Patents

Literature

115results about How to "Automatic fall off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

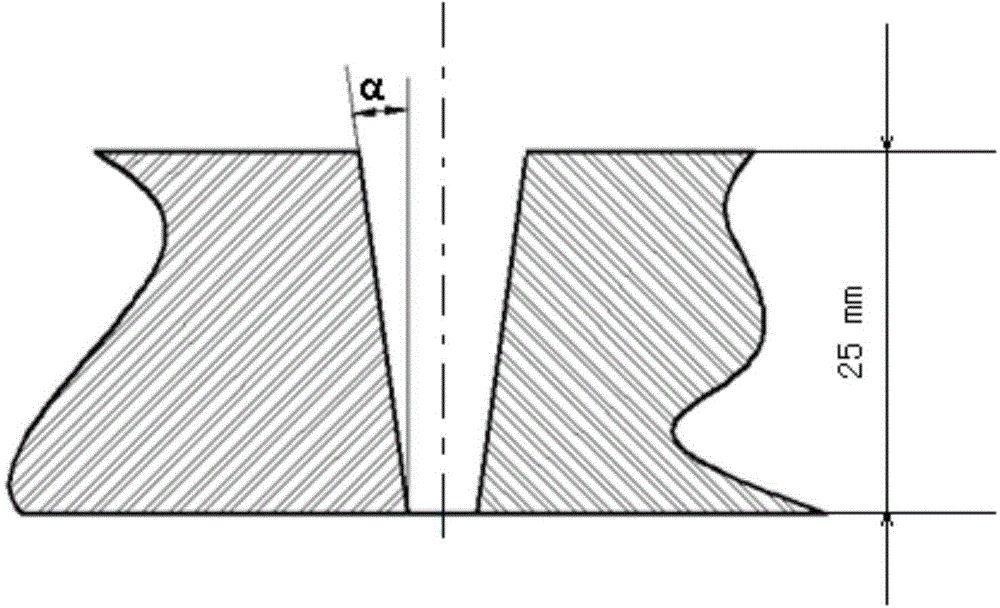

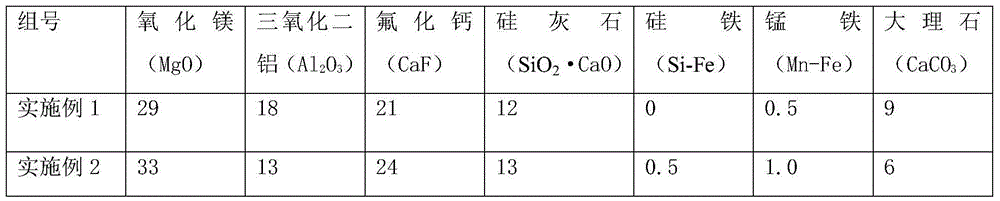

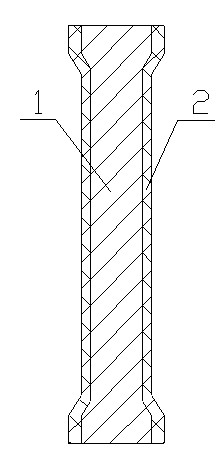

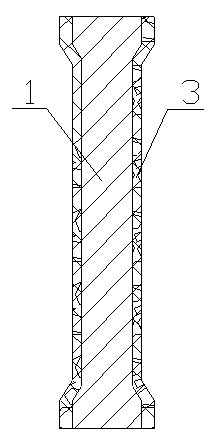

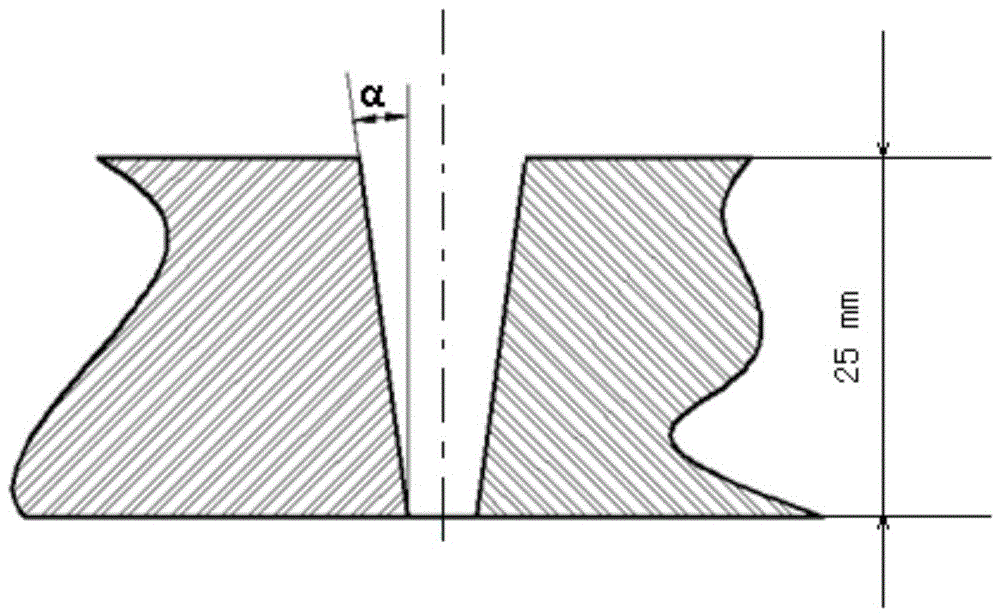

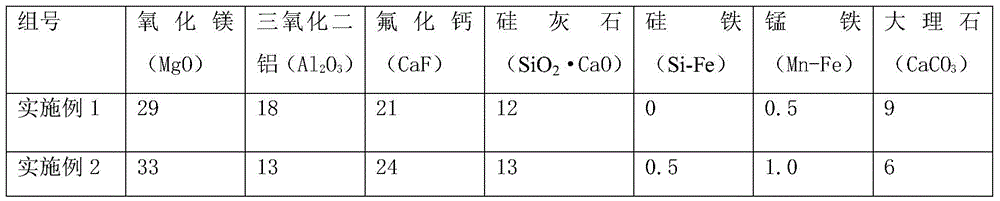

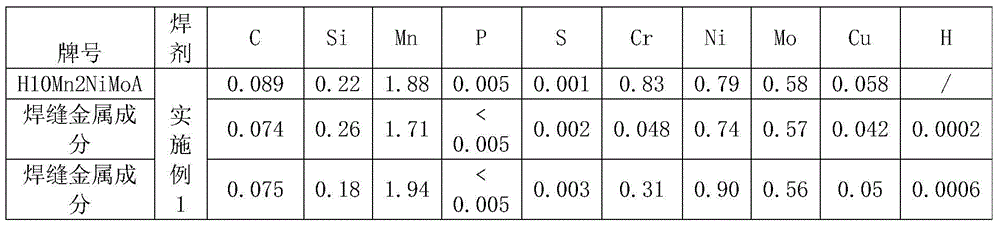

Submerged-arc welding flux for low-alloy-steel narrow-gap welding and preparation method thereof

ActiveCN104668816AExcellent transition abilityEasy transitionWelding/cutting media/materialsSoldering mediaSlagMechanical property

The invention relates to a submerged-arc welding flux for low-alloy-steel narrow-gap welding and a preparation method thereof. A high-alkalinity MgO-CaO-Al2O3-CaF slag system is adopted, and the submerged-arc welding flux is mainly made from raw materials including calcium fluoride, aluminum oxide, wollastonite, marbles, silicon iron and ferromanganese iron. The preparation method of the submerged-arc welding flux mainly comprises the steps of 1 dry mixing in proportion, 2 impurity removal, 3 bonding agent adding for wet mixing and 4 baking and high-temperature sintering. The alkalinity of the welding flux ranges from 2.0 to 3.0, low-hydrogen and low-oxygen deposited metal containing ultra low P and S impurity contents can be obtained through welding, and accordingly it can be ensured that the deposited metal has excellent comprehensive mechanical property. When the submerged-arc welding flux is matched and welded with a low-purity low-alloy steel welding wire, S and P are not added into the deposited metal by adopting the welding flux. The submerged-arc welding flux has excellent alloy transition capacity.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

TiAl-based alloy high-temperature oxidation resistant coating and method for implementing same

InactiveCN101519274AEasy to implementThe implementation process is simpleMetallurgyOxidation resistant

The invention discloses a TiAl-based alloy high-temperature oxidation resistant coating, which comprises the following components: SiO2, Na2O and CaO. The method for implementing the TiAl-based alloy high-temperature oxidation resistant coating comprises the following steps of: firstly, taking the components of the TiAl-based alloy high-temperature oxidation resistant coating according to a proportion; heating the components to about 1,500 DEG C, keeping the temperature, and allowing the components to cool to obtain a raw material of the oxidation resistant coating; heating the raw material of the oxidation resistant coating till the raw material of the oxidation resistant coating is in a viscous state; and coating the raw material in the viscous state on the surface of TiAl-based alloy or completely immersing the TiAl-based alloy in the raw material in the viscous state to apply oxidation resistant protection to the TiAl-based alloy during processing at a high temperatue of 1,300 DEG C. The coating is reasonable in component mixing ratio, simple in production process, convenient in operation and use and low in cost, effectively prevents the oxidization of TiAl-based alloy, avoids influencing the high-temperature deformation capacity of the TiAl-based alloy, separates conveniently from a substrate at normal temperature, effectively overcomes the drawbacks of uneven deformation of easy cracking of the TiAl-based alloy, and difficult separation of a covering sleeve and the alloy in the prior art, is applicable to industrial application, and can replace the prior TiAl-based alloy high-temperature oxidation resistant process.

Owner:CENT SOUTH UNIV

Grafting breeding method for plukenetia volubilis

The invention discloses a grafting breeding method for plukenetia volubilis. Mature plukenetia volubilis seeds are sown in a nutritious cup filled with flower soil to carry out seedling raising; after the seeds sprout and before hypocotyls grow to 5cm and seed leaves completely expand, seedlings are disinfected and the hypocotyls are cut off and are used as rootstocks for later use; plukenetia volubilis sprouts to be grafted are collected to be used as scions and are inserted into notches of the rootstocks and then the junctions of the scions and the rootstocks are wrapped tightly and bundled solidly by Parafilm sealing films; and grafted nursery stocks are moved into a greenhouse and after the wounds at the junctions of the scions and the rootstocks are healed, the seedlings are exercised for one week and then can be moved into the land to be planted. The grafting breeding method has the characteristics that the grafting breeding method is simple to operate, needs a small number of scion materials, has high survival rate, low cost and high growth speed and can be applied to rapid propagation of superior individual plants and fine varieties; a great amount of high-quality nursery stocks can be propagated in short time; and the grafting breeding method has good market application prospect.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

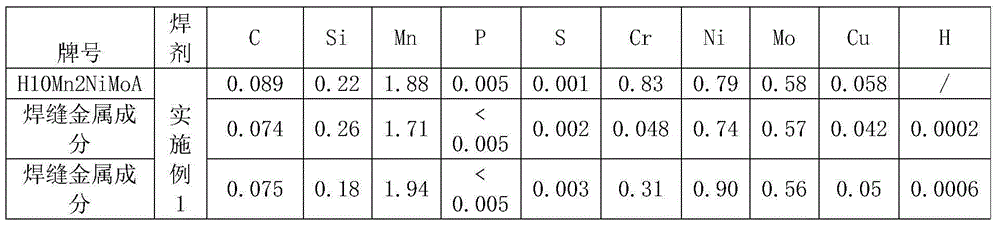

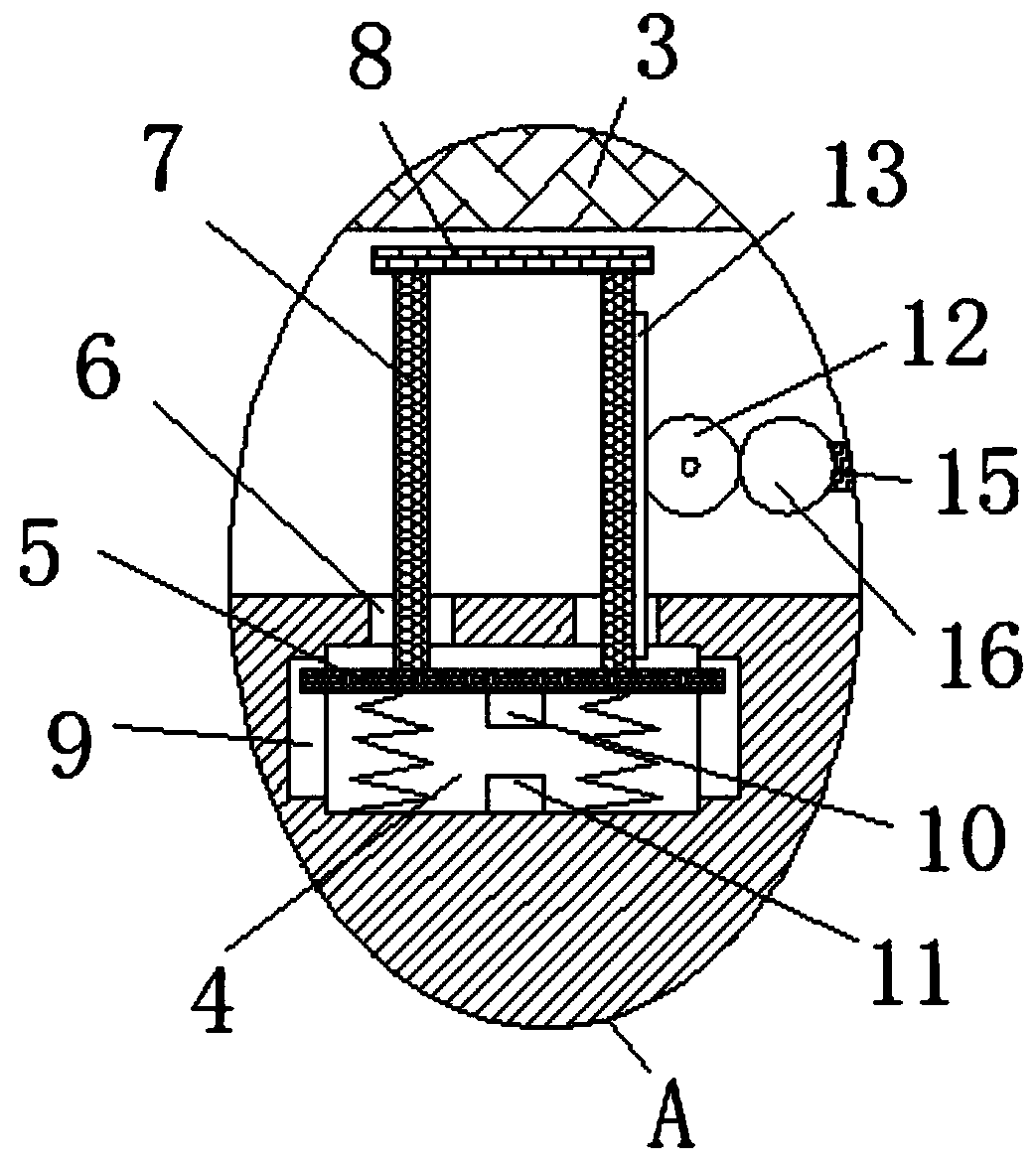

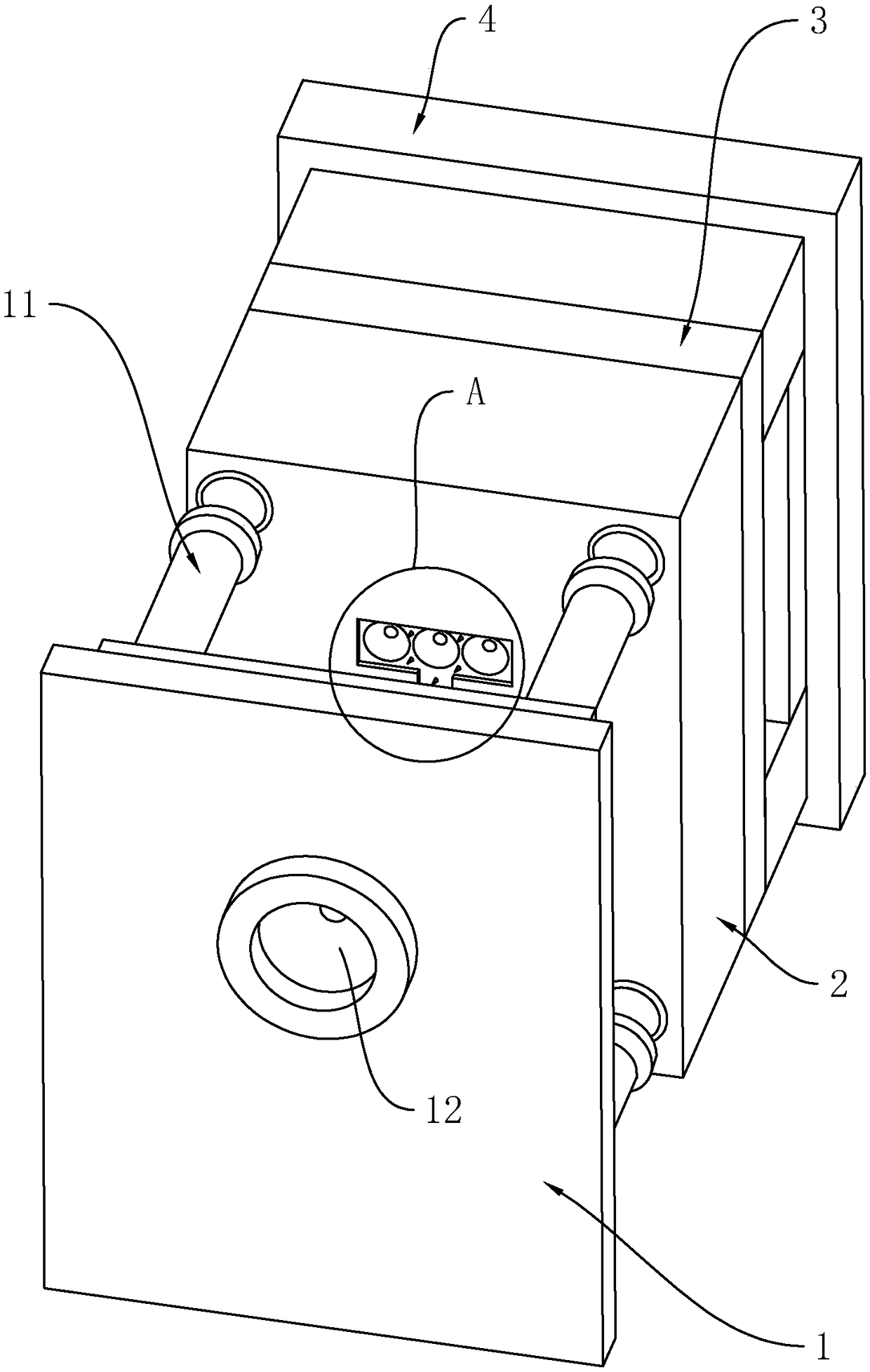

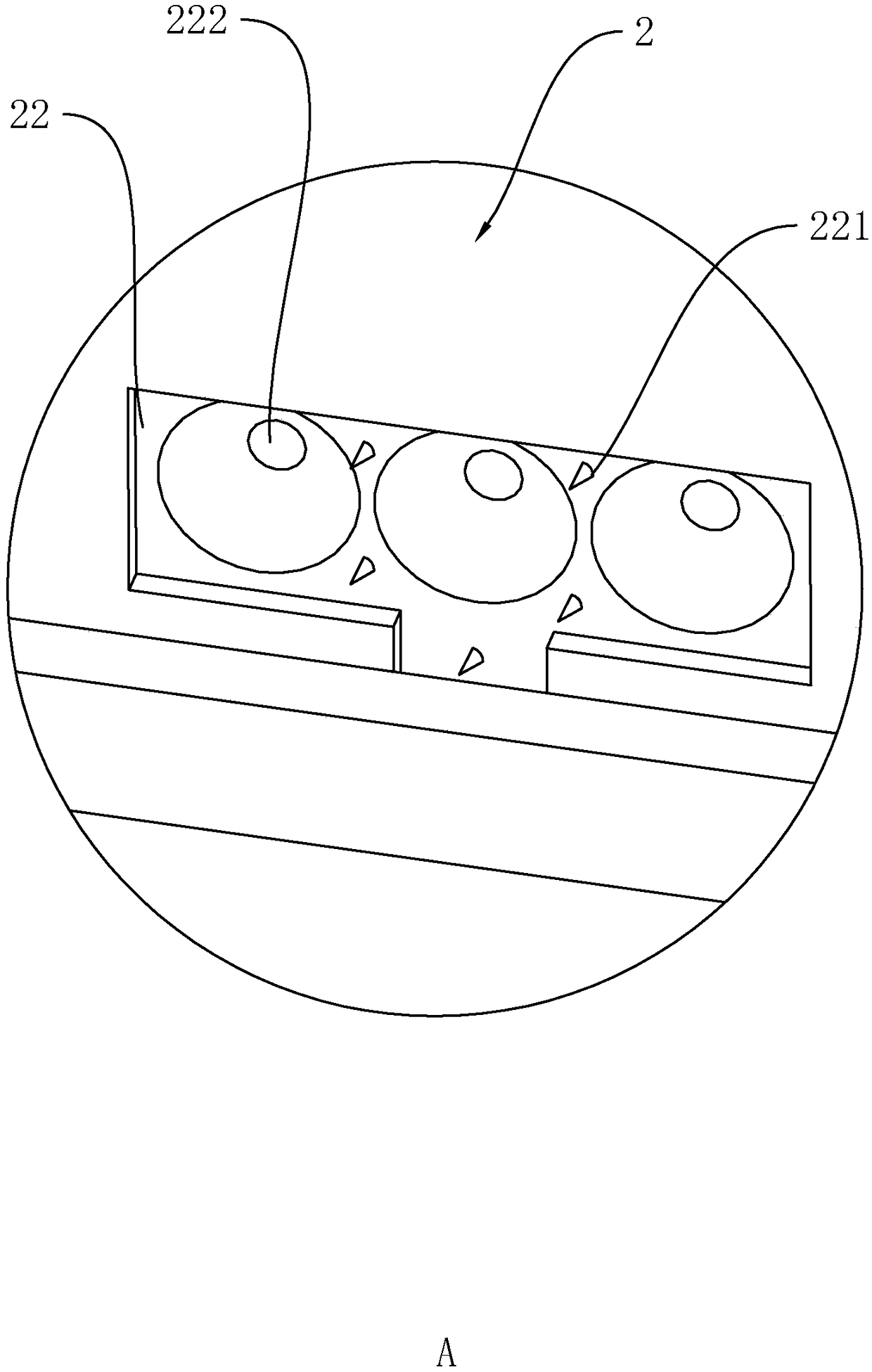

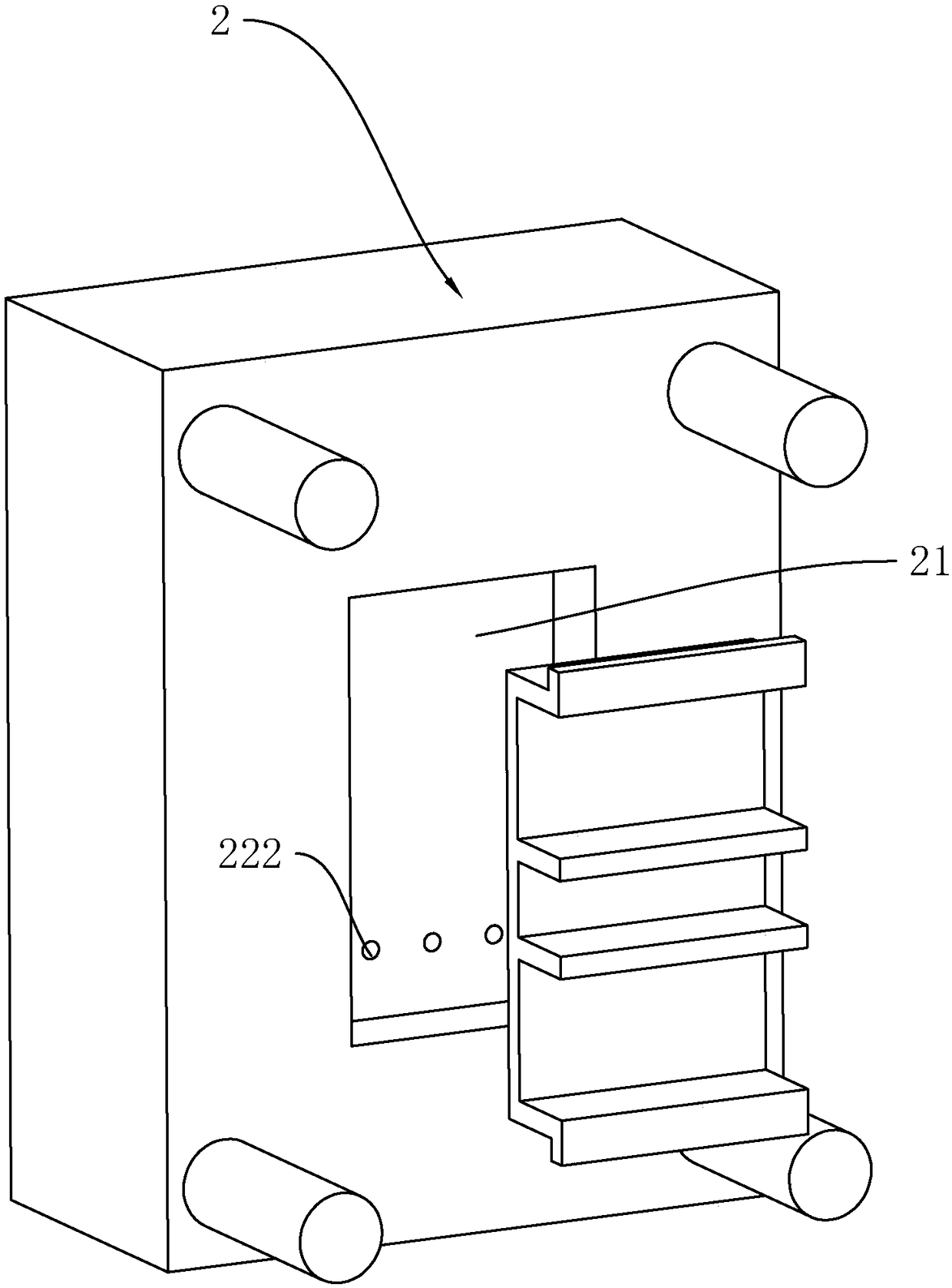

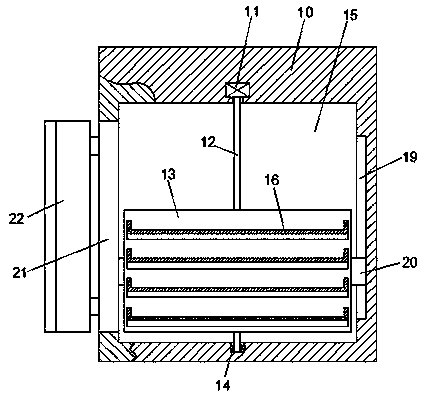

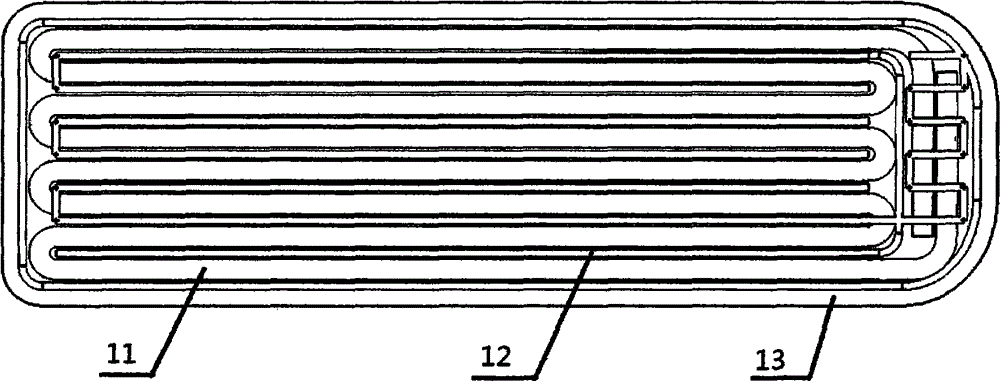

Cover for a furnace for receiving molten material, particularly metal, and furnace for receiving molten material

