Rapid pressing machine for flywheel gear ring

A flywheel ring gear and pressing machine technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of high labor intensity and low efficiency of workers, and achieve the effect of improving efficiency, simplifying structure and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

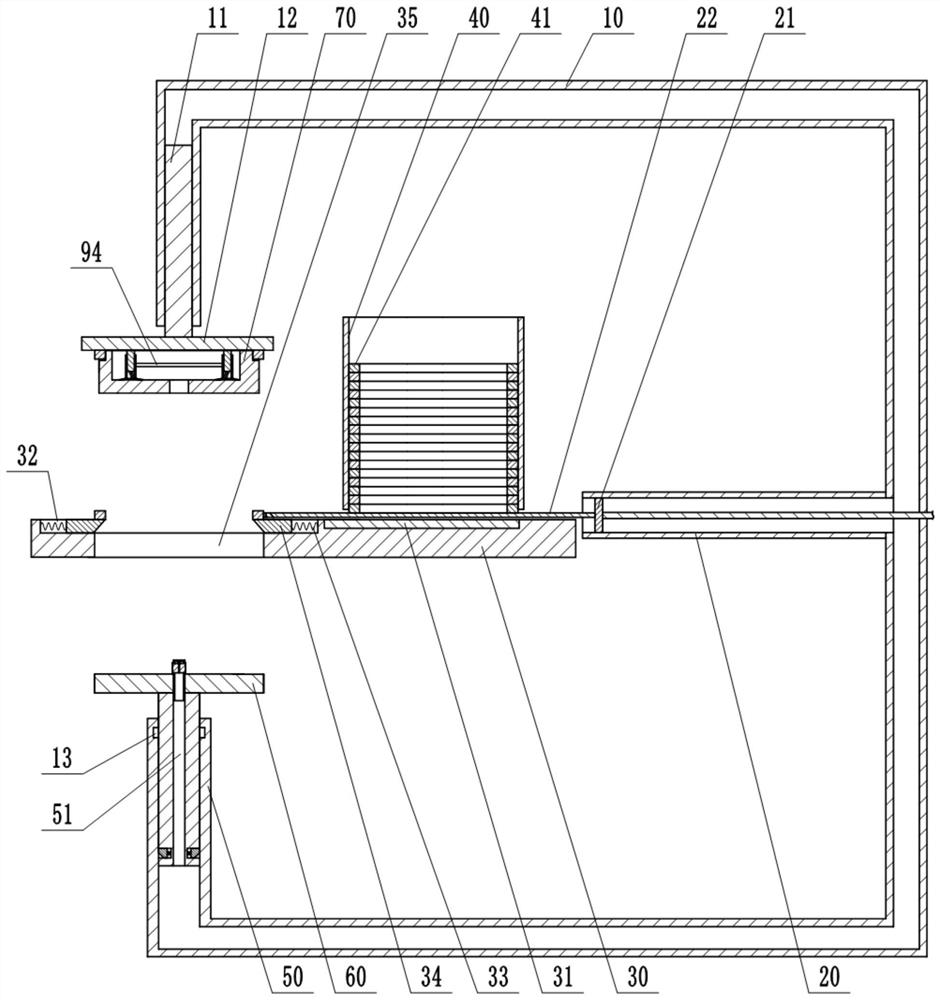

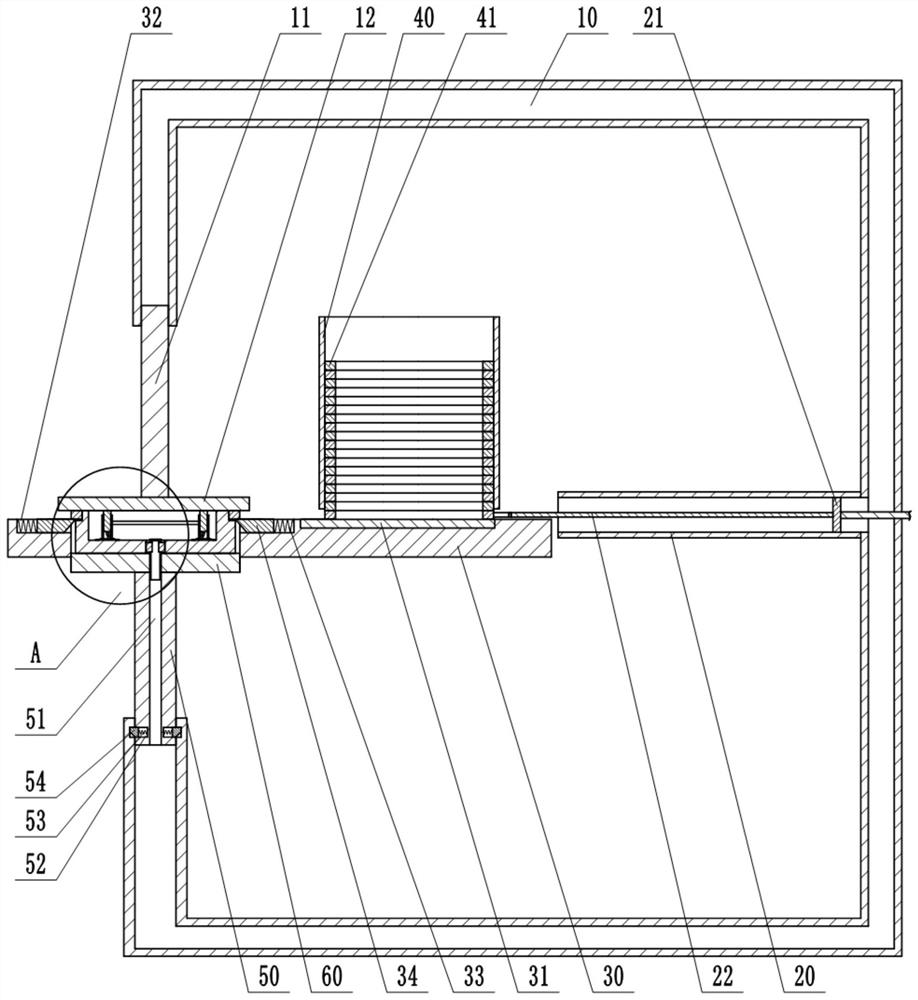

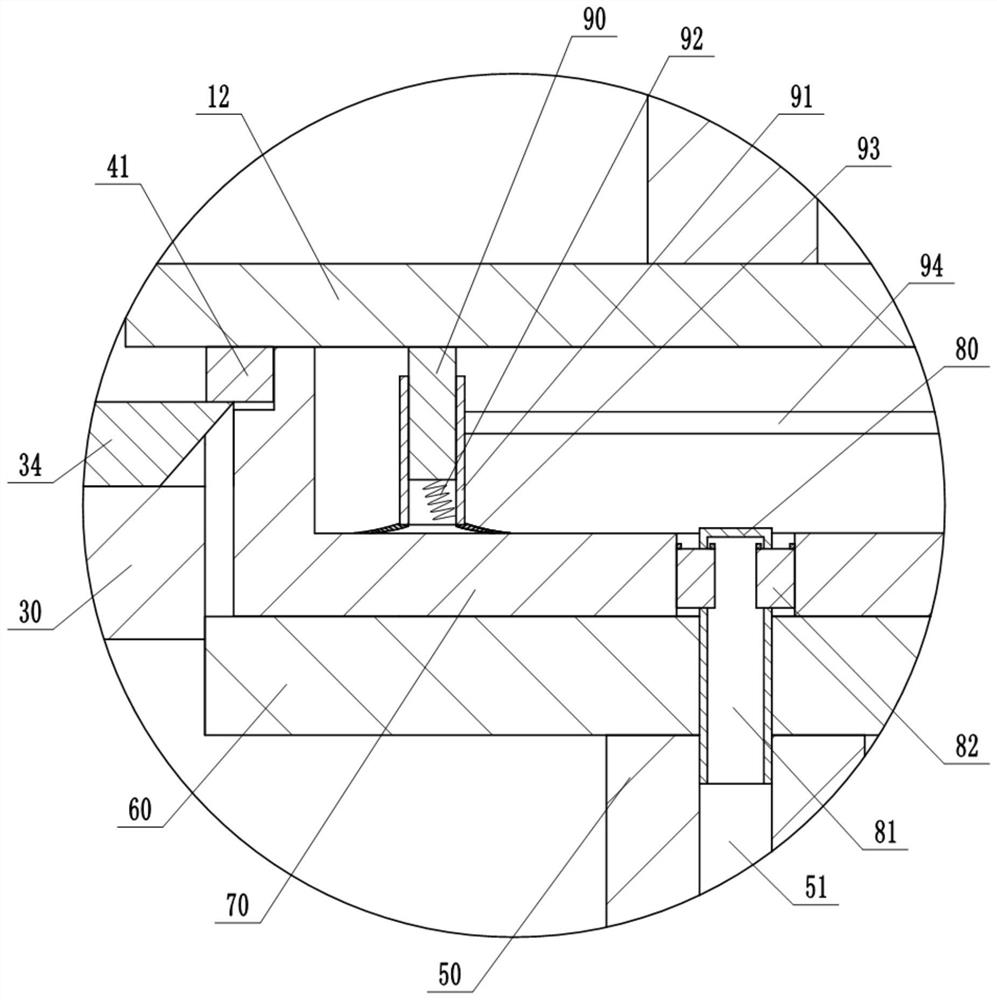

[0022] The reference signs in the drawings of the description include: pressing column 10, first pressing column 11, pressing plate 12, card slot 13, fixing cylinder 20, pushing plate 21, pushing rod 22, workbench 30, heating mechanism 31, slide Groove 32, reset member 33, slide block 34, port 35, storage barrel 40, ring gear 41, second pressure column 50, through groove 51, accommodation groove 52, first elastic member 53, wedge 54, support seat 60. Flywheel body 70, post 80, groove 81, clamp block 82, pressing rod 90, sleeve 91, second elastic member 92, suction cup 93, connecting rod 94.

[0023] This embodiment is basically as figure 1 , figure 2Shown: flywheel ring gear fast pressing machine, including frame, workbench 30, pressing column 10, fixed cylinder 20, material storage cylinder 40, suction mechanism, power mechanism and heating for heating ring gear 41 agency31. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com