Beancurd forming equipment

A molding equipment and tofu technology, applied in the field of food processing, can solve the problems of tofu pollution, complex structure, and many parts, etc., and achieve the effects of ensuring safety and hygiene, reducing labor level, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

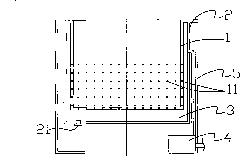

[0019] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention. It at least includes a container 1 for holding bean curd flower, the outside of the container 1 is provided with an outer cup 2 integrally connected with it (such as welded or tightly connected by a seal), and a water chamber 3 is formed between the outer cup 2 and the container 1 , the wall and the bottom of the container 1 are provided with the filter structure 11 that communicates with the water chamber 3 and is used to discharge the moisture in the bean curd flower. The outer cup 2 is connected with a negative pressure device 4, which is connected with the water chamber 2 connected. The negative pressure device 1 is a vacuum pump.

[0020] The filter structure 11 in this embodiment is a filter hole directly arranged on the container 1 . In addition, for the needs of safety and aesthetics, a safety cover 5 is provided outside the outer cup 2, and the negative pressure device 4 ...

Embodiment 2

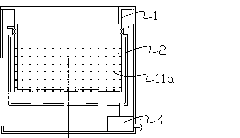

[0023] Embodiment 2 has basically the same structure as Embodiment 1. as attached figure 2 As shown, the difference is that the container 1 and the outer cup 2 are in a sealed fit relationship, and are sealed with a silicone sealing ring. Of course, when the tofu is formed, their positions are relatively fixed, and the container 1 can be pulled out from the outer cup 2 after the tofu is formed. In addition, its negative pressure equipment can be a drainage pump. The accumulated water in the outer cup 2 can be poured out directly or discharged through a drainage pump. Therefore, when the drain pump is turned on, since there is no accumulated water or less accumulated water in the water chamber 3, the opening of the drain pump will form a negative pressure in the water chamber 3, so that the moisture in the bean curd flower in the container 1 can pass through. The filter hole 11a drains into the water chamber 3 and is discharged in time through the drain pump. When the wate...

Embodiment 3

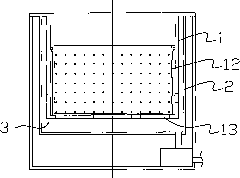

[0025] The difference between embodiment 3 and embodiment 1 mainly lies in that the filter structure is different, as attached image 3 As shown, the filter structure in Embodiment 3 includes a filter screen 12 that is sleeved in the container 1 and forms a sealed state (this sealing degree does not need to be very high, only need to be in contact with each other or a sealing ring is provided) and set A water outlet 13 communicated with the water chamber 3 on the container 1 . The filter screen 12 can also be replaced by a filter cloth, and the wet filter cloth can be attached to the inner wall of the container 1 directly. Therefore, when bean curd flower is packed in the container 1 and the negative pressure device is turned on, a negative pressure state is formed between the outer cup 2 and the filter screen 12, so that the moisture in the bean curd flower is detached to form tofu.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com