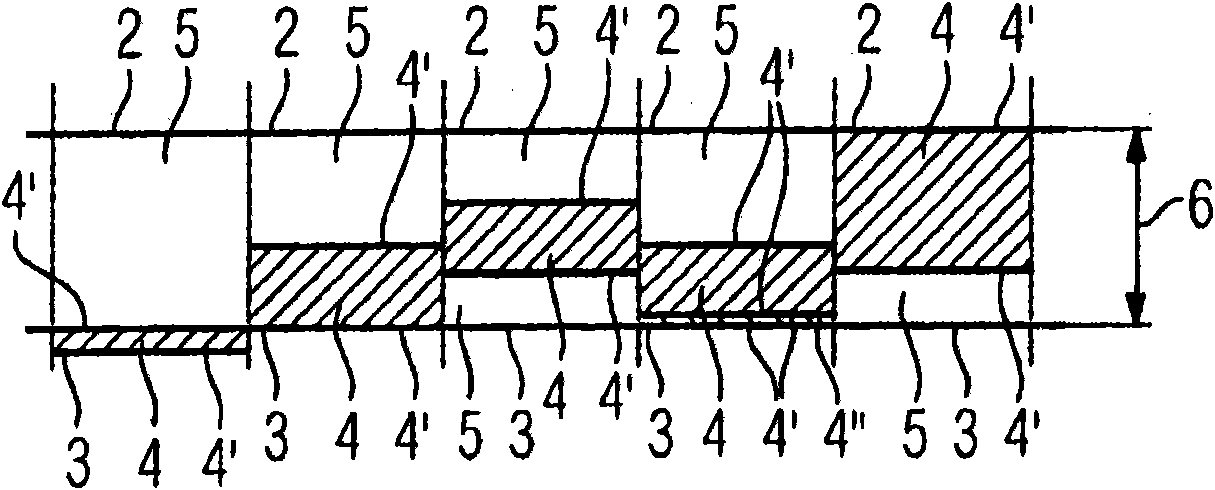

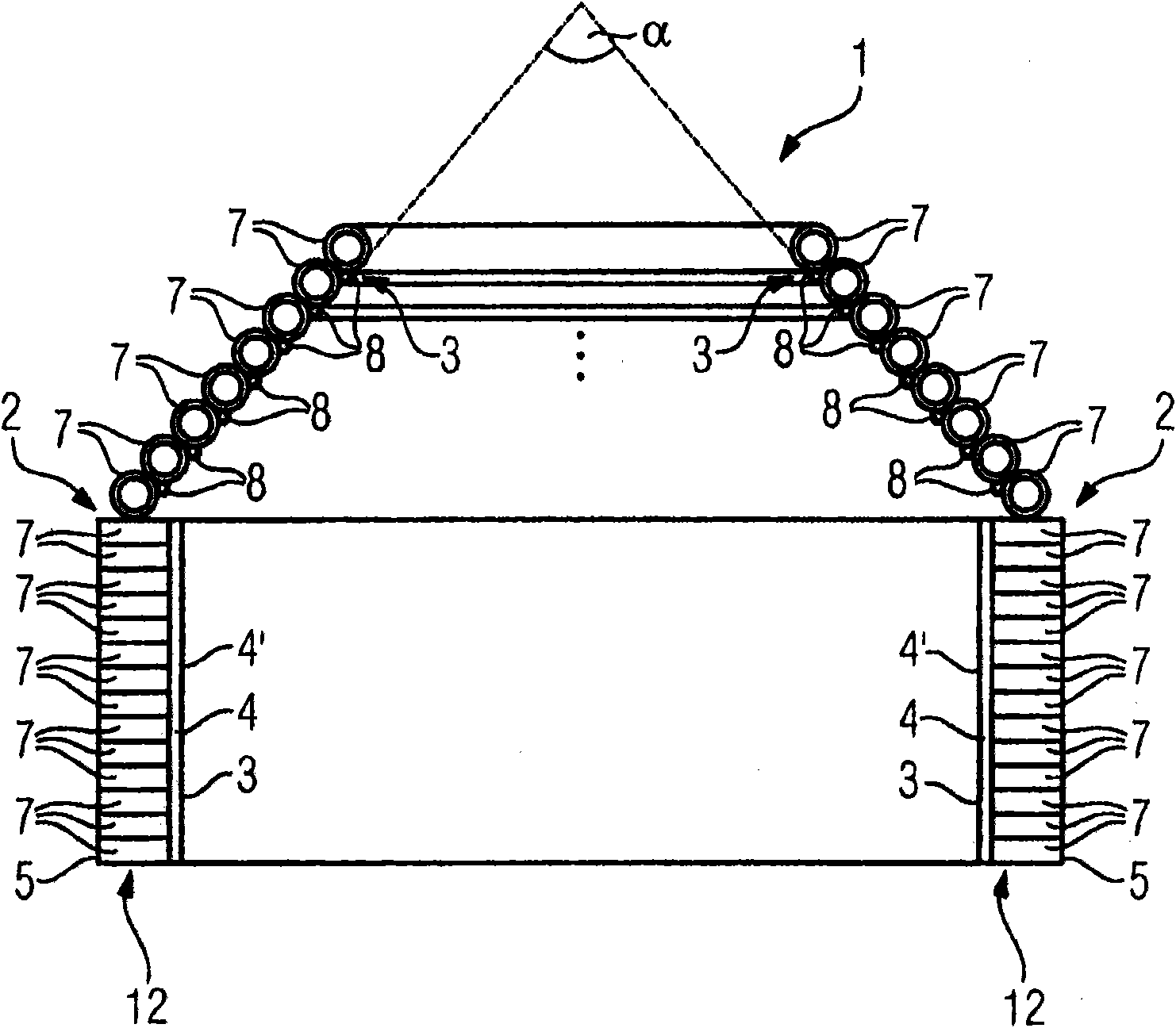

InactiveCN101802535AAutomatic fall offAvoid depositionMelt-holding vesselsFurnace coolingCrucibleHeat transfer coefficient

The invention relates to a cover (1) for a furnace (10) for receiving molten material (S), particularly metal. According to the invention, the cover comprises at least one layer (4, 4'') formed of a material having a heat transfer coefficient greater than that of steel, so that a furnace cover can be provided in which baked-on residue of molten particles discharged from a melt can be reduced or even entirely prevented on the inner surface (3) of the cover. The invention further relates to a furnace (10) for receiving molten material (S), particularly metal, having a crucible (11) that can be filled with molten material (S) and having a cover (1) for closing the crucible (11). Because the cover (1) and / or crucible (11) comprise a layer (4, 4'') made of a material having a heat transfer coefficient greater than that of steel, undesired baked-on residue of molten material particles can be reduced or prevented on the cover surface (3) and / or crucible surface (13).

