Plastic product extrusion granulation machine

A plastic product and granulator technology, which is applied in the field of plastic production, can solve the problems of electrostatic accumulation of plastic foam particles, and achieve the effects of preventing granules from foaming, removing excess air moisture, and facilitating material transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

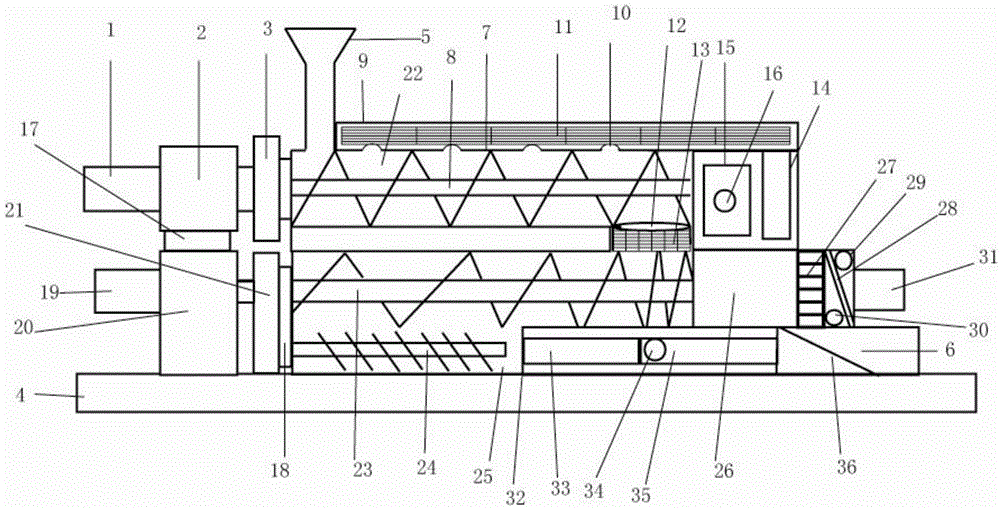

[0019] This embodiment includes a stabilizer A1, a motor A2, a reducer A3, a base 4, a material inlet 5, a material outlet 6, a sprinkler channel 7, a screw conveying rod 8, an exhaust channel 9, an exhaust hole 10, and a filter screen 11 , feeding port 12, filter screen B13, water tank 14, fan A15, adjustment key A16, support seat 17, transmission device 18, stabilizer B19, motor B20, reducer B21, barrel A22, screw A23, screw B24, machine Cylinder B25, granulator 26, perforated plate 27, spiral reamer 28, antistatic ball A29, antistatic ball B30, motor C31, cooling net 32, motor D33, adjustment key B34, fan B35, air outlet 36, base 4 Under the motor B20, reducer B21, barrel B25, motor D33, fan B35, and discharge port 6, the support seat 17 is between the motor A2 and the motor B20, and the barrel A22 is on the top of the barrel B25. 5 On the top of the machine barrel A22, the feeding port 12 is under the machine barrel A22, the filter screen B13 is in the feeding port 12, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com