Tail processing device for garment manufacturing and processing method thereof

A technology of a processing device and a control device, applied in the direction of de-floating yarn, etc., can solve the problems of high labor intensity, low production efficiency, increased labor cost, etc., and achieve the effect of avoiding counting errors and improving cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

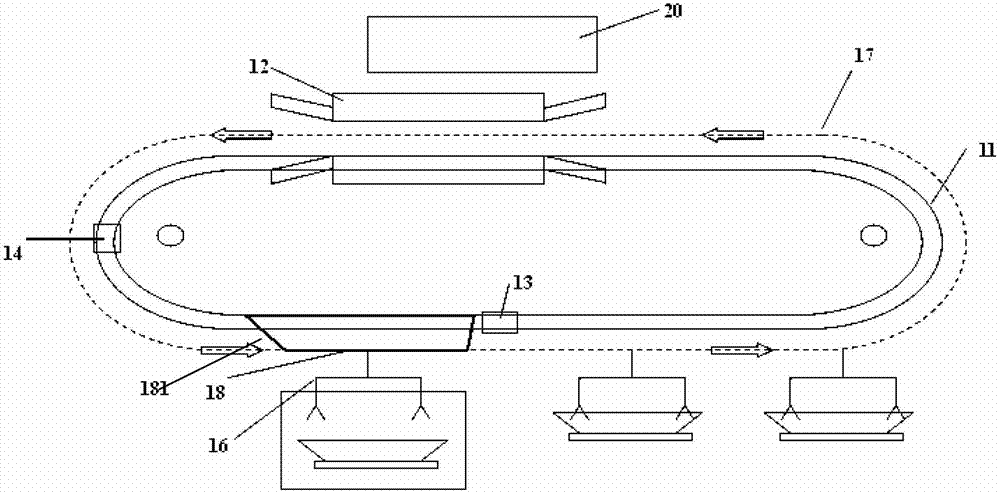

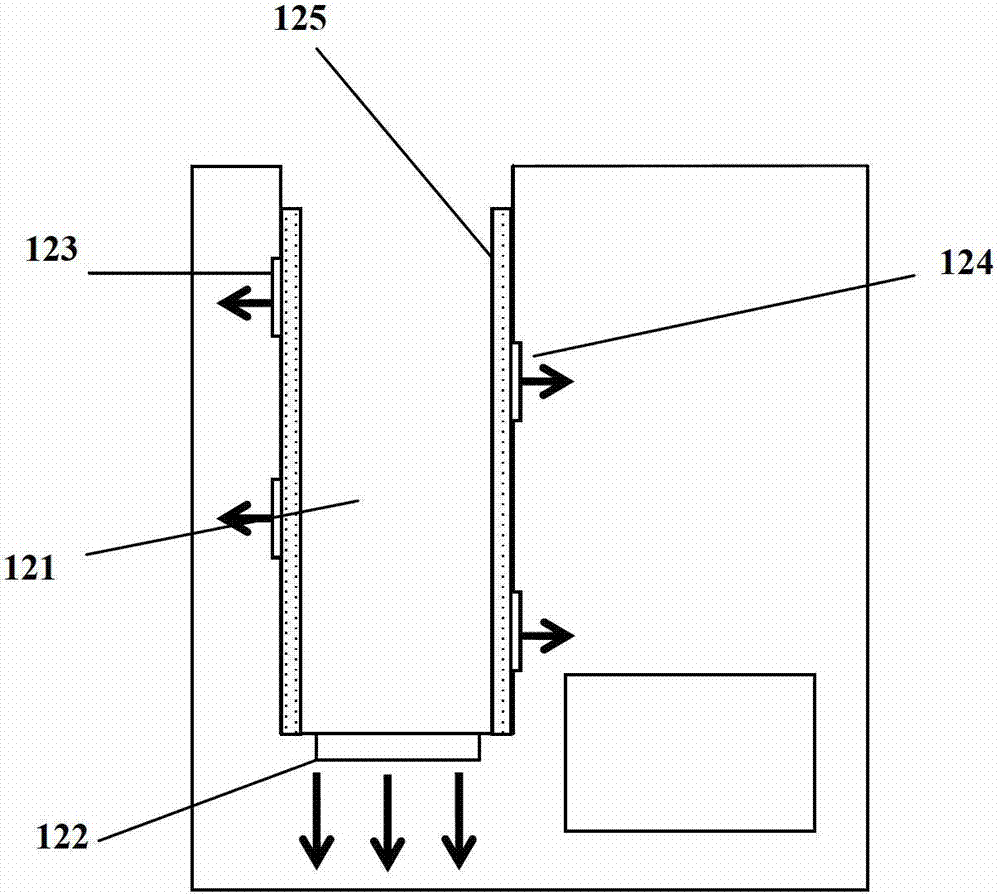

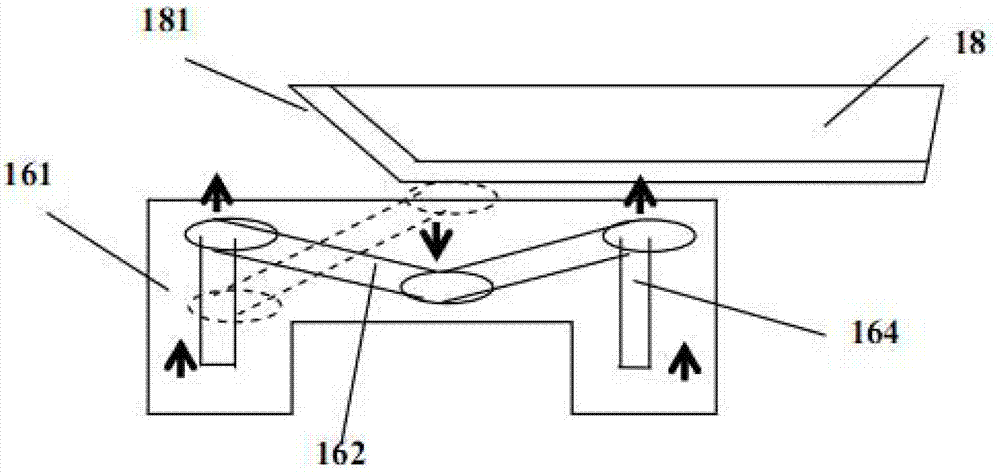

[0029] Such as figure 1 As shown, the garment making tail processing device of the present invention includes a track 11, a thread suction machine 12, a first piece counting sensor 13, a second piece counting sensor 14, a clothes hanger 16, a support 17 and a control device 20.

[0030] The track 11 is a tunnel-type suspension wire, which adopts a chain-type suspension design. The shape of the track 11 can be oval or circular. This embodiment takes a circular track as an example. An oil-proof groove is arranged under the chain to prevent dirt such as oil from the chain from falling down and staining clothes. Furthermore, a frequency conversion speed regulating device is used to adjust the traveling speed of the tunnel-type hanging wire, and the frequency conversion speed regulating device can be controlled by the control device 20, so as to realize different thread suction times for different fabrics.

[0031] The shape of the bracket 17 is oval or circular similar to the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com