Patents

Literature

46 results about "Eco-Block" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Eco-Block, which was invented by the Hong Kong Polytechnic University in 2006, is an environmental friendly brick made from recycled materials and construction waste. The major feature of Eco-Block is to catalyze the nitrogen oxide and other pollutants in air into non-hazardous substances. Eco-Block has been mainly used as paving brick in pedestrians and vehicular areas in Hong Kong and it is now the 3rd generation.

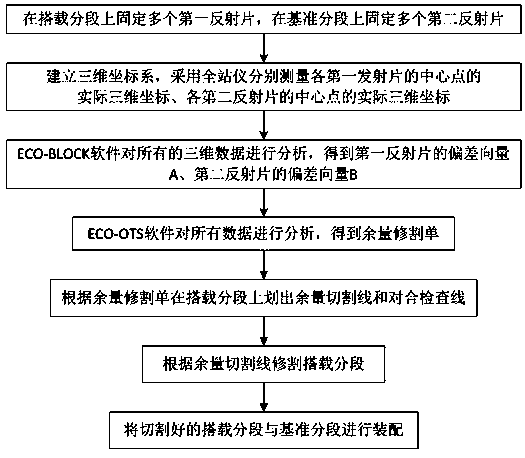

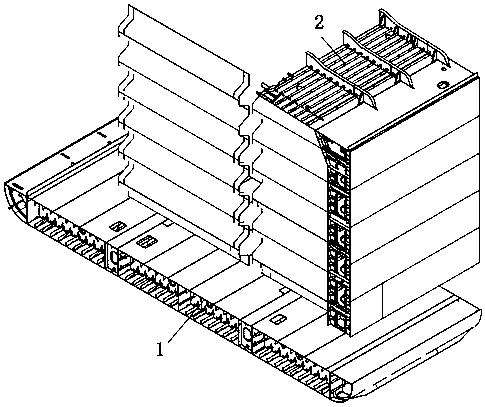

Accuracy control method capable of rapidly carrying ship body

InactiveCN110329423AHigh precisionImprove construction efficiencyVessel designingDeviation vectorMarking out

The invention discloses an accuracy control method capable of rapidly carrying a ship body. The accuracy control method specifically comprises the following steps: fixing a plurality of first reflector plates on carrying segments, and fixing a plurality of second reflector plates on reference segments; measuring the actual three-dimensional coordinate of each first reflector plate and the actual three-dimensional coordinate of each second reflector plate respectively by using a total station; generating the deviation vectors A of the first reflector plates and the deviation vectors B of the second reflector plates by using ECO-BLOCK software; generating a margin trimming list by using ECO-OTS software; marking out margin cutting lines and involution check lines on the carrying segments according to the margin trimming list; trimming the carrying segments according to the margin cutting lines; and assembling the carrying segments and the reference segments which are cut. The accuracy control method is simple and convenient in operation, and accurate cutting can be carried out on the carrying segments by carrying out simulation carrying on the carrying segments, so that the accuracyof ship construction is improved, and the construction efficiency of ships is also improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

