A device and method for wet flue gas desulfurization combined with fine particle removal

A technology of wet flue gas desulfurization and fine particles, applied in the field of flue gas treatment, can solve the problems of difficult removal of fine particles, high mist content in flue gas, complex removal process, etc., and achieve the solution of wet flue gas desulfurization Particle and mist discharge, efficient removal, and effect of improving agglomeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

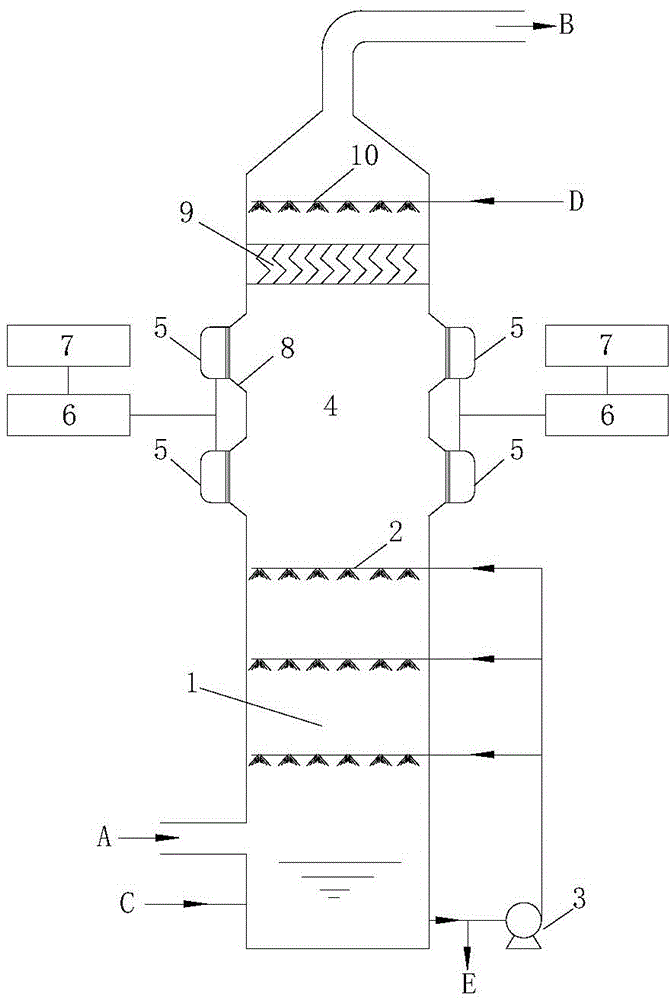

[0025] see figure 1 , the device for wet flue gas desulfurization combined with fine particle removal is equipped with a flue gas desulfurization washing device 1, a desulfurization liquid washing system 2, a desulfurization liquid circulation pump 3, an acoustic wave agglomeration device 4, a droplet trapping device 9 and a flushing nozzle 10.

[0026] The flue gas desulfurization washing device 1, the acoustic wave agglomeration device 4 and the droplet trapping device 9 are connected in series from bottom to top to form a whole. Outlet E, desulfurization liquid outlet E is connected to the desulfurization liquid washing system 2 installed in the flue gas desulfurization washing device 1 through the desulfurization liquid circulation pump 3, and the desulfurization liquid storage area and the desulfurization washing area are sequentially formed from bottom to top according to the direction of flue gas flow , sonic agglomeration area and droplet trapping area; the sonic aggl...

Embodiment 2

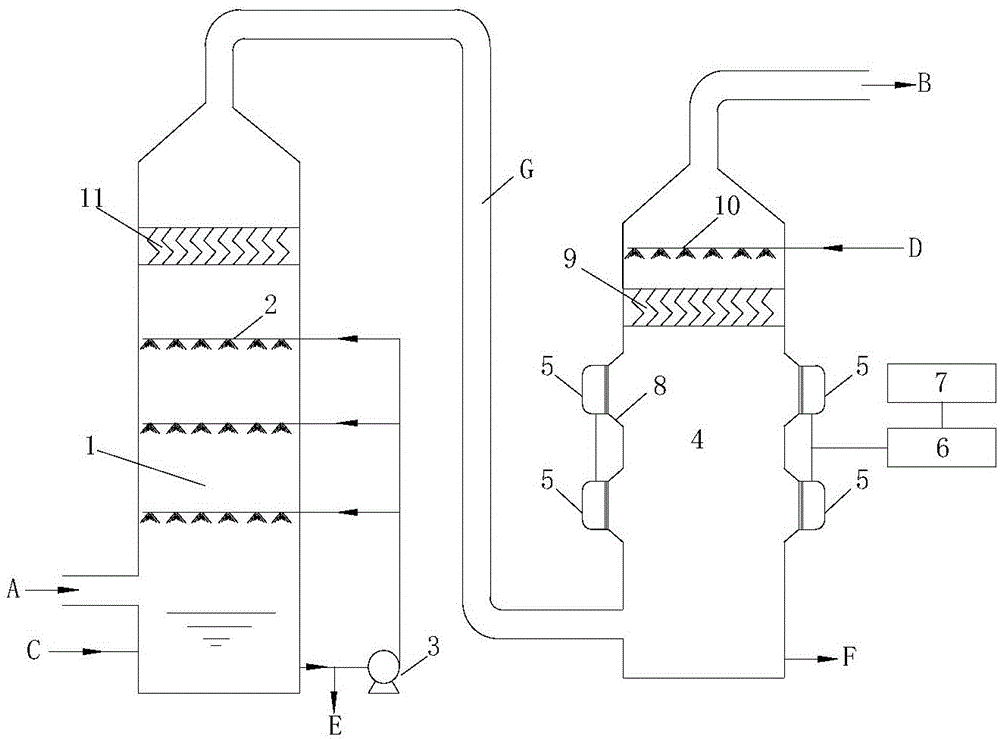

[0038] see figure 2 , similar to Example 1, the difference is that the acoustic wave agglomeration device 4 and the flue gas desulfurization washing device 1 are split structures, the flue gas desulfurization washing device 1 includes a desulfurization liquid storage area, a desulfurization washing area, and the flue gas desulfurization washing device 1 It can be a desulfurization device such as a spray washing tower, a packed washing tower, a sieve washing tower, etc.; the acoustic wave agglomeration device 4 includes an acoustic wave agglomeration growth area and a droplet trapping area, and a waste liquid discharge port F is arranged at the bottom of the acoustic wave agglomeration device 4 . A desulfurization tower demister 11 is provided above the desulfurization liquid washing system 2 for pretreatment of wet desulfurization flue gas.

[0039] This solution does not change the structure of the original desulfurization tower, and only needs to install the acoustic wave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com