Owner:PRIMETALS TECH GERMANY

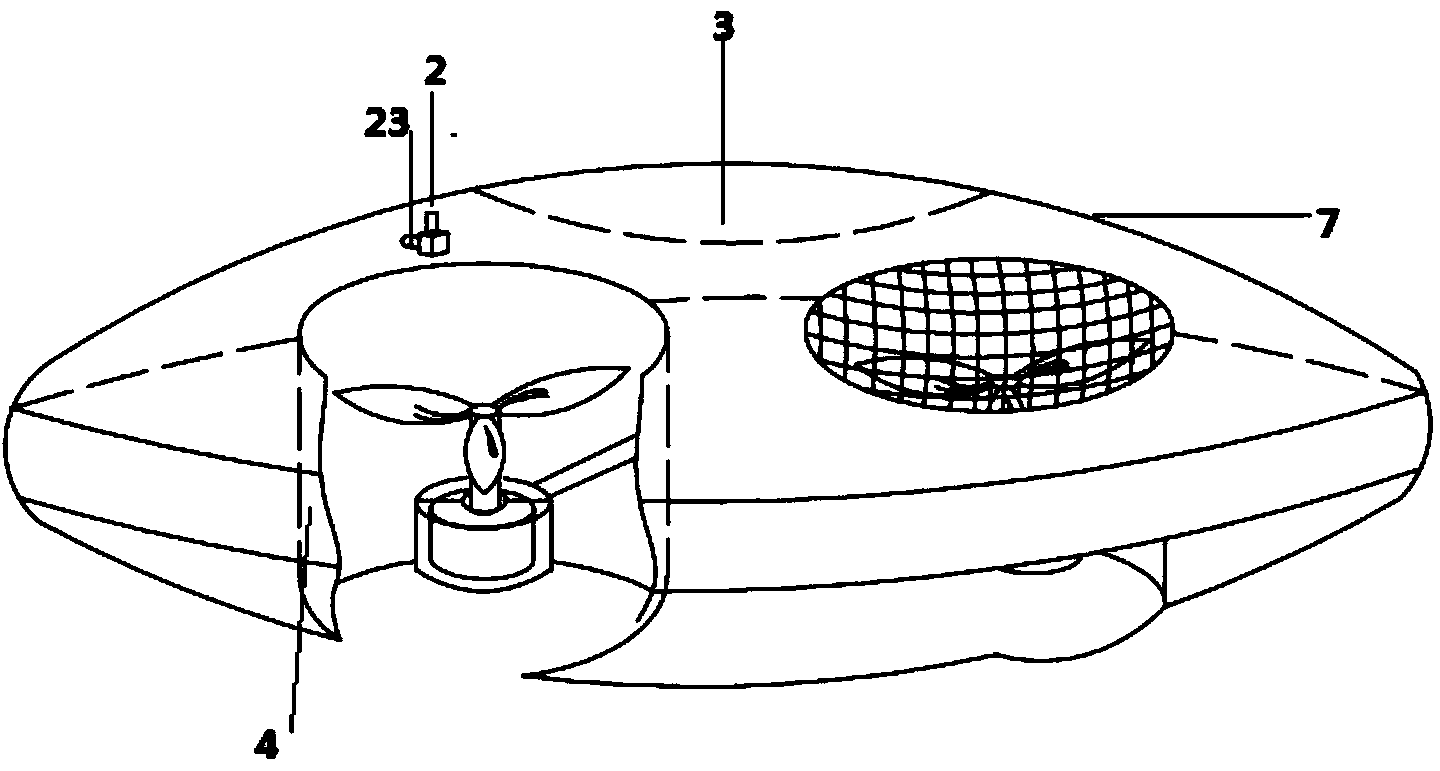

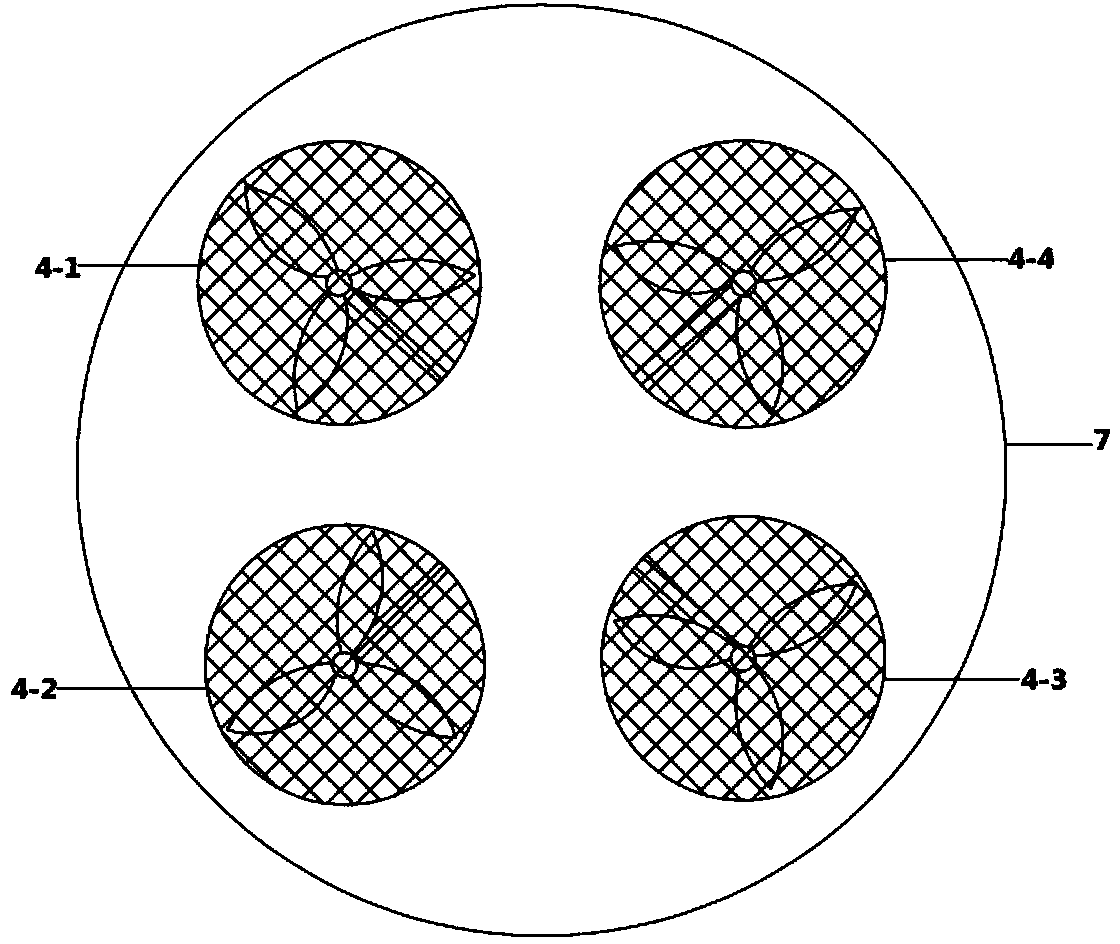

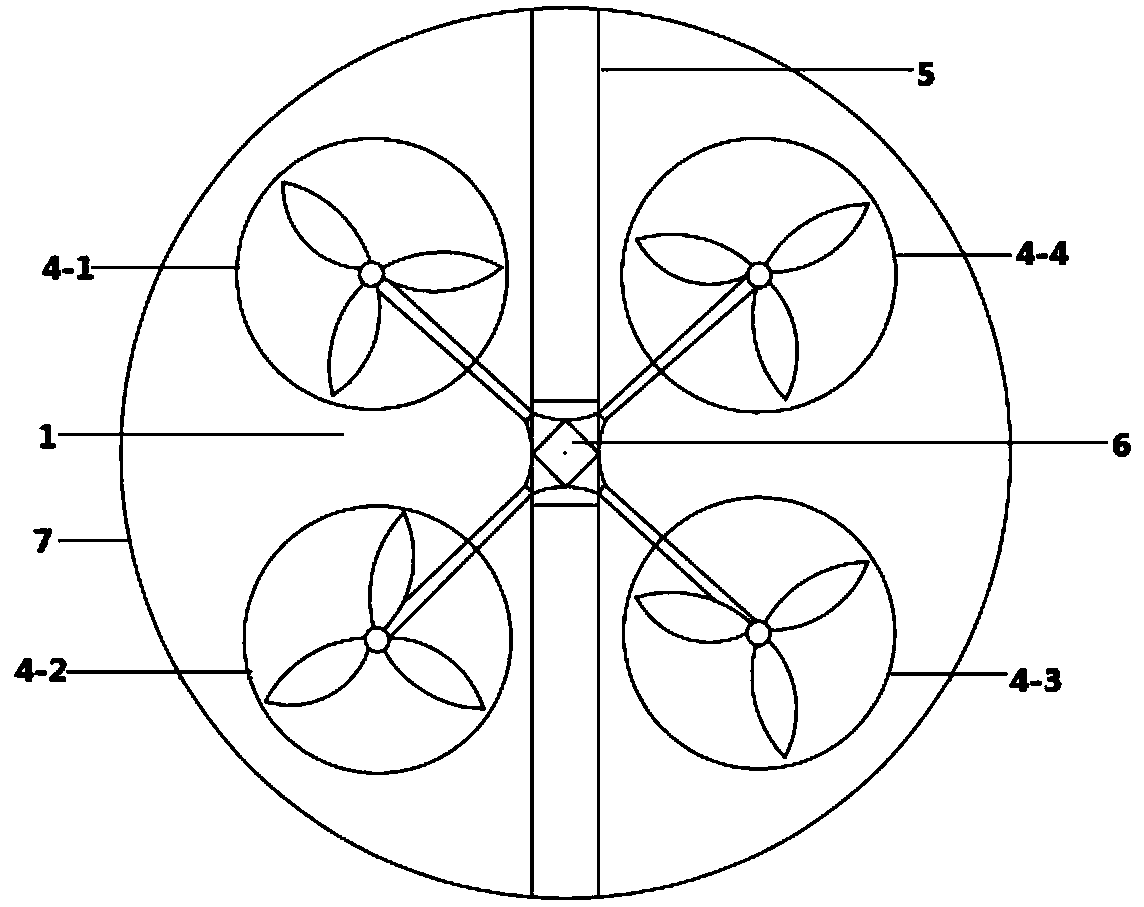

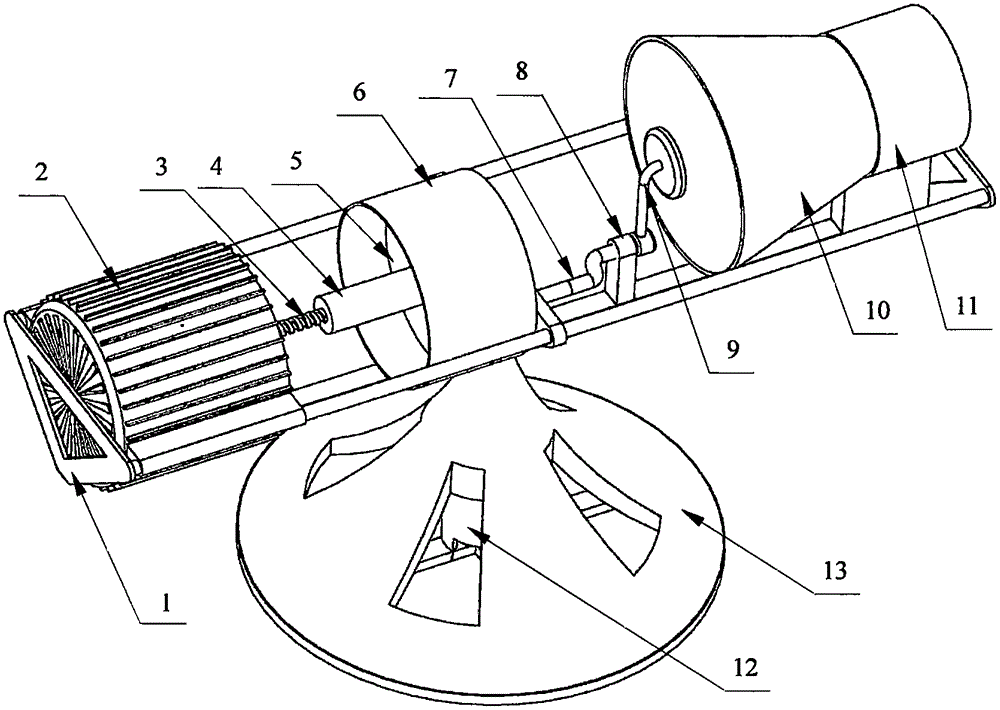

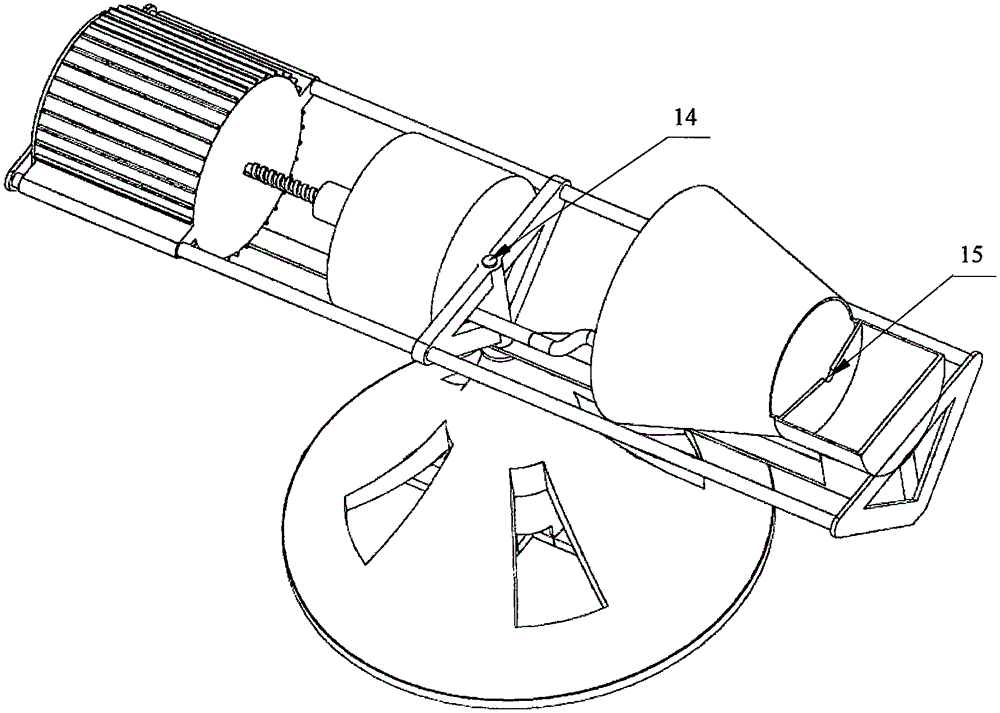

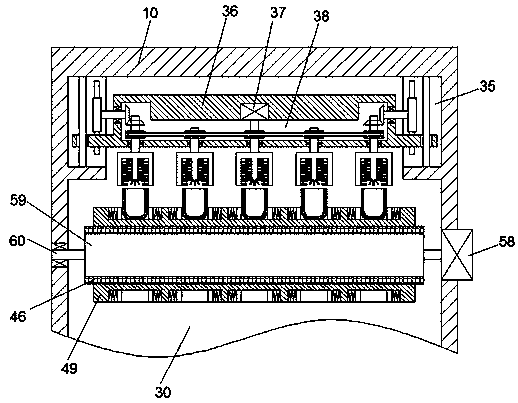

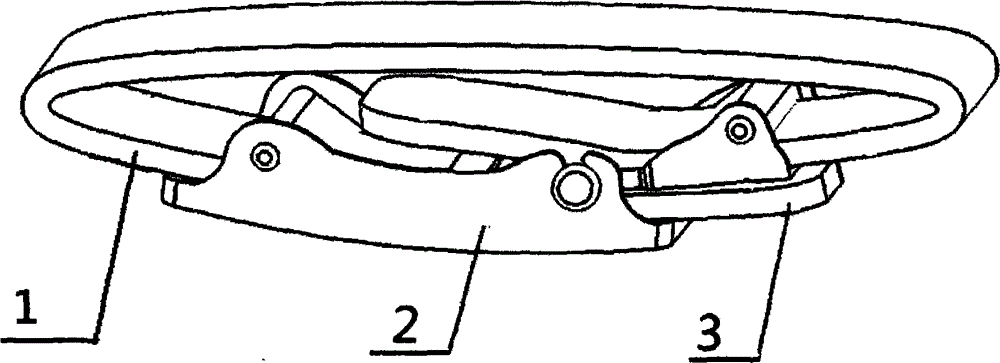

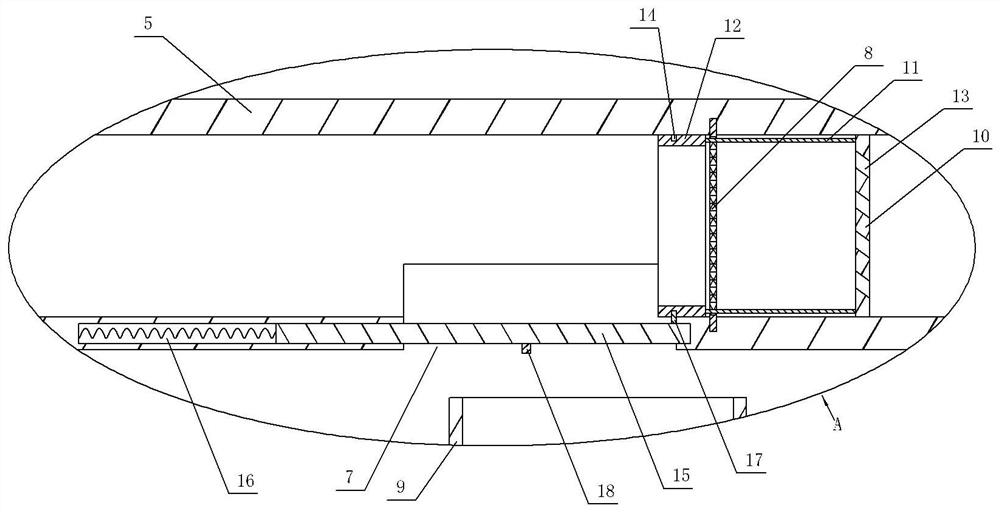

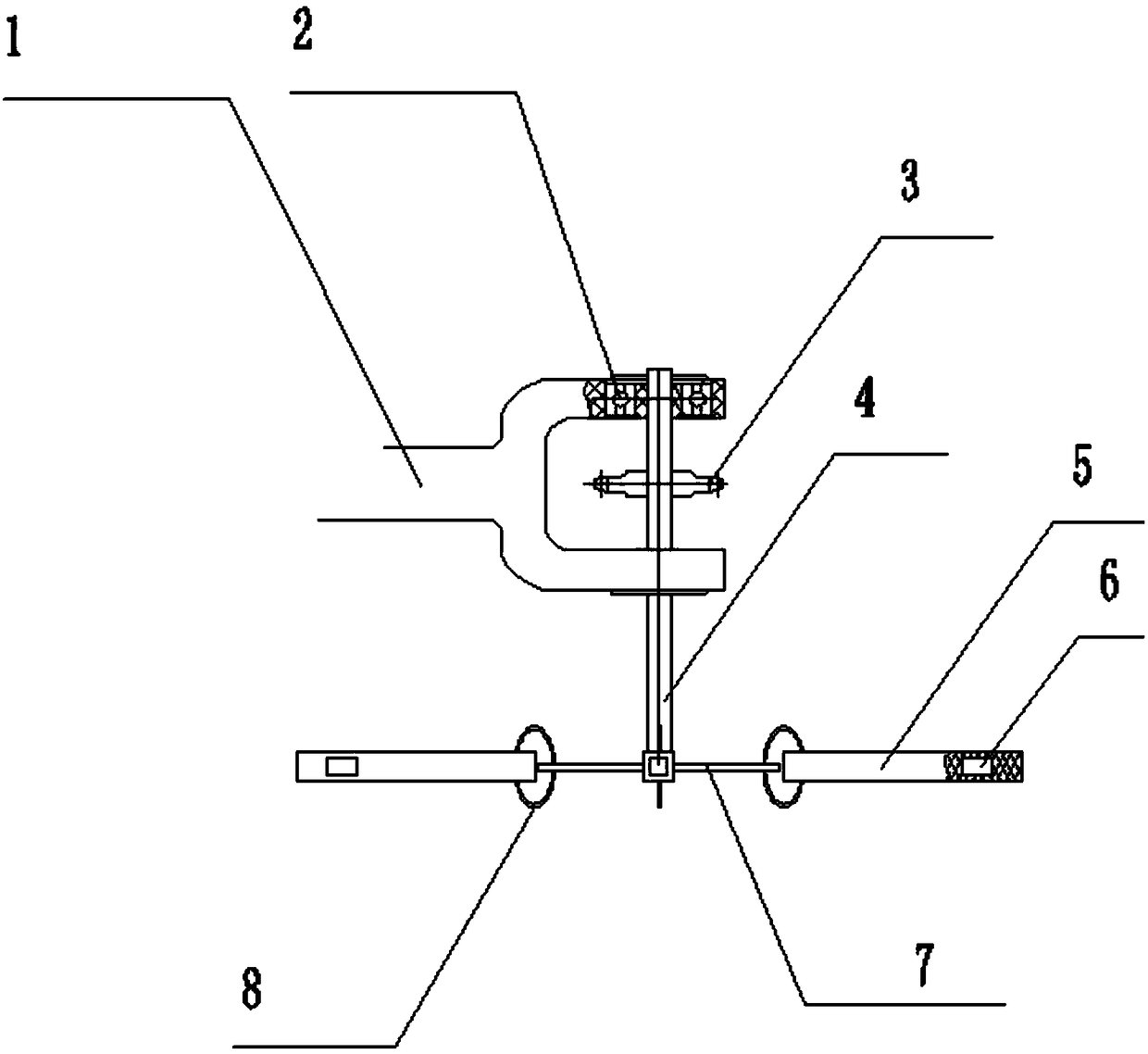

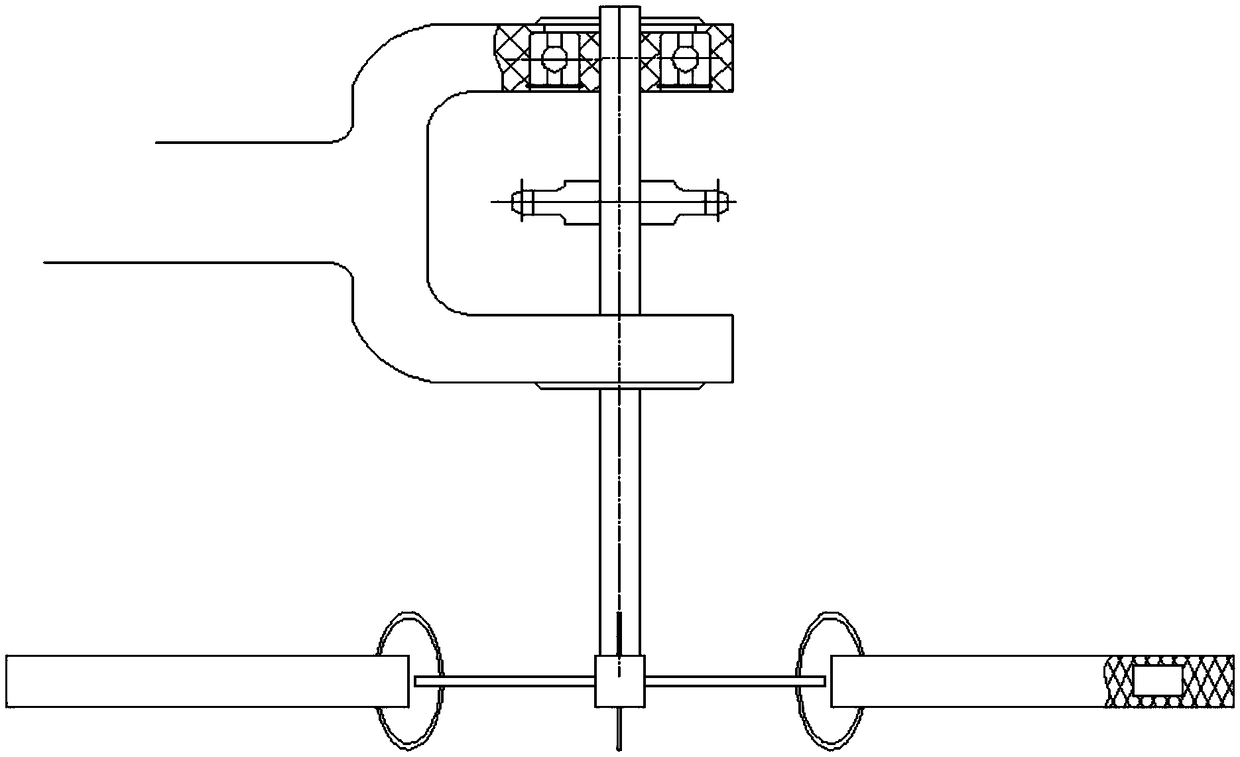

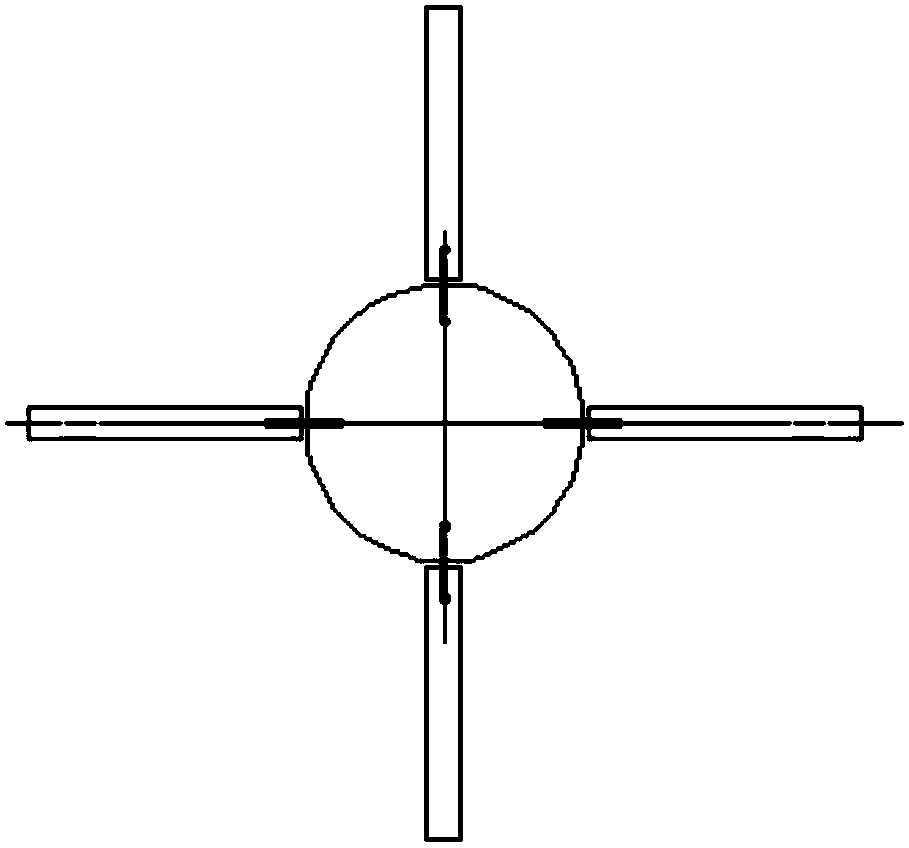

Multi-rotor wing robot in liquid medium

ActiveCN103847939ARealize automatic control flightLow movement resistanceUnderwater vesselsUnderwater equipmentLiquid mediumRemote control

The invention provides a multi-rotor wing robot in a liquid medium. The multi-rotor wing robot comprises a streamline closed shell, an N-rotor wing body, a control unit, N cylindrical seal covers, an automatic floating device, a remote control system, a sensory perceptual system and a man-machine interactive system, wherein the N cylindrical seal covers penetrate through the closed shell from top to bottom, and are uniformly and symmetrically distributed; a plurality of rotor wings of the multi-rotor wing body are respectively positioned inside the N seal covers, and rotary surfaces of the N rotor wings are positioned on the same plane; the control unit is used for controlling the motion of the multi-rotor wing robot. The multi-rotor wing robot solves the problem that the robot in the liquid medium is single in posture and inflexible during motion in the prior art, and can automatically float in emergency circumstances such as power failure or power shortage.

Owner:南京赫曼机器人自动化有限公司

Electrolysis method of polymetallic blister copper

InactiveCN101392388AAutomatic fall offOvercoming anode passivationPhotography auxillary processesProcess efficiency improvementSludgeCupric nitrate

The invention provides an electrolytic method of polymetallic raw copper. The method takes raw copper as an anode, a copper plate or stainless steel as a cathode and carries out electrolysis under the process conditions as follows: (1) the electrolytic solution contains 10g / l to 30g / l of nitric acid, 15g / l to 180g / l of cupric nitrate and the residual quantity of water, which form a cupric nitrate- nitric acid system which keeps the components of the electrolytic solution in the concentration range of the system during the electrolytic process; (2) salt chloride is added into the electrolytic solution and during the electrolytic process, the concentration of the chloride ion is kept between 1 to 10g / l; and (3) cathode current density 100A / m<2> to 300A / m<2>. During the electrolytic process, the method can loosen the anode sludge to cause the anode sludge to fall off automatically, thus overcoming the anodic passivity and the electrolytic process can be conducted smoothly. The method also has the advantages of lowering the cost for separating copper and other metal, shortening the production cycle and reducing environment pollution.

Owner:SIHUI CITY HONGMING PRECIOUS METALS +1

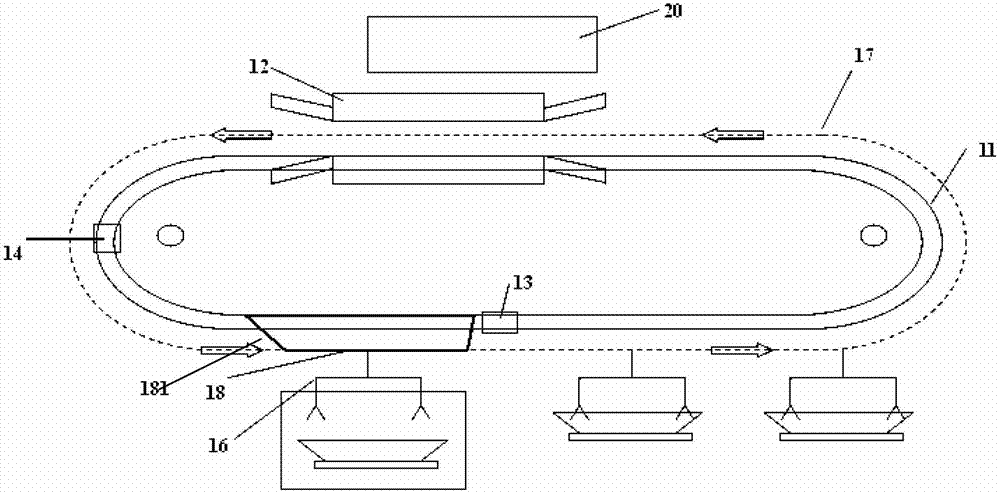

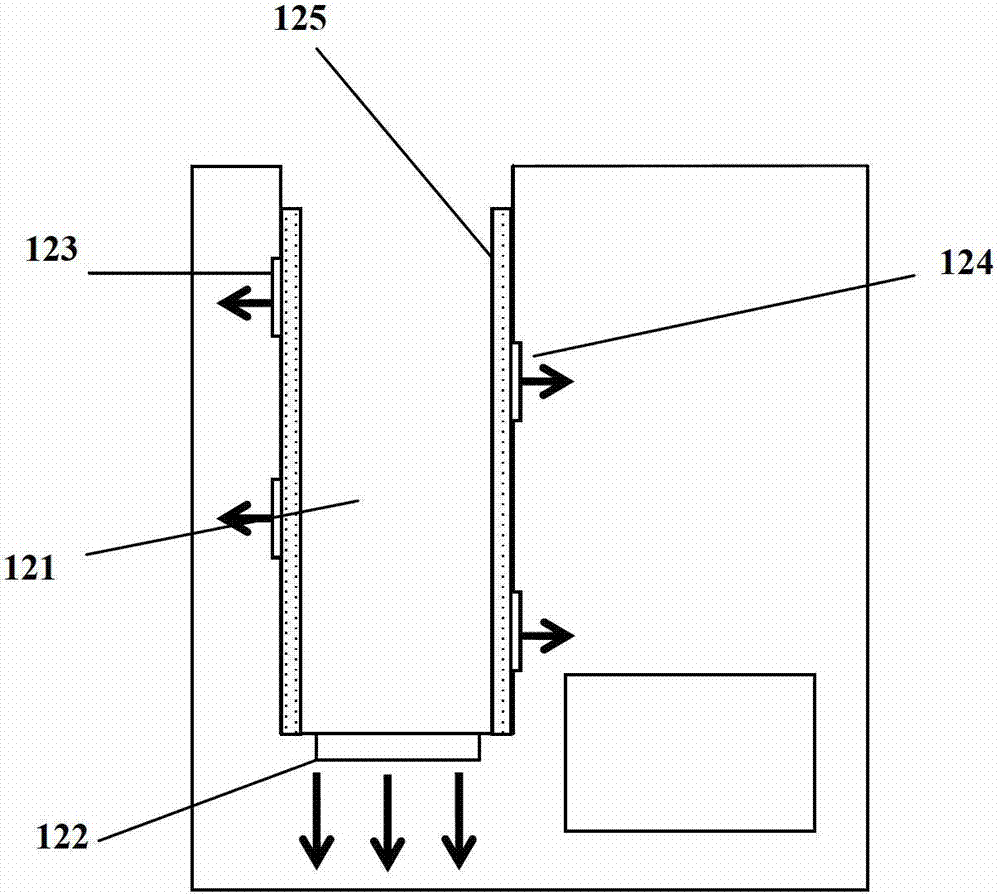

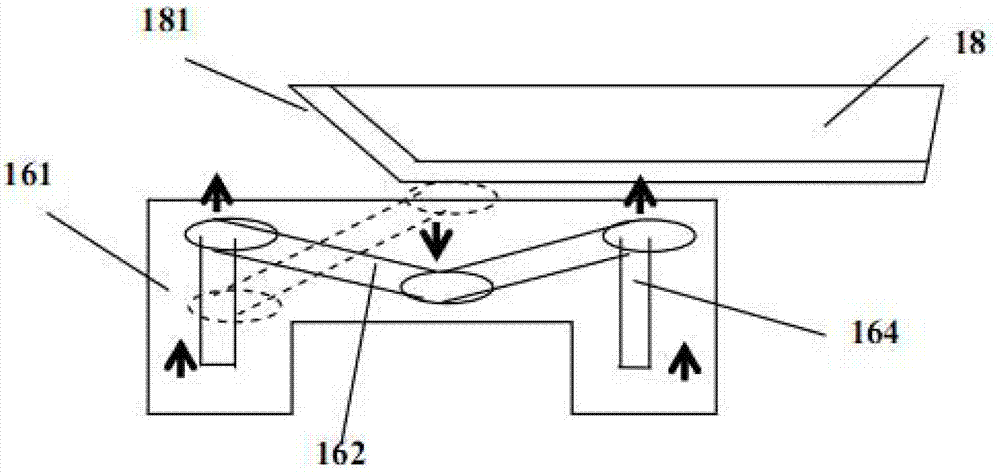

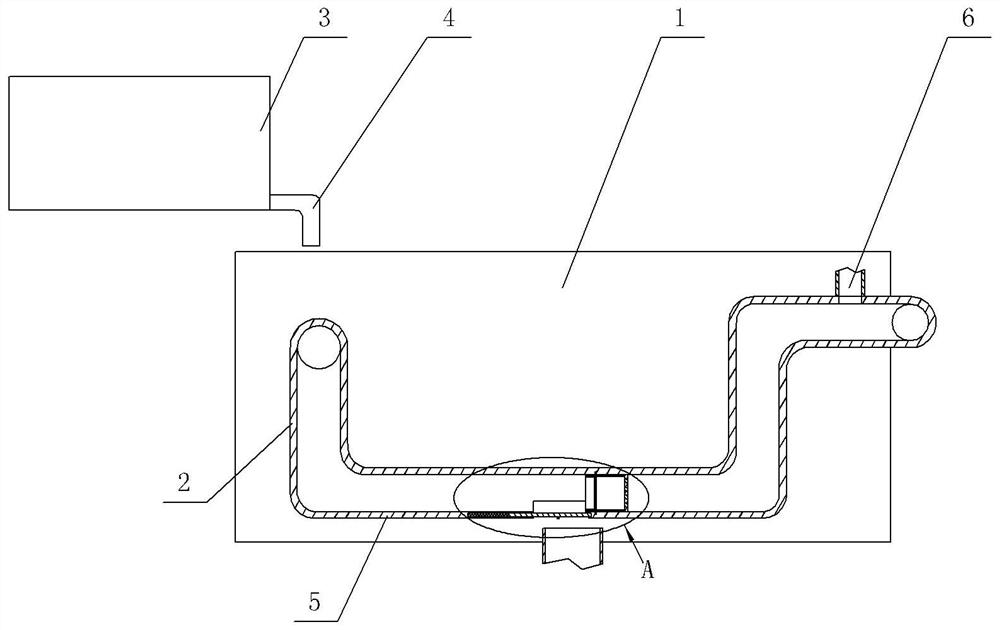

Tail processing device for garment manufacturing and processing method thereof

The invention discloses a tail processing device for garment manufacturing and a processing method thereof. The tail processing device comprises a rail and a rail power device, a thread end sucking machine, piecework sensors, a hanger and a control device, wherein the hanger is fixed on the rail; the thread head sucking machine is arranged below the rail; the piecework sensors are fixed at the periphery of the rail; the rail power device, the thread head sucking machine and the piecework sensors are all connected with the control device; and the rail power device drives the rail to rotate, and synchronously drives the hanger thereon to pass through the thread end sucking machine and the piecework sensors. According to the tail processing device for garment manufacturing and the processing method thereof, the thread end sucking machine and the piecework sensors are arranged at the periphery of the rail, so that garment is hung on the rail and circularly rotates along with the rail; when the garment passes through the thread end sucking machine, thread ends on the garment are sucked by the thread end sucking machine, and the piecework is performed by the piecework sensors, thereby achieving the automation of tail processing during garment manufacturing.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

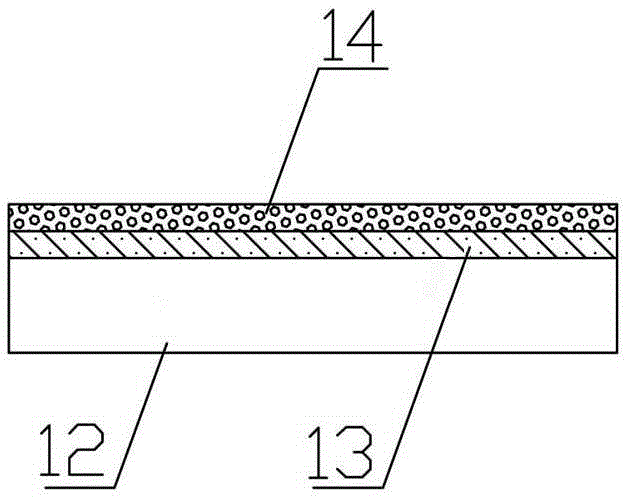

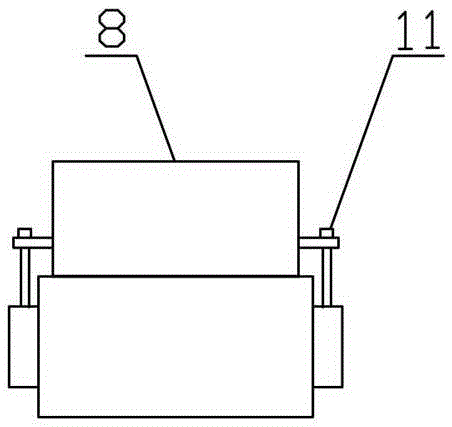

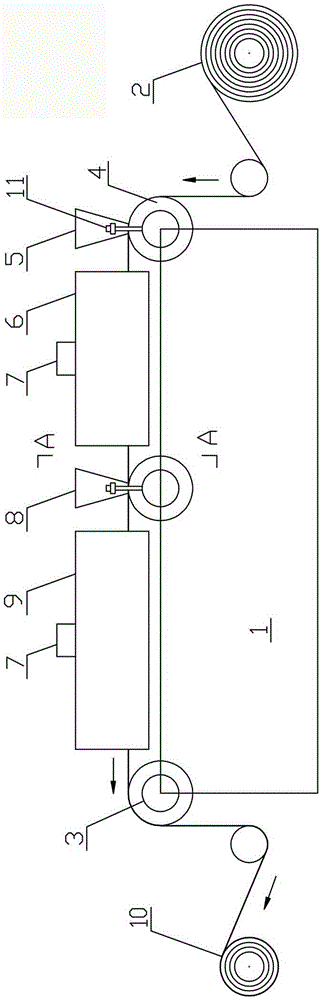

Thermal-expansion strippable pressure-sensitive adhesive sheet and coater

ActiveCN105400443ASolve tangentialSolve the deformationLiquid surface applicatorsFilm/foil adhesivesCross-linkMicrosphere

The invention relates to a thermal-expansion strippable pressure-sensitive adhesive sheet and a coater, and belongs to the technical field of manufacturing of electronic components. The thermal-expansion strippable pressure-sensitive adhesive sheet comprises an adhesive layer and a foamed layer which are coated on a PET film substrate, the adhesive layer comprises, by weight, 50-100 parts of polyurethane resin, 1-30 parts of a polyisocyanate cross-linking agent and 10-50 parts of ethyl acetate and is dried at 60-120DEG C, and the thickness of the dried adhesive layer is 10-30[mu]m; and the foamed layer comprises, by weight, 50-100 parts of polybutyl methacrylate or polymethyl methacrylate, 100-500 parts of organic ultrafine powder, 10-20 parts of dicapryl phthalate, 100-500 parts of ethyl acetate and 10-50 parts of expanded microspheres, the adhesive layer is coated with the foamed layer, the foamed layer is dried at 40-80DEG C, and the thickness of the dried foamed layer is 20-30[mu]m. The adhesive layer and the foamed layer become dry adhesives from non-setting adhesives, so the problems of adhesion, offset cutting and deformation of chips are solved. The coater has the advantages of flattened and uniform coating, uniform drying, and consistent thickness.

