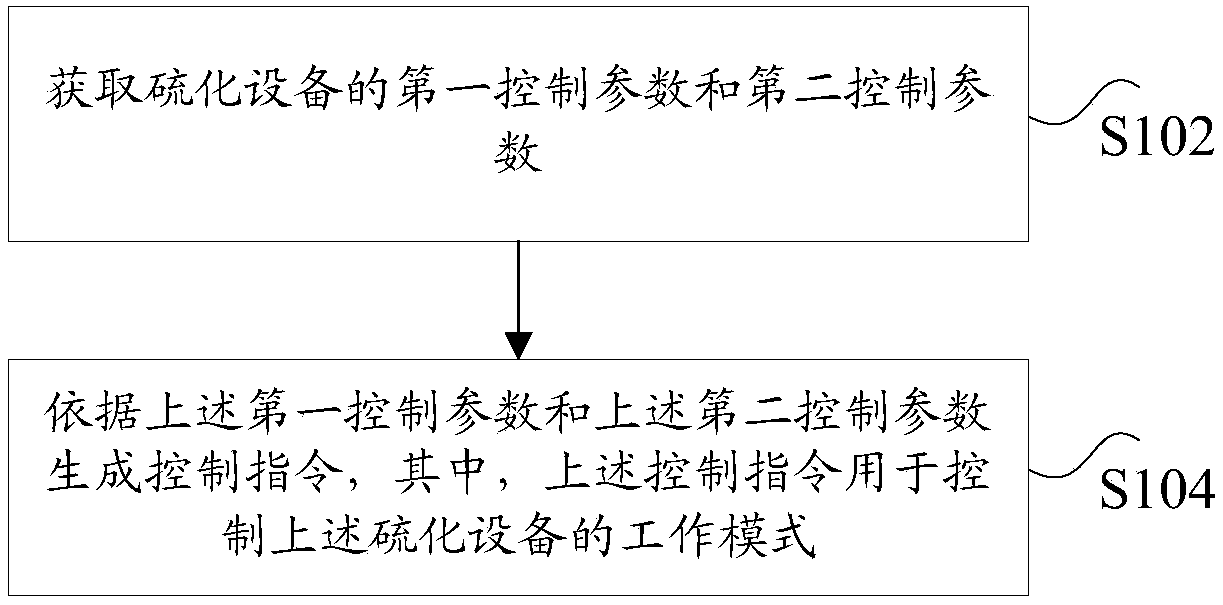

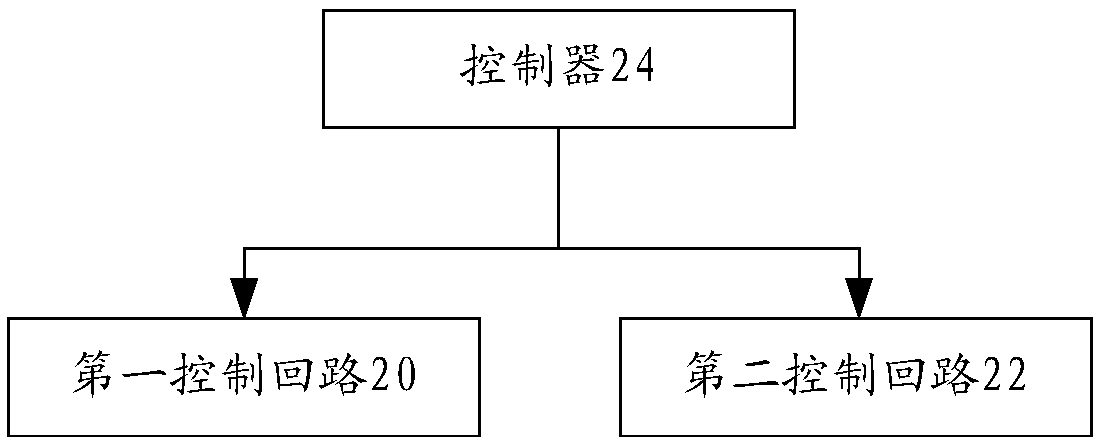

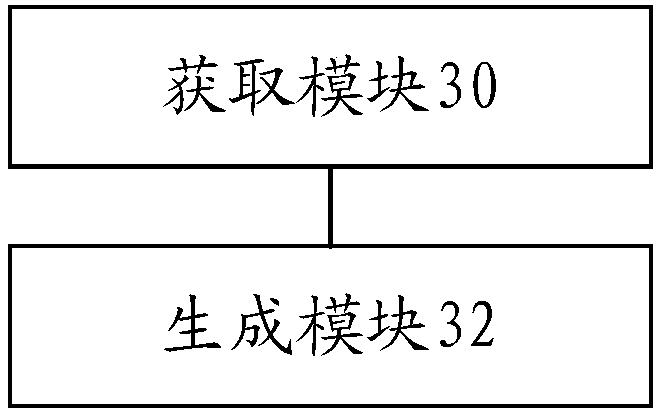

Method, device and system for controlling vulcanization equipment

The invention discloses a method, device and system for controlling vulcanization equipment. The method comprises the following steps: acquiring first control parameters and second control parametersof the vulcanization equipment, wherein the first control parameters are at least composed of the set value of a sulfide, the measurement value of the sulfide, the addition amount of limestone and thetotal amount of coal, and the second control parameter are at least composed of the change value of the sulfide, a total amount of the coal, a ratio of the addition amount of the limestone to the total amount of the coal, the change value of the total amount of the coal and a difference between the set value and the measured value; and generating control commands according to the first control parameters and the second control parameters, wherein the control commands are used for controlling the operation mode of the vulcanization equipment. The method, device and system provided by the invention overcome the technical problem that the amount of sulfide emissions of vulcanization equipment cannot be effectively controlled in the prior art.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

SNCR-PNCR combined denitration system for high-temperature furnace and flue gas denitration method

PendingCN110141944ALess investmentLow costGas treatmentLighting and heating apparatusAir compressionFlue gas

The invention discloses a SNCR-PNCR combined denitration system for a high-temperature furnace and a flue gas denitration method, belonging to the field of treatment of flue gas from high-temperaturefurnaces. The SNCR-PNCR combined denitration system comprises an SNCR pretreatment system and a PNCR system. The SNCR pretreatment system comprises an ammonia-based reductant storage tank, a meteringsystem, an SNCR equalization system, an air compression system and an ammonia-based reductant injection system; and the SNCR pretreatment system controls NOx output concentration at 200-250 mg / m<3>. The PNCR system comprises a fan system, a dehumidification work cell, a PNCR equalization system and a PNCR powder spray gun system; and the PNCR system controls the NOx emission concentration of fluegas to be less than 100 mg / m<3>. The system of the invention comprises the SNCR pretreatment system and the PNCR system; and through cooperation between the SNCR pretreatment system and the PNCR system, the characteristics of low investment and low cost of original SNCR and high efficiency, stability and no pollution of original PNCR are given to full play, and the problems of low efficiency and excessive ammonia slip of SNCR technology are effectively avoided.

Owner:南京澎湃动力科技实业有限公司

Method for producing energy-saving environmentally-friendly coal by using sludge

InactiveCN102229830ASave resources and energyCreate economic and social benefitsSludge treatmentSolid fuelsDewatered sludgeProcess engineering

The invention discloses a method for producing energy-saving environmentally-friendly coal by using sludge. The method comprises the following steps of: deodorizing dewatered sludge with waste acid and lime, adding additives such as crushed raw coal, alumina, magnesium hydroxide, glass dust and the like in a certain percentage by weight, mixing and stirring uniformly; stacking for fermenting at normal temperature; and after fermentation is finished, shaping and drying by baking to obtain the energy-saving environmentally-friendly coal. According to the method, sludge treatment and coal energy conservation and emission reduction technologies are combined, the heat and the stickiness of sludge can be used effectively, the combustion ratio of raw coal can be increased to more than 98%, the difficult of sludge treatment is solved better, and the energy-saving environmentally-friendly coal can be provided. The method has the advantages of large sludge treatment quantity, high treatment speed, no pollution in the production process, simple process and low treatment cost, can be used for creating great economic benefit and social benefit and has a high comprehensive utilization value and a sustainable development prospect.

