Comprehensive recovery technology of multi-metal low-grade ore and ore-bearing waste rock resources thereof

A low-grade, polymetallic technology, applied in the field of metallurgy, can solve problems such as affecting the economic benefits of mines, abandoning them, easy oxidation, etc., to achieve the effect of improving the utilization rate of mineral resources, high production efficiency, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

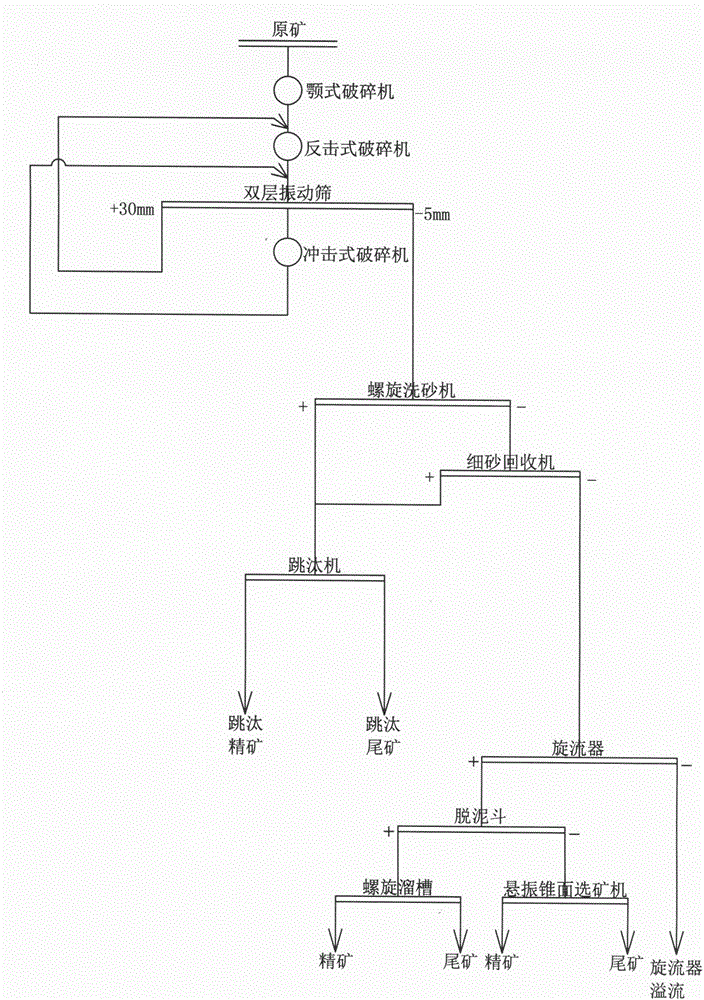

[0024] Example 1 :Such as figure 1 , the zinc-tin-copper polymetallic ore in a certain area of Yunnan, the low-grade ore and the mineral aggregates in the ore-bearing waste rock have a small particle size, the distribution of metal minerals is relatively concentrated, and the dense disseminated and lamellar structures are the main ones. A small amount is in the form of dense blocks and strips, 60% to 80% of the useful minerals are distributed in 10% to 30% of the mineral aggregates, and the following process is used for recovery: firstly, the ore is sequentially crushed by jaw crusher and impact crushing After the crushing machine is crushed, it is screened by a double-layer vibrating screen, the size of the upper screen is 30mm, and the size of the lower screen is 5mm. The product on the upper screen is returned to the impact crusher for crushing, and the product on the lower screen is crushed by an impact crusher. After crushing, return to the double-layer vibrating scr...