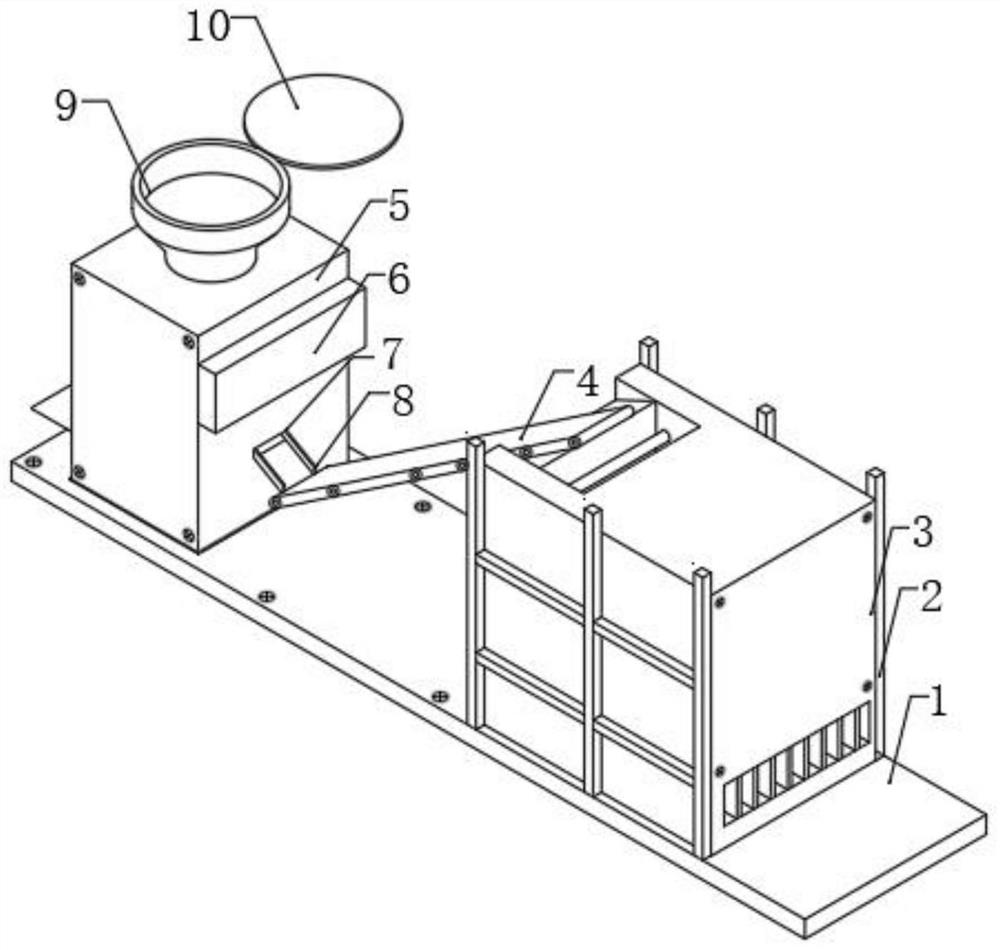

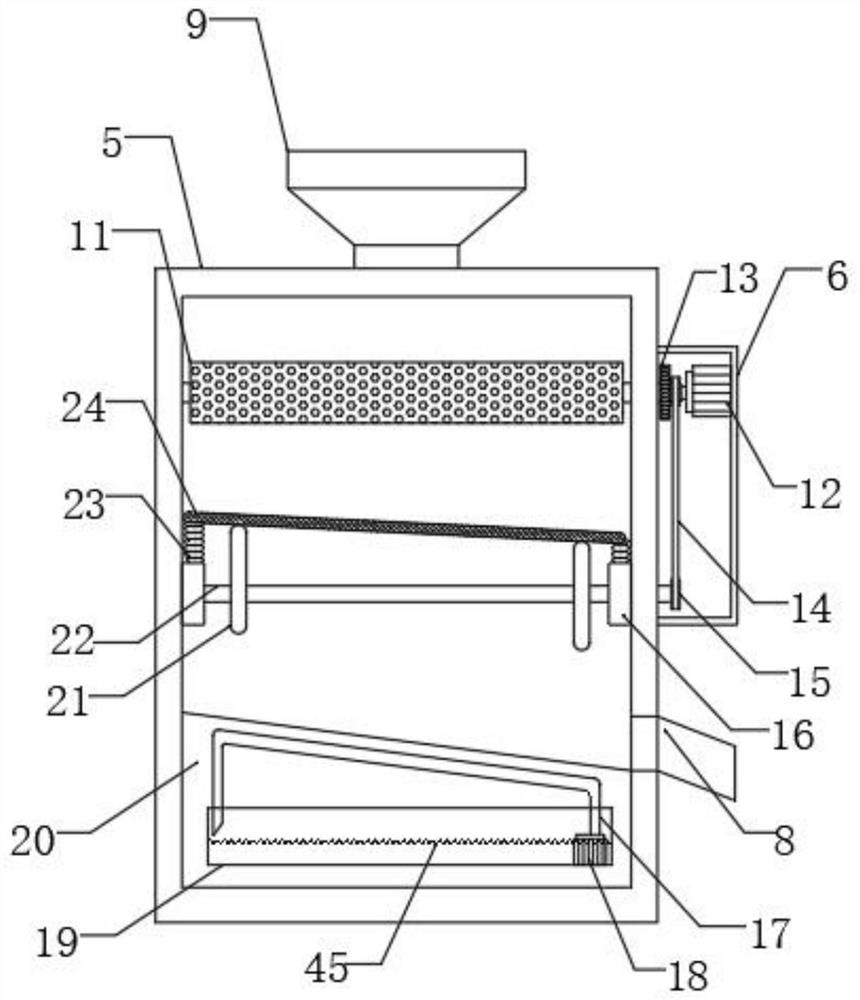

