Internal-combustion high temperature furnace for ferro-coke pellets/lump ores

A high-temperature furnace and pellet technology, which is applied in the direction of furnaces, furnace types, furnace components, etc., can solve the problems of polluting the environment, large amount of harmful smoke emissions, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

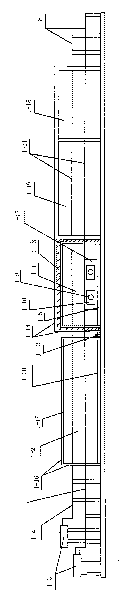

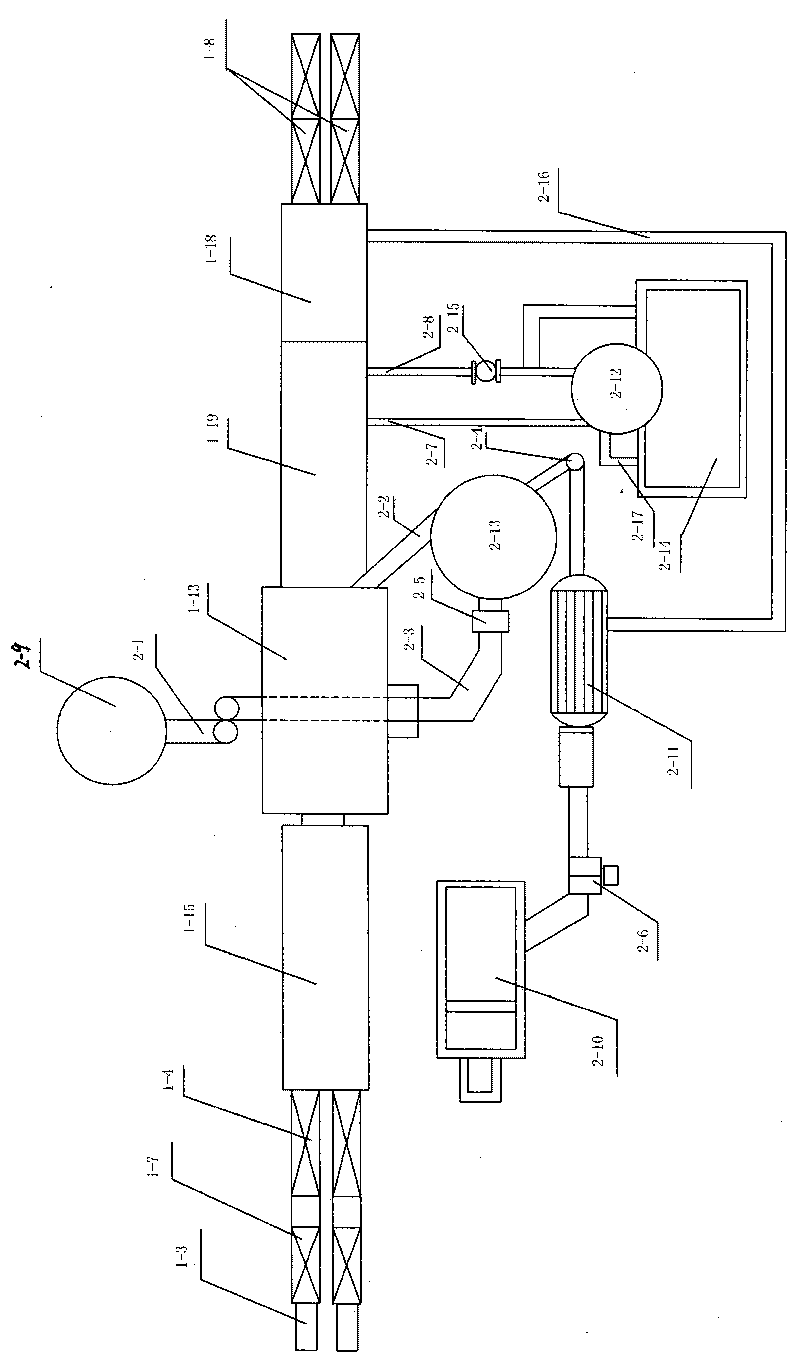

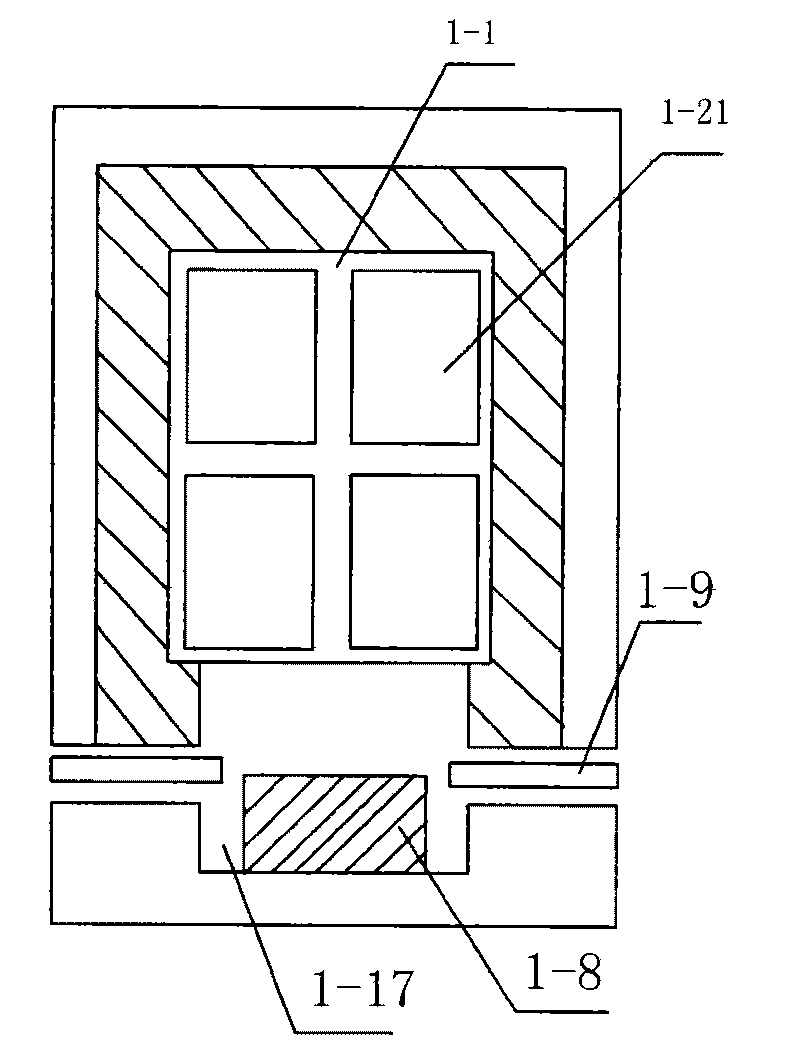

[0017] Such as figure 1 As shown, a kind of internal combustion iron coke pellet / lump ore high-temperature furnace provided by the present invention comprises a high-temperature furnace body 1-13, and a preheating furnace 1-15 is respectively arranged at the front end and rear end of the high-temperature furnace body 1-13 And the cooling system, the cooling system is divided into two sections, respectively, the steam injection cooling section 1-18 and the water spacer cooling section 1-19, the unloading platform 1-8 is arranged at the rear end of the cooling system, and the preheating furnace 1- The front end of 15 is provided with an upper loading platform 1-4 and a lower loading platform 1-7 located below the upper loading platform 1-4, and the ends of the upper loading platform 1-4 and the lower loading platform 1-7 are respectively There are trolley machines 1-3, the upper charging platform 1-4 and the lower charging platform 1-7 respectively pass through the preheating fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com