Fuel gas with high calorific value, preparation method thereof and equipment for carrying out the preparation method

A high calorific value, gas technology, applied in the direction of fuel, gas fuel, petroleum industry, etc., can solve the problems of no cost advantage, high cost, easy leakage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

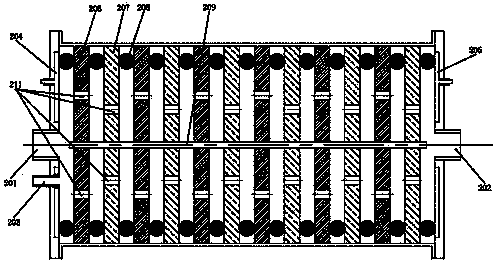

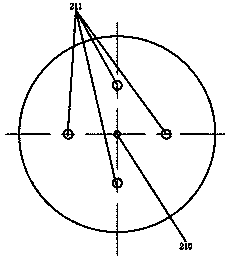

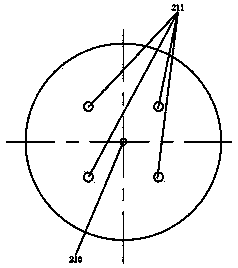

[0125] The high calorific value gas of the invention has the characteristics of high safety, good environmental protection and high calorific value. Such as figure 1 The first embodiment of the equipment for preparing high calorific value fuel gas according to the present invention is shown. It is provided with a control system 1, a water ion electrolysis system, and a hydrocarbon reforming system. The control system 1 is used to control the water ion electrolysis system and the hydrocarbon hydrogenation system. The material supply, running time, internal pressure and temperature in the reforming system and combustion system are monitored and controlled; the water ion electrolysis system mainly conducts capacitive electrolysis of water or electrolyte to produce hydronium ions H 3 O + And hydroxide ion OH - ; The hydrocarbon reforming system allows the gaseous ions produced by the water ion electrolysis system to undergo hydrocarbon reforming, and the high calorific value gas obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com