Owner:肇庆森荣地新材料科技有限公司

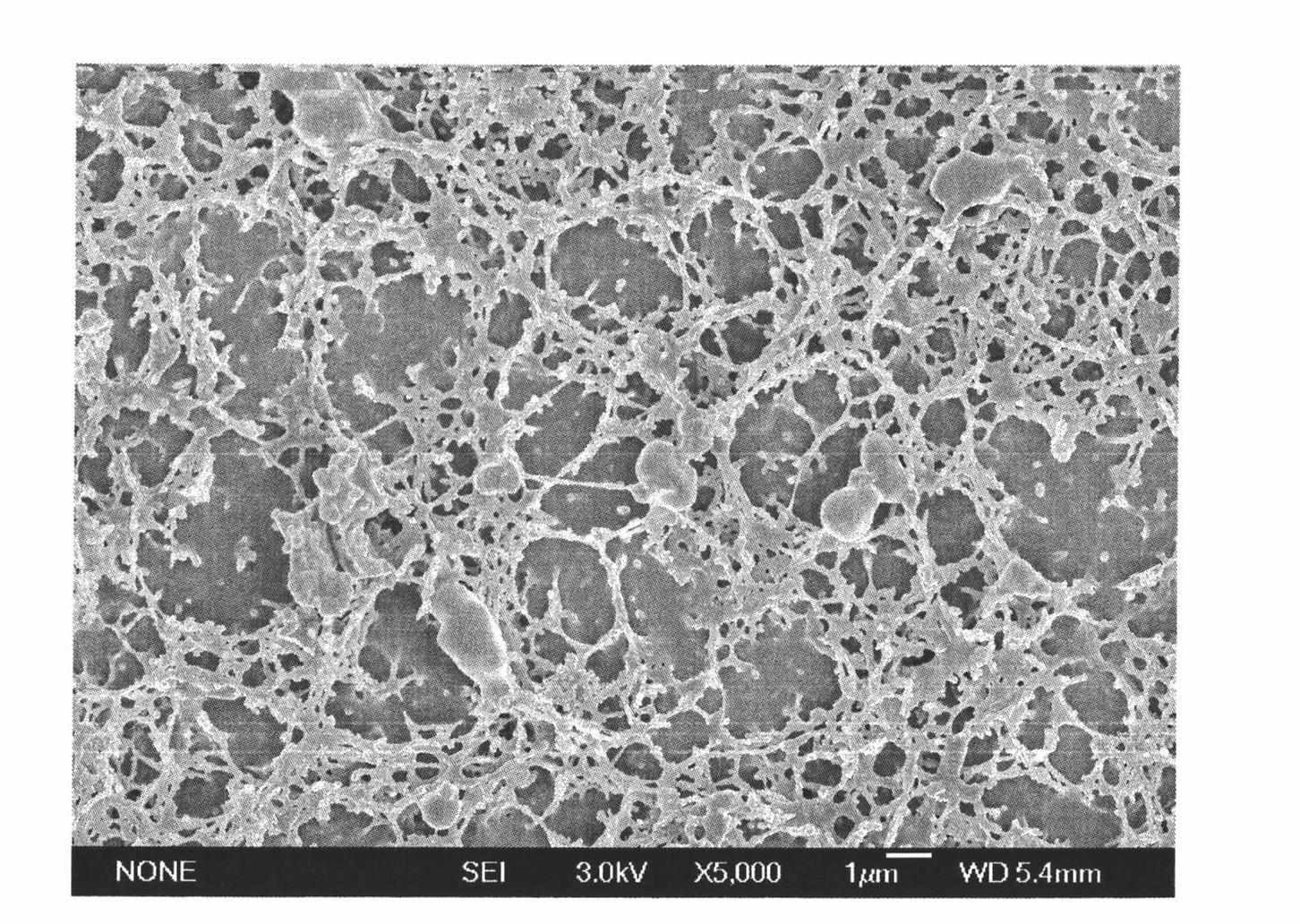

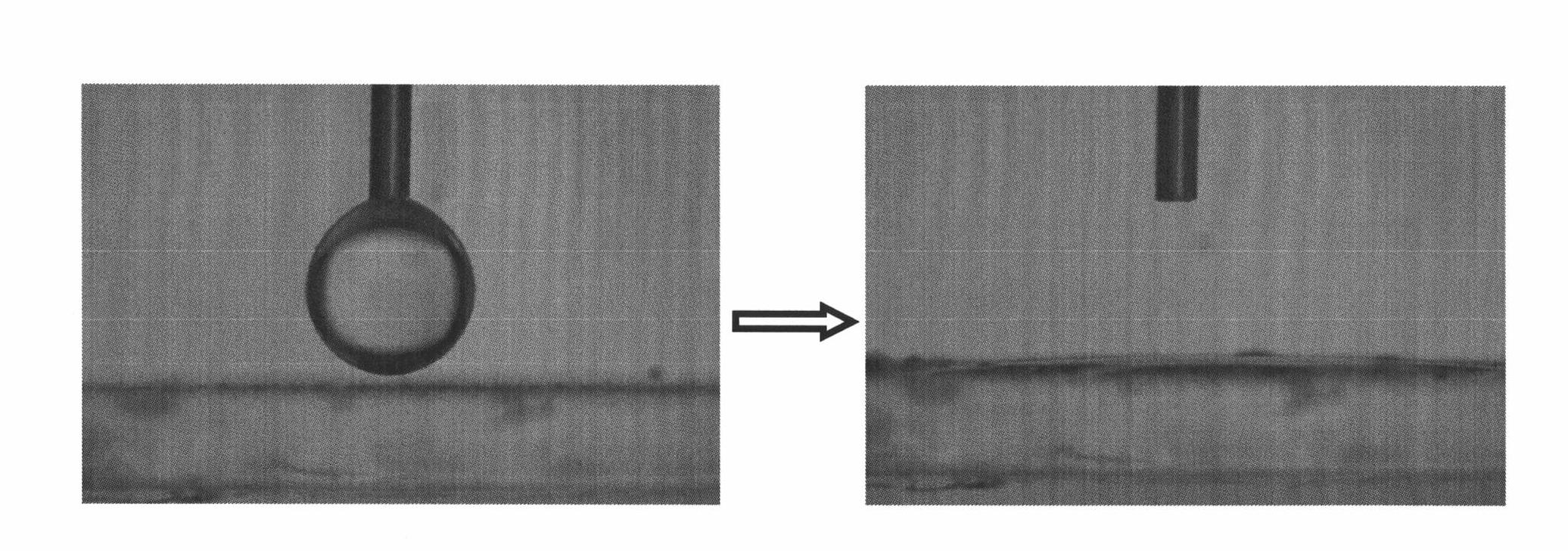

Underwater oil droplet collection material and method for preparing same

InactiveCN102029080AAutomatic fall offNovel surface wettabilityLiquid separationFiberNetwork structure

The invention belongs to the field of the oil absorption material and particularly relates to an underwater oil droplet collection material and a method for preparing the same. Fluorine-containing organic trichlorosilane monomers and a small quantity of water are used as raw materials, and the fluorine-containing organic trichlorosilane monomers are grafted and subjected to hydrolysis and condensation reaction on the surface of a substrate so that the surface in the micron-particle and nano-fiber interlaced three-dimensional network structure is prepared at normal temperature in one step. Underwater oil droplets spread on the surface of the underwater oil droplet collection material so that a stable oil film is formed on the surface of the underwater oil droplet collection material and oil droplets are collected. The method for preparing the underwater oil droplet collection material adopts simple equipment, has low cost, can not cause pollution to environment and can be used for rapidly preparing the underwater oil droplet collection material in a larger area at normal temperature in one step. The prepared functional film has good oil droplet collection function, and the underwater oil droplet collection material can be used repeatedly.

Owner:DALIAN MARITIME UNIVERSITY

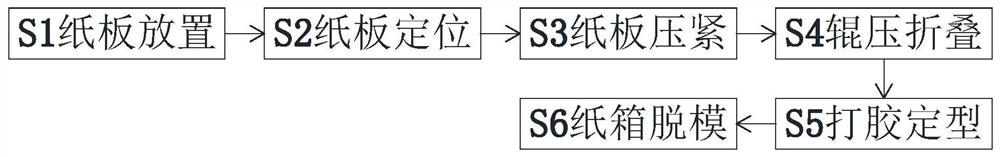

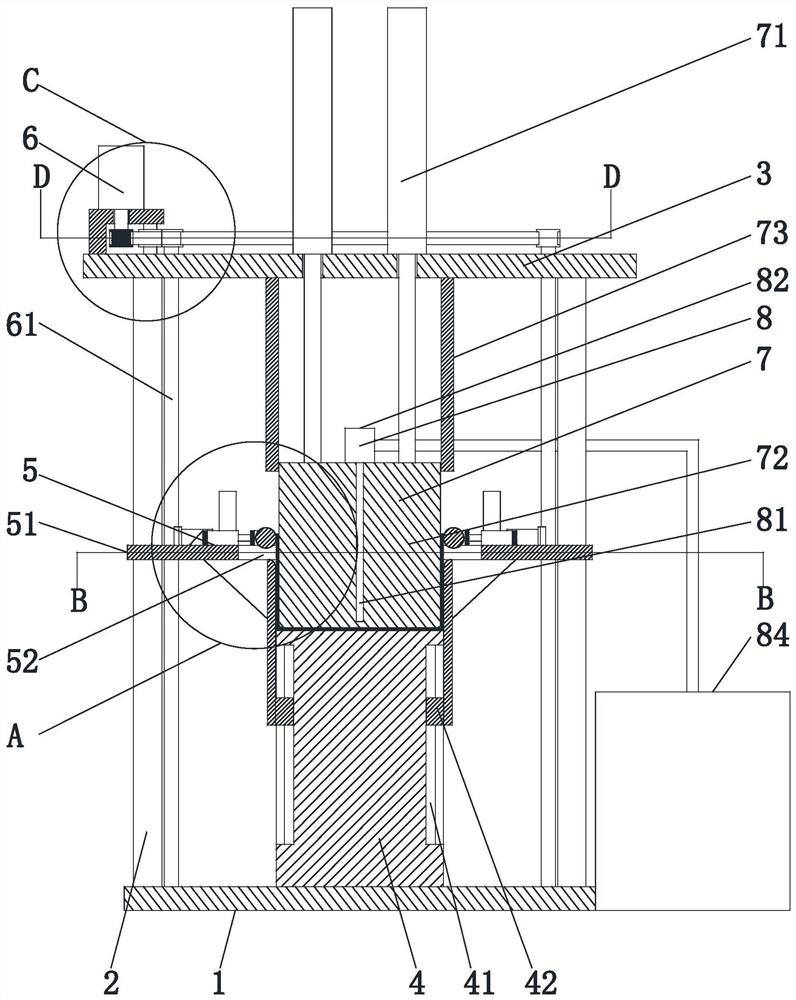

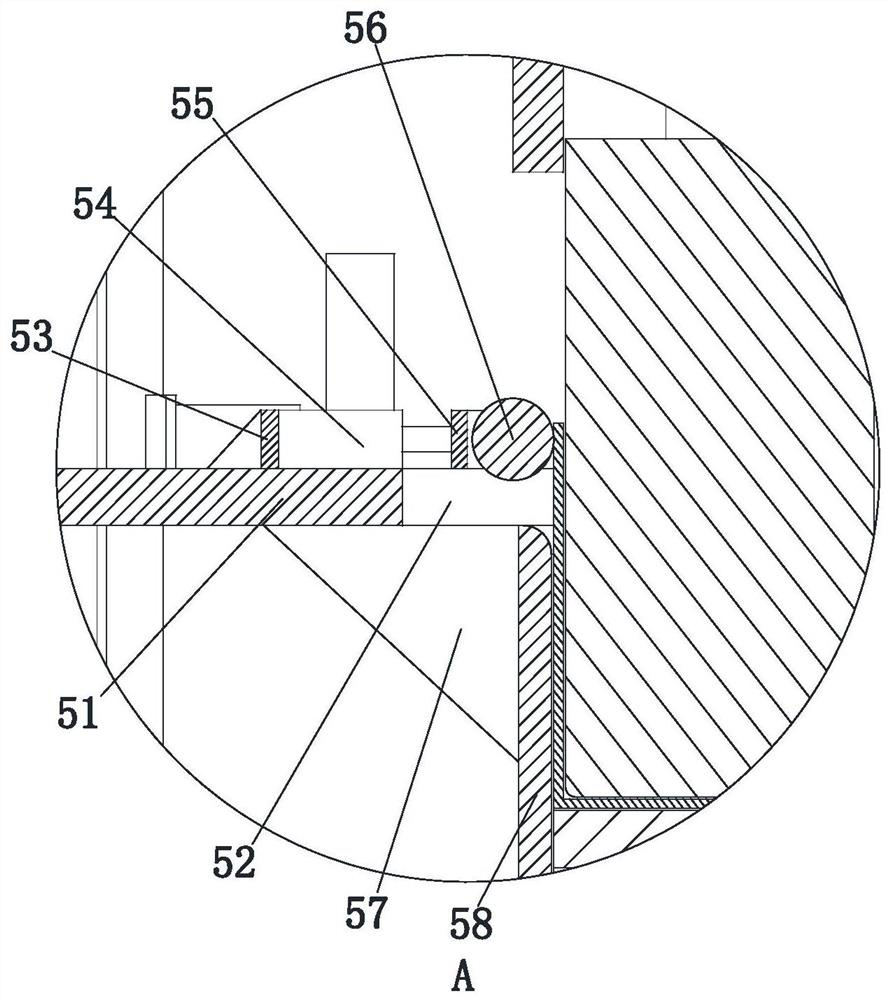

Logistics packaging box manufacturing method

InactiveCN112677550ANo accidental deformationFold validPaper-makingBox making operationsLogistics managementCarton

