Waste incineration tail gas emission purification treatment process and special apparatus thereof

A tail gas emission and purification treatment technology, which is applied in the direction of incinerators, climate change adaptation, lighting and heating equipment, etc., can solve problems such as air pollution, human body, animal and plant harm, and soil environment damage, so as to solve pollution problems and reduce pollution. The generation of harmful substances in exhaust gas and the effect of controlling emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1, firstly, the flue gas is sent into the sealed water tank by the heat-resistant air pump, and the water wave and the mist are aroused to circulate and rotate, so that the flue gas is dedusted and enters the spray tower through the perlite gravel layer on the top of the water tank, and the dust is It settles at the bottom of the water tank, and then, the exhaust gas enters the spray tower, and under the spraying action of the alkaline emulsion atomizer, it decomposes sulfur dioxide, hydrogen chloride and acid gas, and controls the conditions for dioxin formation. Then, the tail gas enters the processor and undergoes agitation and disinfection treatment of mixed medicaments. The mixed medicaments include lime, alum, xanthic acid, and 6501 agents, and are mixed in the following weight ratio: 2 parts of lime, 0.2 parts of alum, 0.15 parts of xanthic acid , 0.15 part of 6501 agent, the preferred weight ratio is as follows: 2 parts of lime, 0.2 part of alum, 0.15 par...

Embodiment 2

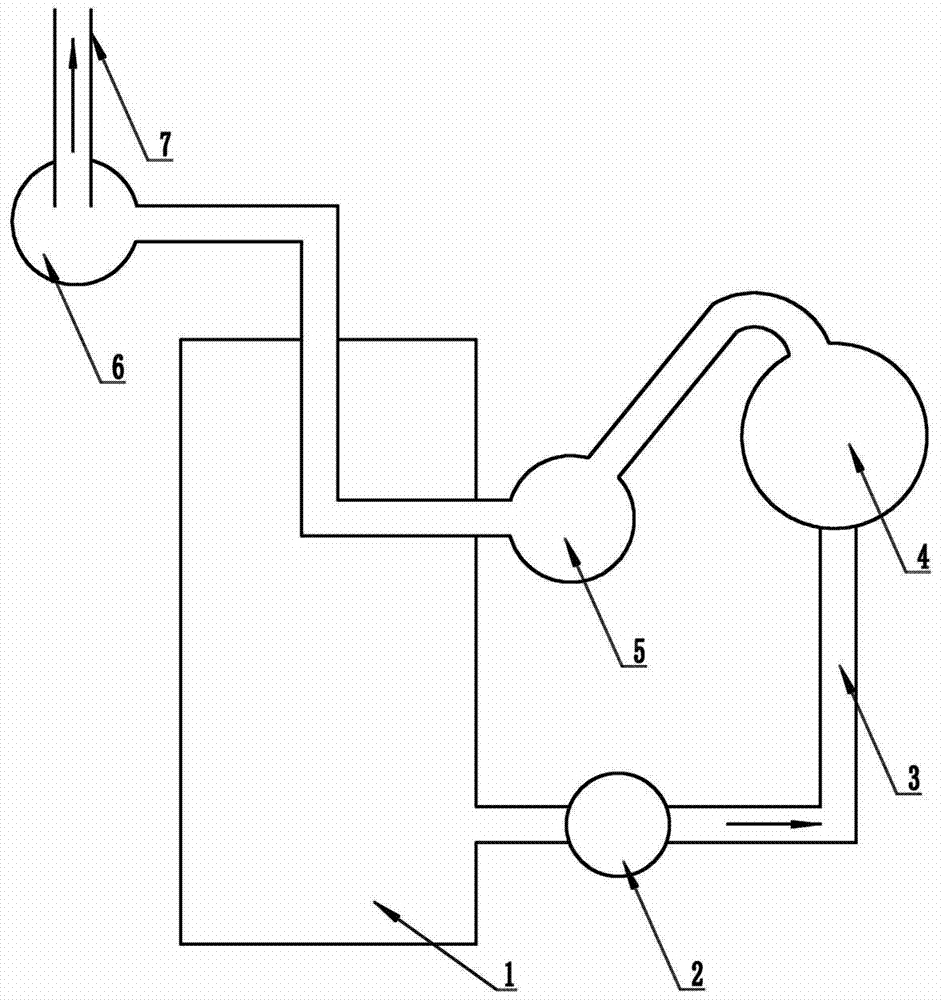

[0012] Embodiment 2, fan 2 is installed on the flue 3 of the present invention, one end of the flue 3 communicates with the smoke outlet of the incinerator 1, and the other end of the flue 3 is connected in series with the processor 5 and the filter 6 respectively, and the filter 6 Smoke exhaust duct 7 is arranged on. refer to figure 1 , all the other are with embodiment 1.

Embodiment 3

[0013] Embodiment 3, the processor 5 of the present invention is designed as a sealed box, and a box partition is arranged in the box, the box partition is filled with water in the lower part of the box, and the box partition is filled with perlite The gravel layer is provided with a spray device on the upper part of the perlite gravel layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com