Pressure relieving dust preventing and filtering system for dual-sealing arch-shaped material guiding chute

A filtration system and material guide technology, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve problems affecting environmental quality, etc., and achieve convenient maintenance and repair, good dust and gas separation and purification effect, and low maintenance cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

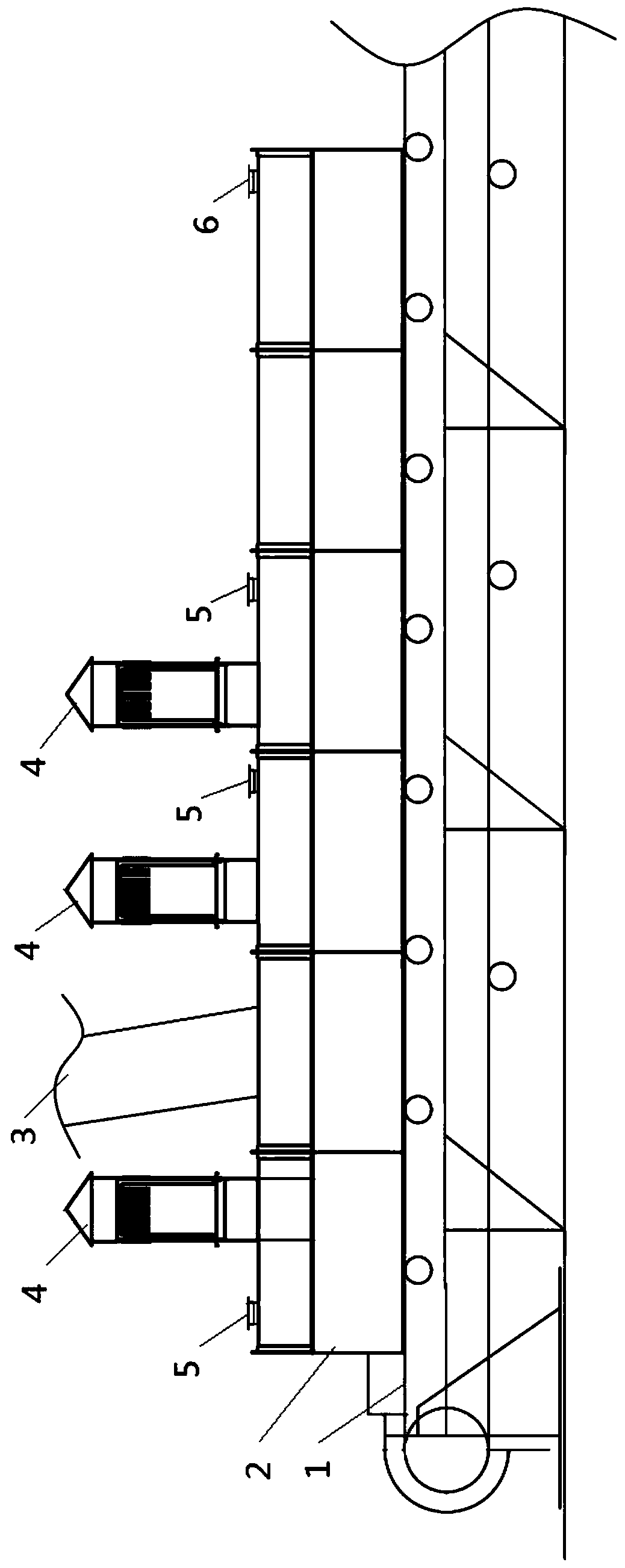

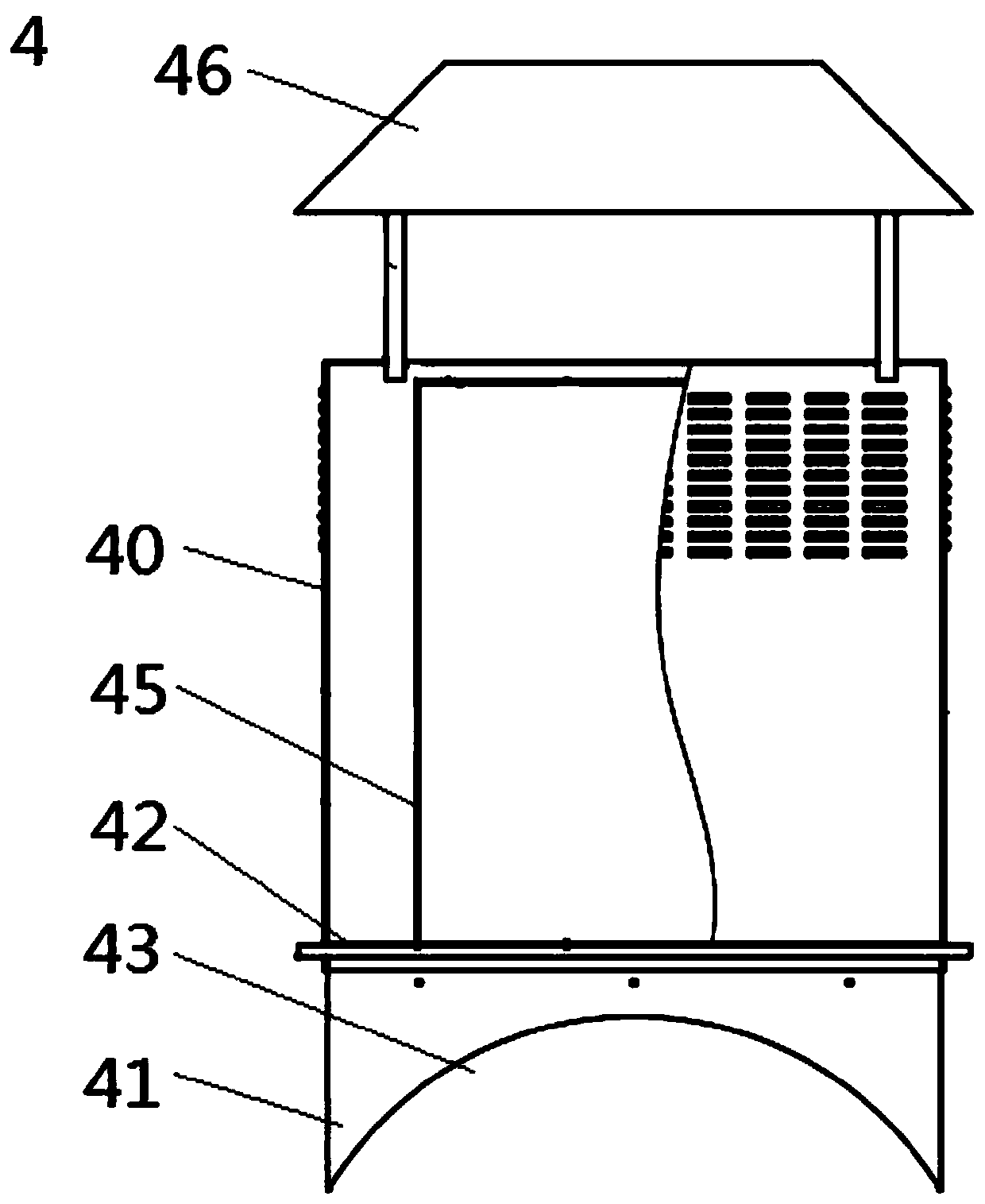

