Vertical industrial pulverized coal boiler system

A pulverized coal boiler, vertical technology, applied to steam boilers, boiler cleaning devices, water tube steam boilers, etc., can solve the problems of high cost of pulverizing equipment in front of the furnace, increased cost of pulverized coal manufacturing, and uneven combustion. Achieve the effect of low operation and maintenance cost, small footprint and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

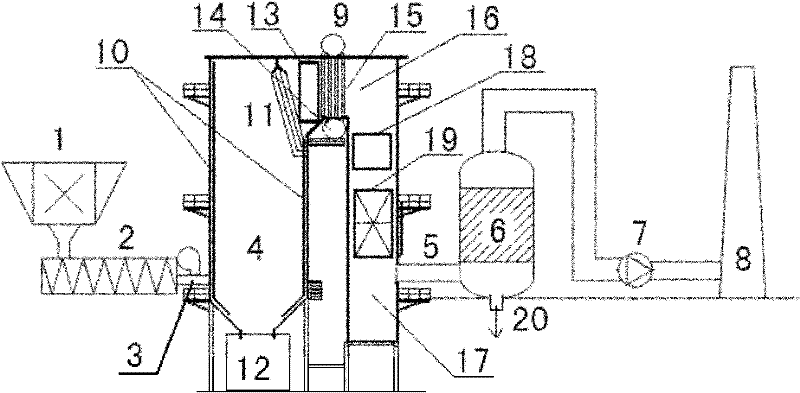

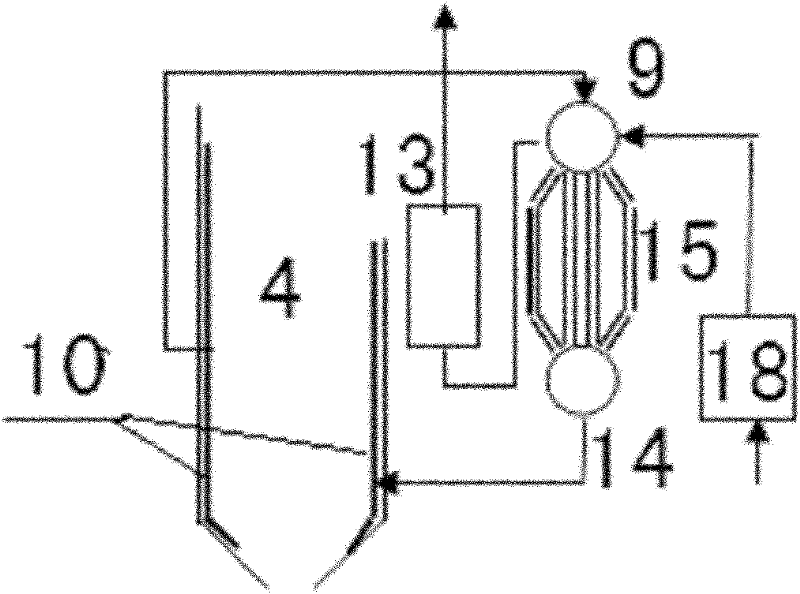

[0030] Such as figure 1 As shown, a vertical industrial pulverized coal boiler system includes a pulverizing device in front of the furnace, a pulverized coal boiler body, a flue gas treatment device and a chimney 8 . The pulverizing device in front of the furnace is composed of a high-pressure suspension roller mill 1 and a spiral coal feeder 2; the flue gas treatment device is composed of a cyclone water film desulfurization dust collector 6 and an induced draft fan 7. After the coal is transported to the boiler room, it is further pulverized by the high-pressure suspension roller mill 1 to meet the combustion needs of the pulverized coal boiler. The qualified coal powder enters the spiral coal feeder 2 with the airflow and is transported to the burner 3 with a blower, and enters the boiler body for combustion. .

[0031] The boiler body includes a furnace 4, a horizontal flue 16, and a vertical smoke shaft 17. The three are arranged in a vertical "∏" shape. The furnace 4 i...

Embodiment 2

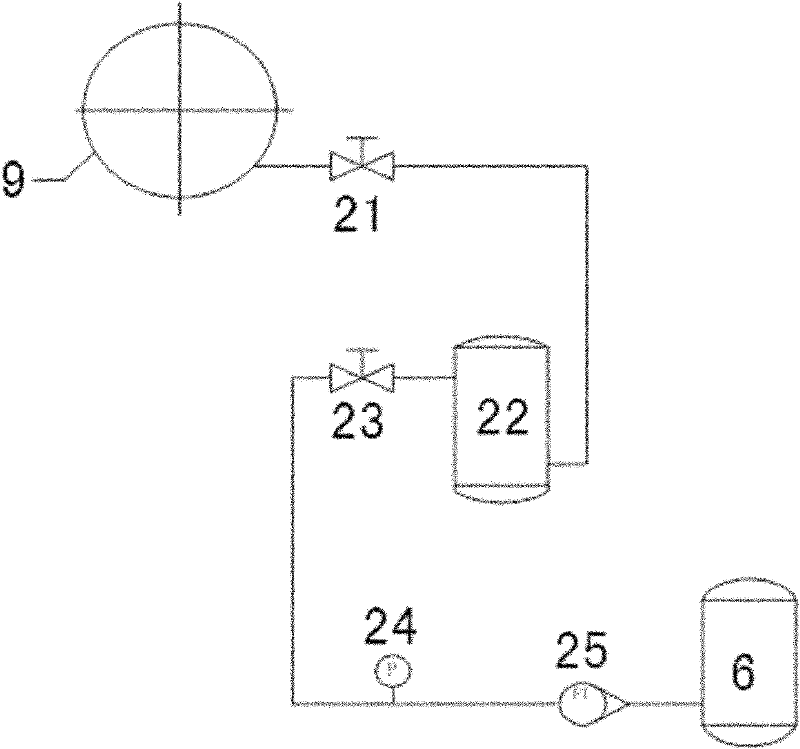

[0040] Such as image 3 As shown, a sewage discharge device is added between the upper drum 9 and the cyclone water film desulfurization dust collector 6, so that the sewage from the upper drum 9 is decompressed by the sewage discharge device and introduced into the water film desulfurization dust collector 6, which reduces the Sewage discharge, recycling resources.

[0041] The sewage discharge device includes main and auxiliary regulating valves 21, 23, a continuous sewage discharge expansion vessel 22, a pressure gauge 24, and a rotameter 25. The main regulating valve 21 is connected in the pipeline between the upper drum 9 and the continuous sewage expansion vessel 22, and the auxiliary regulating valve 23, pressure gauge 24, and rotameter 25 are connected between the sewage expansion vessel 22 and the cyclone water film desulfurization dust collector 6 in the pipeline between them.

[0042] This embodiment can effectively utilize boiler blowdown water. The boiler blowdo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com