Device for mounting tooth elements on a component of a textile machine

A technology for fixing devices and textile machinery. It is used in deburring devices, textiles and papermaking, combing machines, etc. It can solve the problems of cumbersome installation and replacement of toothed parts, and achieve the effect of easy waste disposal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

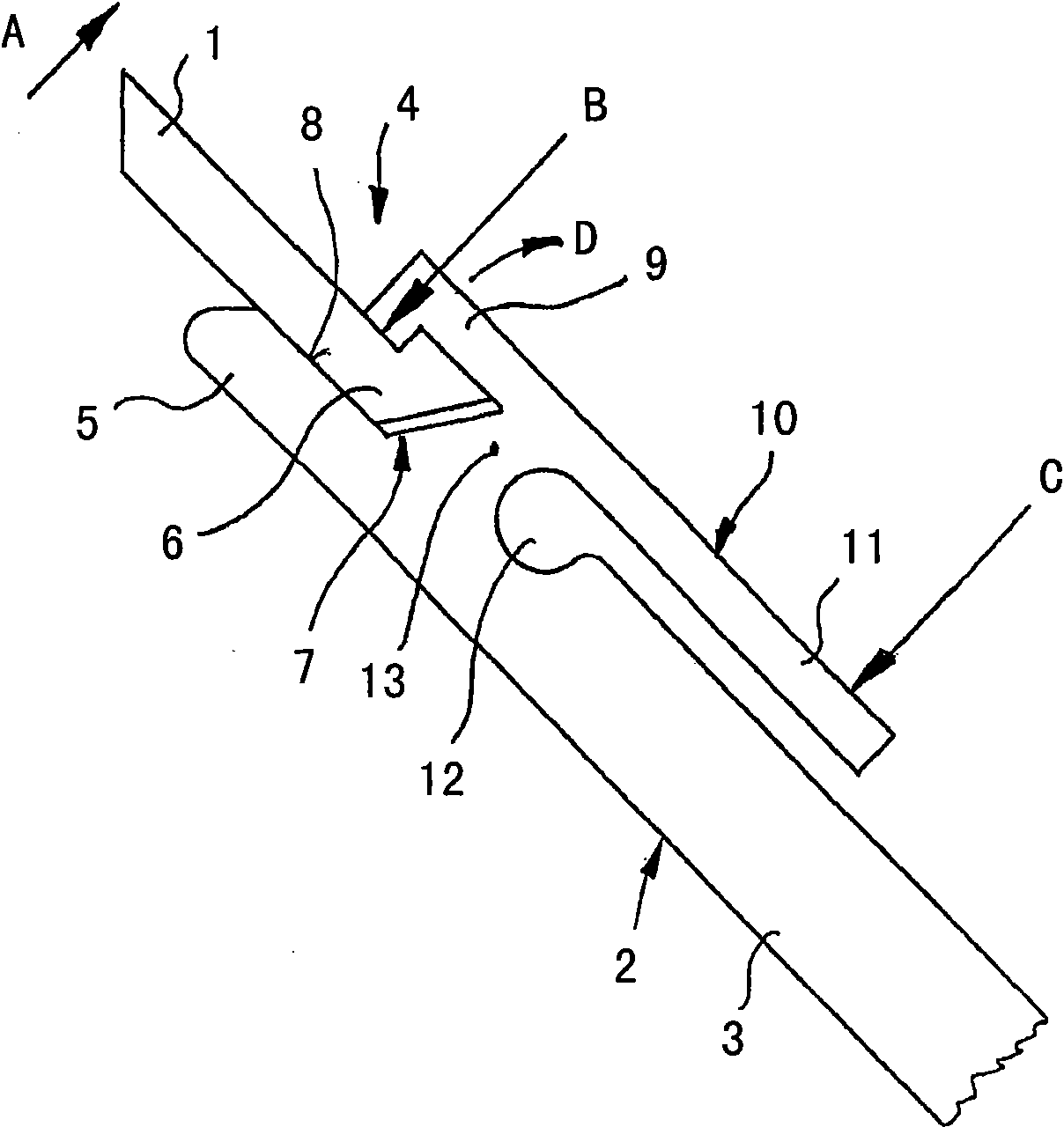

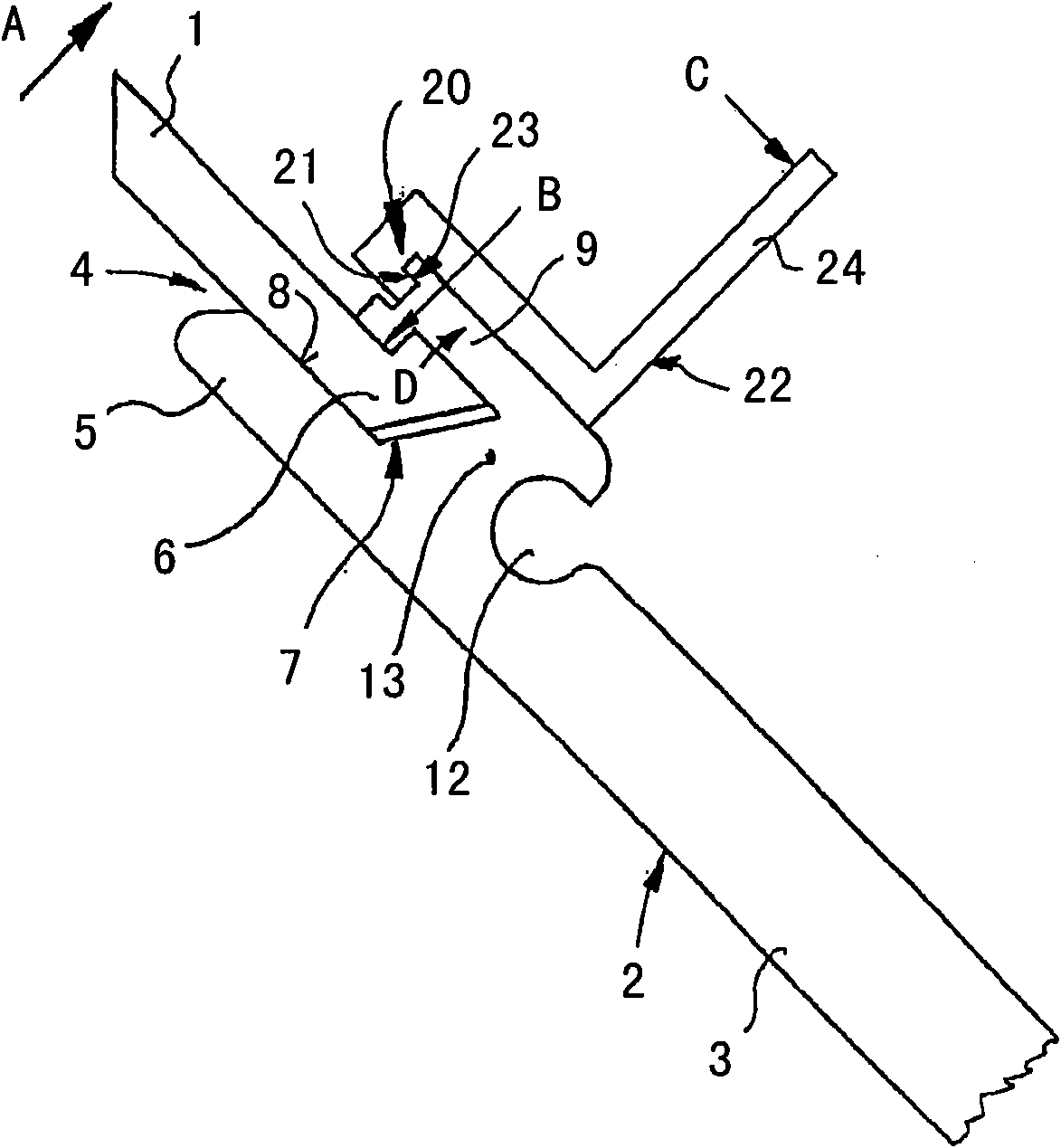

[0019] exist figure 1 A top comb 2 for a combing machine is shown by way of example for a component 2 of a textile machine containing a toothed part 1 . The top comb 2 essentially consists of a needle strip 3 and a fastening device 4 for the toothed part 1 itself. The top comb 2 is installed in the comber so that the toothed part 1 combs the fibrous material consisting of short fibers along the working direction A. The actual thickness dimension of the needle strip 3 viewed along the working direction A is several millimeters, and perpendicular to figure 1 The actual width dimension of the drawing is several hundred millimeters. The ends of the needle strips 3 form supports 5 for the toothed part 1 .

[0020] The toothed part 1 consists of a stamped part or a needle, the foot part 6 of which is located in the clamping mechanism 7 of the support body 5 . The toothed part 1 is held in the clamping mechanism 7 by the fixing device 4 . The fastening device 4 has a stationary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com