Owner:罗炽良

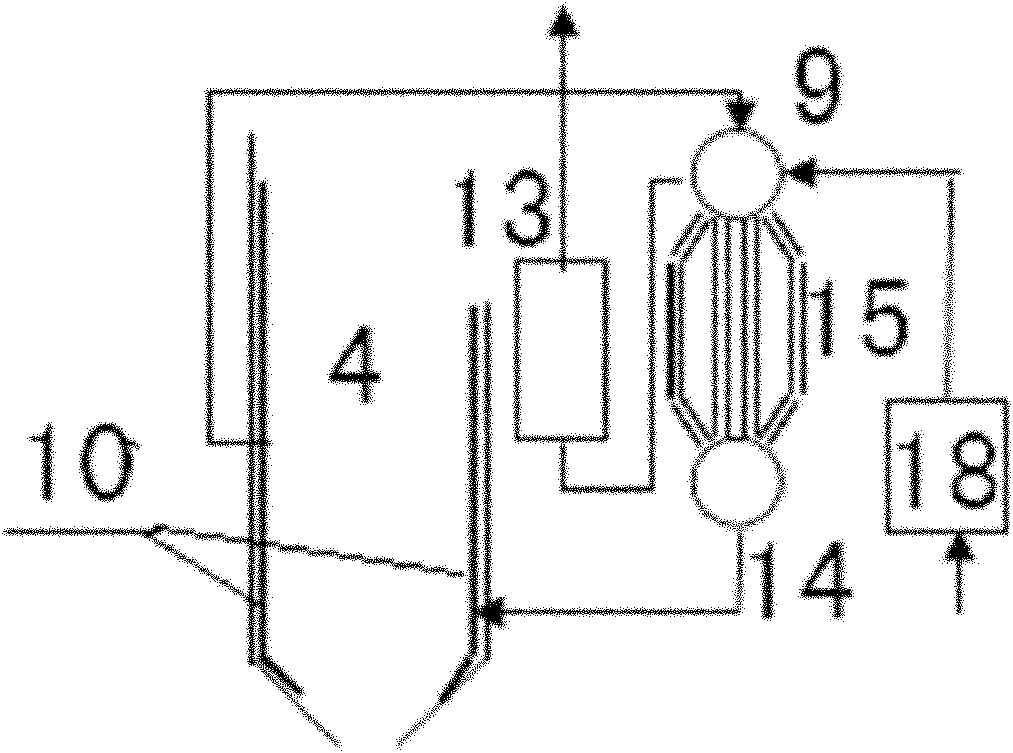

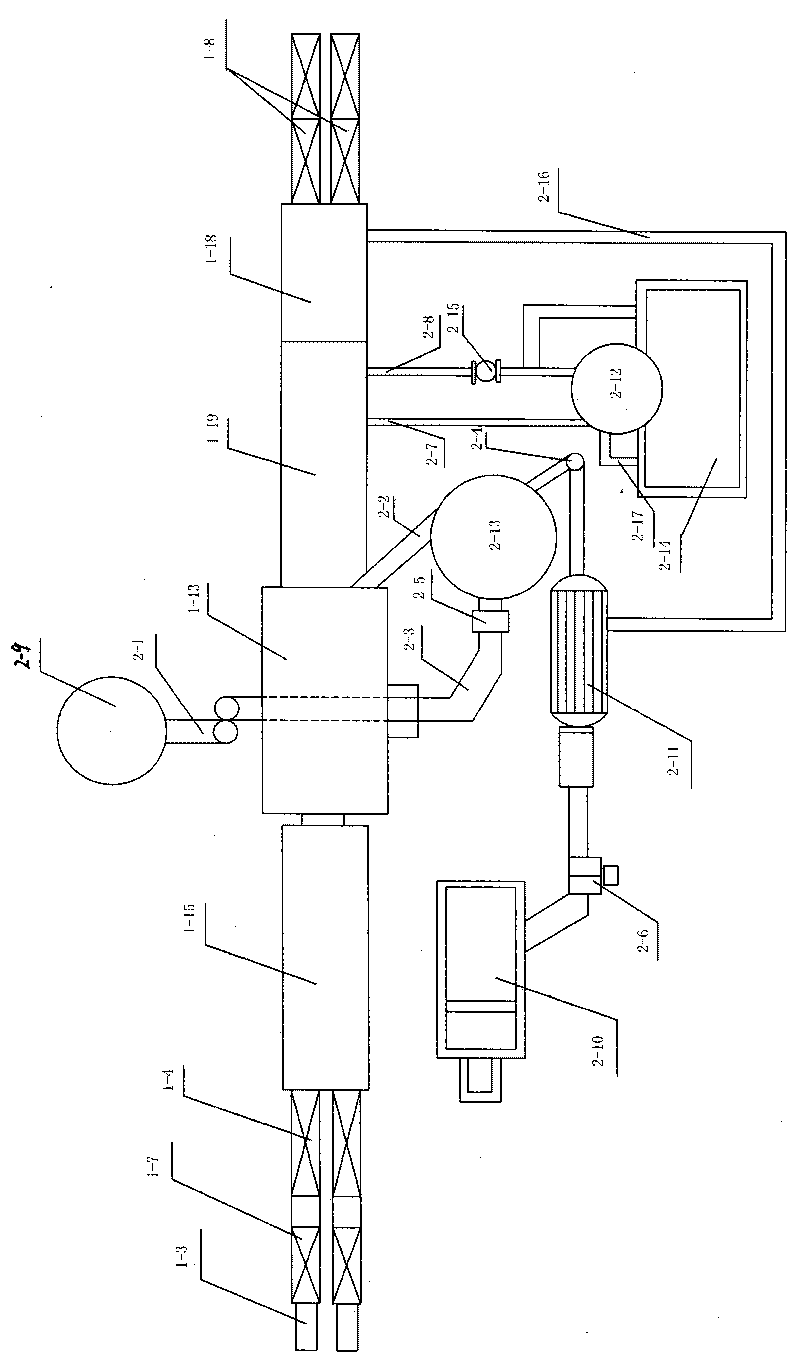

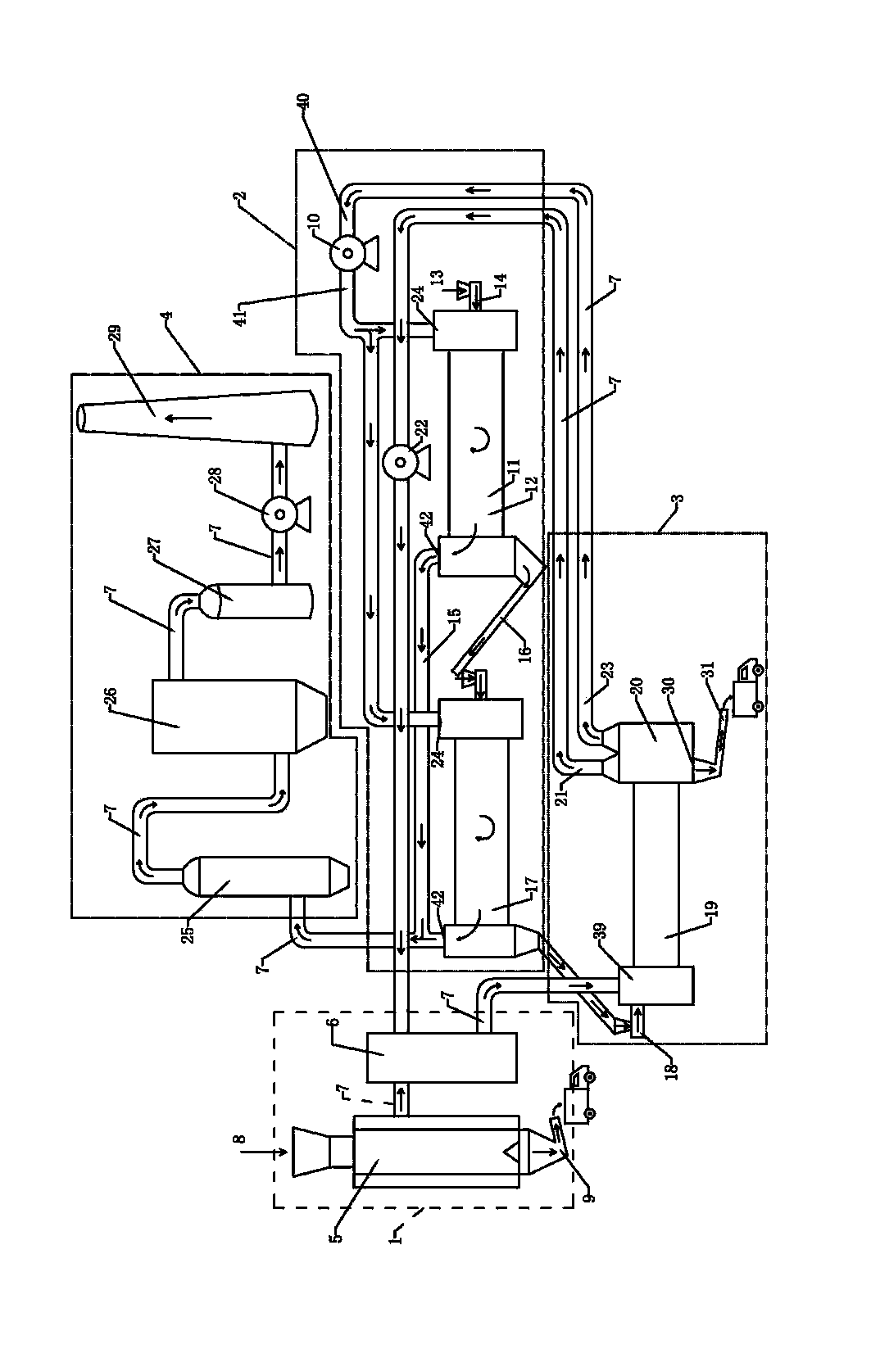

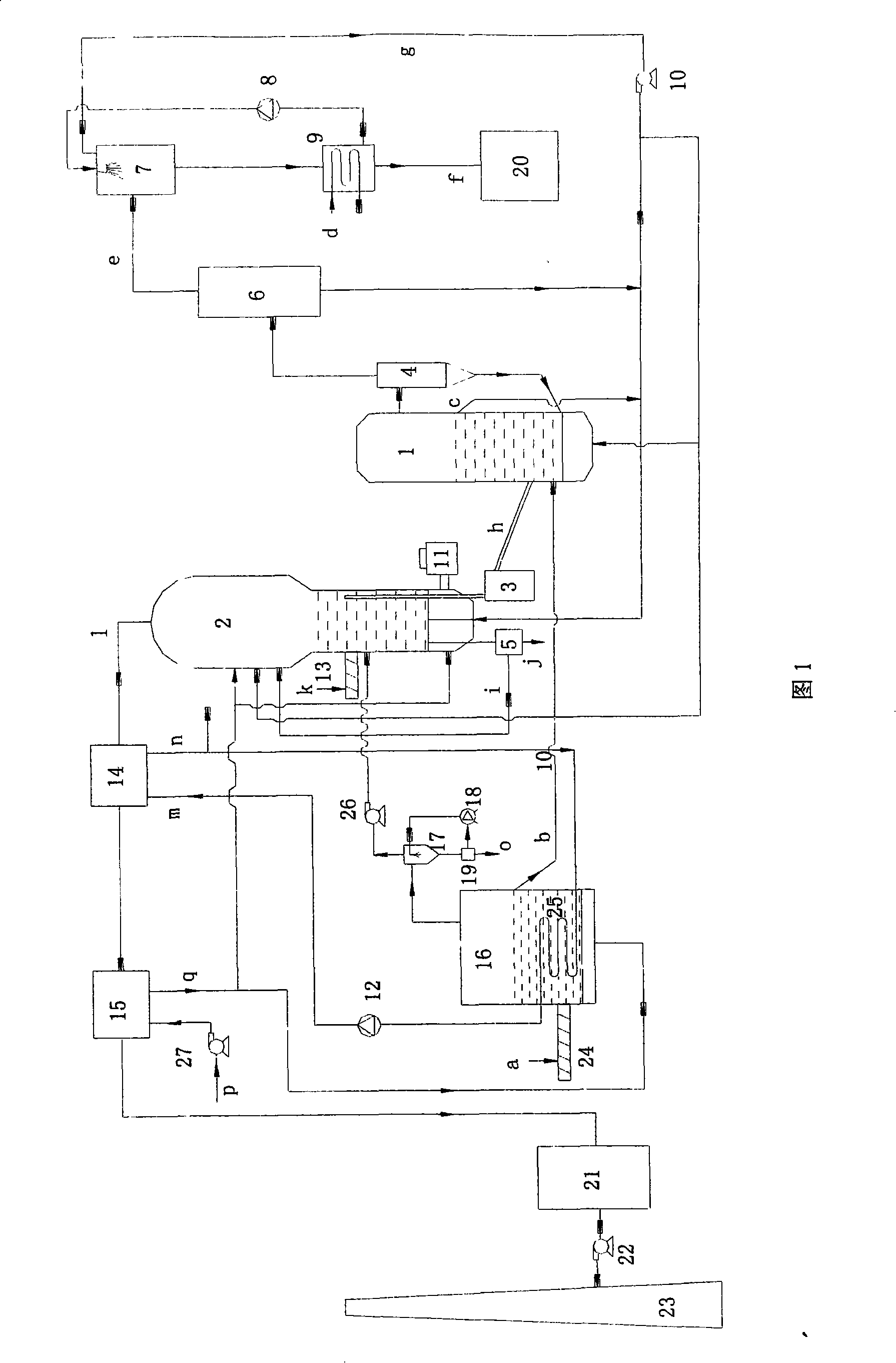

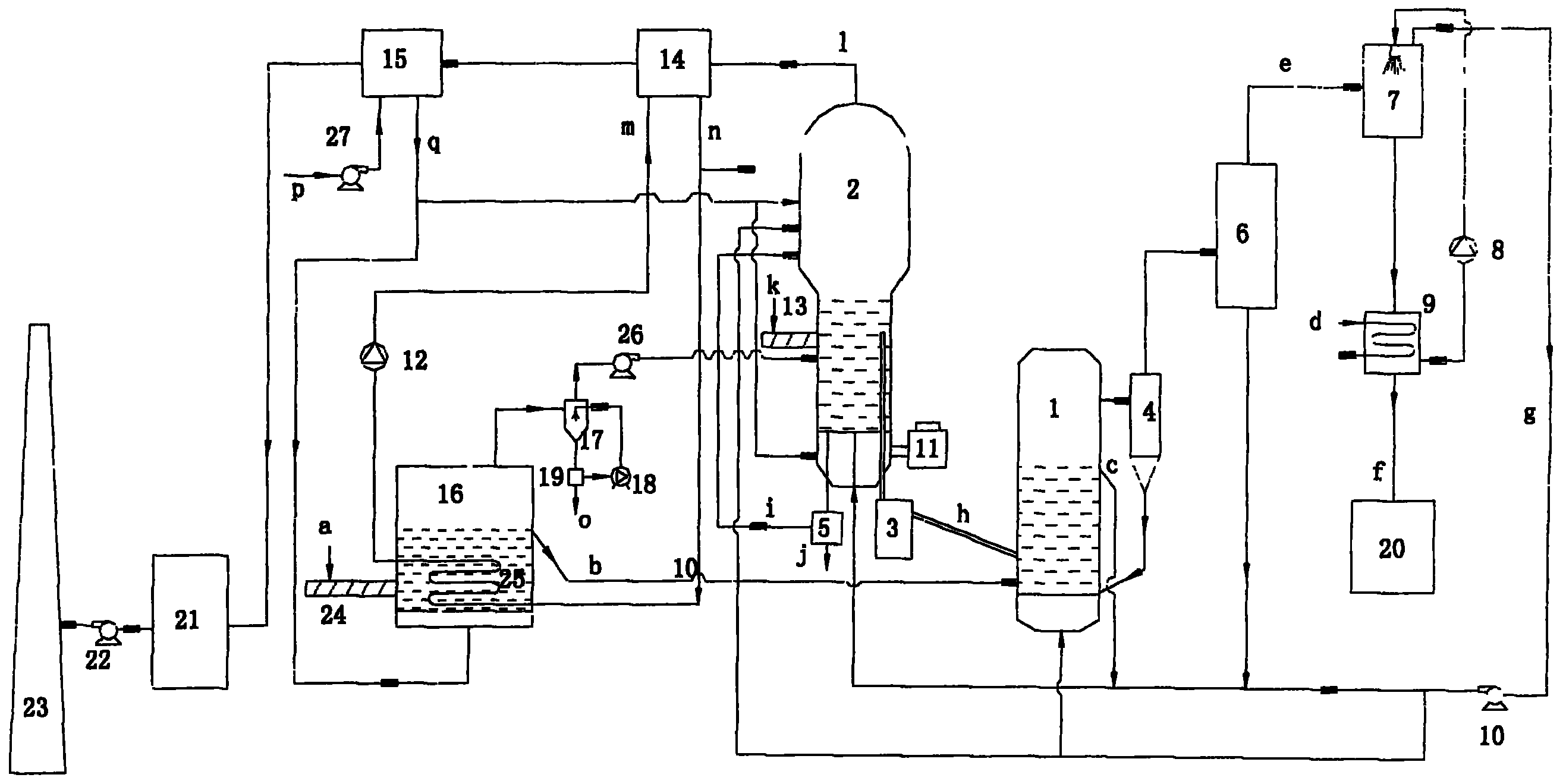

Oil-making method of double-bed interactive and circling type for pyrolyzing sludge

ActiveCN101307244BHigh yieldSimple structureSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisFluidized bed dryingHeat carrier

The invention provides a method for making oil by double bed cross circulation type pyrolysis of sludge, belonging to the energy environmental protection technical field. Between double beds of a fluidized bed pyrolysis reactor(1) and a fluidized bed combustion reactor(2), inert solid particle bed materials are used as heat carriers for the cross circulation, and the heat generated by pyrolysis carbon residues and incondensable gases burning in the fluidized bed combustion reactor(2) is transferred to sludge in the pyrolysis reactor as the heat source for the pyrolysis of sludge; a high temperature non-mechanical valve (3) is used to control the flow rate of the high temperature inert solid particle bed materials entering the pyrolysis reactor from the combustion reactor and further control the temperature of the pyrolysis reactor; the fluidized bed pyrolysis reactor(1) discharges excessive solid particle materials in the overflow mode, and the inert solid particle bed materials, the pyrolysis carbon residues and incondensable gases are transferred to the combustion reactor in the pneumatic transport mode; the wet sludge is dried by an internal heating type fluidized bed(16); and pyrolysis gases are condensed into oil-water mixture and incondensable gases in a spray tower(7).