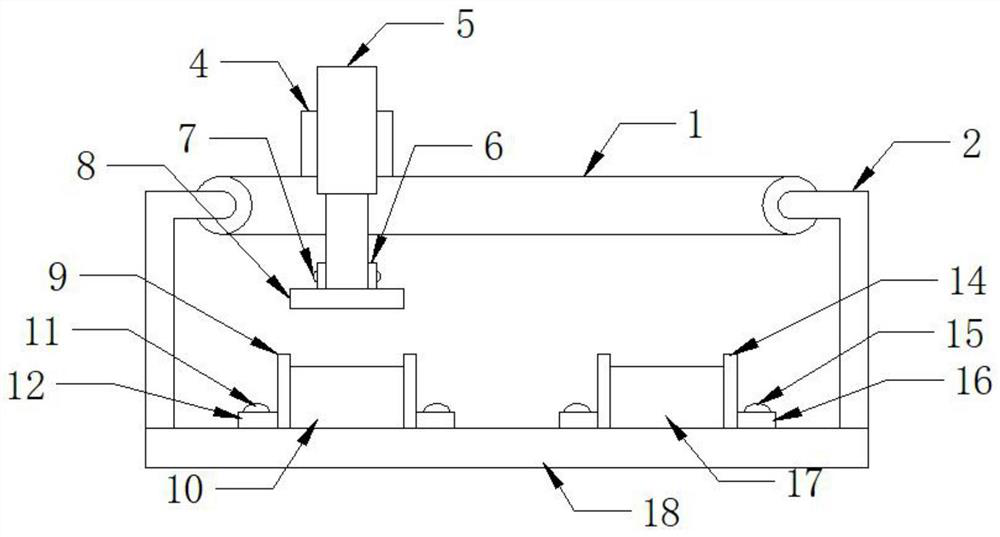

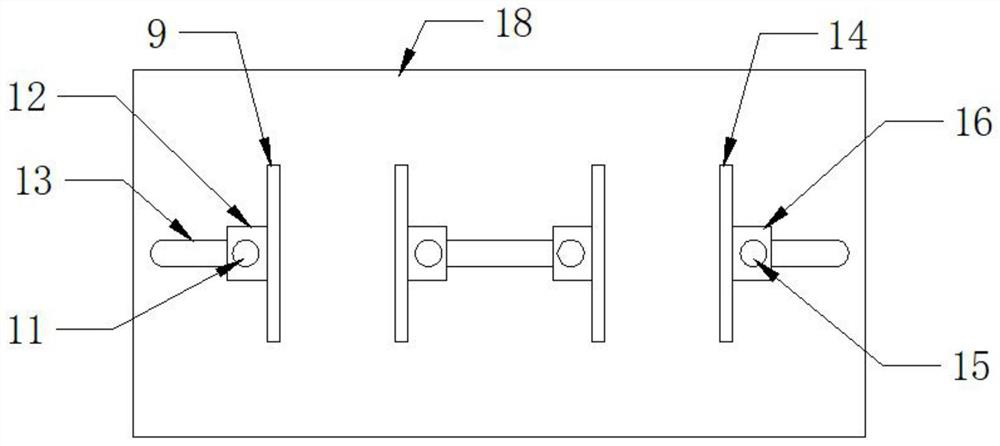

