Special nano-filter plate for filter press

A technology of nanofiltration and filter press, applied in the direction of filtration and separation, chemical instruments and methods, separation methods, etc., can solve the problems of diaphragm filter plate damage, affecting material quality, and failure to achieve complete gel drop of filter cake, so as to improve durability Effects of friction, static electricity elimination, and good anti-fouling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

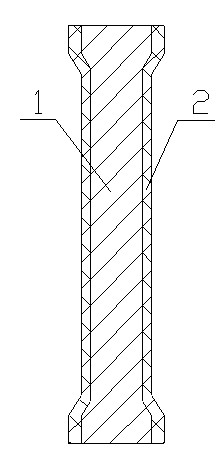

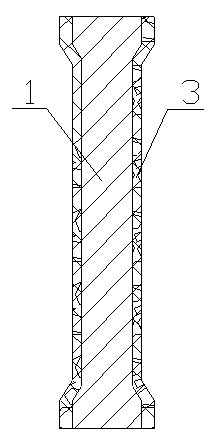

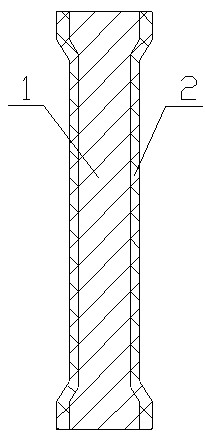

[0017] Embodiment 1: with reference to attached figure 1 . A special nano filter plate for a filter press, which includes a filter plate 1, the surface layer of the filter plate is a nano layer 2, the nano layer is larger than 0.1 micron, and the nano layer 2 on the filter plate 1 surface is made in the prior art, No description here.

Embodiment 1-1

[0018] Example 1-1: On the basis of Example 1, the surface layer of the filter plate is a nano-ceramic material layer 2 .

Embodiment 1-2

[0019] Embodiment 1-2: On the basis of Embodiment 1, the surface layer of the filter plate is a nano-metal material layer 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com