Owner:SOUTHEAST UNIV

Domestic water purifier with graded drainage function and manufacturing method of domestic water purifier

InactiveCN103936198AEffective filteringImprove filtration efficiencyMultistage water/sewage treatmentPotable waterAnti bacteria

The invention discloses a domestic water purifier with a graded drainage function and a manufacturing method of the domestic water purifier. The domestic water purifier comprises a water supply pump, an elevated impounding tower, a pure water tank, a manual graded drainer, a multi-medium filtering device and an antibacterial descaling device. The domestic water purifier is characterized by further comprising a nanofiltration membrane filtering device, wherein an inner screw hole which is screwed with a shell is formed in an upper end seal of a nanofiltration membrane shell; an outer screw hole which is screwed with the upper end seal is formed in the upper end of the shell; a nanofiltration membrane filter element is arranged in the middle of a sealed container; a water inlet is formed in the bottom of the nanofiltration membrane shell; a water outlet is formed in the right side surface of the upper part of the nanofiltration membrane shell; the water outlet of the antibacterial descaling device is communicated with the water inlet of the nanofiltration membrane filtering device. The domestic water purifier is economic and practical, and can provide qualified and healthy living drinking water for rural families.

Owner:四川金堂海纳生物医药技术研究所

Combustible solid waste pyrolysis device and pyrolysis method

InactiveCN110484284ASimple structureEase of large-scale continuous productionDirect heating destructive distillationSpecial form destructive distillationHeat carrierProcess engineering

The invention discloses a combustible solid waste pyrolysis device and a pyrolysis method. The pyrolysis device comprises a fluidized bed pyrolysis reactor and a fluidized bed combustion reactor whichadopt heat carrier bed material interactive circulation. Combustible solid waste fuel is pyrolyzed in the fluidized bed pyrolysis reactor, and a heat carrier bed material overflows and is sent to thecombustion reactor through a star-shaped return feeder; the heat carrier bed material is heated again by utilizing heat released by pyrolysis oil gas combustion in the combustion reactor; and the heated heat carrier bed material enters the pyrolysis reactor again through a fluidized bed return feeder. Heat generated by combustion is transmitted to a pyrolysis process by utilizing interactive circulation of the heat carrier bed material between the two reactors, so that the problem of non-uniform temperature in reactors caused by heat transfer of conventional reactors is solved; the star-shaped return feeder for pyrolysis material returning achieves a good sealing effect, the fluidized bed material return feeder for combustion material returning avoids high oxidation and deformation of mechanical moving parts, and meanwhile the solid circulation flux can be controlled.

Owner:SOUTHEAST UNIV

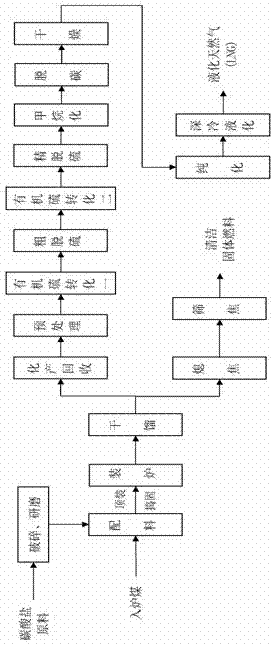

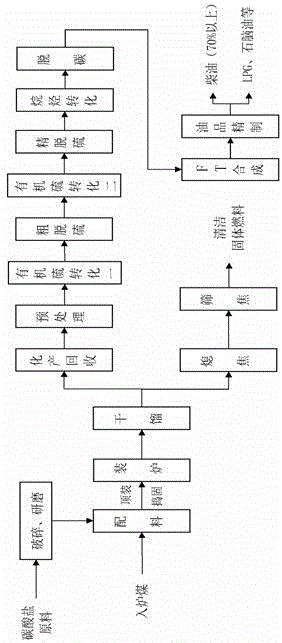

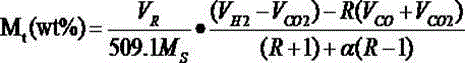

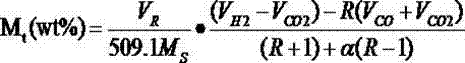

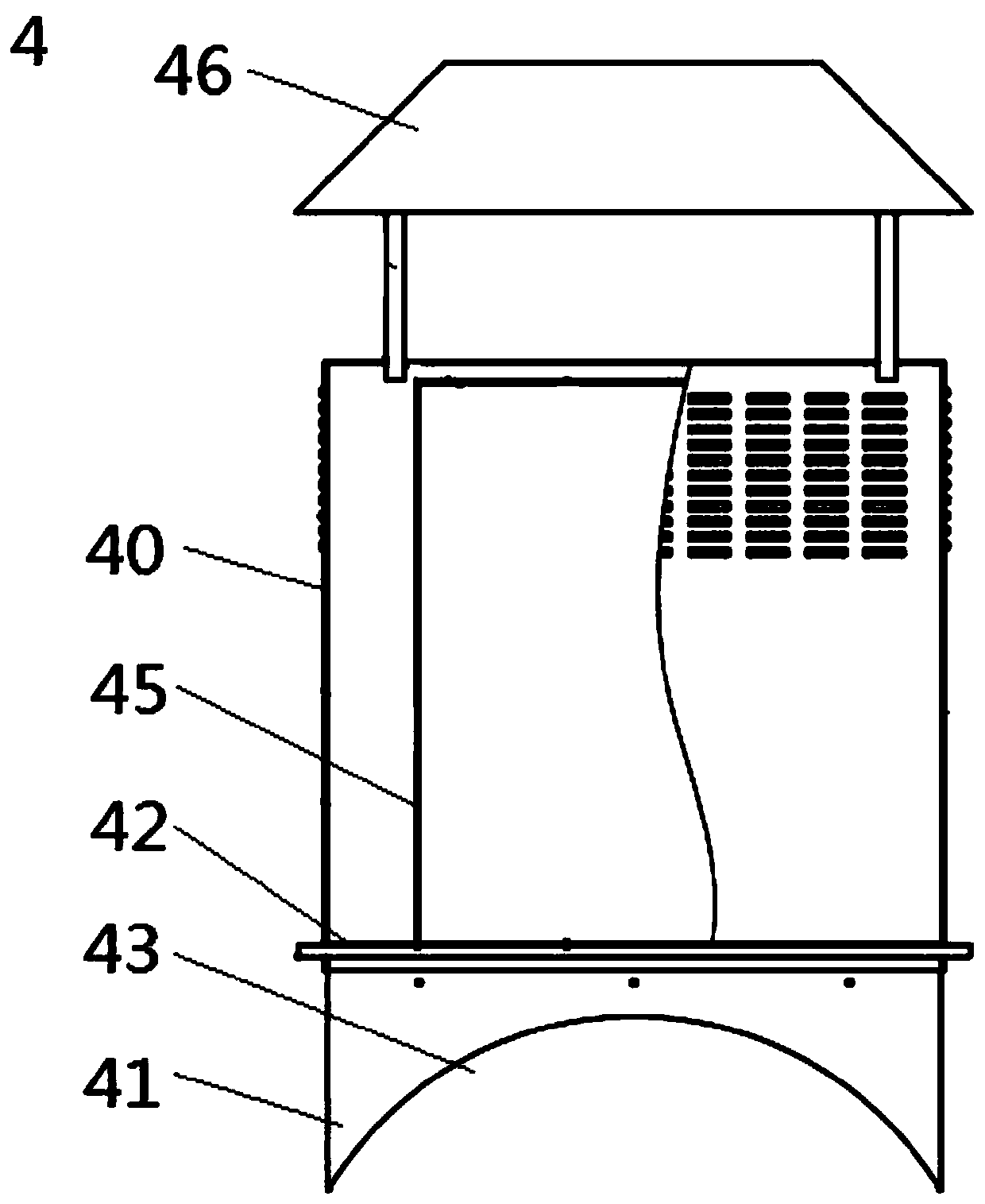

Method for producing liquefied natural gas by automatically supplementing carbon by using retort gas as raw material