Owner:高鑫宇

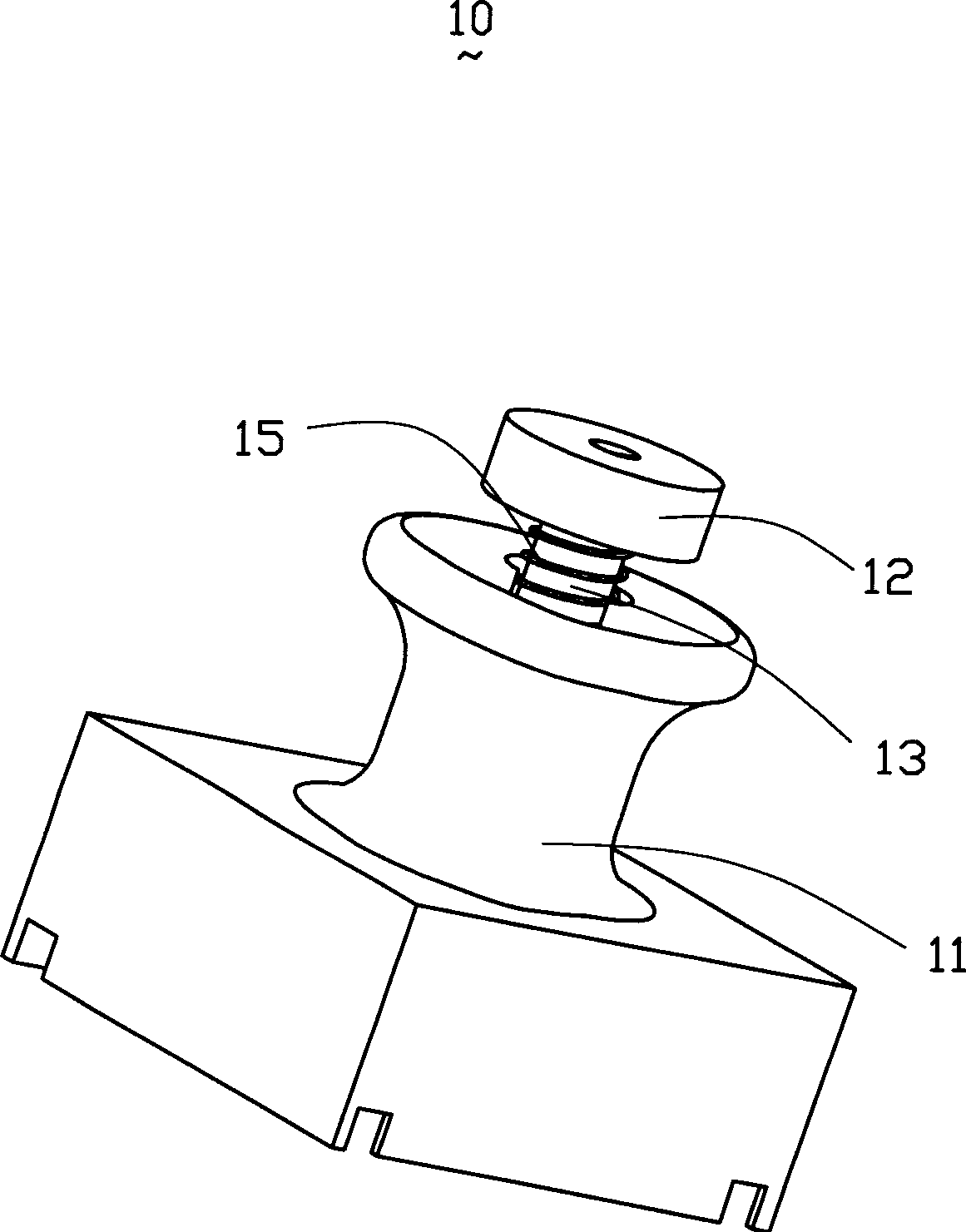

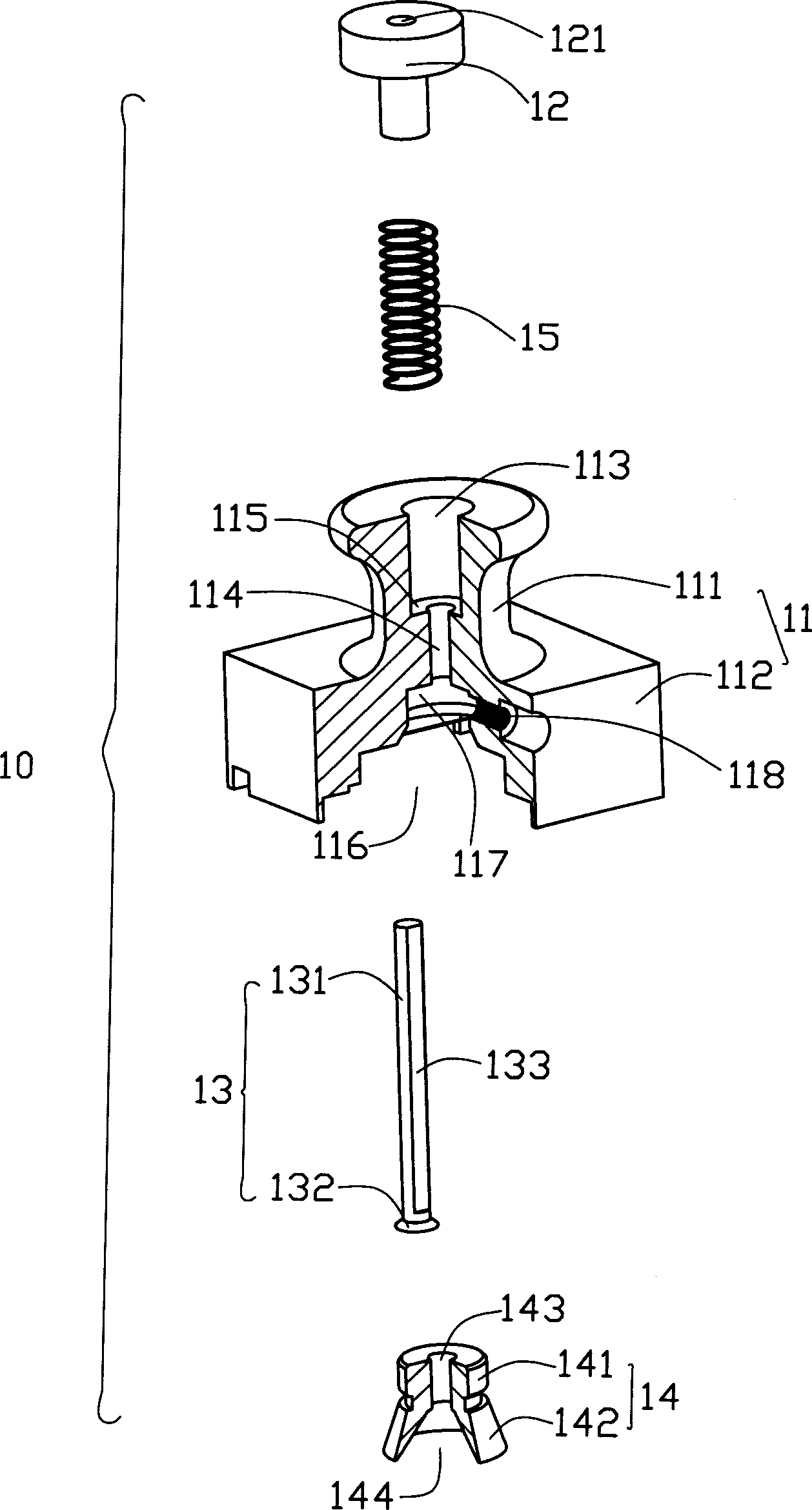

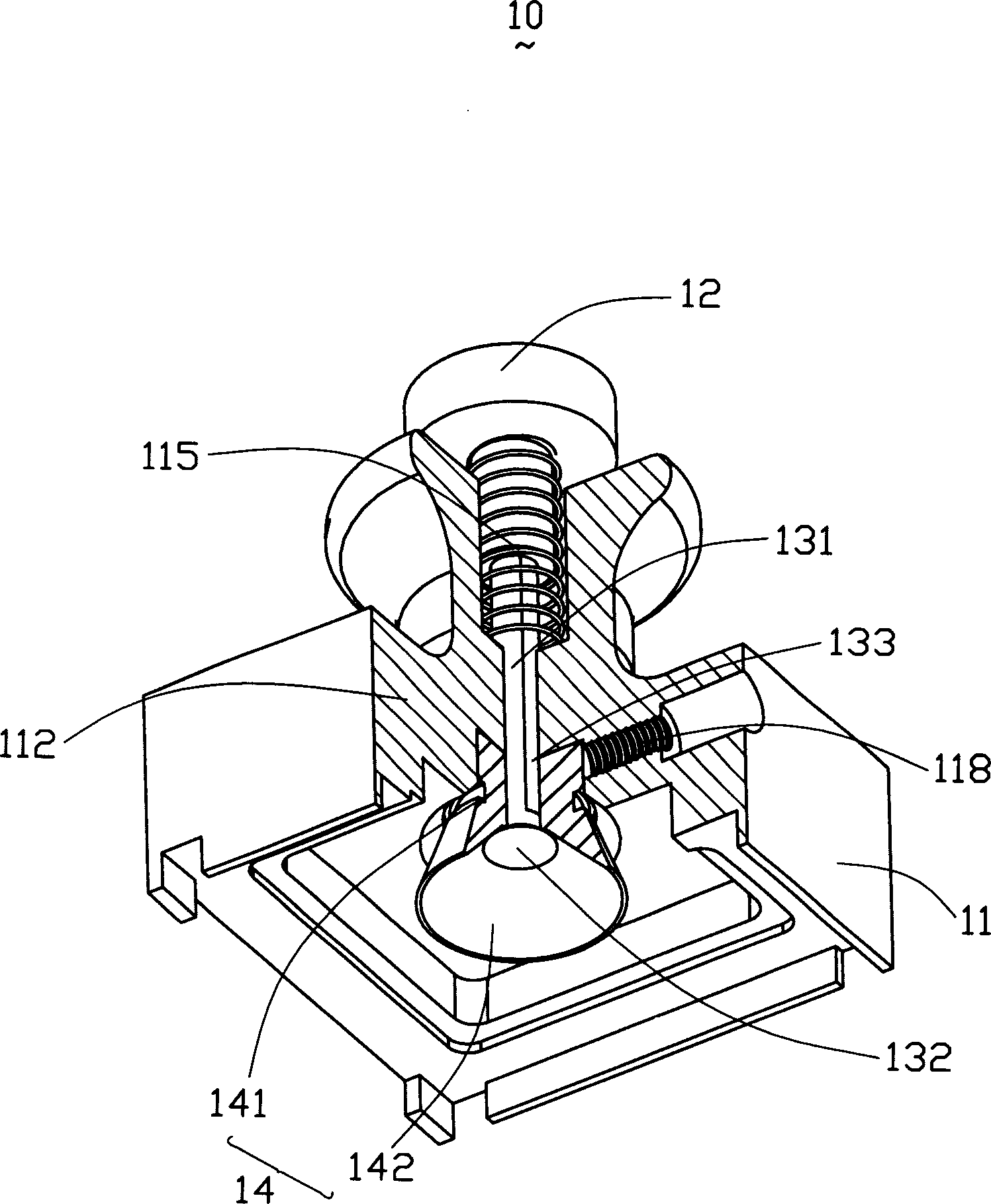

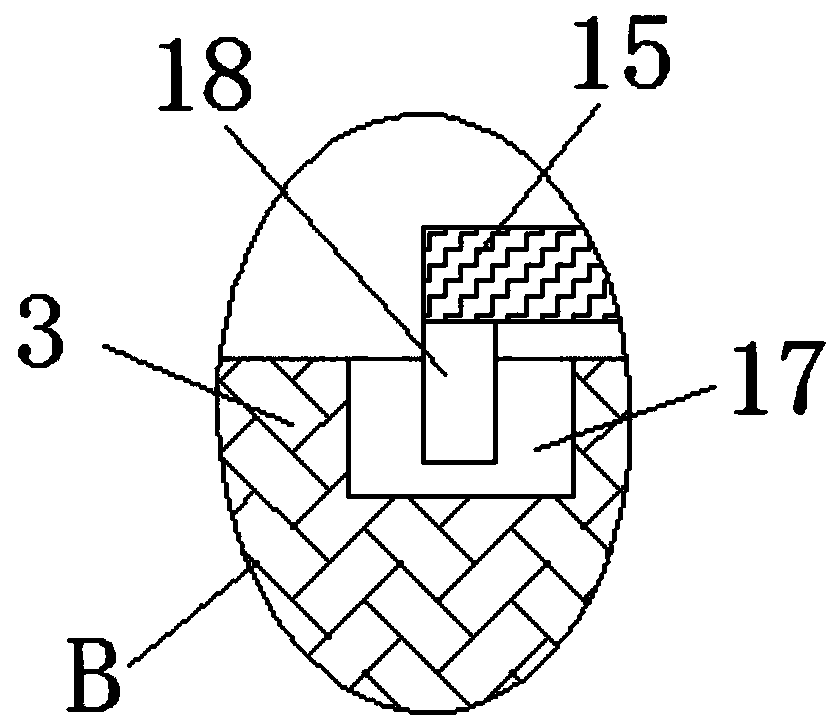

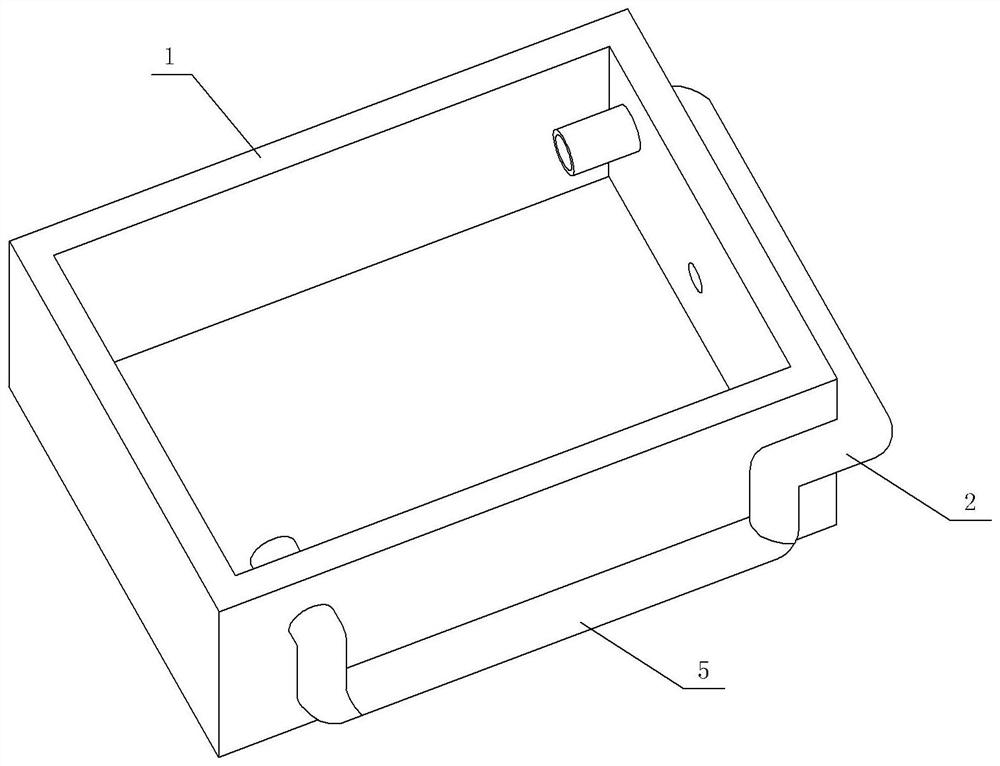

IC loading and unloading clamp and its using method

InactiveCN1790647AAvoid wear and tearAutomatic fall offSemiconductor/solid-state device manufacturingWork holdersForming gasEngineering

The invention relates to a assembly and unassembly clamp for IC, which comprises: a shell, a push part, a connecting rod with head end connected to push part and tail end with same shape as seal part of piton and propped to the seal part, and a seal piton with a hold part fixed in shell and a shape-instable seal part extended from hold part to form gas cavity; wherein, on normal condition, the tail end of connecting rod props to seal part and separates the hold and seal parts of piton. The usage of the clamp comprises, assembly: sticking the seal part to IC top surface and extruding to remove some gas and produce adsorption force; convey: moving the IC to objective element; and unload: forcing the push part to make tail end of connecting rod into gas cavity, connecting cavity and outside, and falling the IC automatically.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

