SNCR-PNCR combined denitration system for high-temperature furnace and flue gas denitration method

A high-temperature furnace and denitrification technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of excessive ammonia escape, achieve the effects of less ammonia escape, avoid equipment corrosion and damage, and reduce usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

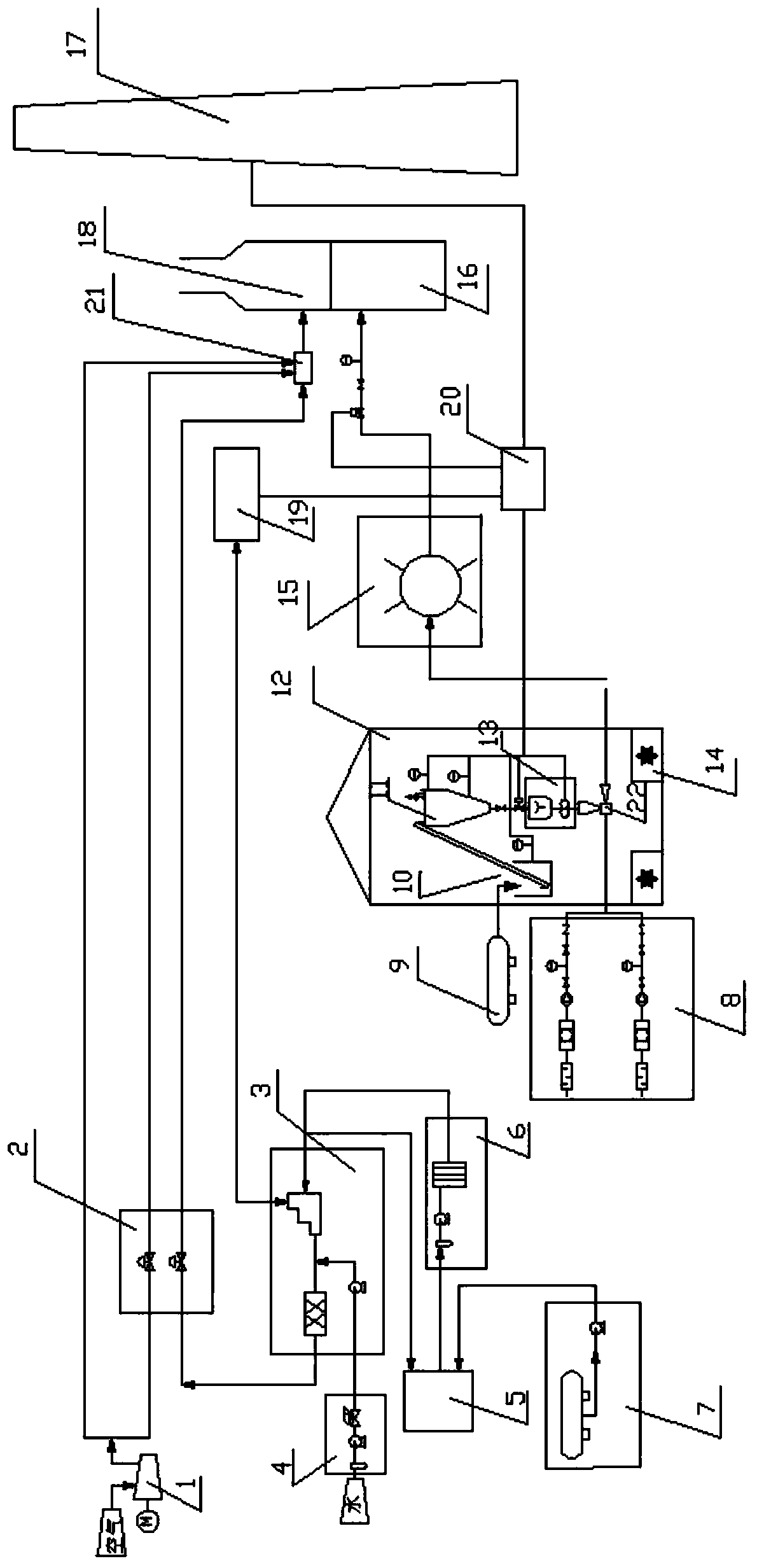

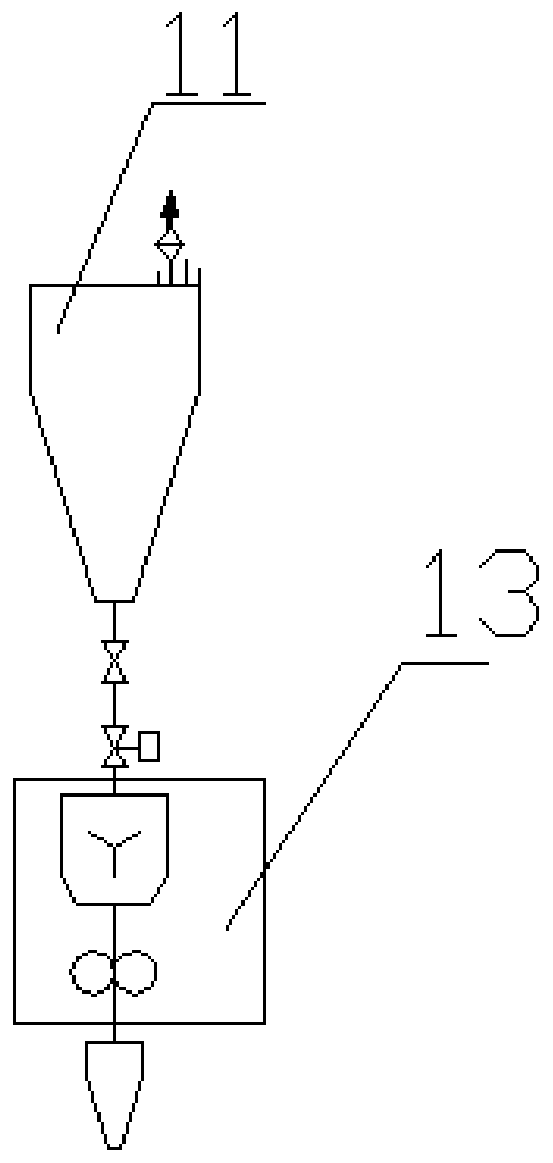

[0043] The technical solution of the present invention is described in detail below by accompanying drawing, but protection scope of the present invention is not limited to described embodiment.

[0044] At present, the tail gas NOx emission reduction of high-temperature furnaces such as cement kilns basically adopts a combination of primary emission reduction and secondary treatment technologies. Since the primary NOx emission reduction technology belongs to the combustion control technology in the generation of NOx, because of its low investment and quick results, It has almost no impact on normal production, so it is widely used, but its denitrification efficiency of 15% to 30% makes it necessary to combine secondary treatment technology in the control of NOx emissions.

[0045] The present invention is a SNCR and PNCR synergistic joint denitrification system for high-temperature furnaces, mainly for the NOx-containing tail gas after the tail gas of cement furnaces and other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com