The invention relates to a method for producing liquefied natural gas by automatically supplementing carbon by using retort gas as a raw material, which comprises the following steps: adding carbonate carbon supplementing raw powder into coal, mixing, putting into a retort, heating, cooling for coke quenching, screening to obtain a solid clean fuel, directly sending generated CO2 and CO gases into retort gas to be matched with surplus H2 gas, carrying out chemical recovery and deep purification on the spilled retort gas to obtain methane synthetic gas, carrying out methanation to obtain crude synthetic natural gas, carrying out decarbonization, drying and purification to obtain purified synthetic natural gas, and liquefying by copious cooling to obtain the liquefied natural gas. The carbonate mineral is directly added into the coal for the retort, and the CO2 and CO gases generated by thermal decomposition are used as retort gas to supplement carbon; and thus, the method has the characteristics of abundant raw material sources, simple technical process, equipment investment saving, low carbon supplementing cost, favorable economical efficiency and the like, and can be widely used in comprehensive utilization projects of high / medium-temperature retort gas.

Owner:太原科瑞康洁净能源有限公司

Arsenic removal method for preparing bio-adsorbent from traditional Chinese medicine waste residues

PendingCN112473632AEasy accessLow costOther chemical processesWater contaminantsSorbentProcess engineering

The invention discloses an arsenic removal method for preparing a biological adsorbent from traditional Chinese medicine waste residues, which comprises the following steps: washing the traditional Chinese medicine waste residues, performing drying in an oven, taking the traditional Chinese medicine waste residues out, performing pulverizing and screening to obtain waste residue powder; adding theobtained waste residue powder into a FeCl3 solution, performing stirring to react, and performing filtering, cleaning and drying to obtain a biological adsorbent; and adding the obtained biological adsorbent into arsenic-containing waste liquid to be treated, and stirring for reaction to remove arsenic. According to the method, traditional Chinese medicine waste residues obtained after a pharmaceutical process in the traditional Chinese medicine industry is finished are subjected to physicochemical treatment and then modified to obtain the biomass adsorption material, the biomass adsorption material reacts with low-concentration arsenic-containing wastewater, the final arsenic removal efficiency can reach 98%, and compared with other methods, the method is low in cost, raw materials are easy to obtain, the process is simple, and the removal efficiency is high.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

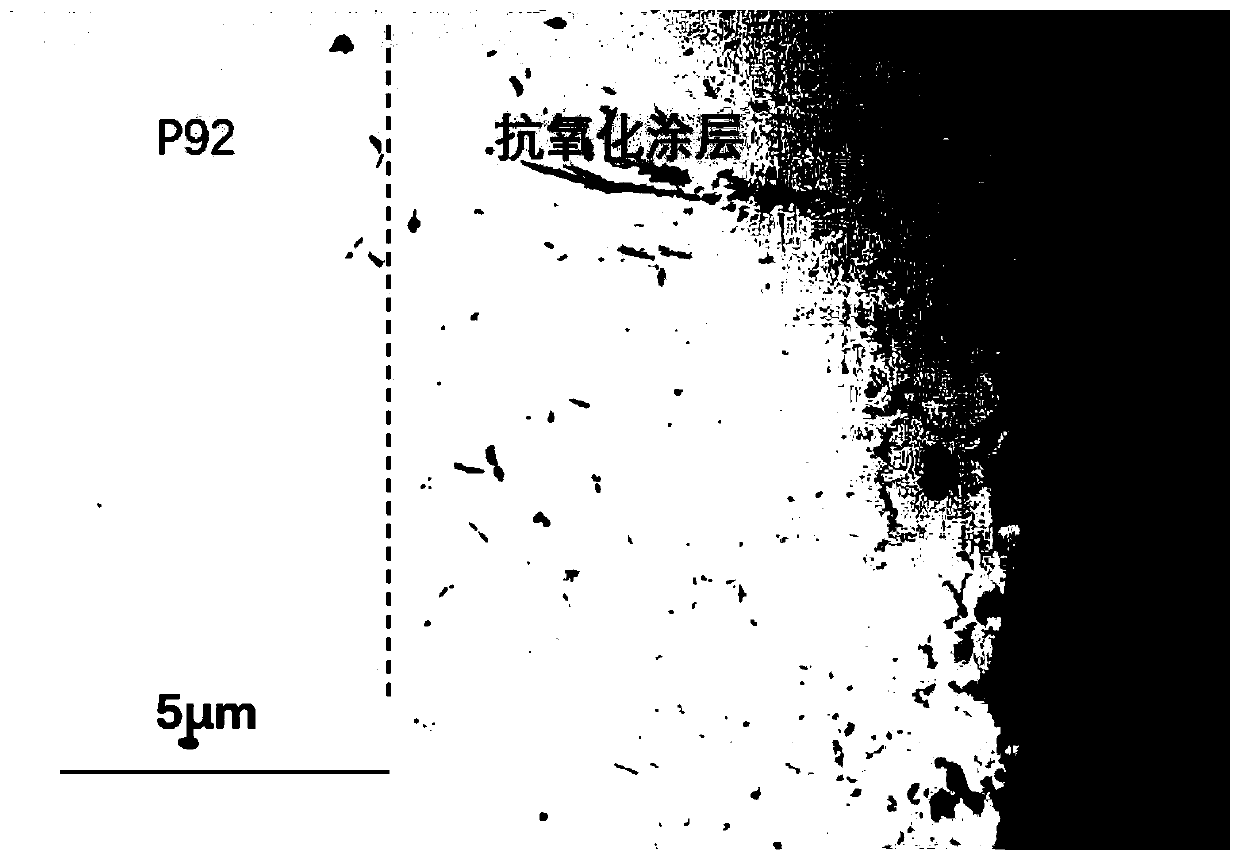

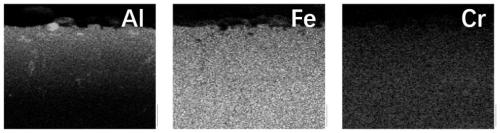

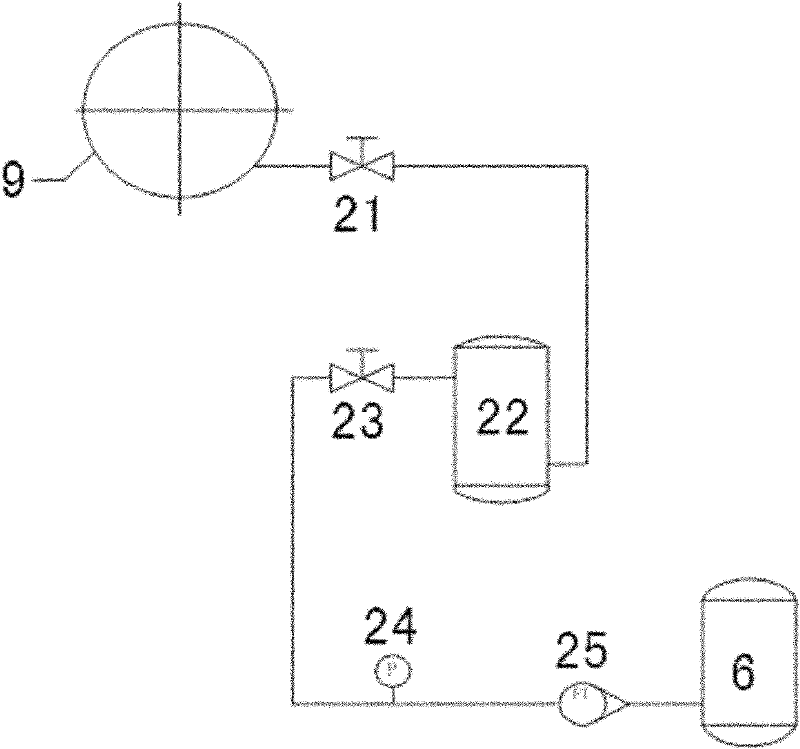

Preparation device and method for oxidation resistant coatings on inner walls of boiler header and pipe base

PendingCN109852923AAvoid problems such as degradationEffective control of deposition rateSolid state diffusion coatingAir pumpEngineering

The invention discloses a preparation device and method for oxidation resistant coatings on inner walls of a boiler header and a pipe base. The oxidation resistance of the inner walls of the boiler header and the pipe base can be remarkably improved. According to the preparation device and method, the coatings are prepared on the inner walls of the header and the pipe base through a vapor deposition method, and the sealed header and the pipe base serve as a part of an air path. The preparation device specifically comprises a heating furnace and a connection loop which is composed of the headerand the pipe base with the inner walls to be provided with the coatings, an impregnation agent tank, an air path guide pipe, a gas circulating pump, a valve, an air pumping / exhausting pipeline and acounterbalance valve. The final heating temperature and the heat insulation time are set according to the materials of the header and the pipe base and a heat processing process, and the oxidation resistant coatings with the different thicknesses can be prepared. The preparation device is simple, low in manufacturing cost and very high in engineering practical value, and the vapor oxidation resistance of the header and the pipe base can be remarkably improved.