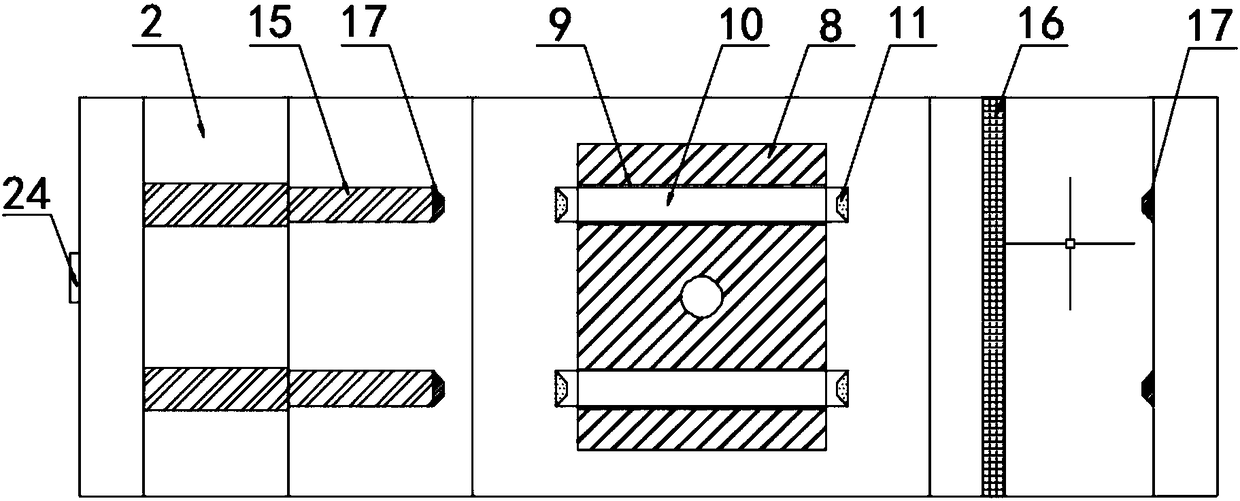

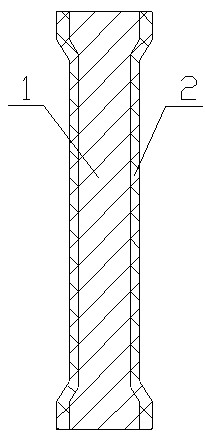

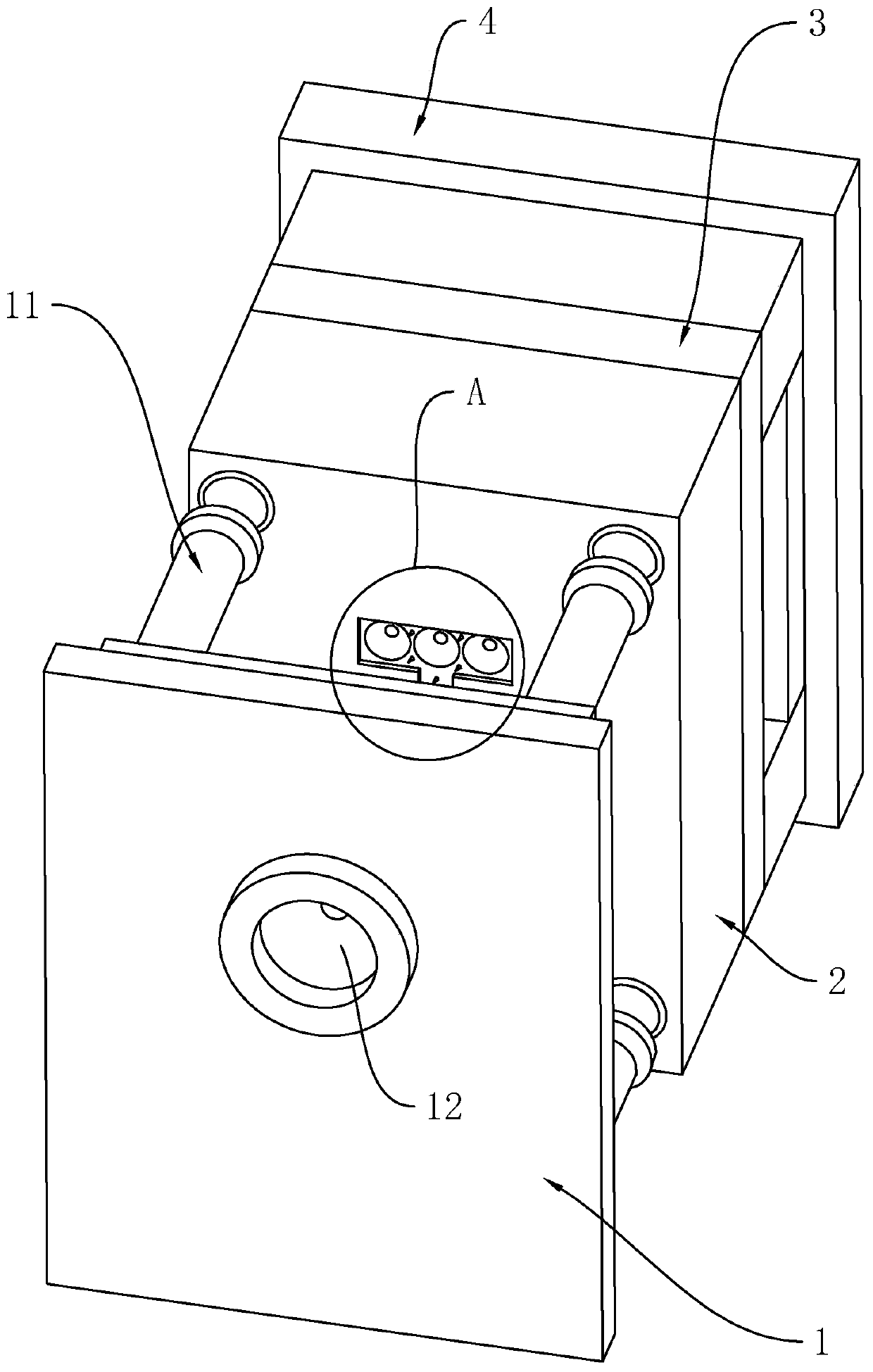

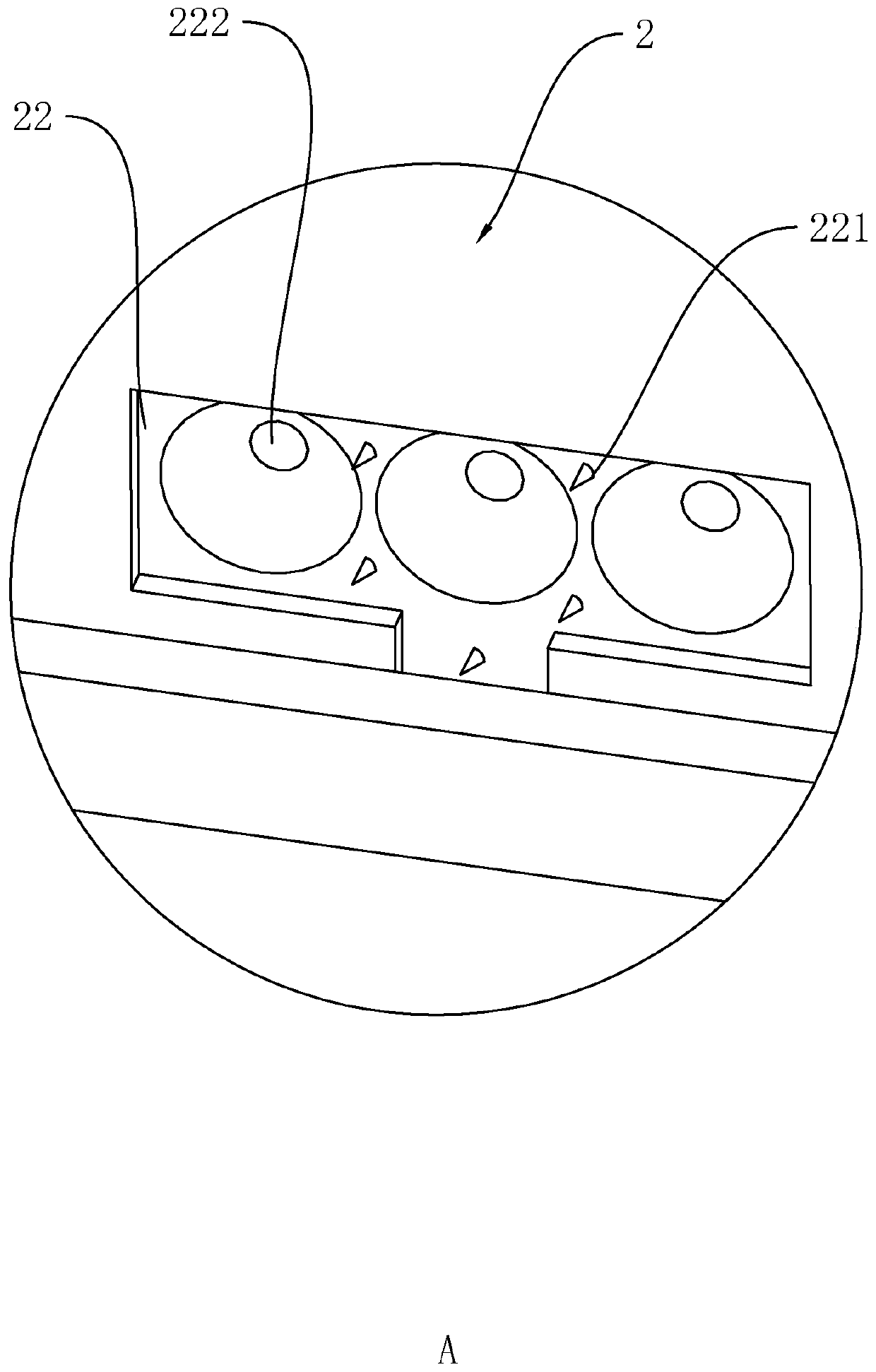

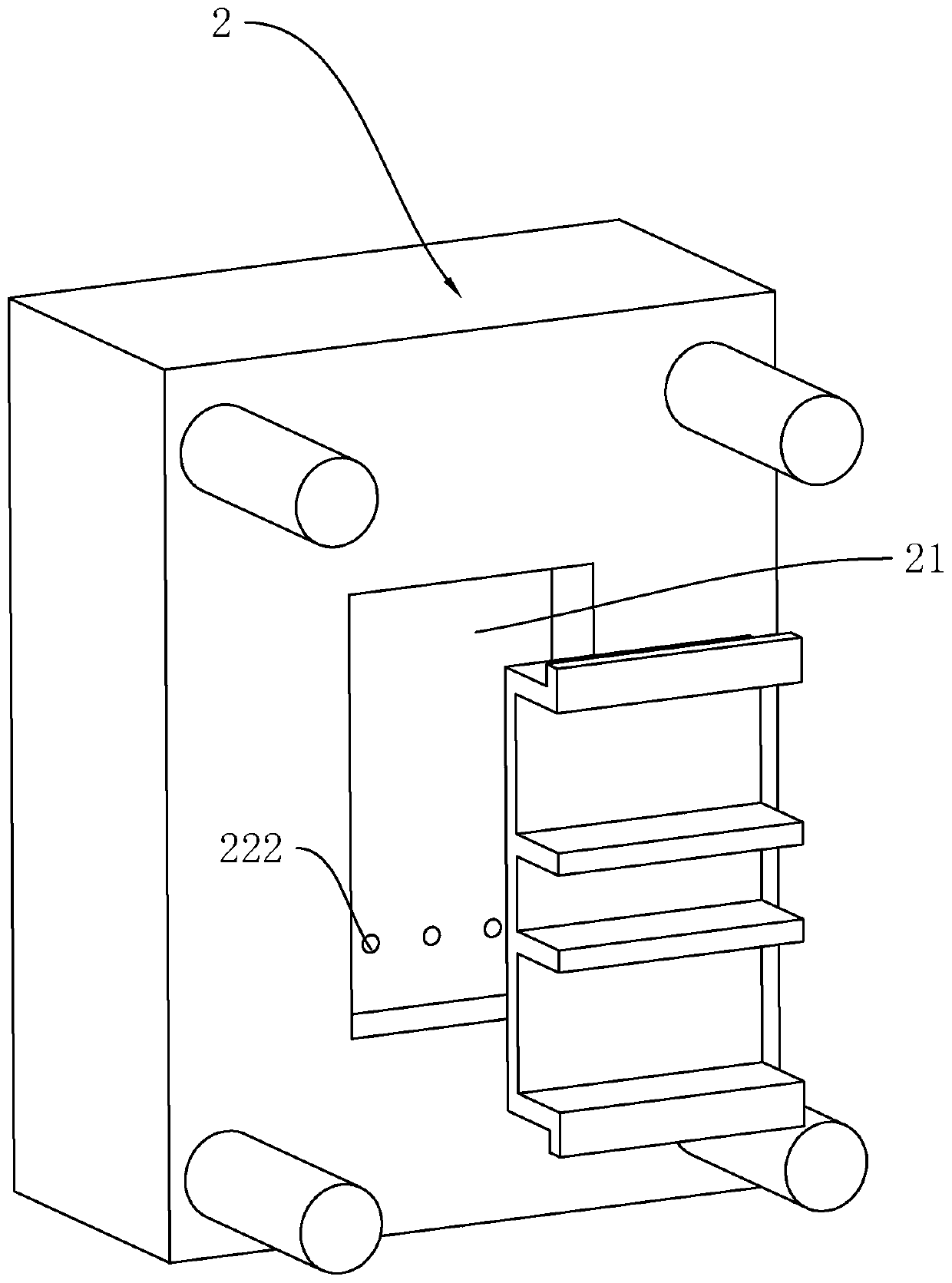

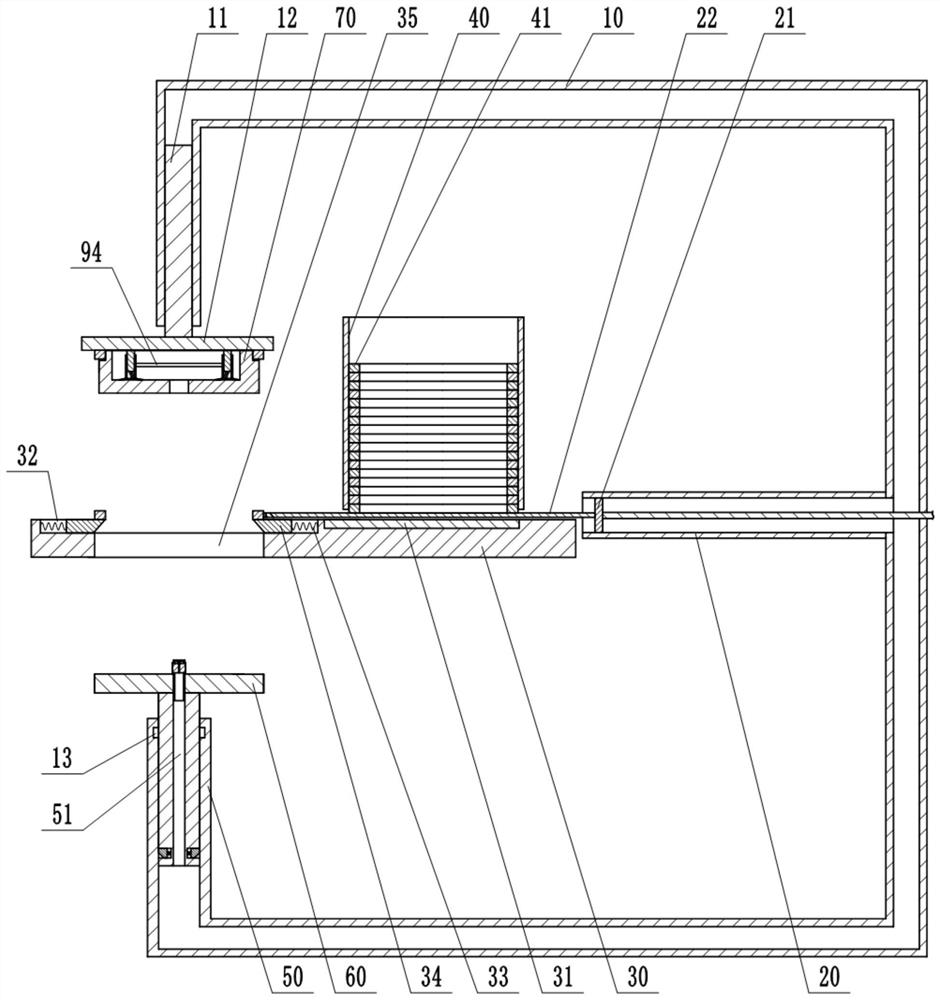

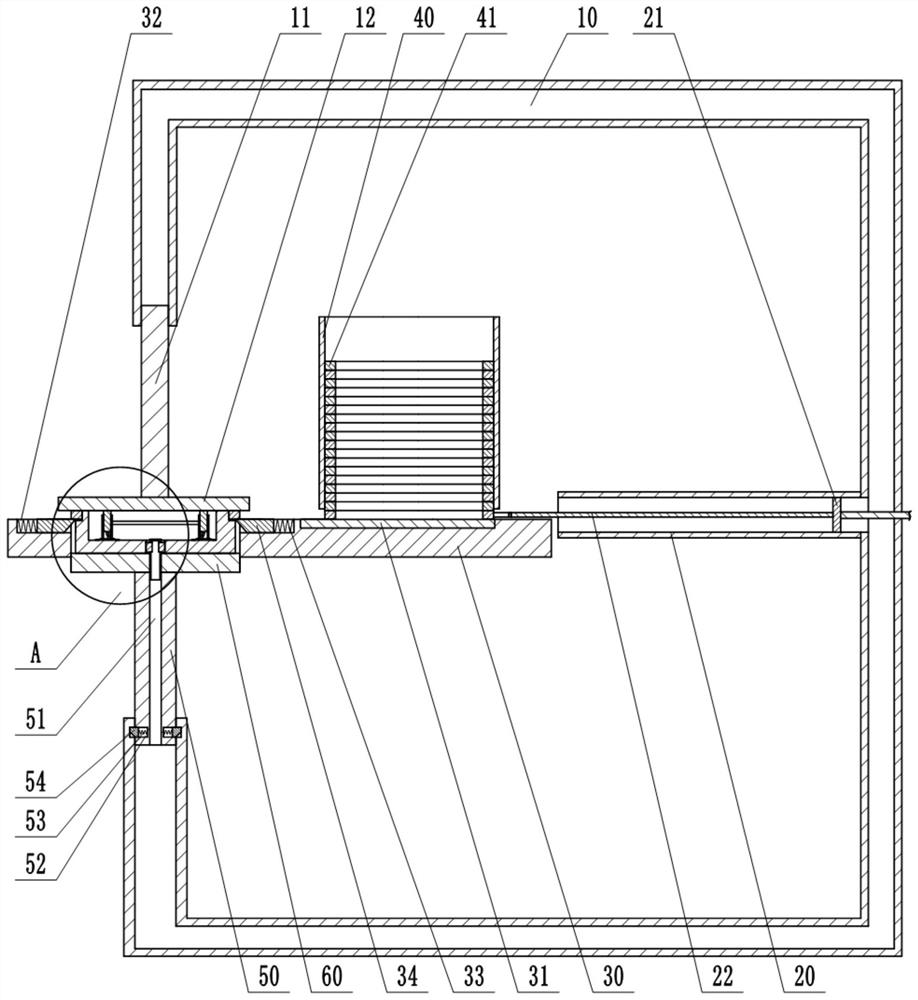

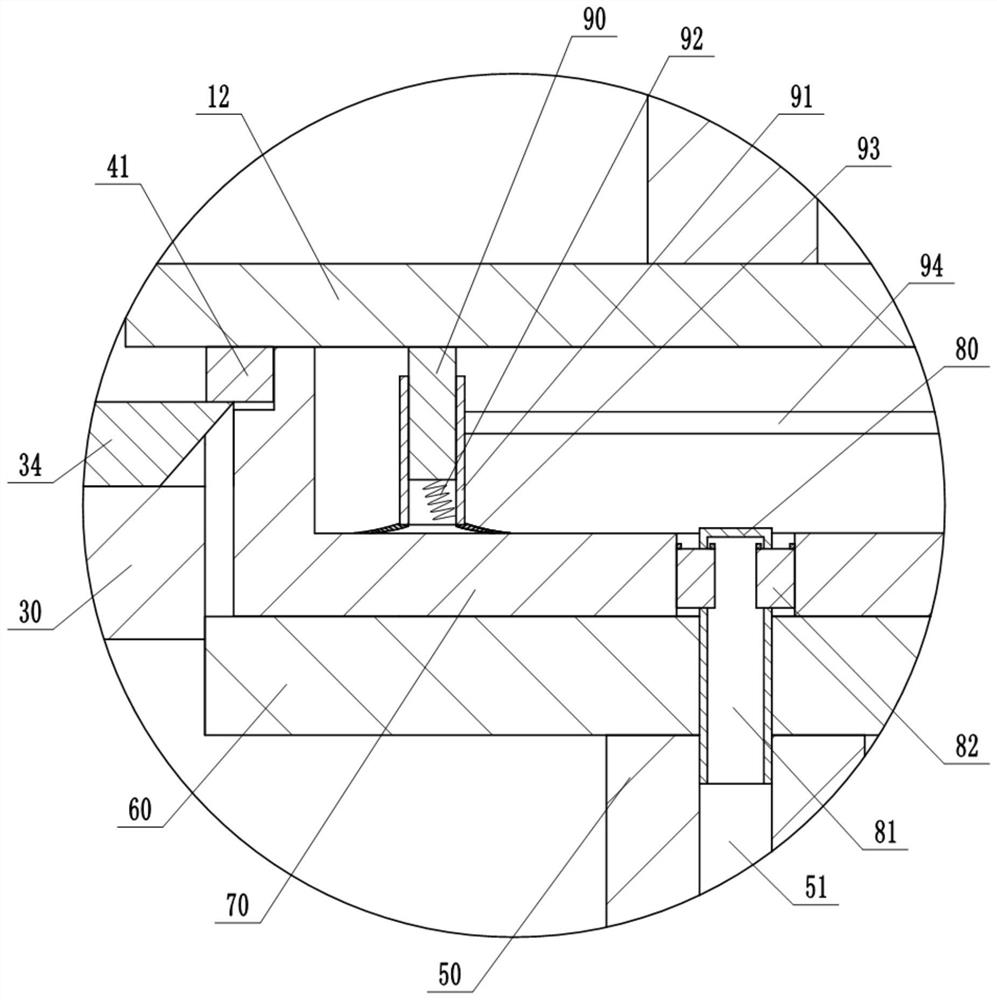

Pin retreating demolding device for compression molding of bamboo-wood integrated material

ActiveCN108340467APrecise positioningAvoid affecting product qualityWood working apparatusFlat articlesCompression moldingHydraulic cylinder

The invention discloses a pin retreating demolding device for compression molding of a bamboo-wood integrated material. The pin retreating demolding device comprises a primary worktable, wherein auxiliary tables are arranged on two sides of the primary worktable; a driving cavity is arranged in the primary worktable; a vacuumizing pump is arranged in the driving cavity; a movable plate is arrangedon the top of the vacuumizing pump; limiting columns are movably arranged at four corners of the movable plate in a sleeving manner; the limiting columns are fixedly connected to the primary worktable; a spring is arranged on the outer side of each limiting column in a sleeving manner; a connecting table is arranged on the top of the movable plate; a through slot is formed in the connecting table; a bolt rod is arranged in the through slot; slots are formed in two ends of the bolt rod; and a supporting plate is arranged on the top of the connecting table. A material suction head is prepared from an electromagnet, so that a hydraulic cylinder can push the bolt rod to achieve pin retreating demolding work, and can drive the bolt rod to recover to the original position for next demolding work. The pin retreating demolding device is high in degree of automation, the bolt rod needs not to be manually inserted, the whole device is stable and smooth to demold, and a product and a mold are not affected.

Owner:ANHUI SHUCHENG HUAZHU IND

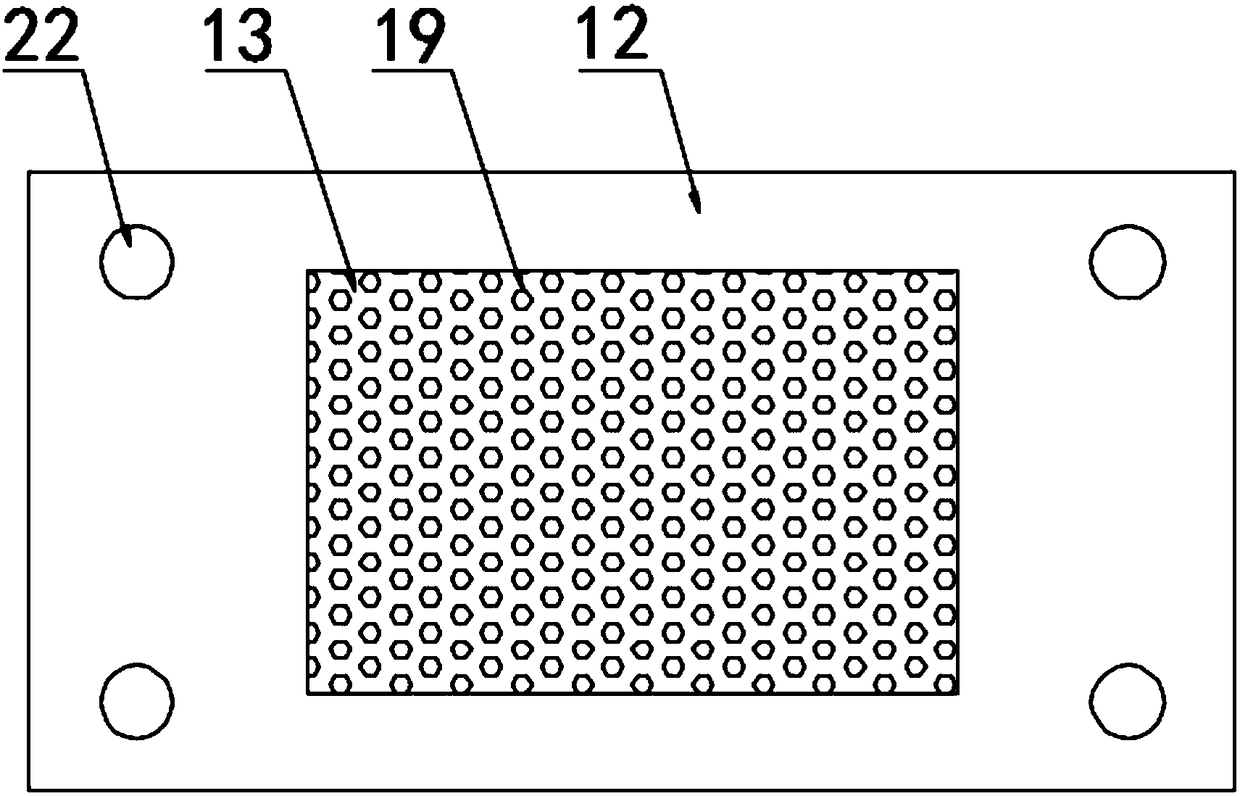

Special nano-filter plate for filter press

InactiveCN102125777AEasy to cleanGood stain resistanceFiltration separationWeather resistanceSurface layer

The invention relates to a special nano-filter plate for a filter press, which has the advantages of ultra-strong dirt resistance, ultra-strong wear resistance, ultra-strong electrostatic resistance and ultra-strong durable efficacy. The special nano-filter plate comprises a filter plate, wherein the surface layer of the filter plate is a nano-layer. The invention has the concrete advantages that: the special nano-filter plate has ultra-strong dirt resistance, has a smooth and exquisite surface, can not adsorb dust and grease dirt easily, is easy to clean and enables the squeezed filter cake to automatically fall off from the surface of the nano-filter plate, and the nano-surface of the special nano-filter plate has good anti-dirt characteristic; the special nano-filter plate has ultra-strong wear resistance, the wear resistance of the surface of the filter plate can be obviously improved, and extruding scratches can not be generated easily; the special nano-filter plate has ultra-strong electrostatic resistance, can effectively eliminate the electrostatic phenomenon, and can not adsorb dust particles easily; the special nano-filter plate has superior acid resistance and alkali resistance and high weather resistance; and the surface of the special nano-filter plate is water-proof, can resist grease dirt, is simple and convenient to clean and is nearly not cleaned with water, thereby greatly saving the water resources.

Owner:HANGZHOU XINGYUAN FILTER TECH

Novel ball picking robot

The invention discloses a novel ball picking robot. The robot comprises a robot body and a collecting box, an installing groove is formed in one side of the robot body, the collecting box is movably installed in the installing groove, and an installing cavity is formed in the robot body; the installing cavity is located below the installing groove, a moving rod is movably installed in the installing cavity, and a first conductive block is fixedly installed at the bottom side of the moving rod; a second conductive block is fixedly installed on the inner wall of the bottom side of the installingcavity, the first conductive block is matched with the second conductive block, two moving holes are formed in the inner wall of the top side of the installing cavity in the vertical direction, and jacking rods are movably installed in the two moving holes. The robot is simple in structure, when the collecting box is full with balls in the ball collecting process, balls can automatically fall from the robot body, the collecting box can timely give an alarm to warm a worker of handling the situation, the training environment of a stadium is ensured, the labor amount of the worker is reduced, and the requirements of people are met.

Owner:丁亦芬

Special shower

A special shower consists of a rotation portion and a fixed portion. The fixed portion comprises a base, an electric motor B and a rotary shaft of the electric motor B. The base is a hollow bucket-shaped body and is thin in upper portion and thick in lower portion. The electric motor B is installed inside the base, the rotary shaft of the electric motor B extends out of the upper portion of the base, and the central axis of the rotary shaft coincides with the symmetrical axis of the base. The rotation portion comprises a rack, an electric motor A, an inner threaded rod, an outer threaded rod, a piston, a bucket, a water outlet pipe, a spray head turning mechanism, a spray head, a showering bucket and a water collecting bucket. The electric motor A is installed at one end of the rack, a shaft of the electric motor A is connected with the inner threaded rod, the inner threaded rod is meshed with one end of the outer threaded rod, the other end of the outer threaded rod is connected with the piston, and the piston is inserted into the bucket and can perform reciprocating motion in the bucket. The open position of the bottom of the bucket is connected with the water outlet pipe, the water outlet pipe is connected with the spray head turning mechanism, and the spray head which can be turned is installed on the spray head turning mechanism. The spray head can be aligned to the showering bucket through turning. The showering bucket is in a shape of a hollow circular truncated cone, the larger bottom face of the circular truncated cone is close to the spray head, and the other bottom face is movably connected with the top of the water collecting bucket. The top of the water collecting bucket is an outer concave circular cone, and a middle opening serves as a water inlet of the water collecting bucket. The special shower has the advantages that an astronaut can have a shower like showering on the earth, and water drops automatically fall from a human body and do not cause choking; water for showering is always flowing water, and dirty water is discharged out in time; the astronaut can have a shower for the whole body rather than head exposure in the outside; a function of spin-drying water left on the body after showering is provided.

Owner:怀远县翰邦科技咨询有限公司

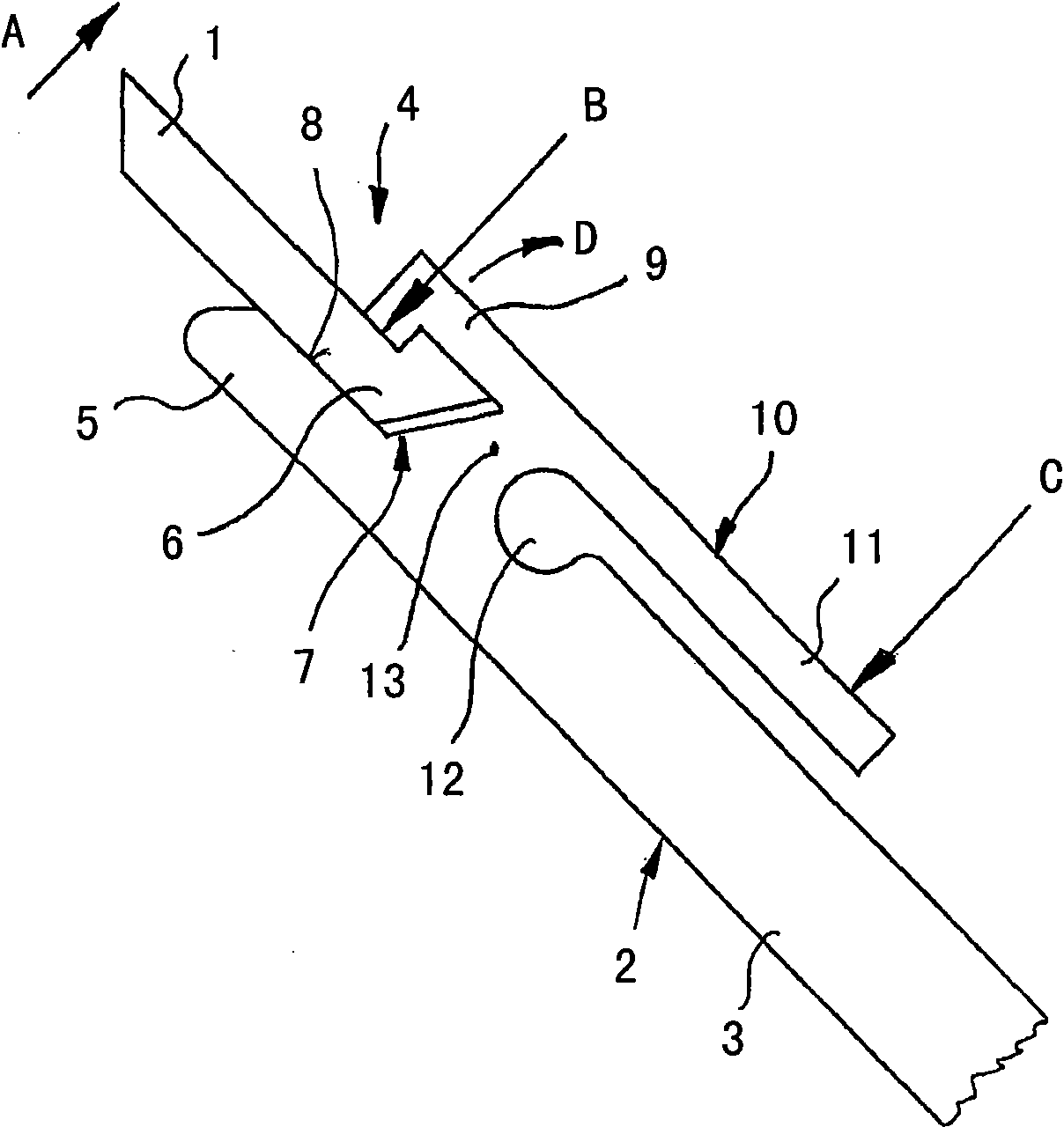

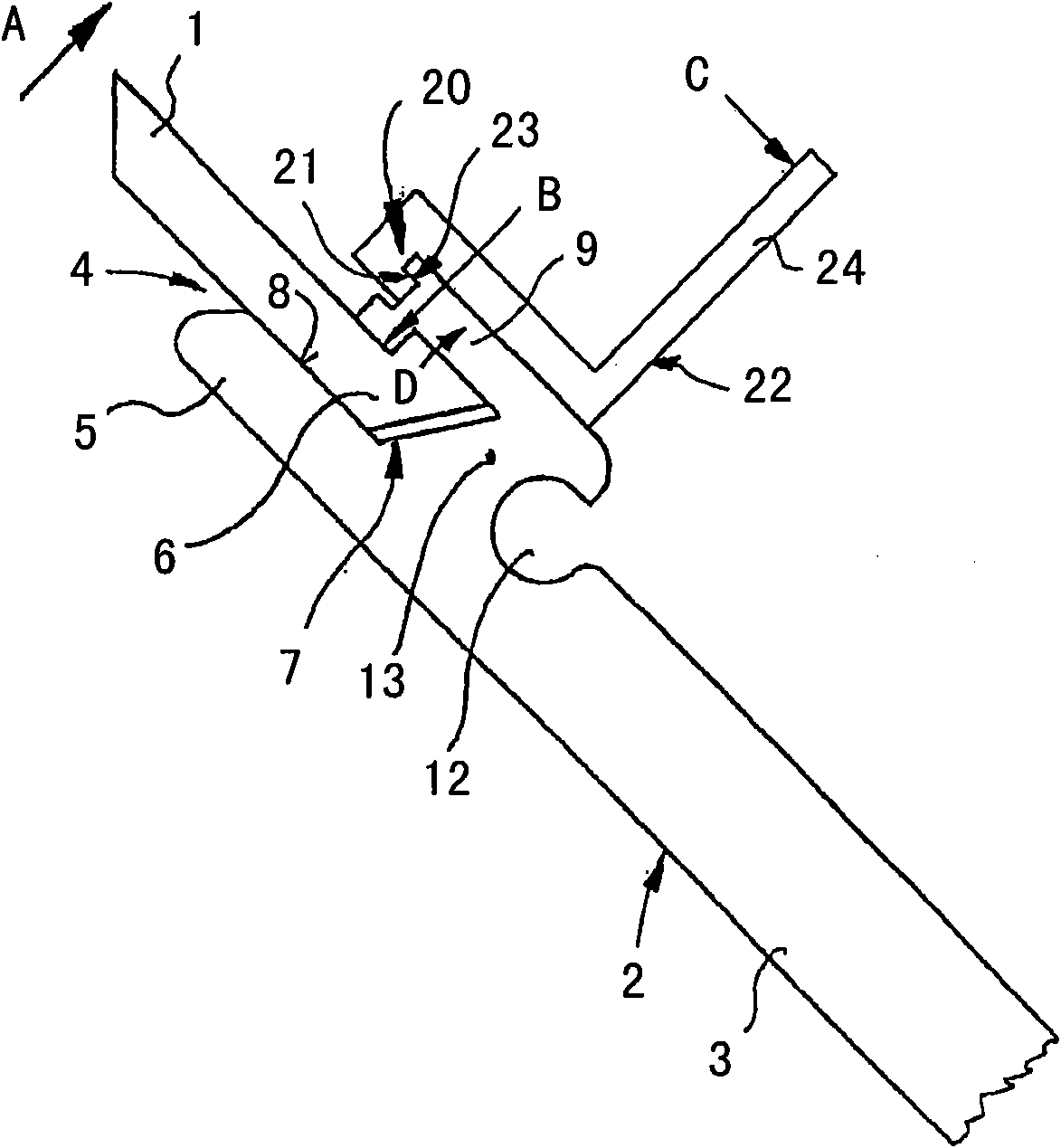

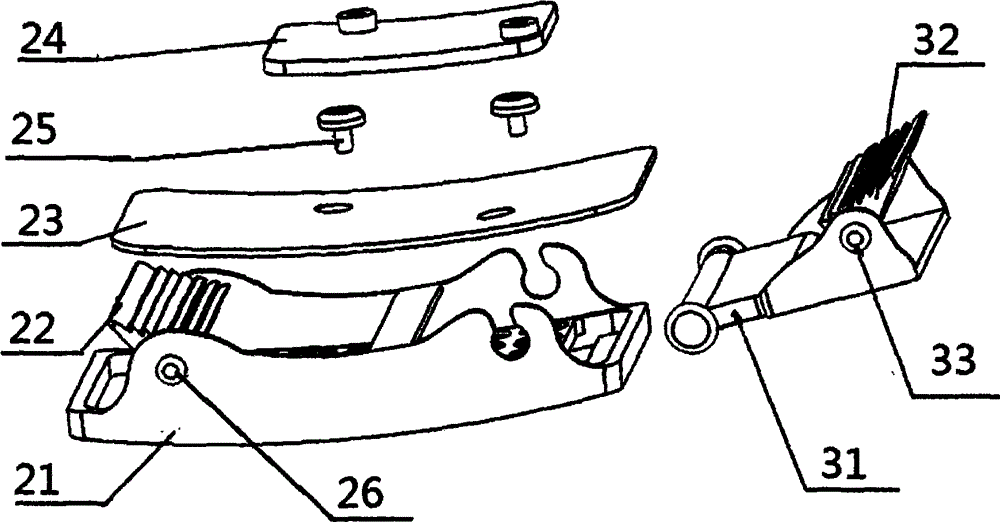

Device for mounting tooth elements on a component of a textile machine

InactiveCN101560703AEasy to fixClosely spacedCombing machinesCarding machinesEngineeringBearing surface

A fixing device fixes toothed elements to a component of a textile machine. The component of the textile machine can be either a top comb, a circular comb or a card flat. The fixing device includes a stationary bearing surface for the toothed elements and a flexible spring leg for pressing the toothed elements to the bearing surface by use of a holding force. The fixing device includes a device for neutralizing the holding force of the spring leg.

Owner:GROB & CO AG

Injection mold with automatic waste removal

The invention discloses an injection mold with an automatic waste discharging function, and relates to the field of injection molding machines. The injection mold comprises a front base plate and a front mold frame. A sprue groove is formed in the side, close to the front base plate, of the front mold frame. A plurality of branched sprues are formed in the sprue groove. Sliding columns are connected to the side, close to the front mold frame, of the front base plate. A cavity is formed in the front mold frame. A swing rod is rotatably connected into the cavity. Strip-shaped grooves are formedin the swing rod. The sliding columns are fixedly connected with short columns inserted into the strip-shaped grooves. An arc-shaped block is fixedly connected to the lower end of the swing rod. A slitting plate is slidably connected into the cavity. Annular knives are separately arranged at the positions, corresponding to the branched sprues, of the slitting plate. The upper end of the slitting plate abuts against the arc-shaped block. A push rod is also slidably connected into the cavity. One end of the push rod can extend into the sprue groove, and the other end of the push rod abuts against the arc-shaped block. By adoption of the injection mold, the problem that in the prior art, waste in a sprue is difficult to remove is solved, and waste in sprue of the injection mold can be discharged automatically.

