Chain coal-fired boiler capable of reducing nitrogen oxide emission

A technology for nitrogen oxide and coal-fired boilers, which is applied in the direction of solid fuel combustion, non-flammable liquid/gas transportation, combustion methods, etc. Issues such as nitrogen oxide emissions are not used, and the effect of solving insufficient combustion, preventing the formation of nitrogen oxides, and complete combustion is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

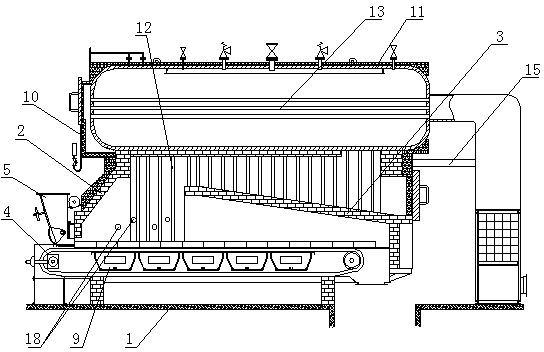

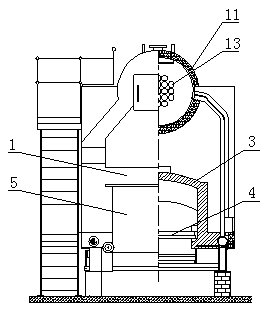

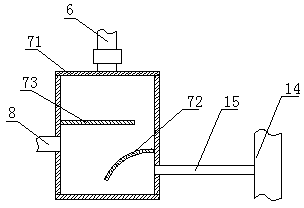

[0016] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

[0017] Such as figure 1 As shown, the chain coal-fired boiler that can reduce nitrogen oxide emissions provided by the present invention includes a furnace body 1 with a furnace inside. The furnace is jointly surrounded by a furnace wall 10, a drum 11 and a water wall tube 12. Connected with the drum 11, the furnace is equipped with a front furnace arch 2 and a rear furnace arch 3, and a chain-plate type fire grate 4 driven by a power mechanism is provided under the furnace, and an air supply device located under the chain-plate type fire grate is installed on the furnace body , the air supply device can adopt the air chamber structure shown in the figure, that is, the air supply chamber 9 is located under the chain-plate grate, and the air supply chamber 9 has two side air inlet doors, so that the air inlet is more uniform, and the front of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com