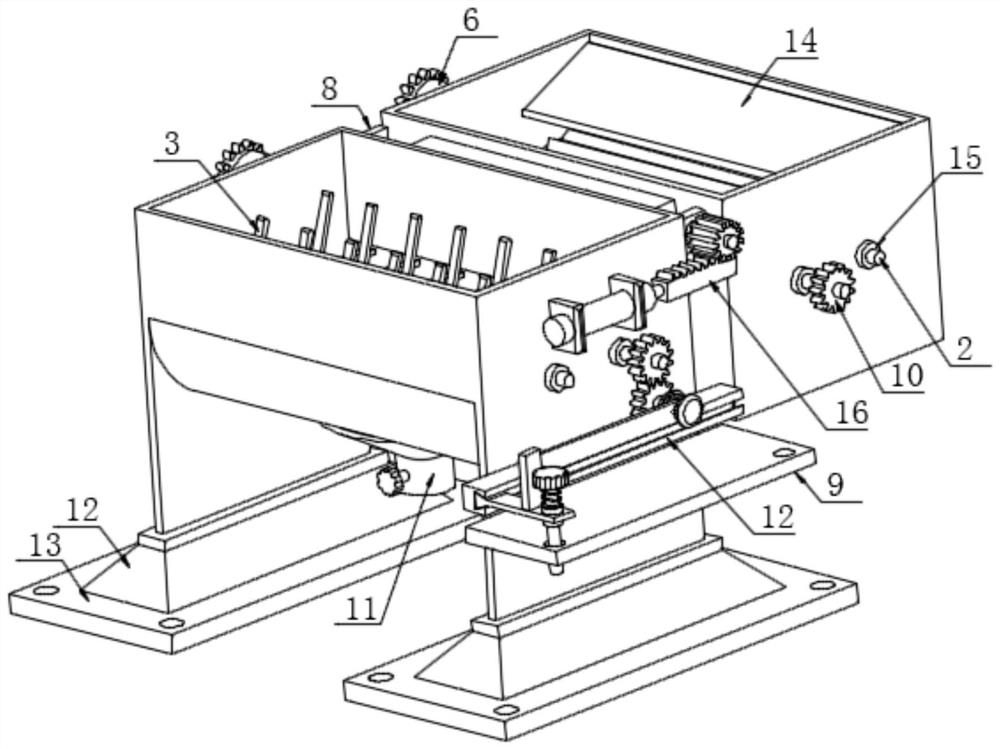

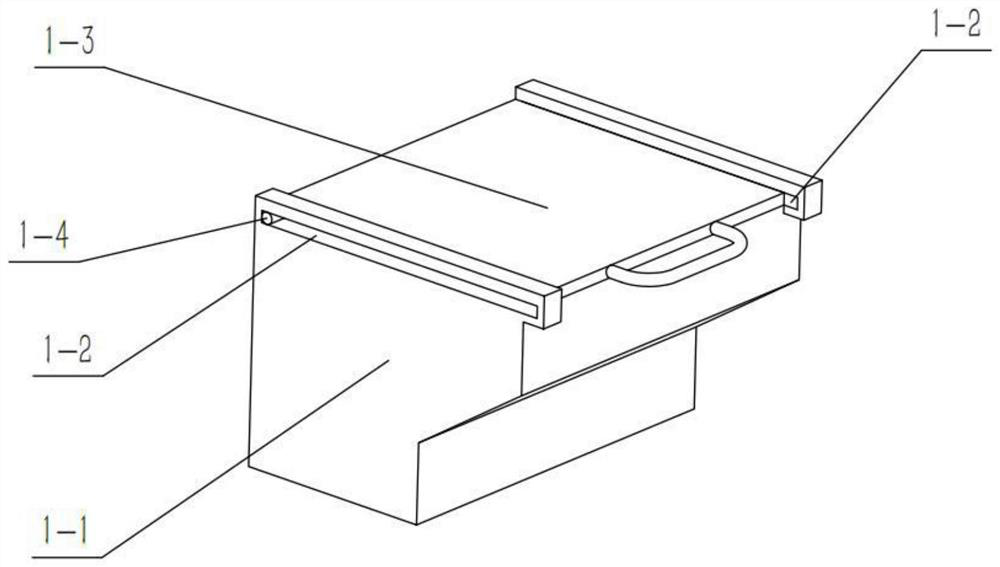