example 2

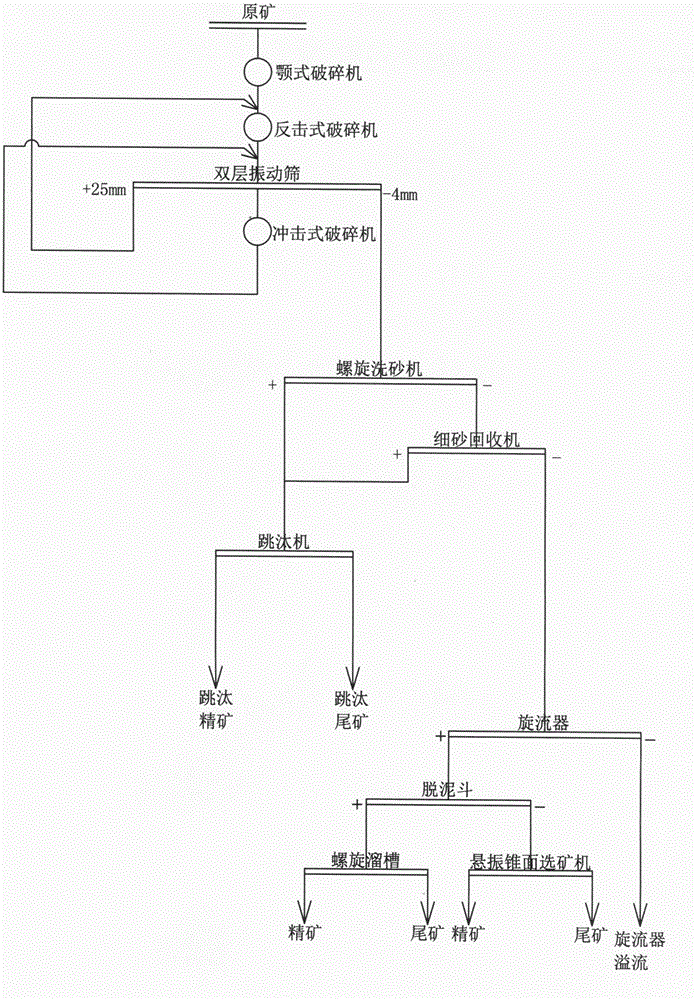

[0039] Example 2 :Such as figure 2 , Zn-Sn-Cu polymetallic deposits in a certain area of Yunnan, the mineral aggregates in the low-grade ores and waste rocks containing them are small in size, and the distribution of metal minerals is relatively concentrated, mainly in veinlets and plaques, with a small amount of It is a dense massive, striped, and layered structure, 60% to 80% of useful minerals are distributed in 10% to 30% of mineral aggregates, and the following process is used for recovery: firstly, the ore is sequentially used in a jaw crusher 1. After being crushed by the impact crusher, it is fed into the double-layer vibrating screen for screening. The screen size of the upper screen is 25mm, and the screen size of the lower screen is 4mm. The products on the upper screen are returned to the impact crusher for crushing, and the products on the lower screen are After being crushed by the impact crusher, return to the double-layer vibrating screen for screening, an...

example 3

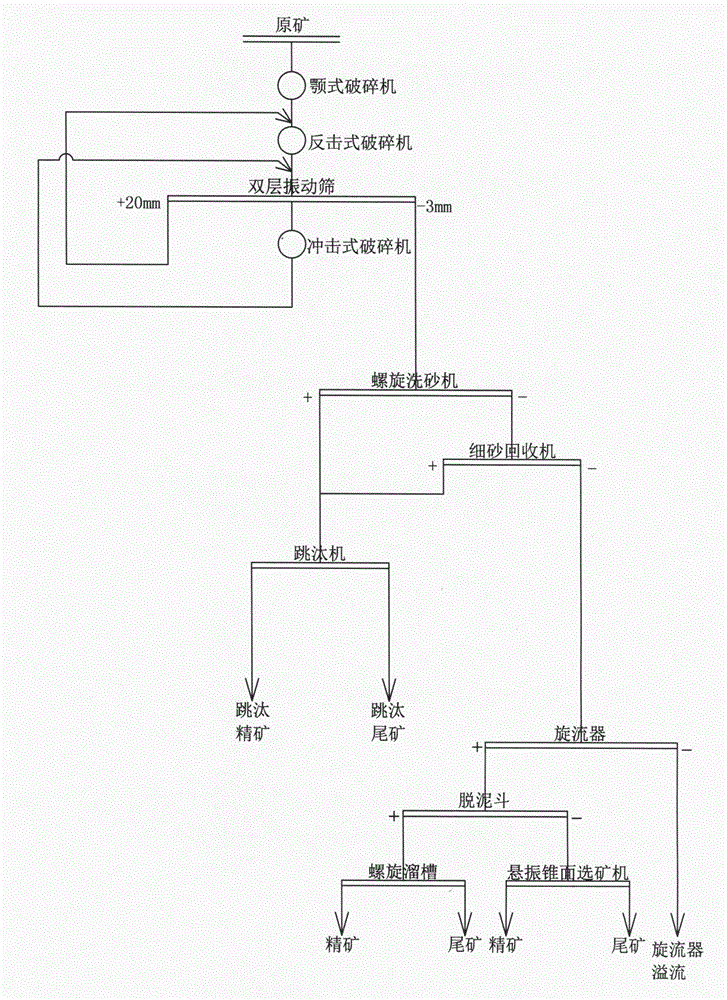

[0054] Example 3 :Such as image 3 , the zinc-tin-tungsten polymetallic ore in a certain area of Yunnan, the particle size of the mineral aggregates in the low-grade ore and the waste rock containing it is small, the distribution of metal minerals is relatively concentrated, mainly scattered spots, spots, and structures, and a small amount is dense Massive, striped and layered structures, 60% to 80% of useful minerals are distributed in 10% to 30% of mineral aggregates, and the following processes are used for recovery: firstly, the ore is sequentially crushed by jaw crusher, counterattack After being crushed by the type crusher, it is fed into the double-layer vibrating screen for screening. The screen size of the upper screen is 20mm, and the screen size of the lower screen is 3mm. After being crushed by the crusher, return to the double-layer vibrating screen for screening, and the product under the lower sieve is the material with a particle size of -3mm; then use the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com