Automatic casting device, casting method and material boxes of device

A technology of automatic feeding device and feeding box, applied in cooking utensils, household utensils, applications, etc., can solve the problems of insufficient flexibility, hidden dangers of hygiene and safety of feeding device, complicated automatic feeding mechanism, etc., achieve high feeding efficiency, simple structure, The effect of ensuring hygiene and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings.

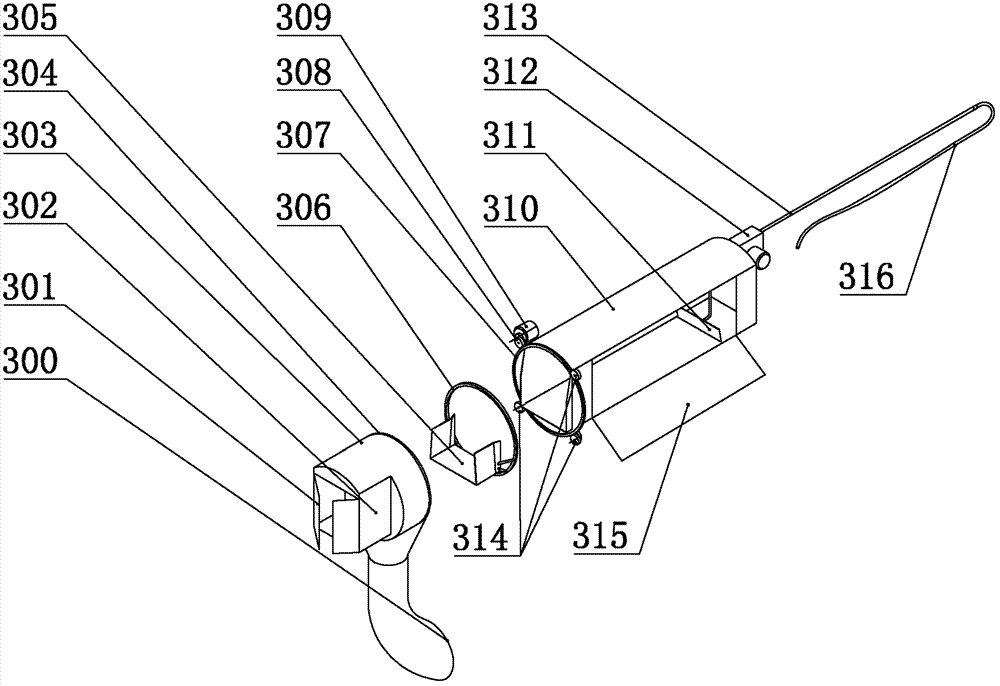

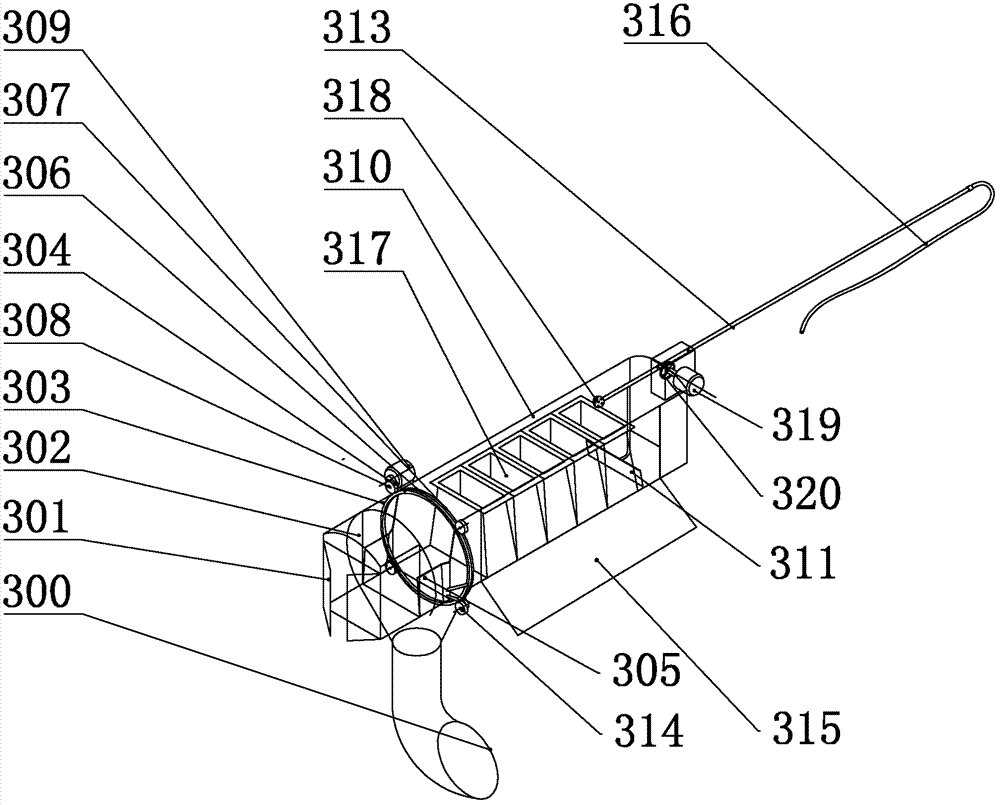

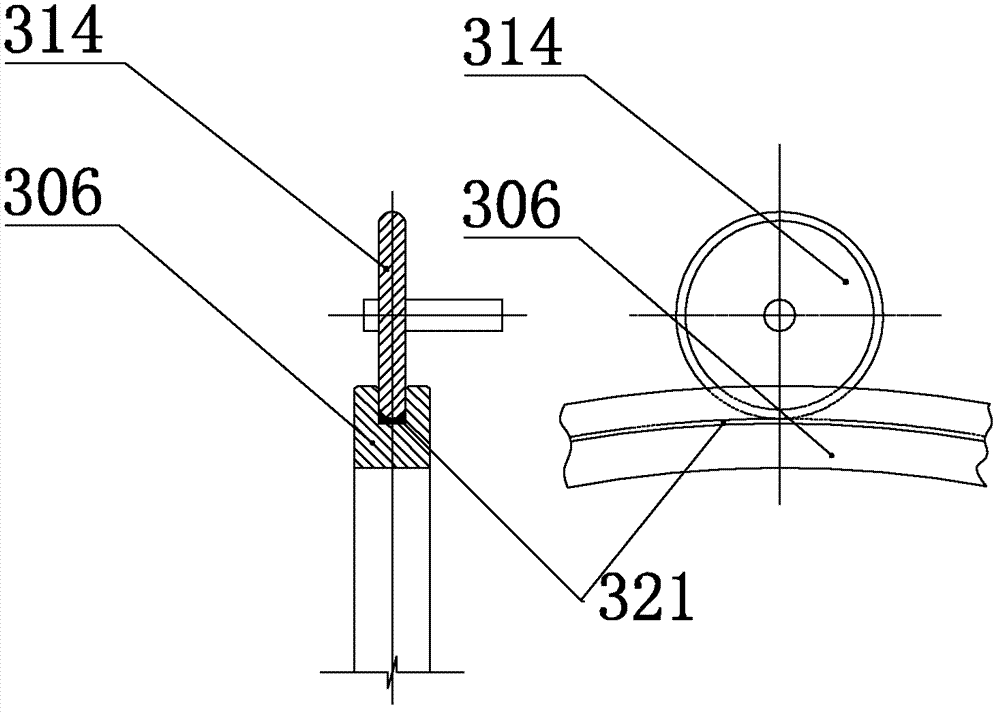

[0052] Figure 1A A schematic diagram showing the assembly of an automatic feeding device according to one aspect of the present invention, Figure 1B show Figure 1A A schematic perspective view of each assembly part of the automatic feeding device in . exist Figure 1A and 1B Among them, the components represented by the corresponding numbers are: 300-discharging channel, 301-the outlet valve of the material box, 302-the outer shell of the material box, 303-the shell of the turning part of the material box, 304-dynamic seal, 305-the material box Clamping mechanism, 306-outer ring, 307-dynamic seal, 308-drive wheel, 309-overturn driver, 310-box box, 311-box push plate, 312-push plate driving device, 313-hollow rack, 314-support wheel, 315-feed box inlet valve, 316-wash liquid inlet hose, 317-material box, 318-cleaning nozzle, 319-drive motor for driving dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com