Owner:SHENZHEN CARES PLASTIC ELECTRONICS

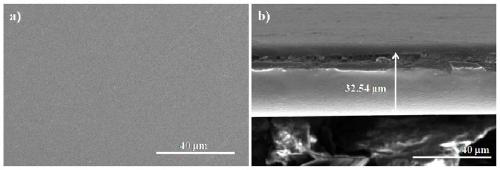

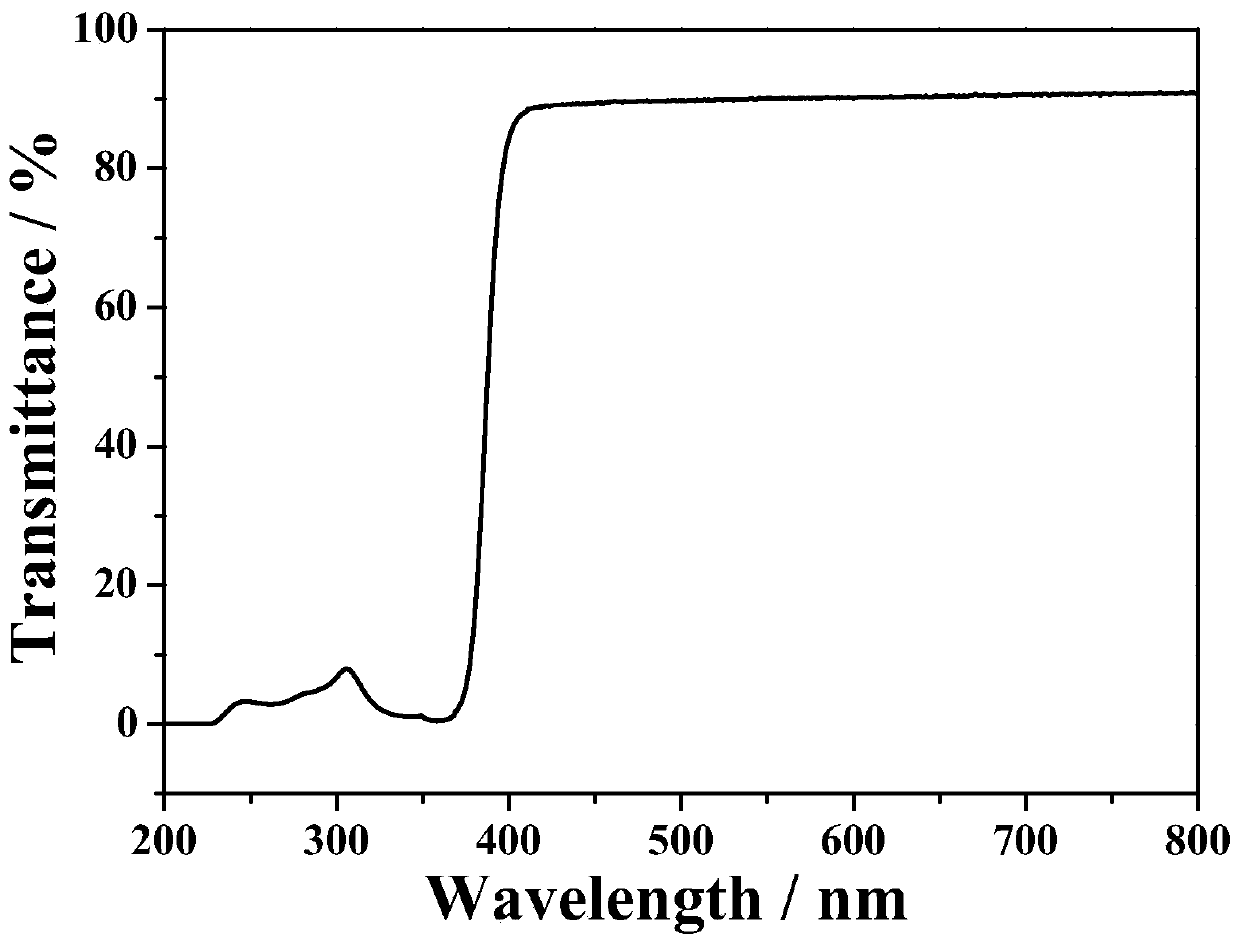

Flexible rare earth transparent luminescent film applied to silicon-based solar cell and preparation method thereof

InactiveCN109721918AHigh transparencyLow priceLuminescent compositionsPhotovoltaic energy generationRare-earth elementSolar cell

The invention relates to a flexible rare earth transparent luminescent film applied to a silicon-based solar cell and a preparation method thereof. The composition of the film comprises a rare earth complex and a polymer matrix material (PMMA); wherein the mass ratio of rare earth complex: PMMA is 1: 40-60; and the rare earth complex is Ln(L1)3(L2)1, Ln is a rare earth element, L1 is a first organic ligand, L2 is a second organic ligand, and L1 and L2 are different; wherein the rare earth element Ln is specifically one or more of Eu, Tb and Yb. The preparation method is simple and rapid, and the flexible rare earth transparent luminescent film is 20-30 or more times larger than the film in the conventional work. The size of the film provides a good foundation for further improving the utilization of sunlight and promoting the large-scale use of the silicon-based solar cell.

Owner:HEBEI UNIV OF TECH

Injection mold with automatic waste discharging function

The invention discloses an injection mold with an automatic waste discharging function, and relates to the field of injection molding machines. The injection mold comprises a front base plate and a front mold frame. A sprue groove is formed in the side, close to the front base plate, of the front mold frame. A plurality of branched sprues are formed in the sprue groove. Sliding columns are connected to the side, close to the front mold frame, of the front base plate. A cavity is formed in the front mold frame. A swing rod is rotatably connected into the cavity. Strip-shaped grooves are formedin the swing rod. The sliding columns are fixedly connected with short columns inserted into the strip-shaped grooves. An arc-shaped block is fixedly connected to the lower end of the swing rod. A slitting plate is slidably connected into the cavity. Annular knives are separately arranged at the positions, corresponding to the branched sprues, of the slitting plate. The upper end of the slitting plate abuts against the arc-shaped block. A push rod is also slidably connected into the cavity. One end of the push rod can extend into the sprue groove, and the other end of the push rod abuts against the arc-shaped block. By adoption of the injection mold, the problem that in the prior art, waste in a sprue is difficult to remove is solved, and waste in sprue of the injection mold can be discharged automatically.

Owner:SHENZHEN CARES PLASTIC ELECTRONICS

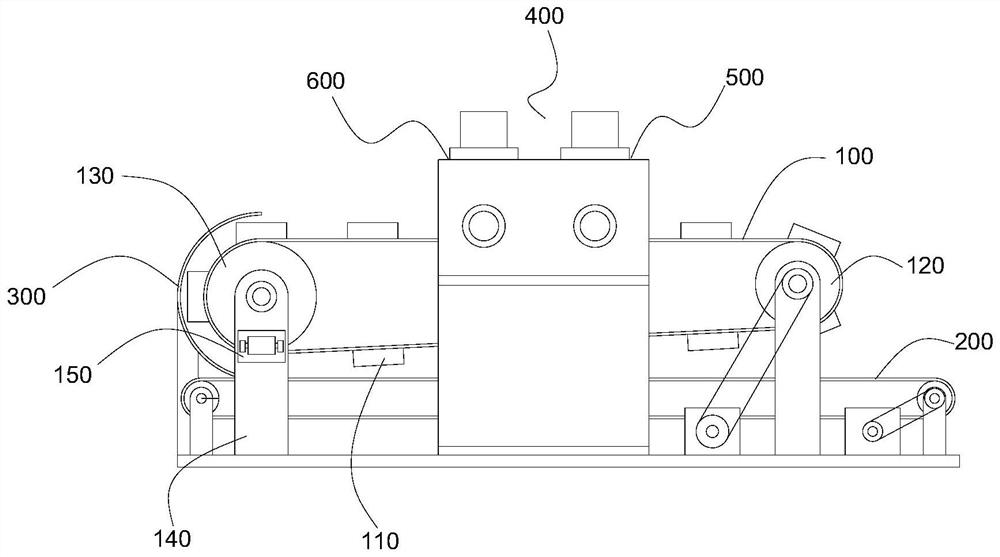

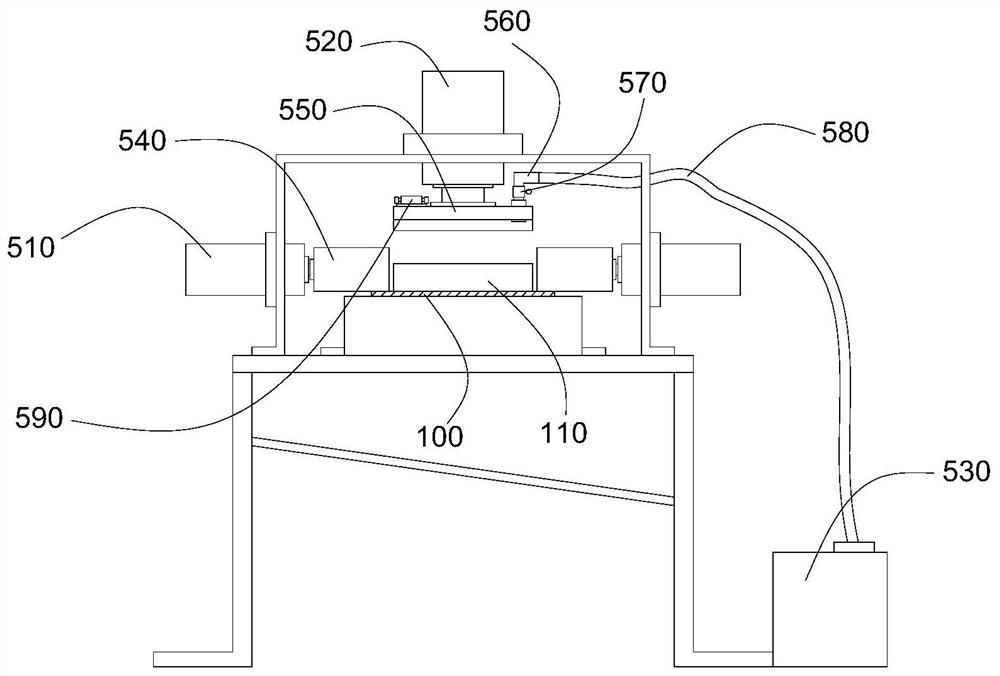

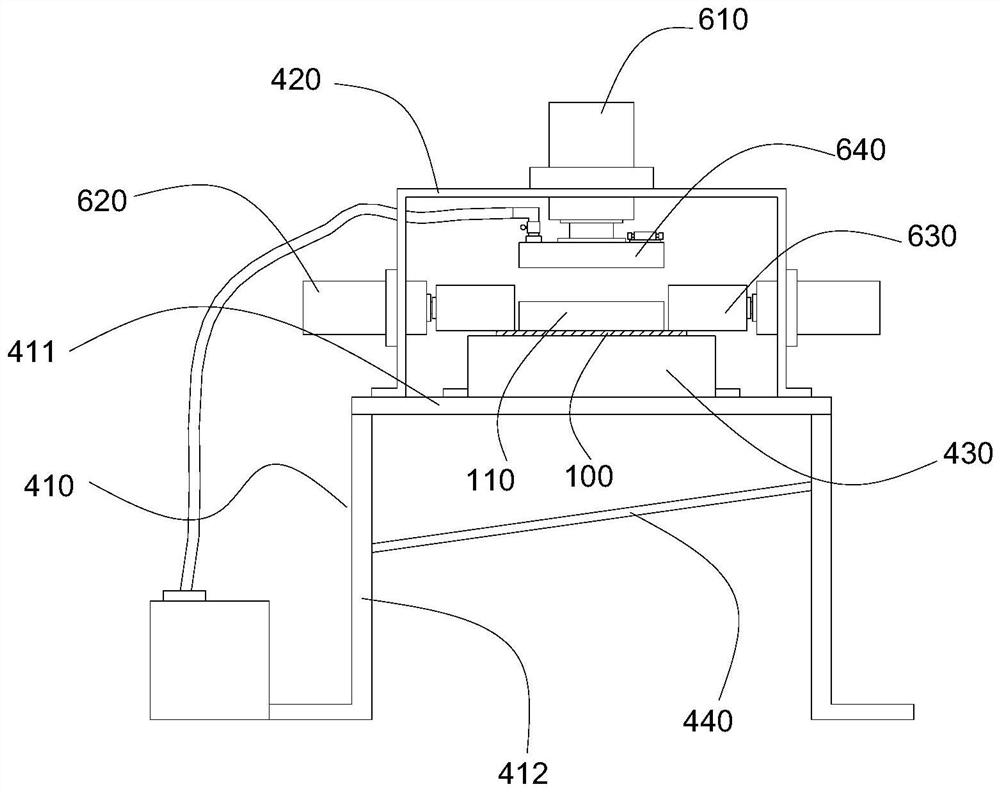

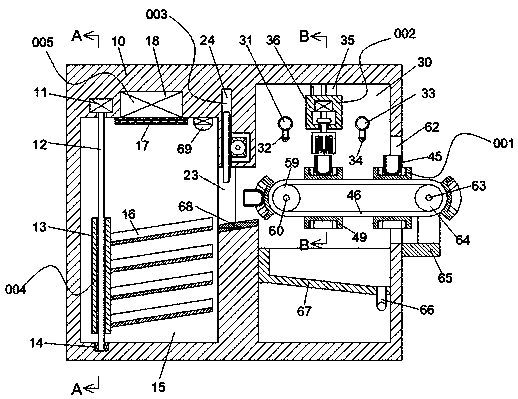

Environmental-friendly brick continuous forming device

PendingCN111687998ANovel structural designIncrease productivityDischarging arrangementFeeding arrangmentsMoulding deviceEco-Block

The invention discloses an environmental-friendly brick continuous forming device. The environmental-friendly brick continuous forming device comprises a first conveying belt and a second conveying belt, the first conveying belt is located above the second conveying belt, and the first conveying belt mutually corresponds to the second conveying belt; the bottom of the first conveying belt is obliquely arranged, a plurality of forming dies are arranged on the first conveying belt, and the forming dies are distributed in a linear array mode; the forming dies are made of rubber, the tops of the forming dies are open, and the forming dies are fixedly connected with the first conveying belt; a striker plate is arranged on the outer side of one output end of the first conveying belt in a covering mode, the striker plate is of an arc structure and is adaptive to a corner position of the first conveying belt, and the bottom end of the striker plate abuts against the top surface of the second conveying belt; and a brick forming mechanism is arranged on the outer side of the first conveying belt in a covering mode, and a feeding structure and a pressure forming structure are sequentially arranged on a mounting frame in the conveying direction of the first conveying belt. According to the environmental-friendly brick continuous forming device, the structural design is novel, the continuous forming production of environmental-friendly bricks can be realized, the production efficiency is improved, produced green bricks can automatically fall off from the forming dies, and the practicalprocessing production is convenient.

Owner:清远市榕兴新型环保建材有限责任公司

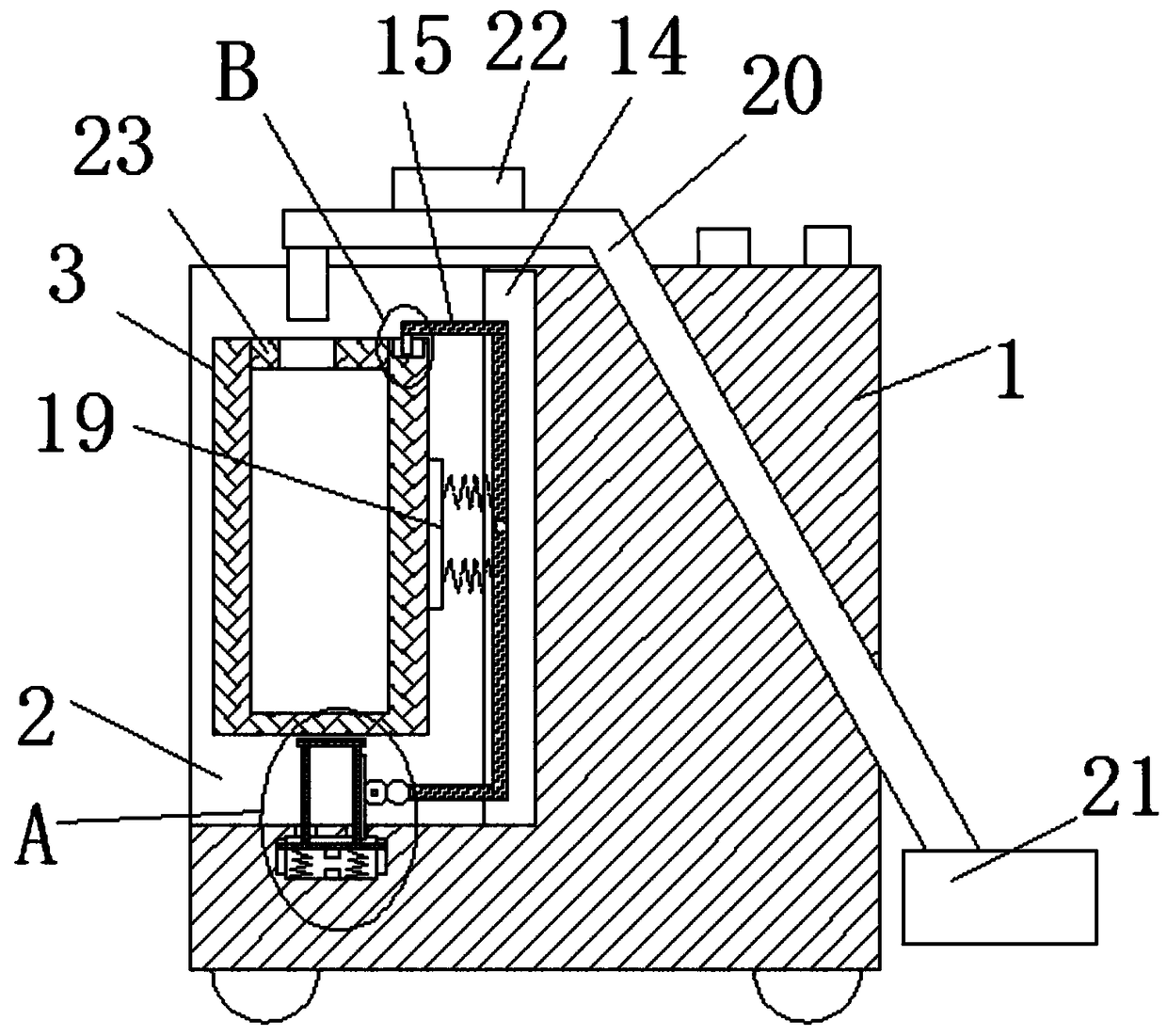

Medical medicine cup cleaning and disinfecting machine

InactiveCN111589823AEasy to cleanAutomatic fall offHollow article cleaningRadiationSurgeryBiomedical engineering

The invention discloses a medical medicine cup cleaning and disinfecting machine. The medical medicine cup cleaning and disinfecting machine comprises a device body with a cleaning cavity in the rightside end face, wherein the right side wall of the cleaning cavity communicates with the right side end face of the device body and is provided with a cleaning inlet; supporting bases are fixedly arranged at the positions, positioned below the cleaning inlet, of the right side end face of the device body in a front-back corresponding manner; and a first belt wheel is rotationally arranged betweenthe supporting bases in front-back corresponding manner through a first rotation shaft. According to the cleaning device, a cleaning liquid mixed with water is used for flushing a medical medicine cupfirstly, then a cleaning brush is used for brushing, residual dirt is flushed through purified water, and through the combined cleaning manner, the medical medicine cup can be efficiently cleaned.

Owner:牛俊静

Rapid pressing machine for flywheel gear ring

ActiveCN112935765AReduce labor levelImprove pressing efficiencyMetal working apparatusEngineeringMachine

The invention belongs to the technical field of flywheel machining devices, and particularly relates to a rapid pressing machine of a flywheel gear ring. The rapid pressing machine comprises a workbench, a pressing column, a fixed barrel, a power mechanism, a storage barrel and a heating mechanism. A through cavity is formed in the pressing column, a first press column is slidably connected in one side of the pressing column, and a second press column is slidably connected in the other side of the pressing column. The pressing column is filled with transmission fluid. A pressing plate is arranged on the first press column, and a supporting seat is arranged on the second press column. A through groove is formed in the second press column, an inserting column with the upper portion penetrating through the supporting seat is fixed in the through groove, and a groove is formed in the inserting column. Multiple clamping blocks are slidably connected to the side wall of the inserting column. A through hole allowing a flywheel body to pass through is formed in the workbench. The storage barrel is located above the workbench, and the distance between the lower end of the storage barrel and the workbench is 1-1.5 gear ring thicknesses. The fixed barrel communicates with the pressing column, and a push column is slidably connected in the fixed barrel. By using the scheme, the problems that when the gear ring is manually pressed on the flywheel body, the efficiency is low, and the labor intensity of workers is high can be effectively solved.

