Pin retreating demolding device for compression molding of bamboo-wood integrated material

A technology of compression molding and demoulding device, which is applied in the direction of wood processing appliances, flat products, household components, etc. It can solve the problems of lower demoulding efficiency, damage to molds and products, and unstable demoulding movement, so as to achieve smooth and rapid demoulding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

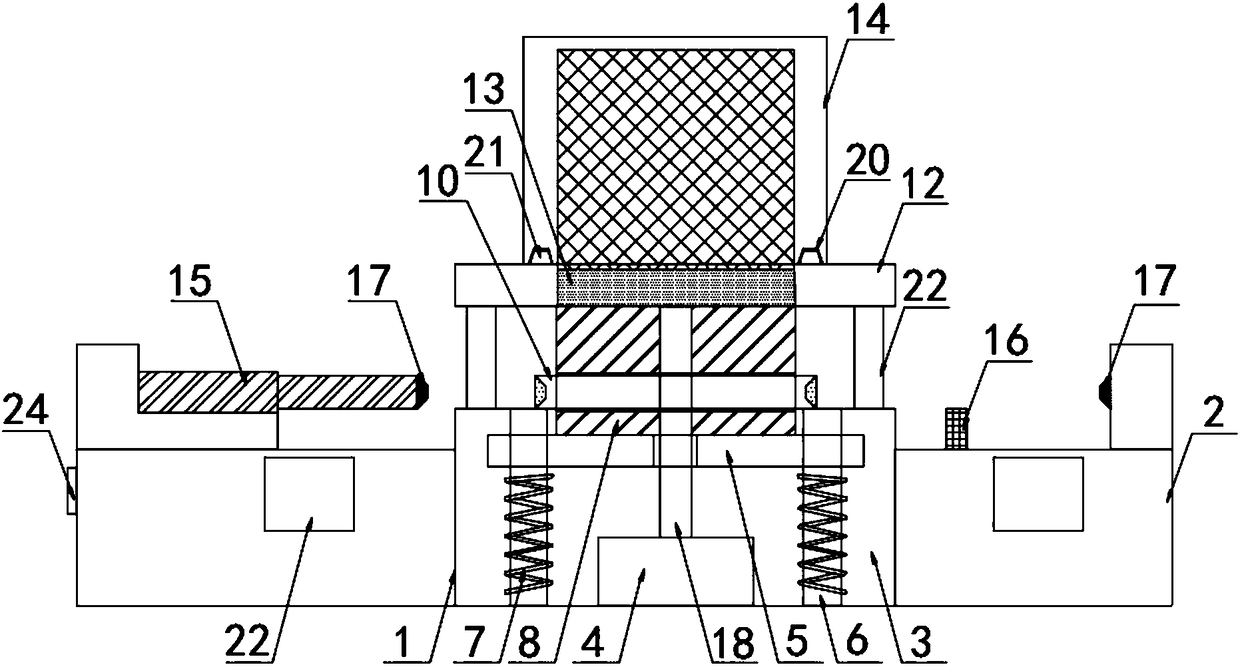

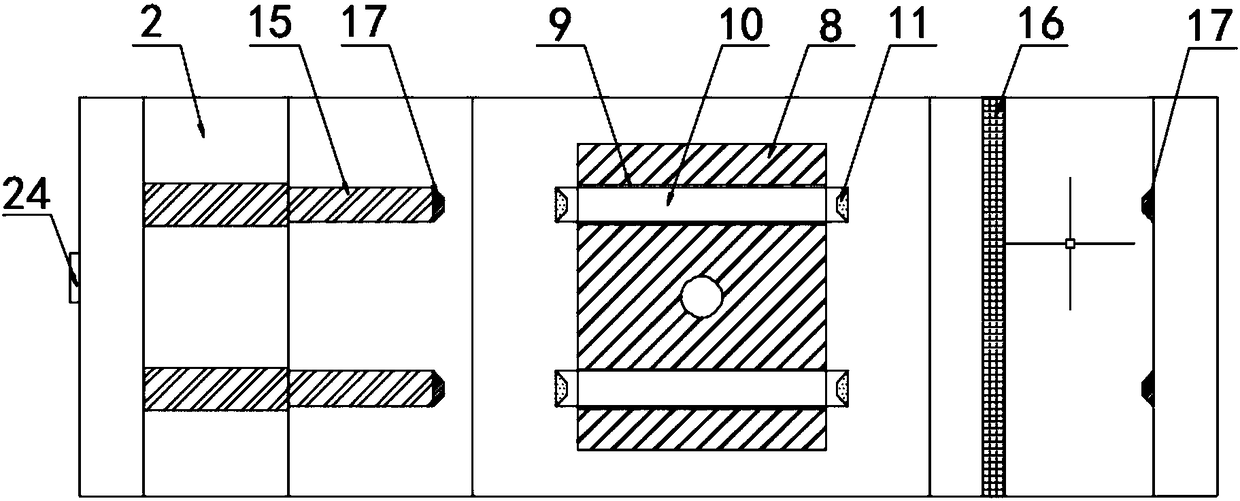

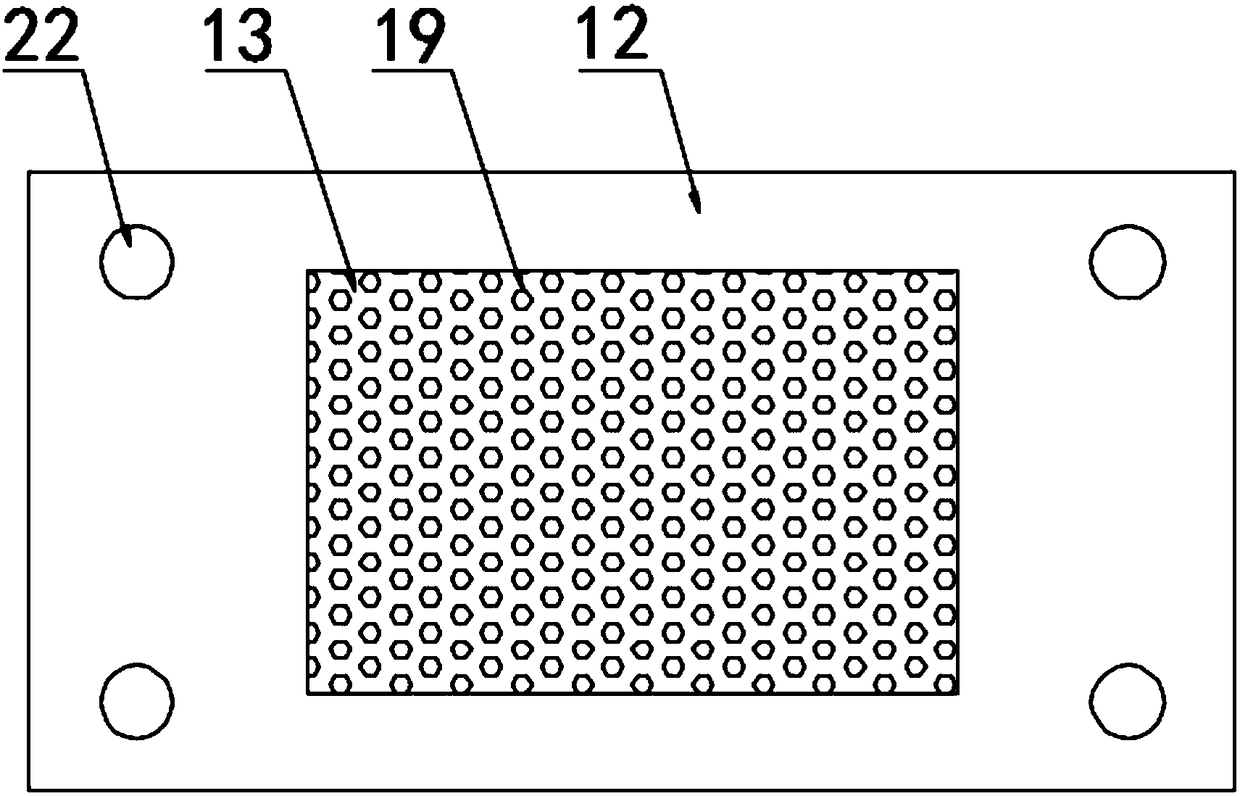

[0026] according to Figure 1-2 The demoulding device of a bamboo-wood glulam after being pressed and molded includes a main workbench 1, auxiliary platforms 2 are arranged on both sides of the main workbench 1, and a driving cavity 3 is arranged inside the main workbench 1, The drive chamber 3 is provided with a vacuum pump 4, the top of the vacuum pump 4 is provided with a movable plate 5, and the four corners of the movable plate 5 are movably provided with a limit column 6, and the limit column 6 is fixed to the main workbench 1 connection, the limit column 6 is provided with a spring 7 outside, the top of the movable plate 5 is provided with a connecting platform 8, and the connecting platform 8 is provided with a through groove 9 inside, and the inside of the through groove 9 is provided with a latch rod 10 , the two ends of the latch rod 10 are provided with slots 11, the top of the connection table 8 is provided with a support plate 12, the inner side of the support pl...

Embodiment 2

[0033] according to figure 1 Shown is a kind of stripping device for pins after pressing and forming bamboo-wood glulam. The latch rod 10 is made of steel material, and the slot 11 is arranged correspondingly to the suction head 17. 17 are all arranged in the shape of a circular table, the suction head 17 is made of electromagnets, the auxiliary table 2 is provided with a battery 23, and the side of the auxiliary table 2 is provided with a PLC controller 24, and the suction head 17 And the PLC controller 24 are all connected with the battery 23 by wires, and the battery 23 is controlled by the PLC controller 24 to power on and off the suction head 17, so as to realize the fixed connection and separation of the suction head 17 and the latch rod 10.

[0034] The working principle of the present invention:

[0035] When in use, first buckle the mold 14 upside down on the support plate 12, and refer to the attached figure 1 , so that the positioning grooves 20 at the four corner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com