Steel for 13-dwt vehicle axle housing and production method thereof

A technology of axle housing and tapping temperature, which is applied in the steel for 13-ton axle axle housing and its production field, can solve problems affecting product quality and service life, unsatisfactory plastic characteristics, and large differences in technical conditions, etc., to achieve The effect of energy saving and emission reduction is obvious, thermal fatigue damage is eliminated, and the actual mechanical properties are good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

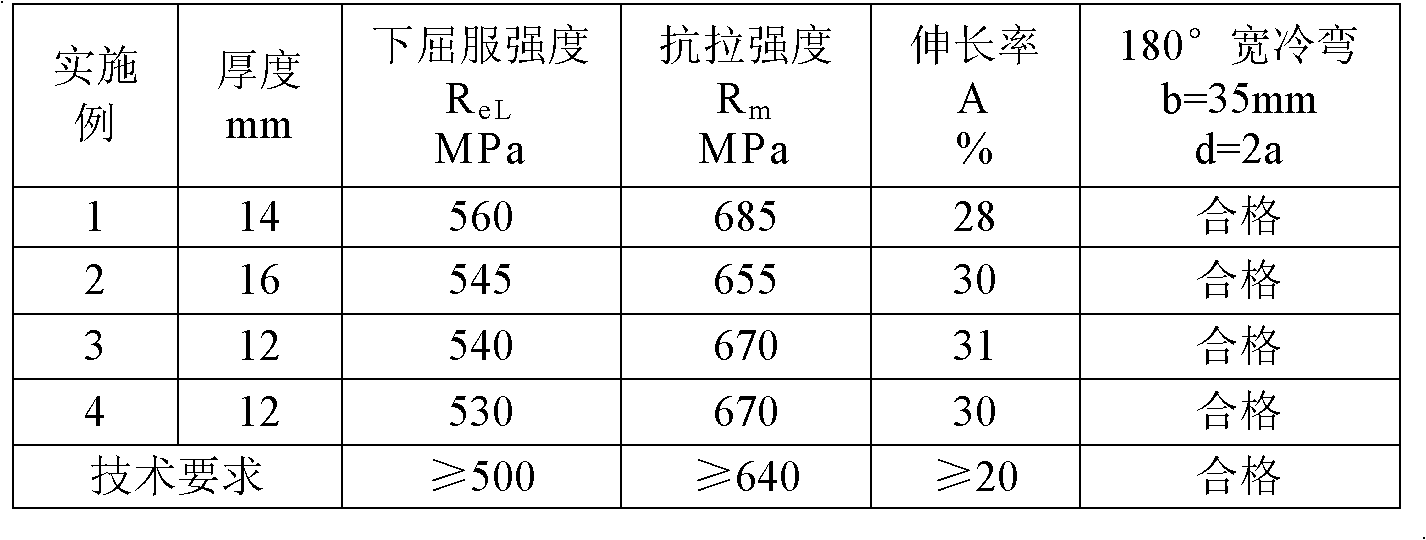

Embodiment 1

[0031] The steel plates for axle housings produced are 14 mm thick.

[0032] The chemical composition and weight percentage of 13-ton axle housing steel are: C: 0.042%, Si: 0.10%, Mn: 1.31%, P: 0.025%, S: 0.005%, Al: 0.01%, Nb: 0.06%, Ti: 0.031%, the remainder is Fe and unavoidable impurities.

[0033] The method for producing 13 tons of steel for axle housings, the steps:

[0034] 1) Carry out converter smelting, and control the tapping temperature at 1710°C to 1715°C;

[0035] 2) Carry out vacuum treatment: the treatment time is 13 minutes, and the vacuum degree is kept at 730Pa;

[0036] 3) Carry out continuous casting, control casting speed at 1.0 m / min;

[0037] 4) Heating the slab, the heating temperature is 1240°C-1250°C, and the heating time is 140 minutes;

[0038] 5) Rough rolling is carried out, and the end temperature is controlled at 1050°C to 1060°C;

[0039] 6) Use 7 stands for finish rolling, control the final rolling temperature at 760°C to 770°C, and the...

Embodiment 2

[0043] The steel plates for axle housings produced are 16 mm thick.

[0044]The chemical composition and weight percentage of 13-ton axle housing steel are: C: 0.047%, Si: 0.28%, Mn: 1.35%, P: 0.020%, S: 0.0032%, Al: 0.025%, Nb: 0.053%, Ti: 0.036%, the rest is Fe and unavoidable impurities.

[0045] The method for producing 13 tons of steel for axle housings, the steps:

[0046] 1) Carry out converter smelting, and control the tapping temperature at 1715°C to 1720°C;

[0047] 2) Carry out vacuum treatment: the treatment time is 15 minutes, and the vacuum degree is kept at 740Pa;

[0048] 3) Carry out continuous casting, control casting speed at 1.05 m / min;

[0049] 4) Heating the slab, the heating temperature is 1250°C-12605°C, and the heating time is 145 minutes;

[0050] 5) Rough rolling is carried out, and the end temperature is controlled at 1070°C to 1080°C;

[0051] 6) Use 7 stands for finish rolling, control the final rolling temperature at 770°C to 780°C, and the ...

Embodiment 3

[0055] The steel plates for axle housings produced are 12 mm thick.

[0056] The chemical composition and weight percentage of 13-ton axle housing steel are: C: 0.064%, Si: 0.56%, Mn: 1.40%, P: 0.02%, S: 0.004%, Al: 0.052%, Nb: 0.058%, Ti: 0.045%, the remainder is Fe and unavoidable impurities.

[0057] The method for producing 13 tons of steel for axle housings, the steps:

[0058] 1) Converter smelting is carried out, and the tapping temperature is controlled at 1710°C to 1716°C;

[0059] 2) Carry out vacuum treatment: the treatment time is 15 minutes, and the vacuum degree is kept at 770Pa;

[0060] 3) Carry out continuous casting, control casting speed at 1.1 m / min;

[0061] 4) Heating the slab, the heating temperature is 1260℃~1270℃, and the heating time is 150 minutes;

[0062] 5) Rough rolling is carried out, and the end temperature is controlled at 1070°C to 1080°C;

[0063] 6) Use 7 stands for finish rolling, control the final rolling temperature at 785°C to 795°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com