Owner:HUANENG POWER INTERNATIONAL +1

Vertical industrial pulverized coal boiler system

InactiveCN101929669BImprove air tightnessReduce air leakageCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir preheaterSlag

The invention discloses a vertical industrial pulverized coal boiler system, which comprises a stokehole pulverization device connected with a pulverized coal boiler body through a combustor, and the pulverized coal boiler body is connected with a chimney through a flue gas processing device. The vertical industrial pulverized coal boiler system is characterized in that: the pulverized coal boiler body comprises a horizontal flue, a hearth respectively communicated with two ends of the horizontal flue, and a vertical smoke well which are arranged in a vertical inverted U shape; the hearth consists of membrane water walls; a position of the hearth communicated with the outlet of the horizontal flue is provided with a slag condensing bank used for preventing high temperature flue gas from slagging; the horizontal flue behind the slag condensing pipe bundle is provided with a superheater and an convection bank inside in turn; the convection bank is connected to upper and lower boiler barrels positioned on upper and lower sides of the horizontal flue; the vertical smoke well is provided with an economizer and an air preheater inside from top to bottom; and the lower part of the vertical smoke well is connected with the flue gas processing device through a connecting flue. The vertical industrial pulverized coal boiler system has the advantages of high integration degree, small occupied area, high combustion efficiency, energy conservation, environmental protection, and wide market application prospect.

Owner:XI AN JIAOTONG UNIV

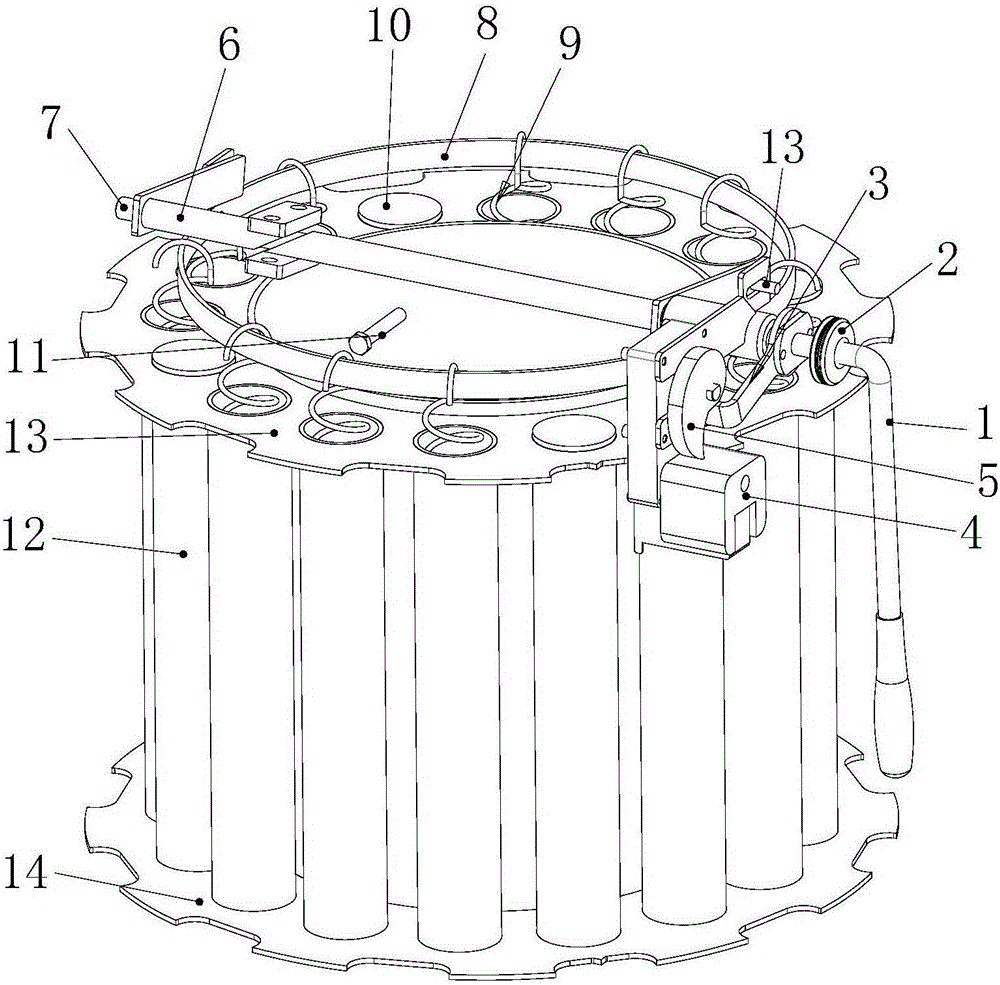

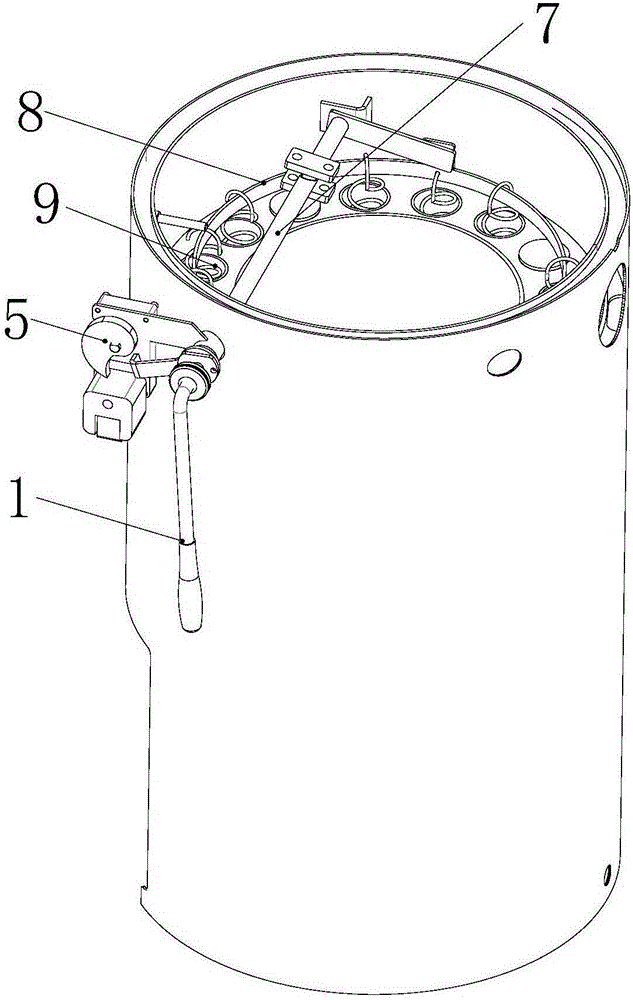

Smoke dust cleaning structure of full-automatic biomass combustion furnace

ActiveCN105202561ARealize automatic cleaning functionImprove work efficiencyLighting and heating apparatusBiomass smokeEngineering

The invention belongs to the technical field of biomass smoke dust cleaning equipment, and particularly relates to a smoke dust cleaning structure of a full-automatic biomass combustion furnace, which comprises a cleaning device main body, wherein the cleaning device main body comprises an upper component, a circular tube and a lower component; the circular tube is arranged between the upper component and lower component; springs and adjusting covers are arranged in the circular tube at uniform intervals; the top end of the spring is provided with a spring support; and the upper end of the spring support is connected with a connecting rotating shaft and a rotating shaft grip. The smoke dust cleaning structure provided by the invention implements the automatic cleaning function on smoke dust, can sufficiently collect the smoke dust without leakage, and has the advantages of no pollution, high work efficiency and obvious environmental benefit; and the arranged main body circular tube has the function of regulating the gas pressure inside the equipment.