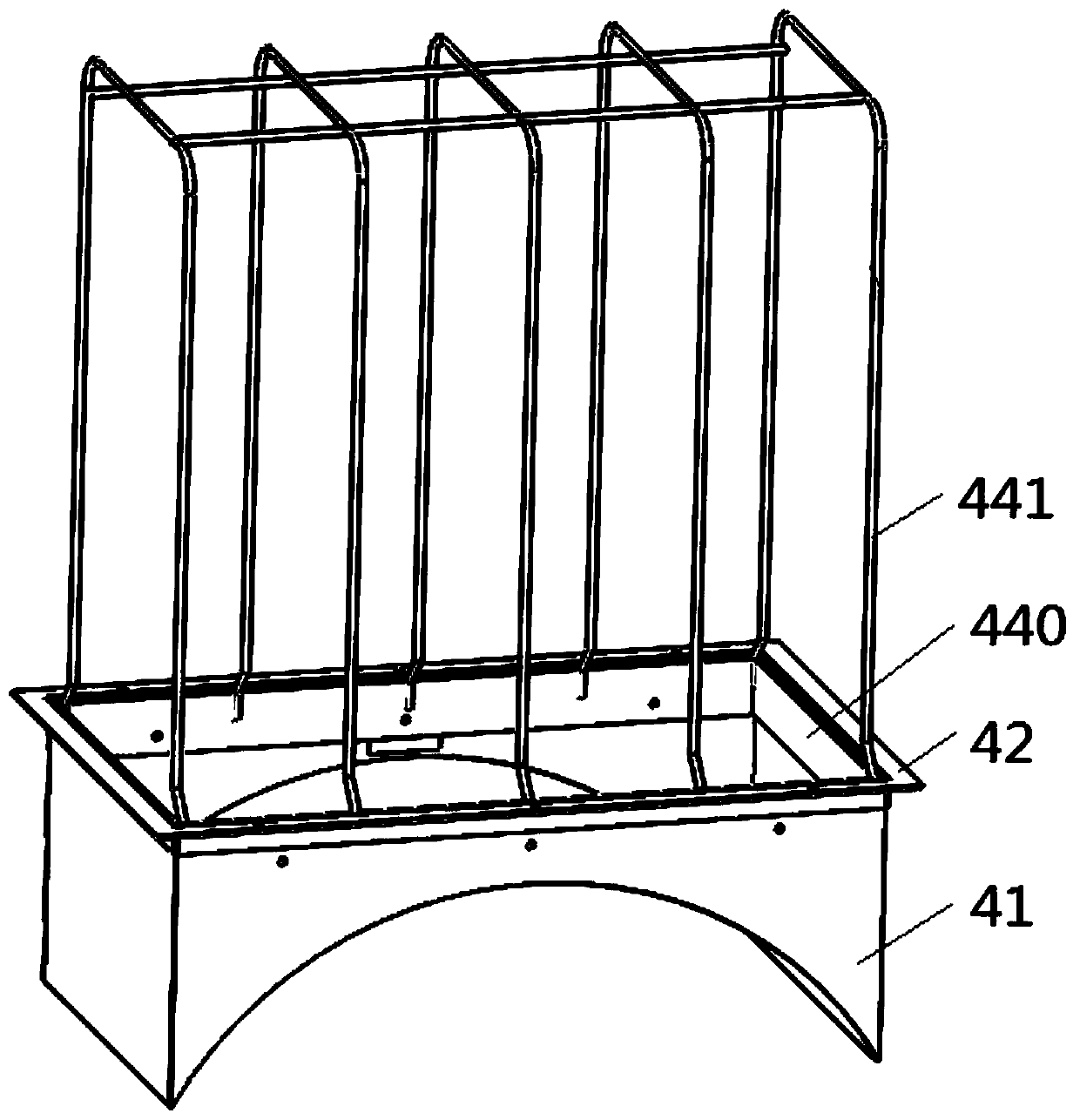

[0034] The invention provides a double-seal bow-shaped material guide groove pressure relief and dust-proof filter system, such as figure 1 As shown, it includes a double-sealed bow-shaped material guide chute 2 arranged above the belt 1, and the said material guide trough 2 is connected with a coal-falling pipeline 3. The double-sealed bow-shaped material guide chute 2 is provided with several pressure-relief and dust-proof filters The device 4 and several adjustable dust-proof sealing devices 5, wherein the pressure relief dust-proof filter device 4 and the adjustable dust-proof sealing device 5 are arranged at intervals on the double-seal bow-shaped material guide groove 2; A double-sealed dust-proof box 6 is provided at the outlet of the double-sealed bow-shaped material guide groove 2 .

[0035] Specifically, the pressure relief dust-proof filter device 4 and the adjustable dust-proof sealing device 5 are provided on both sides of the coal-falling pipeline 3 on the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com