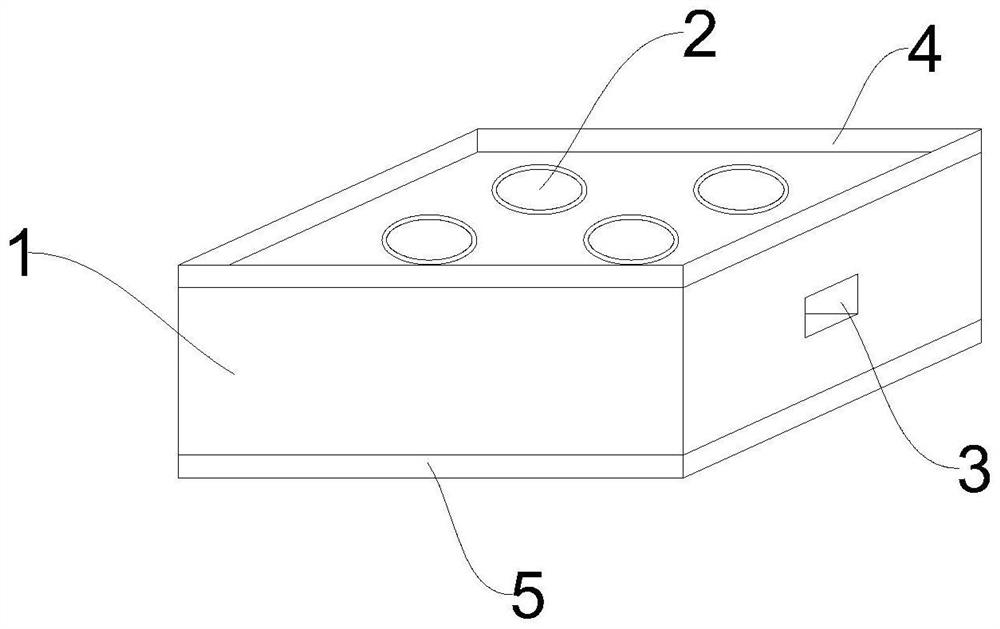