Owner:重庆新炬鑫机械有限公司

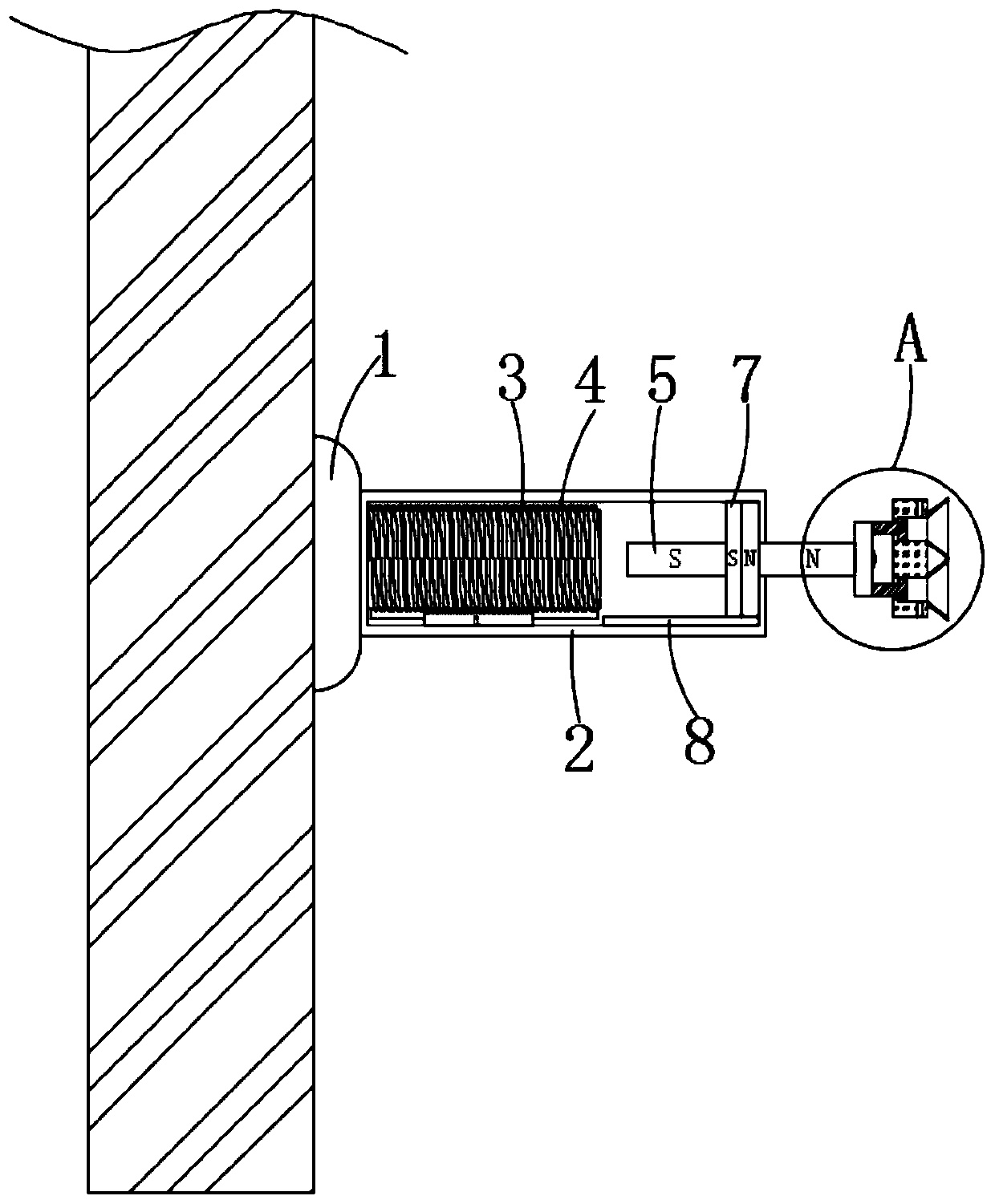

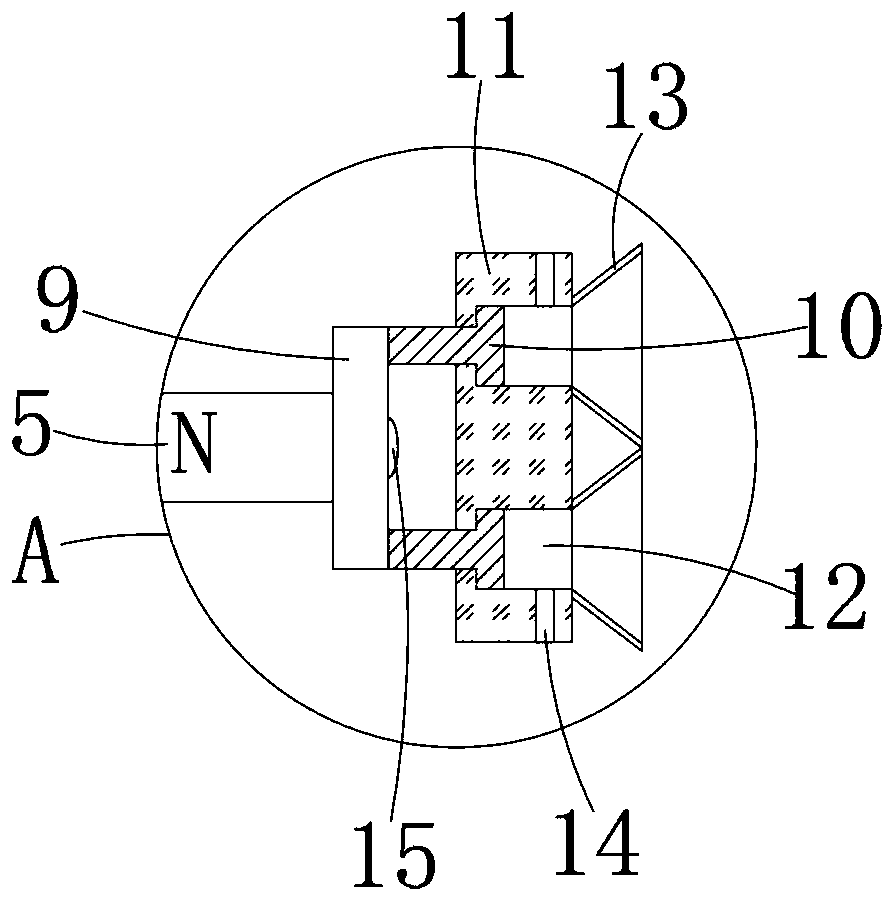

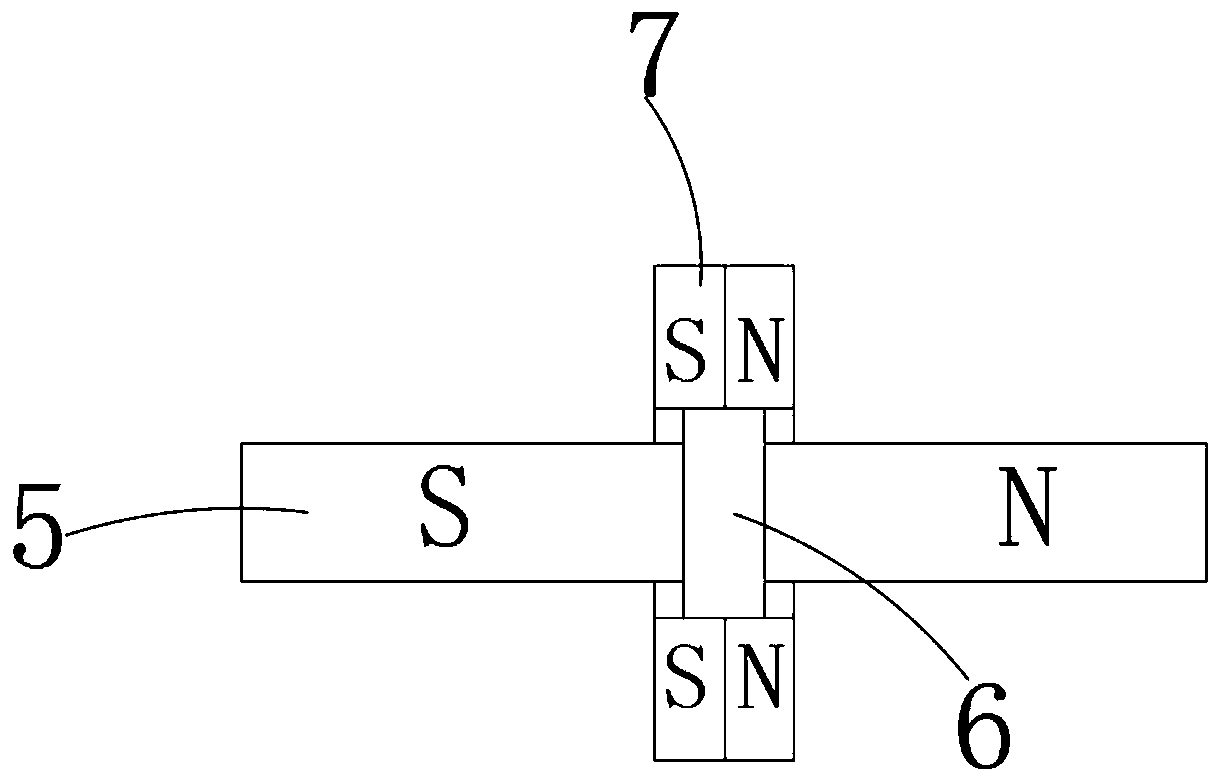

Household silence door stopper durable in use

ActiveCN110512971AMagnetic Field Decays RapidlyAvoid high-speed collisionsWing accessoriesWing fastenersEngineeringKinetic energy

The invention discloses a household silence door stopper durable in use. The household silence door stopper durable in use comprises an installation plate, an insulation shell is fixedly connected toone side wall of the installation plate, a hollow iron core is fixedly connected to the inner wall of the side, close to the installation plate, of the insulation shell, and an on-load solenoid coil is arranged on the outer side wall of the hollow iron core in a winding mode. According to the household silence door stopper durable in use, an electromagnet is driven to run through the kinetic energy of a house door after a user opens the door, the kinetic energy of the house door is declined rapidly, the house door can quickly stop, the high-speed collision phenomenon is avoided, and the door stopper can use for a long time; besides, the electromagnet is driven to run through the kinetic energy, generated when the user closes the door, of the house door, and it is prevented that as the usercloses the door with too much strength, the house door collides with a door frame, and noise is caused; and as the door stopper is unilaterally installed on the house door and does not need to be installed on a wall, punching on the wall is not needed, installation is very easy and convenient, and the problem that a traditional door stopper is likely to loose at an installation position is effectively solved.

Owner:浙江汇德隆家居用品有限公司

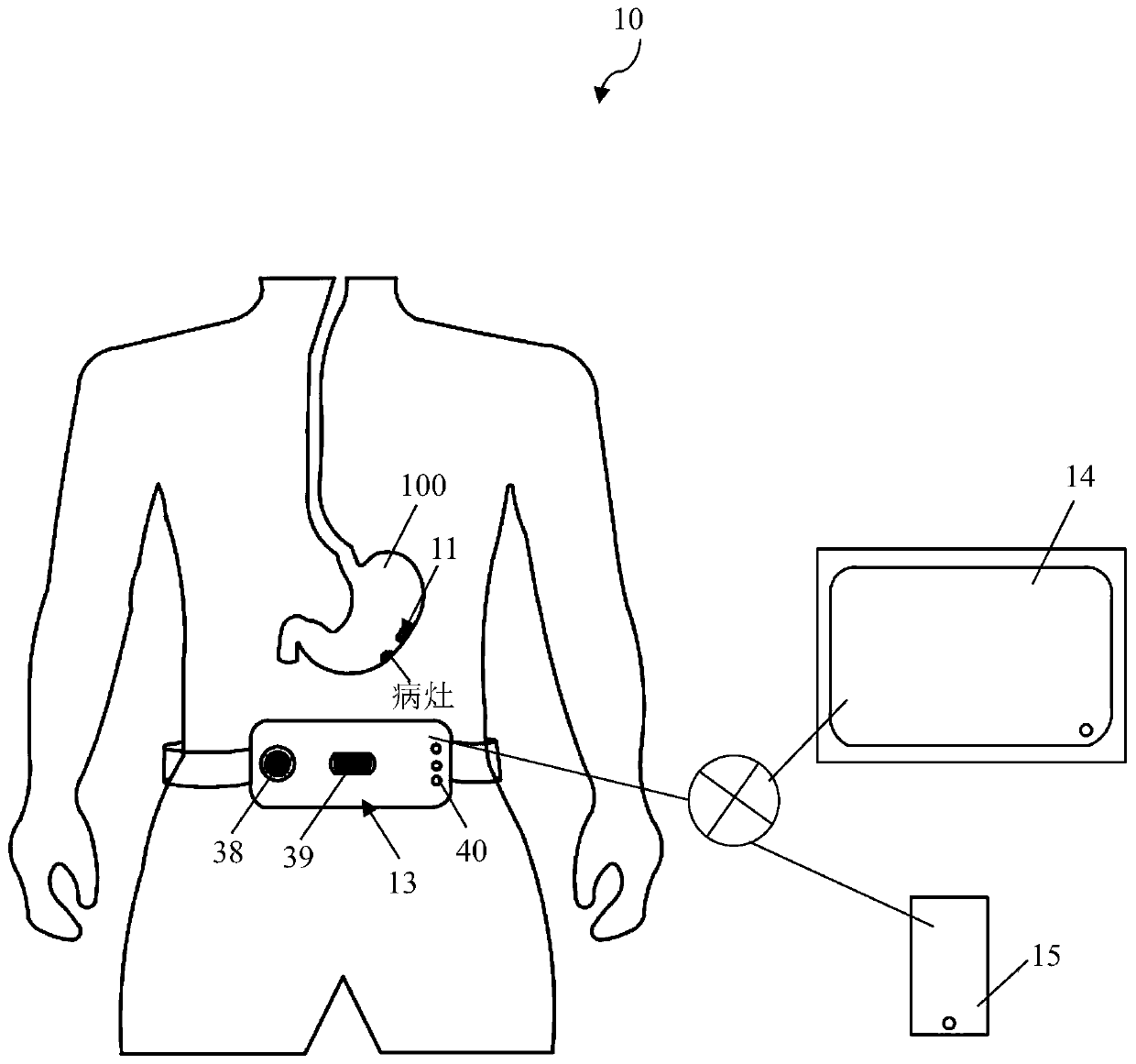

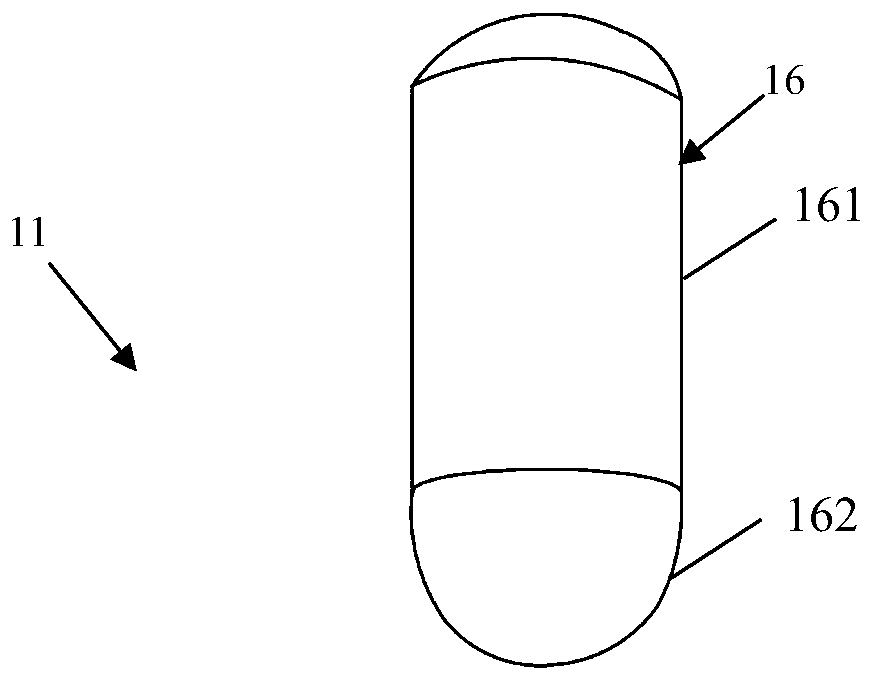

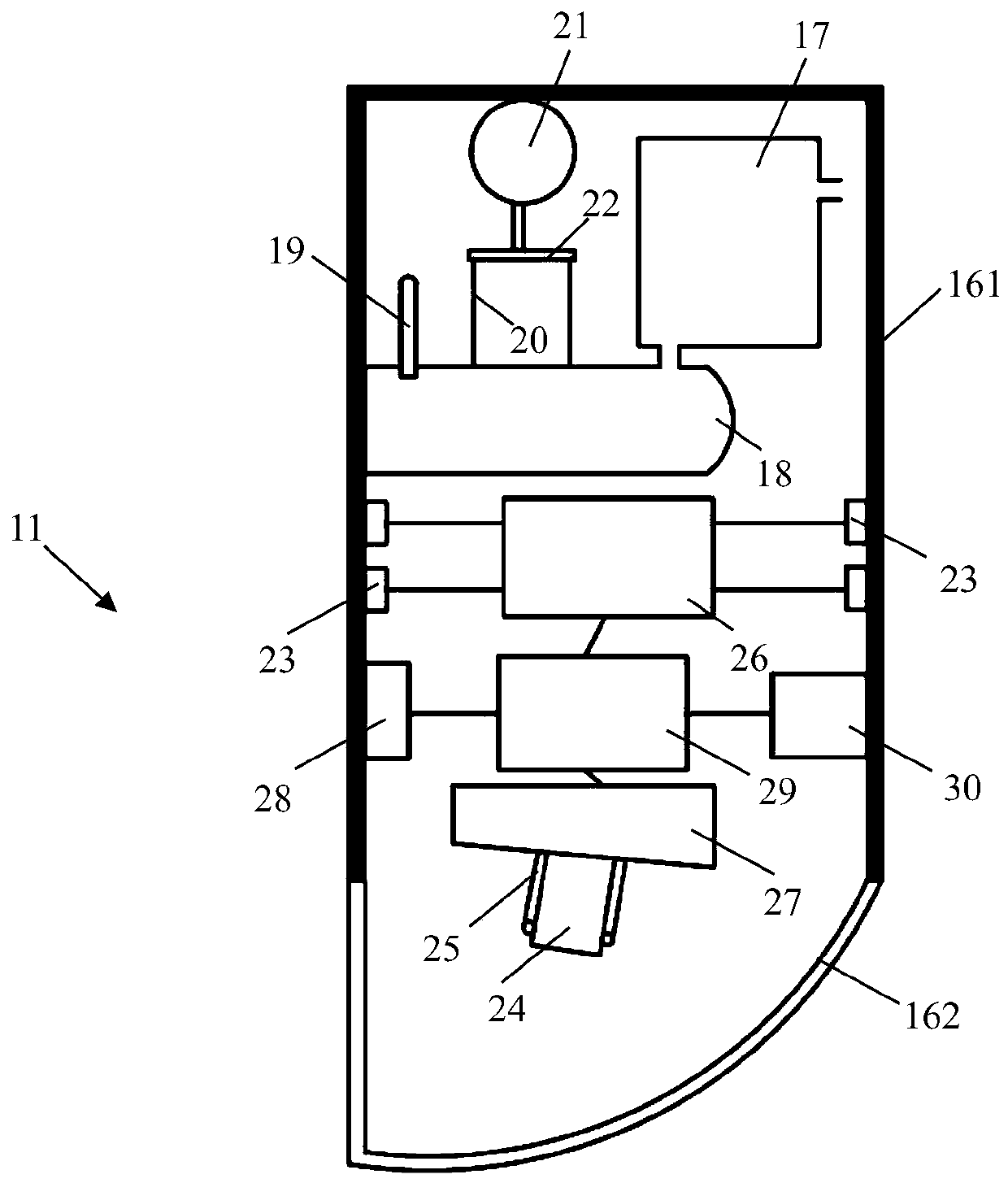

Fixable gastrorrhagia monitoring capsule endoscope and real-time gastrorrhagia monitoring system

PendingCN110151110AReal-time access to bleedingNo painGastroscopesOesophagoscopesMonitoring systemMicro motor

The invention provides a fixable gastrorrhagia monitoring capsule endoscope and a real-time gastrorrhagia monitoring system. The real-time gastrorrhagia monitoring system comprises a capsule endoscope, a connecting cannula, a portable data conversion instrument and a monitor. The fixable gastrorrhagia monitoring capsule endoscope comprises a capsule shell, an endoscope fixing part, an image acquisition part, a signal transmission part, an endoscope-side microprocessor and a power supply. The endoscope fixing part comprises a micro negative-pressure pump fixedly arranged in the non-transparentcapsule shell, a gastric body tissue containing chamber which is connected with the pump and provided with an opening, and a fine needle fixing assembly arranged on the upper side of the gastric bodytissue containing chamber; the fine needle fixing assembly comprises a pressure sensor mounted in the gastric body tissue containing chamber, a fine needle with a head end hermetically inserted into the wall of the gastric body tissue containing chamber, and a micro motor fixedly mounted on the inner wall of the non-transparent capsule shell, wherein the output end of the micro motor is fixedly connected with the tail end of the fine needle.

Owner:SHANGHAI CHANGHAI HOSPITAL

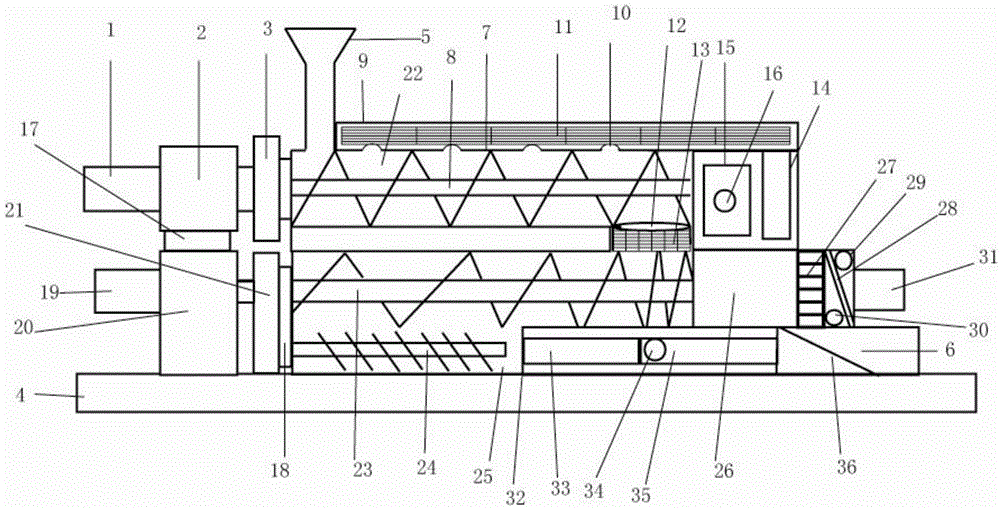

Plastic product extrusion granulation machine

The invention belongs to the field of plastic production, and particularly relates to a plastic product extrusion granulation machine. The plastic product extrusion granulation machine comprises a stabilizer A, a motor A, a speed reducer A, a base, a feed port, a discharge port, a watering way, a spiral conveying rod, an exhaust way, exhaust holes, a filter screen, a discharge port, a filter screen B, a water tank, a motor A, an adjustment key A, a supporting base, a transmission device, a stabilizer B, a motor B, a speed reducer B, a machine cylinder A, a threaded rod A, a threaded rod B, a machine cylinder B, a granulating machine, a perforated plate, a spiral reamer, a static removal ball A, a static removal ball B, a motor C, a cooling net, a motor D, an adjustment key b, a draught fan B and an air outlet. The base is located below the motor B, the speed reducer B, the machine cylinder B, the motor D, the draught fan B and the discharge port. The supporting base is located between the motor A and the motor B. The machine cylinder A is located above the machine cylinder B. The spiral reamer is located between the perforated plate and the motor C. The static removal ball A and the static removal ball B are located on the spiral reamer.

Owner:TIANJIN NAXIANG TECH CO LTD

Waistband with hidden rope

InactiveCN104687647AEasy to unlockAutomatic fall offBucklesGarment beltsMechanical engineeringEngineering

The invention relates to a waistband with a hidden rope. The waistband comprises a waistband body, a concave buckle and a convex buckle, wherein the two ends of the waistband body penetrate through the concave buckle and the convex buckle and are locked; the concave buckle and the convex buckle are buckled by a matched latching manner; the waistband body is sewed into a cavity by leather or cloth; a rope is sewed into the cavity. The concave buckle comprises a concave buckle body, a first locking position clamping plate, an information card, a decorative piece, a first pin and a screw. The convex buckle comprises a convex buckle body, a second locking position clamping plate and a second pin; when convex buckle heads on the two sides of one end of the convex buckle body are buckled, the convex buckle heads are buckled into clamping position holes in the two sides of the other end of the concave buckle body; the second locking position clamping plate is connected with the other end of the convex buckle body by the second pin. According to the waistband, the rope is easily hidden in a belt and is easy to take out; holes are formed in the belt, and the end head of any one end is not locked by the belt so that the rope in the belt is prevented from being drawn. The whole deign of the waistband has a simple structure; the waistband is firm and durable, and is simple to operate.

Owner:万继平

Efficient deoiling and derusting liquid for metal surface treatment

The invention discloses an efficient deoiling and derusting liquid for metal surface treatment. The efficient deoiling and derusting liquid is prepared from the following raw material ingredients in parts by weight: 30-35 parts of phosphoric acid, 20-25 parts of acetic acid, 15-20 parts of benzene sulfonic acid, 10-12 parts of acrylic acid, 10-15 parts of chloric acid, 8-10 parts of carbonic acid, 5-8 parts of ammonia water, 3-5 parts of ferric hydroxide, 3-6 parts of sodium hydroxide, 6-8 parts of potassium dihydrogen phosphate, 5-6 parts of sodium hexametahposphate, 6-8 parts of sodium tripolyphosphate, 7-8 parts of silica, 3-5 parts of calcium silicate, 4-6 parts of thioacetamide, 2-3 parts of urea, 3-5 parts of fatty alcohol-polyoxyethylene ether, 5-6 parts of cocoanut fatty acid diethanolamide, 8-10 parts of oxalic acid, 5-6 parts of sodium chloride, 6-10 parts of p-polyethylene glycol and 55-60 parts of deionized water. The efficient deoiling and derusting liquid for the metal surface treatment has the advantages that the derusting effect is good, the derusting speed is high, the cost is low, the use is convenient and safe, is free from environmental pollution and is free from irritation or damage to human bodies and metal objects, the efficient deoiling and derusting liquid is safe, non-toxic and non-volatile, and the like; and during use, the consumption is low, the cost is low, and oil stains and rust stains can automatically fall off by only soaking at normal temperature after the efficient deoiling and derusting liquid is used.

Owner:司徒建辉

Waste salt refining method

ActiveCN112403096AGood dispersionAccelerated settlementTransportation and packagingEvaporationSorbentWater trap

The invention relates to the field of waste salt processing, in particular to a waste salt refining method which comprises the following steps: step 1, preparing a high-temperature molten waste salt dissolving device which comprises a dissolving tank, a circulating water pipe and a filtering mechanism, and the filtering mechanism comprises a filter screen, a rotary pushing unit and a plugging unit; 2, enabling the molten waste salt to enter the dissolving tank and then to be dissolved to form a solution, enabling the solution to enter a circulating water pipe, adopting the filter screen to adsorb impurities, adopting a rotary pushing unit to enable the solution to flow in a vortex shape, and disperse an adsorbent; 3, when the filter screen is blocked by impurities, adopting the rotary pushing unit to move and promote the solution to impact the filter screen, so that the impurities adhered to the filter screen fall off; 4, enabling the plugging unit to move while the rotary pushing unitmoves, and discharging the solution and falling impurities; 5, after the filter screen is dredged, adopting the solution to drive the rotary pushing unit to reset through the filter screen, and therefore the plugging unit is driven to reset to plug a drain opening; and step 6, carrying out evaporative crystallization and drying. When the technical scheme is adopted, the integration of crushing, dissolving and impurity treatment is facilitated.

Owner:重庆商勤禹水环境科技有限公司

A kind of submerged arc welding flux for low-alloy steel narrow gap welding and preparation method thereof

ActiveCN104668816BExcellent transition abilityEasy transitionWelding/cutting media/materialsSoldering mediaSlagMechanical property

The invention relates to a submerged-arc welding flux for low-alloy-steel narrow-gap welding and a preparation method thereof. A high-alkalinity MgO-CaO-Al2O3-CaF slag system is adopted, and the submerged-arc welding flux is mainly made from raw materials including calcium fluoride, aluminum oxide, wollastonite, marbles, silicon iron and ferromanganese iron. The preparation method of the submerged-arc welding flux mainly comprises the steps of 1 dry mixing in proportion, 2 impurity removal, 3 bonding agent adding for wet mixing and 4 baking and high-temperature sintering. The alkalinity of the welding flux ranges from 2.0 to 3.0, low-hydrogen and low-oxygen deposited metal containing ultra low P and S impurity contents can be obtained through welding, and accordingly it can be ensured that the deposited metal has excellent comprehensive mechanical property. When the submerged-arc welding flux is matched and welded with a low-purity low-alloy steel welding wire, S and P are not added into the deposited metal by adopting the welding flux. The submerged-arc welding flux has excellent alloy transition capacity.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

Flexible soil covering mechanism

PendingCN109451923AImprove uniformityAutomatic fall offPlantingFurrow making/coveringRubber materialCircular disc

The invention relates to a flexible soil covering mechanism, which comprises a supporting structure; the supporting structure supports a vertically arranged vertical rod; the middle part of the vertical rod is fixedly provided with a chain wheel; the chain wheel is driven by an external power mechanism to drive the vertical rod to rotate together; the lower part of the vertical rod is fixedly connected with the center of a disc; the periphery of the disc is fixedly provided with a plurality of connection rings; each connection ring is connected with a rubber long strip; the head of each rubberlong strip is provided with a weighting block in an embedding manner; and each rubber long strip is made of a flexible rubber material. According to the flexible soil covering mechanism provided by the invention, each flexible rubber long strip can continuously deform self, and soils adhered to each flexible rubber long strip can automatically drop; and each rubber long strip is thrown away outward under a centrifugal effect, and the soils and straws can be very rapidly thrown away if being adhered to each rubber long strip, so that soils are difficult to be adhered to each long strip.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com