Method for producing low-temperature polyester fiber double-color strip fabric

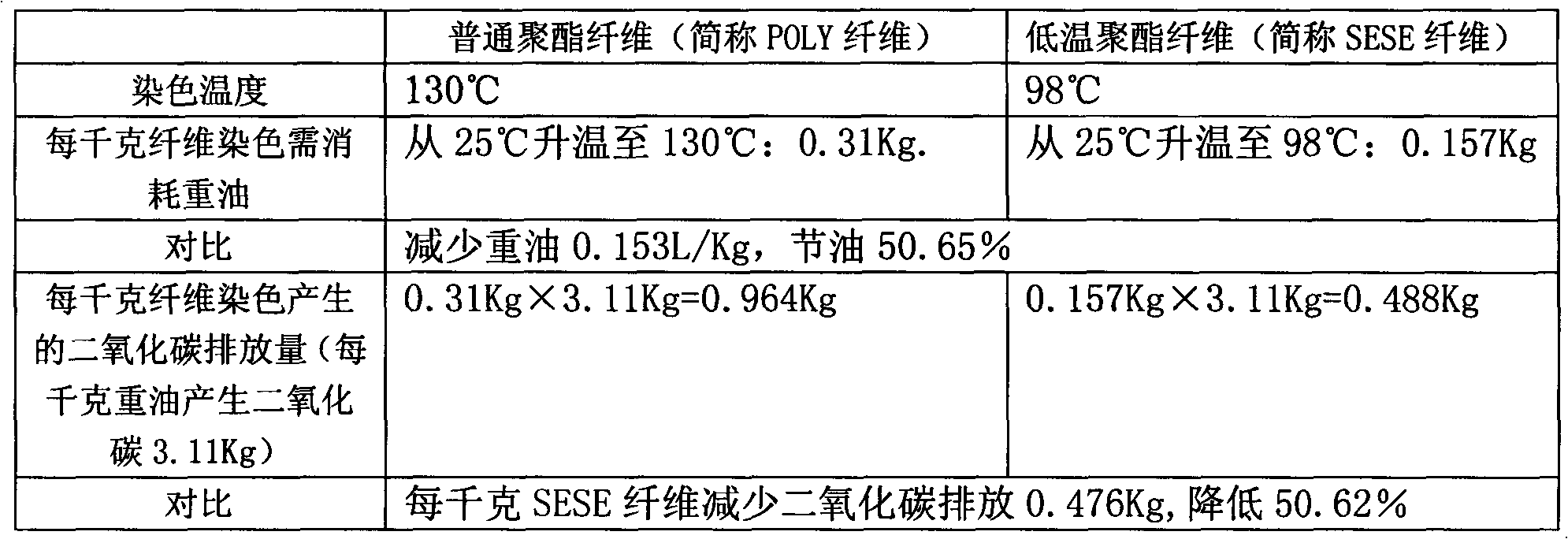

A polyester fiber and production method technology, which is applied in the field of polyester fiber two-color sliver production, can solve problems such as increasing carbon dioxide emissions, generating greenhouse effects, and endangering human survival, and achieves the effects of reducing emissions, saving energy, and clear patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of processing step of the production method of low-temperature polyester fiber two-color sliver cloth is:

[0018] (1) Weaving process of low-temperature polyester fiber sliver cloth spring and summer fabric gray cloth:

[0019] Select low-temperature polyester fiber yarn 75D / 72F and cationic yarn 75D / 72F with a dyeing temperature of less than 100°C, and weave the gray fabric on a 30″28G double-sided knitting large circular machine according to the type of double-sided acrylic fabric. Among them, the upper yarn of the gray fabric is made of low-temperature Polyester fiber yarn 75D / 72F and cationic yarn 75D / 72F are arranged circularly at equal distances according to the total number of machines. The bottom yarn of the gray cloth is made of conventional polyester fiber yarn DTY75D / 72F, and the unit weight of the gray cloth is 160g / m 2 . At this time, since the two-color stripes are arranged in an equidistant cycle, the weight percentages of the low-temperature pol...

Embodiment 2

[0023] This example dyes and finishes dark purple + light purple striped cloth.

[0024] (1) Weaving process, except that the following parameters are changed, its process is the same as Example 1:

[0025] The low-temperature polyester fiber yarn is 100D / 72F, the cationic yarn is 100D / 72F, the conventional polyester fiber yarn is DTY100D / 72F, and the unit weight of gray cloth is 180g / m 2 .

[0026] (2) Dyeing and finishing process, except that following parameters change, its processing step is identical with example 1:

[0027] Gray fabric degreasing temperature is 70°C, heat preservation for 22 minutes, disperse dyes are X-GRL red 0.14kg, X-BL blue 0.05kg, cationic dyes are FB red 0.22kg, F-4R blue 0.24kg, dye auxiliaries HAC 2.0 kg, cationic leveling agent 0.6kg, anti-precipitation agent 1.0kg, the dye liquor is raised from room temperature to 97°C and kept for 50 minutes, the water temperature for reduction washing is 70°C, and the washing time is 25 minutes.

Embodiment 3

[0029] This example dyes and finishes rose red + deep purple striped cloth.

[0030] (1) Weaving process, except that the following parameters are changed, its process is the same as Example 1:

[0031] The low-temperature polyester fiber yarn is 150D / 72F, the cationic yarn is 150D / 72F, and the conventional polyester fiber yarn is DTY150D / 72F. The weight percent of arrangement is 12.5%, 37.5%, 50%, and the unit weight of gray cloth is 200g / m 2 , According to the double-faced acrylic cloth, the gray cloth is woven on a 34″28G double-faced circular knitting machine.

[0032] (2) Dyeing and finishing process, except that following parameters change, its processing step is identical with example 1:

[0033] Gray fabric degreasing temperature 80°C, heat preservation for 20 minutes, disperse dyes are R-FB red 0.57kg, B-E / 4R blue 0.006kg, cationic dyes are R-X / GRL red 0.16kg, B-X / BL blue 0.12kg, dye auxiliaries HAC 2.0kg, anti-precipitation agent 1.0kg, the dye liquor is raised fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com