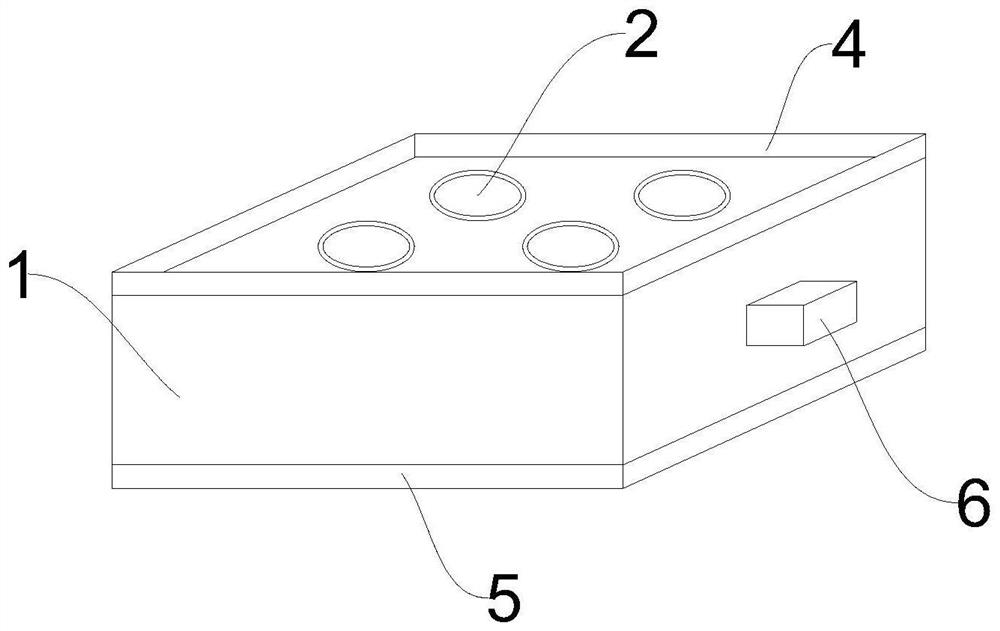

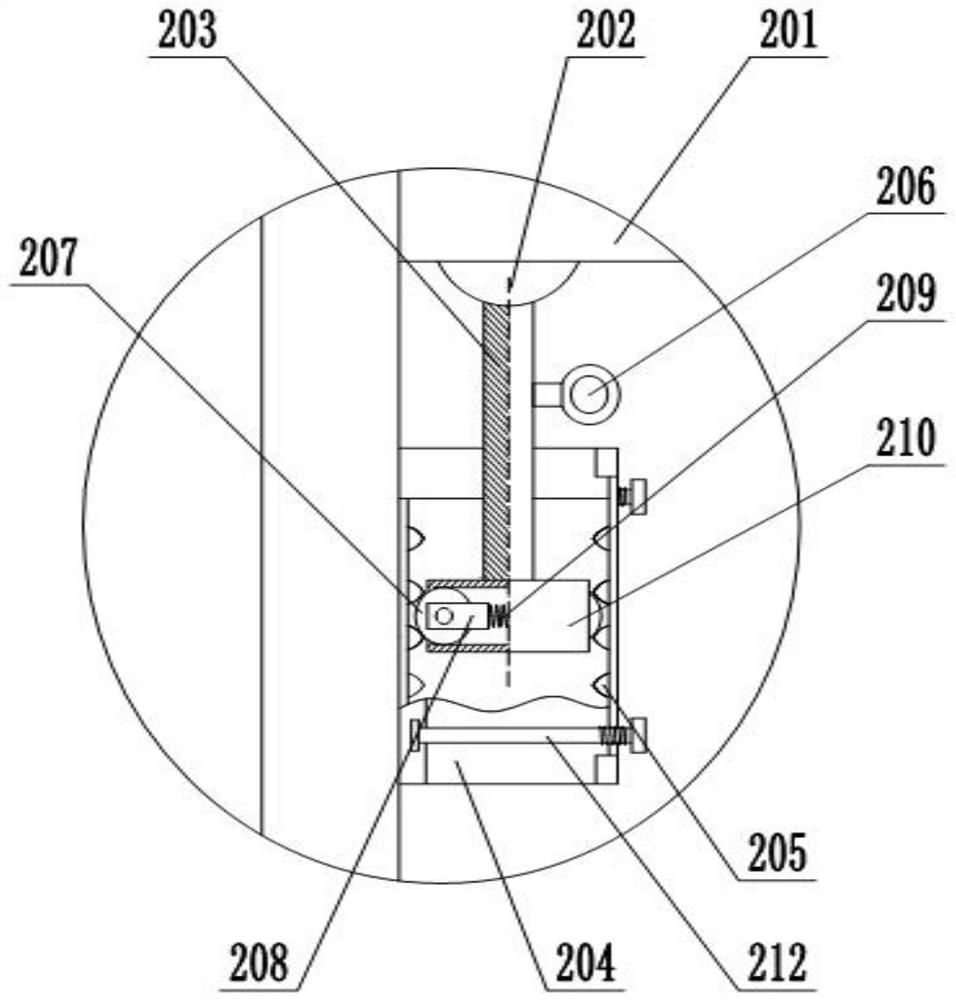

