Waste salt refining method

A refining method and dissolution pool technology, which is applied in separation methods, chemical instruments and methods, and dissolution, can solve problems such as cumbersome procedures, and achieve the effects of avoiding impurities from clogging the filter, improving treatment effects, and saving procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The waste salt refining method comprises the steps of:

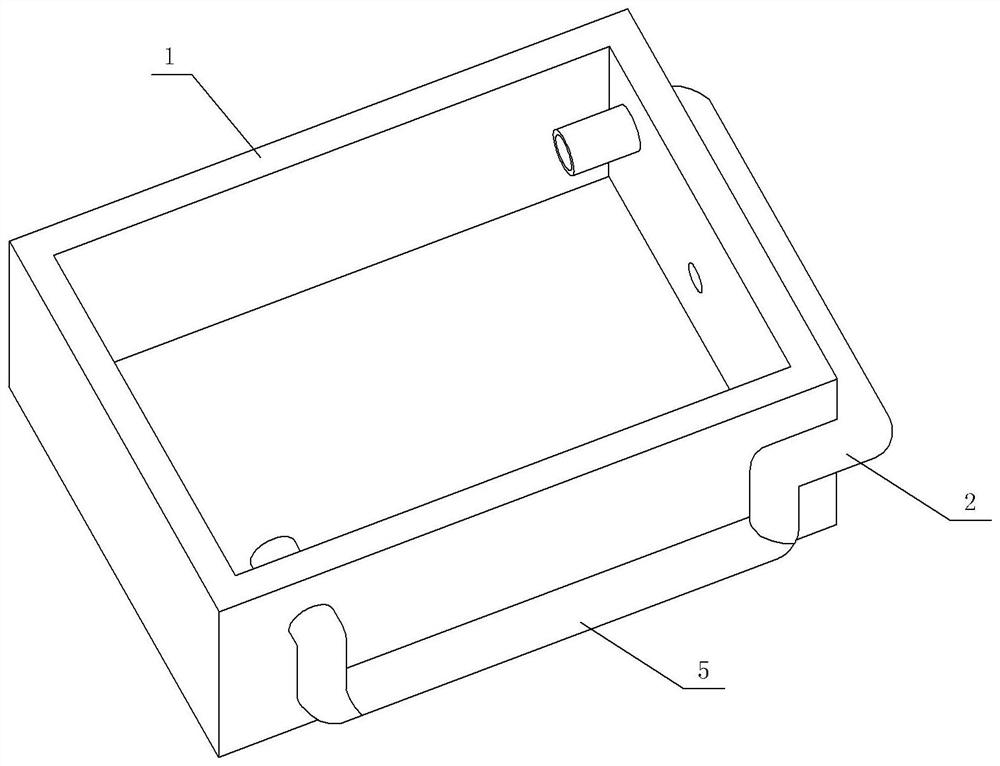

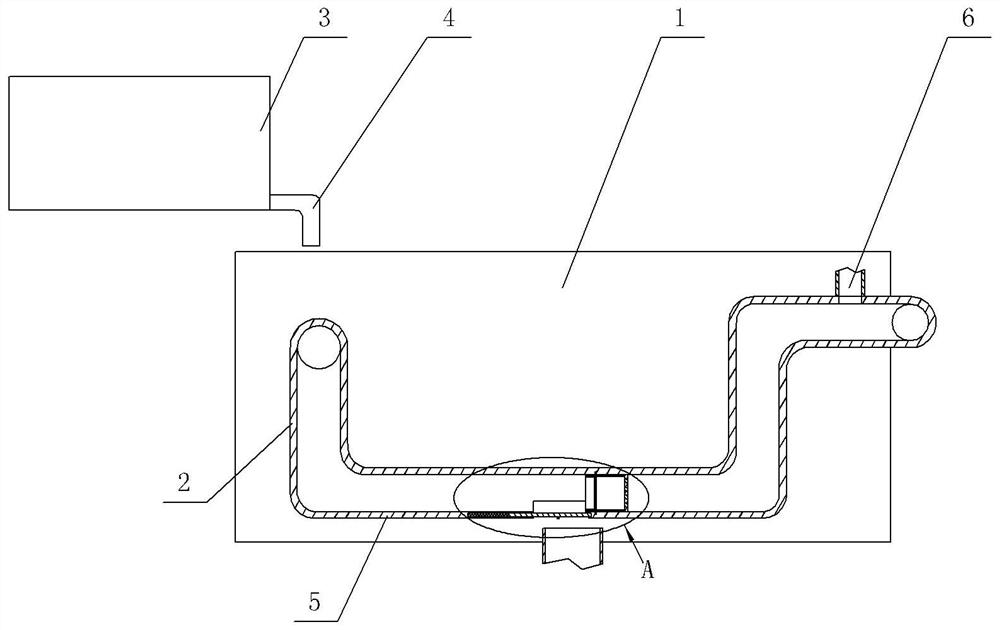

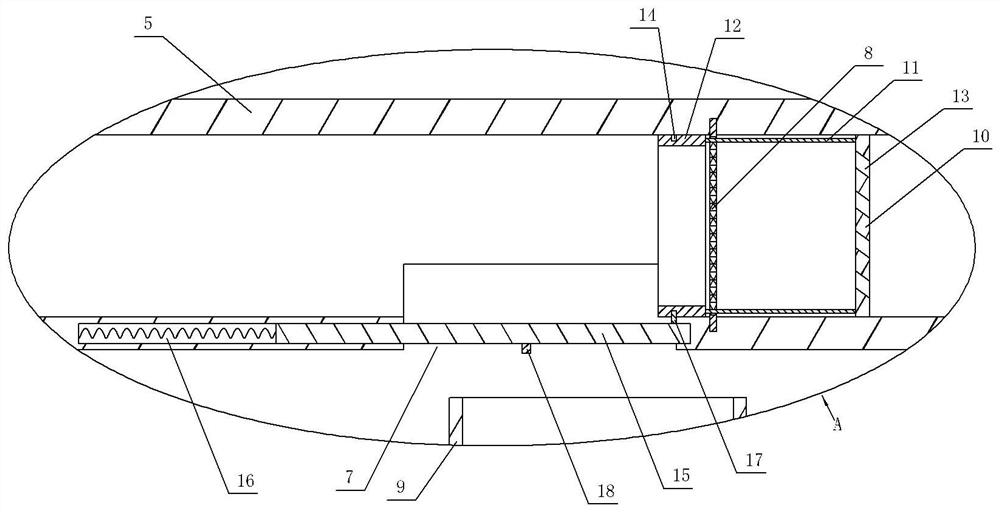

[0025] Step 1: Prepare as attached figure 1 The high-temperature molten waste salt dissolving device shown includes a dissolving tank 1, a circulating water pipe 2 and a filter mechanism. A furnace 3 is installed on the frame above the side of the dissolving tank 1, and a number of drain pipes 4 arranged side by side are connected to the furnace 3. , the flow rate of all drain pipes 4 is 1.5T / h.

[0026] The dissolving tank 1 is located below the drain pipe 4, the water capacity of the dissolving tank 1 is 30T, the water temperature in the dissolving tank 1 is kept between 50-60°C, and the range of temperature rise after the molten waste salt enters the dissolving tank 1 is kept at Below 15°C. The side wall of the dissolving tank 1 has a water outlet and a water inlet. The circulating water pipe 2 is located outside the dissolving tank 1 and is in contact with the outer wall of the dissolving tank 1. The two end...

Embodiment 2

[0038] The difference from Example 1 is that the location of the melting furnace 3 is replaced by a crusher, and the melted waste salt is cooled into lumps and then crushed into powder by the crusher and then enters the dissolution pool 1.

Embodiment 3

[0040] The difference from the first embodiment is that a scraper is slidingly arranged in the melting furnace 3, and the melting furnace 3 includes a burner port and a feed port. The top of the furnace 3 is made of high temperature resistant heat insulation material, the top of the furnace 3 is fixedly installed with a cylinder, and the top of the furnace 3 has a strip groove, and the scraper is welded vertically with a support strip, and the support strip passes through the strip groove And it is slidingly connected with the bar groove, and the upper end of the support bar is welded with the output shaft of the air cylinder.

[0041] After the waste salt enters the melting furnace 3 through the feeding port, the cylinder is started, and the output shaft of the cylinder is extended to drive the scraper to move, which not only helps to disperse the waste salt accumulated at the feeding port evenly in the melting furnace 3, but also makes the spraying The high-temperature flame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com