Owner:创域智能(常熟)网联科技有限公司

Method for producing synthetic oil by self-supplementing carbon by using dry distillation gas as raw material

ActiveCN103881747BSolve the problem of carbon replenishmentRich sourcesLiquid hydrocarbon mixture productionThermodynamicsCoke

A method for producing synthetic oil by self-supplementing carbon by using retort coal gas as a raw material. The method is to add carbonate carbon supplement raw materials with a particle size of ≤80 mesh into the furnace coal in proportion, mix them, put them into a retort furnace for heating, and then After coke quenching and cooling to normal temperature, and then sieving, it becomes a solid clean fuel, and the generated CO2 and CO gas are directly entered into the dry distillation gas to match with the excess H2 gas to achieve the purpose of carbon replenishment. In the present invention, carbonate minerals are directly added to dry distillation furnace coal, and CO2 and CO gases generated by thermal decomposition thereof are used to replenish carbon for dry distillation coal gas. It has the characteristics of rich sources of raw materials, simple process, low equipment investment, low cost of carbon supplementation, and good economy. It can be widely used in comprehensive utilization projects of high and medium temperature dry distillation gas.

Owner:科瑞康洁净能源技术有限公司

Liquid slag type low nitrogen powder burner

ActiveCN105485676BEffective control of emissionsEmission controlPulverulent fuel combustion burnersNon-combustible gases/liquids supplyCombustion chamberLow nitrogen

The invention relates to powder combustors, in particular to a liquid slagging type low-nitrogen powder combustor. The liquid slagging type low-nitrogen powder combustor comprises a powder spray gun, a primary air chamber and a secondary air chamber and further comprises a slag combustion chamber. The primary air chamber is arranged on one side of the slag combustion chamber, the secondary air chamber is arranged on the other side of the slag combustion chamber, and the primary air chamber is connected with the powder spray gun. A primary low-oxygen reflux cooling air inlet is formed in the slag combustion chamber. A liquid slagging mechanism is arranged on the slag combustion chamber, a slag falling opening of the liquid slagging mechanism is led out of the bottom of the slag combustion chamber, and a slag falling water trough is formed corresponding to the slag falling opening. By means of changing of the slagging manner and the combustion atmosphere of the combustor, emission of nitric oxide, hearth coking, low-heating-value coal dust stable combustion, low-ash-fusion-point coal dust combustion and other problems can be effectively controlled, the coal type adaptation capability can be greatly improved, and the liquid slagging type low-nitrogen powder combustor adapts to low-heating-value and low-ash-fusion point coal dust combustion.

Owner:唐山金沙燃烧热能股份有限公司

Method for producing synthetic oil from dry distillation gas through autonomous carbon supplementing

ActiveCN103881747ASolve the problem of carbon replenishmentRich sourcesLiquid hydrocarbon mixture productionThermodynamicsDistillation

The invention relates to a method for producing synthetic oil from dry distillation gas through autonomous carbon supplementing. The method comprises the steps of adding a carbonate carbon supplementing raw material, of which the granularity is not greater than 80 meshes, into furnace charging coal proportionally, mixing, then, loading the mixture to a dry distillation furnace for heating, then, quenching to cool to normal temperature, then, screening, so as to obtain solid clean fuel, and enabling produced CO2 and CO to directly enter the dry distillation gas, so as to be matched with superfluous H2, thereby realizing the aim of carbon supplementing. According to the method disclosed by the invention, a carbonate mineral is directly added into the dry-distillation furnace charging coal, and the CO2 and CO produced due to thermal decomposition are applied to the carbon supplementing of the dry distillation gas; the method has the characteristics of rich source of raw materials, simple process flow, small equipment investment, low carbon supplementing cost, good economical efficiency and the like, and can be widely applied to the project of comprehensive utilization of high and medium-temperature dry distillation gases.

Owner:科瑞康洁净能源技术有限公司

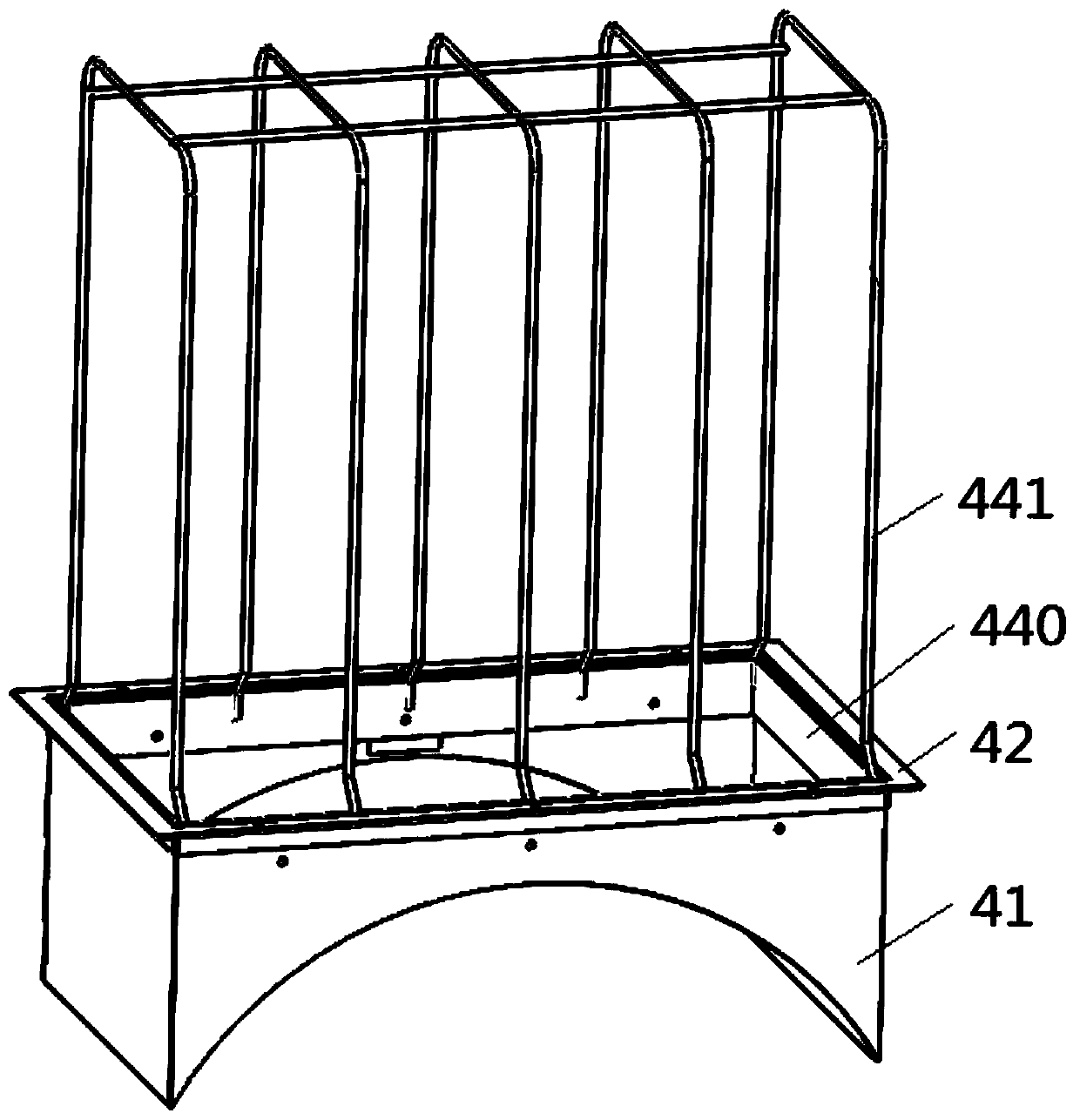

Pressure relieving dust preventing and filtering system for dual-sealing arch-shaped material guiding chute

PendingCN110386486AAdvanced and unique design conceptSimple structureConveyorsLoading/unloadingFilter systemEngineering

The invention discloses a pressure relieving dust preventing and filtering system for a dual-sealing arch-shaped material guiding chute, and belongs to the technical field of dust treatment environmental protection equipment. The pressure relieving dust preventing and filtering system for the dual-sealing arch-shaped material guiding chute comprises the dual-sealing arch-shaped material guiding chute arranged over a belt, the material guiding chute communicates with a coal falling pipeline and is provided with a plurality of pressure relieving dust preventing and filtering devices and a plurality of adjustable dust shielding closing devices, and the pressure relieving dust preventing and filtering devices and the adjustable dust shielding closing devices are arranged at intervals; and a dual-sealing dust shielding box is arranged at an outlet of the dual-sealing arch-shaped material guiding chute. According to the pressure relieving dust preventing and filtering system for the dual-sealing arch-shaped material guiding chute, the design concept is advanced and unique, the system is simple in structure, small in size, low in weight and suitable for installation of the low position ina plant and equipment space, and the large plant building area does not need to be occupied.

