Cover for a furnace for receiving molten material, particularly metal, and furnace for receiving molten material

A melting and lid technology, which is used in casting melt containers, furnace components, metal processing equipment, etc., can solve problems such as furnace generation problems, and achieve the effect of avoiding deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

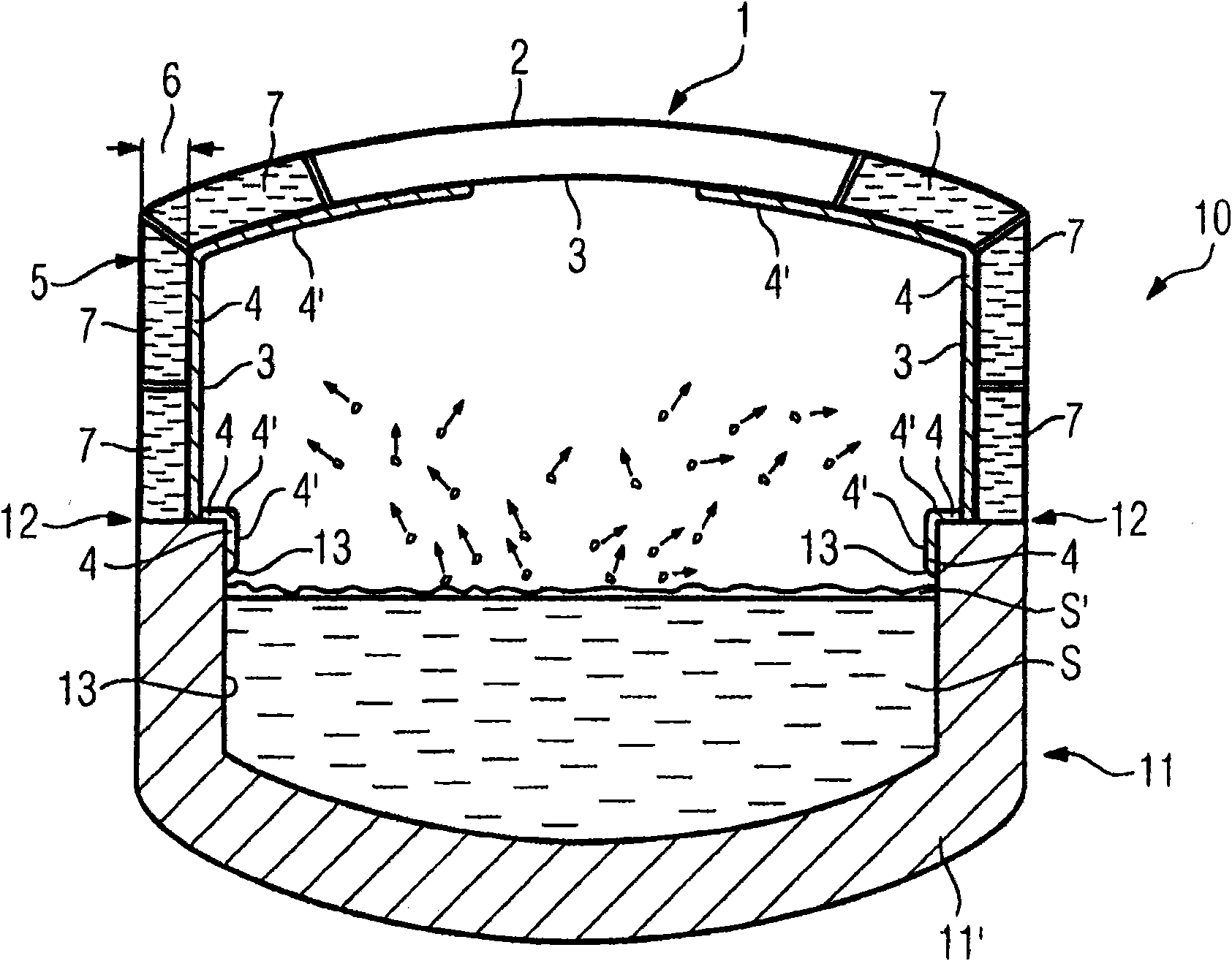

[0035] figure 1 A cross-sectional view of the furnace 10 is shown. This furnace 10 has a lid 1 and a crucible 11 . The furnace 10 is shown in the closed state, ie the lid 1 and the crucible 11 form a closed volume. The molten melt S is located in this crucible 11 . This molten material S constitutes molten steel. The slag S' is located above the liquid steel. Furthermore, metal droplets (Metaltropfen) escaping from the steel pool are shown. They at least partly hit the inner surface 13 or 3 of the crucible 11 or lid 1 . if figure 1 The furnace 10 in is constituted like the prior art, then the metal drop that bumps into the inner surface 13 or 3 of the crucible 11 or the lid 1 will be welded together with the inner surface 3 of the crucible 11 or the lid 1 on the respective positions, which A metallic bond that is difficult to break off may develop, which increases in weight and volume over time. If the sticky matter exceeds a certain size or a certain limit size or a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com