Owner:无锡市华能电力机械有限公司

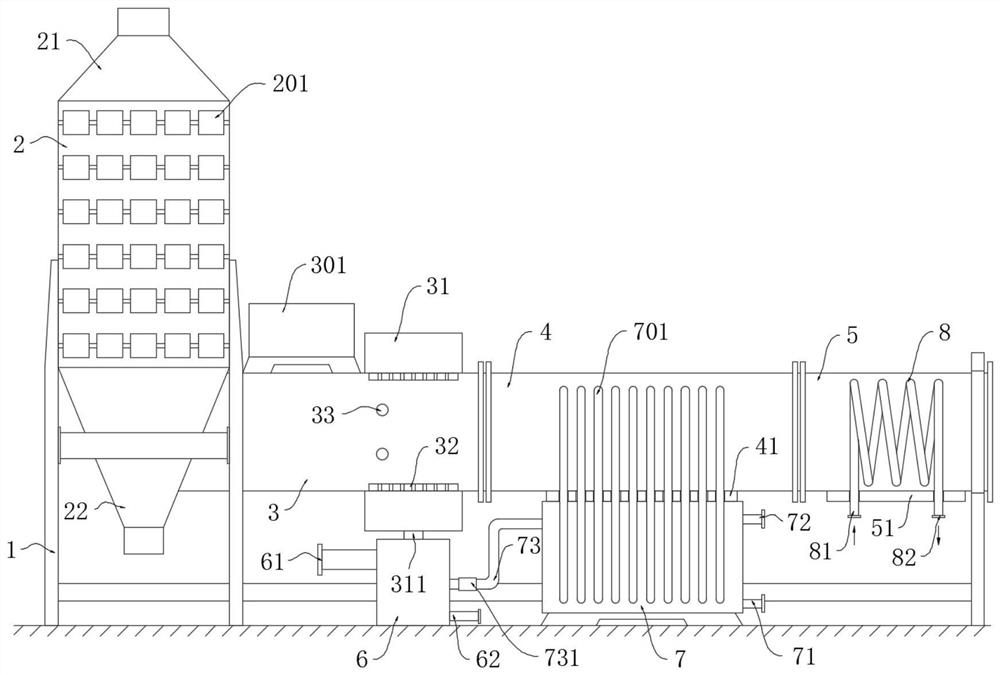

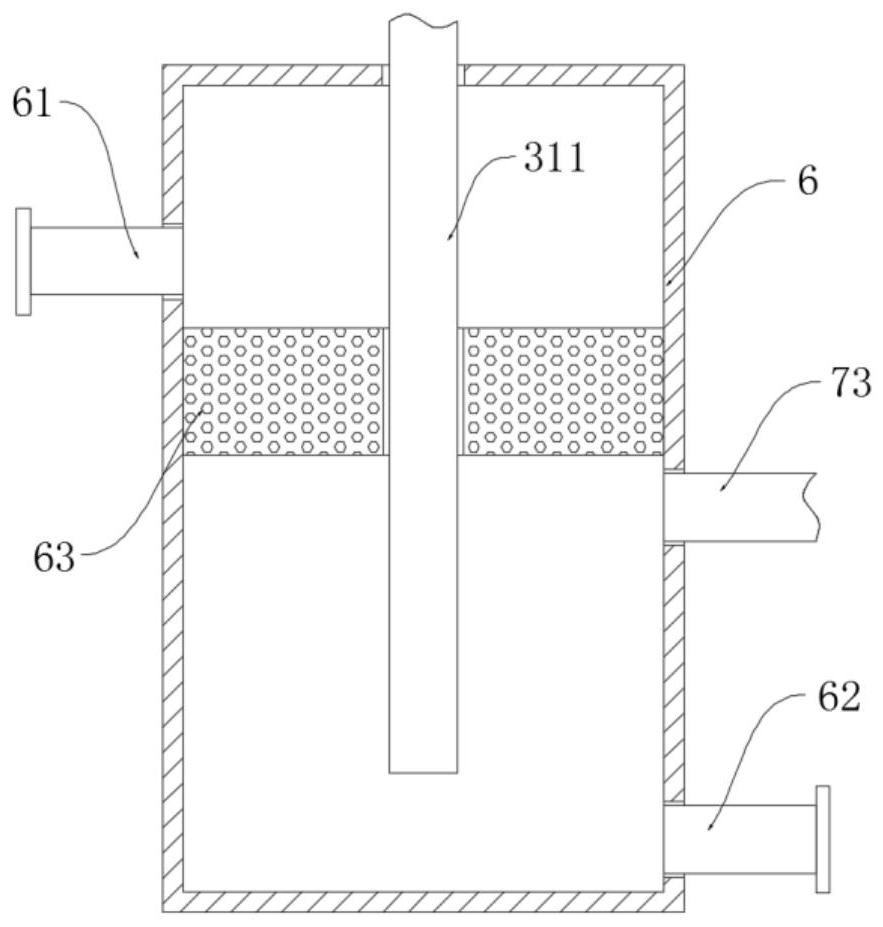

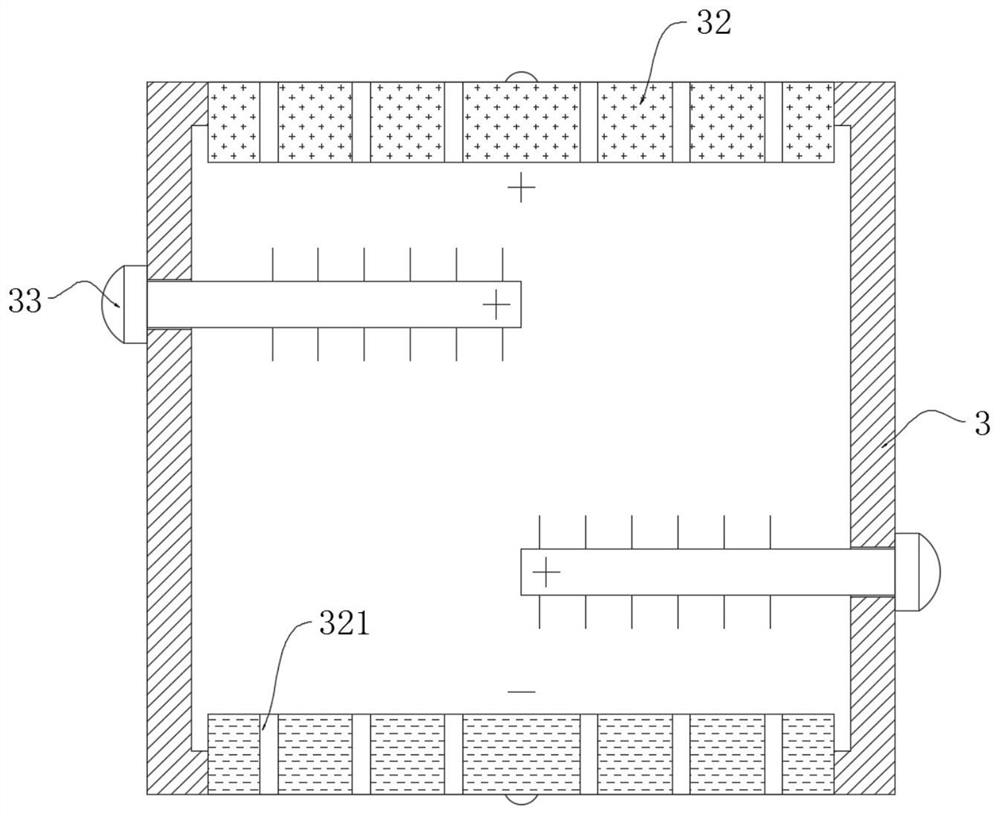

Graded utilization efficient energy-saving waste heat recovery system

ActiveCN111947122AEffective control of emissionsReduce lossIndirect heat exchangersSolid fuel combustionCombustionFlue gas

The invention discloses a graded utilization efficient energy-saving waste heat recovery system. The system comprises an installation frame, a filter box and a steam oven which are fixedly mounted onthe ground, a chimney, a first connecting pipe, a second connecting pipe and a third connecting pipe are sequentially installed on the installation frame from left to right, and the first connecting pipe, the second connecting pipe and the third connecting pipe are sequentially connected in a sealed manner. An air inlet pipe is installed at the upper end of the chimney, and an ash discharge pipe is installed at the lower end of the chimney. Through graded utilization of high temperature, medium temperature and low temperature of flue gas, the utilization efficiency of the system on flue gas waste heat is improved, through dust removal backflow of the filter box, heat loss is reduced, the combustion efficiency is improved, the utilization efficiency of the system on the flue gas waste heatis further improved, and smoke dust emission pollution is reduced.

Owner:JIANGSU HEHAI NEW ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com