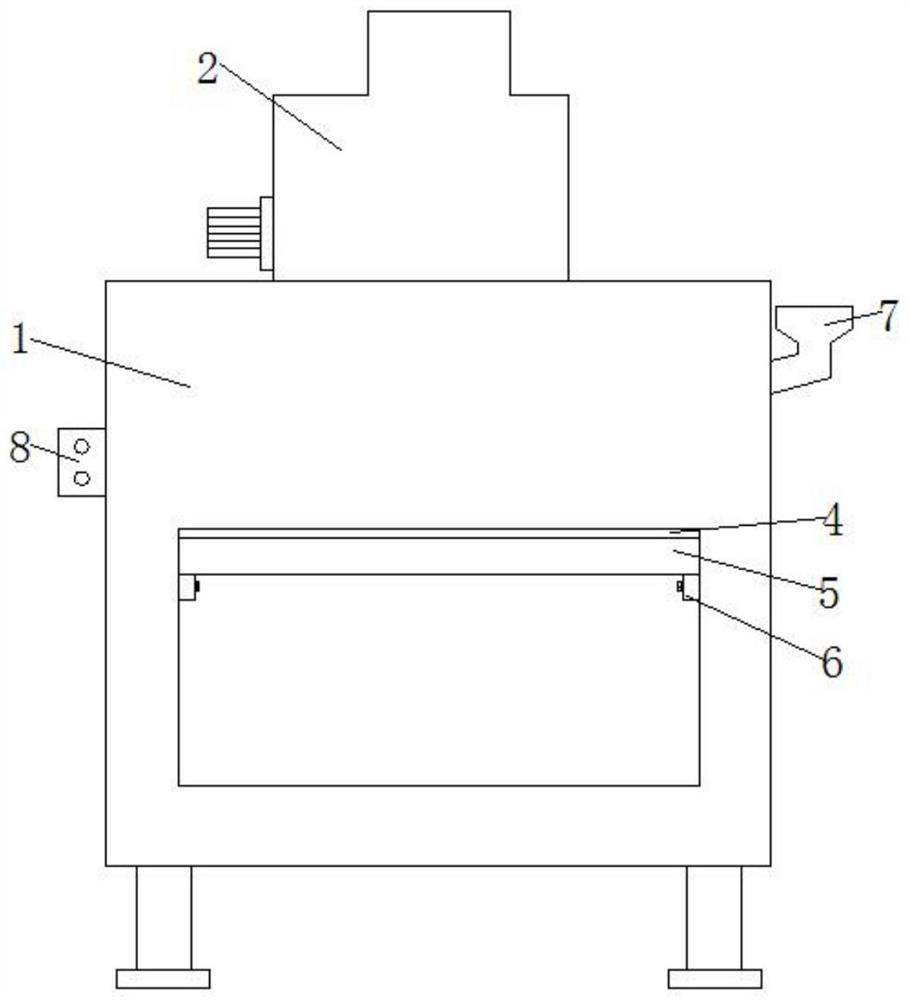

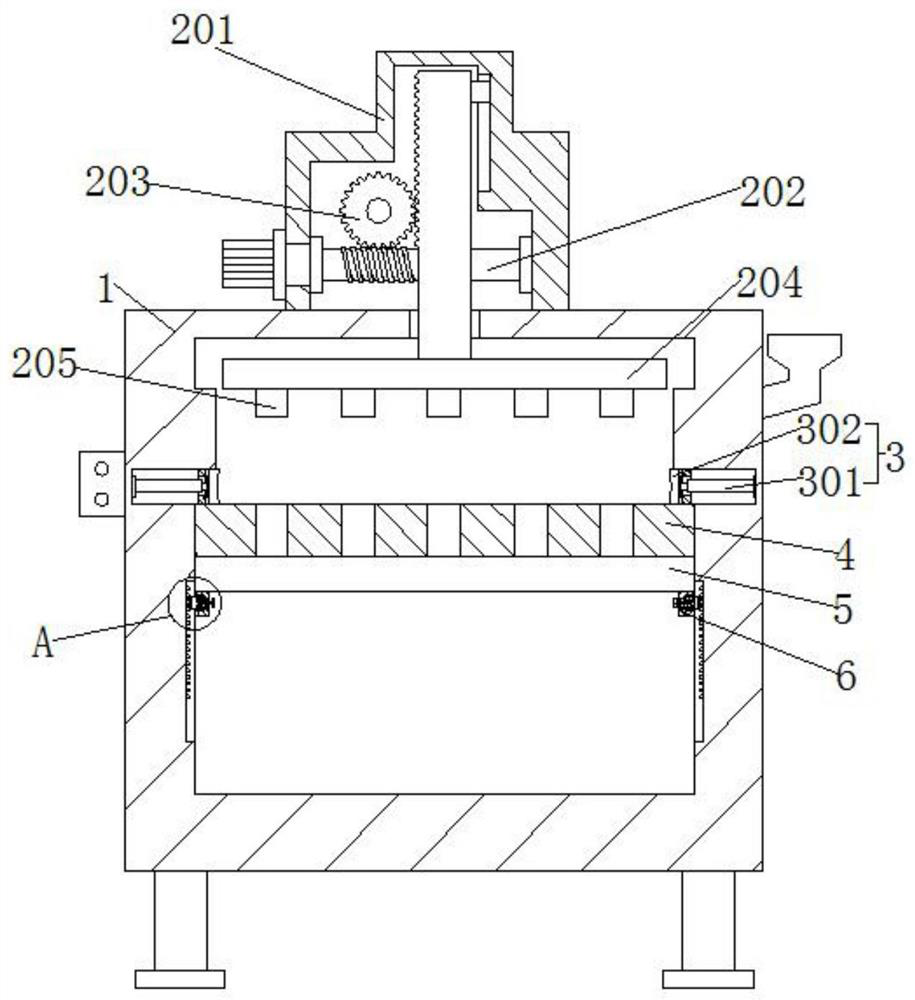

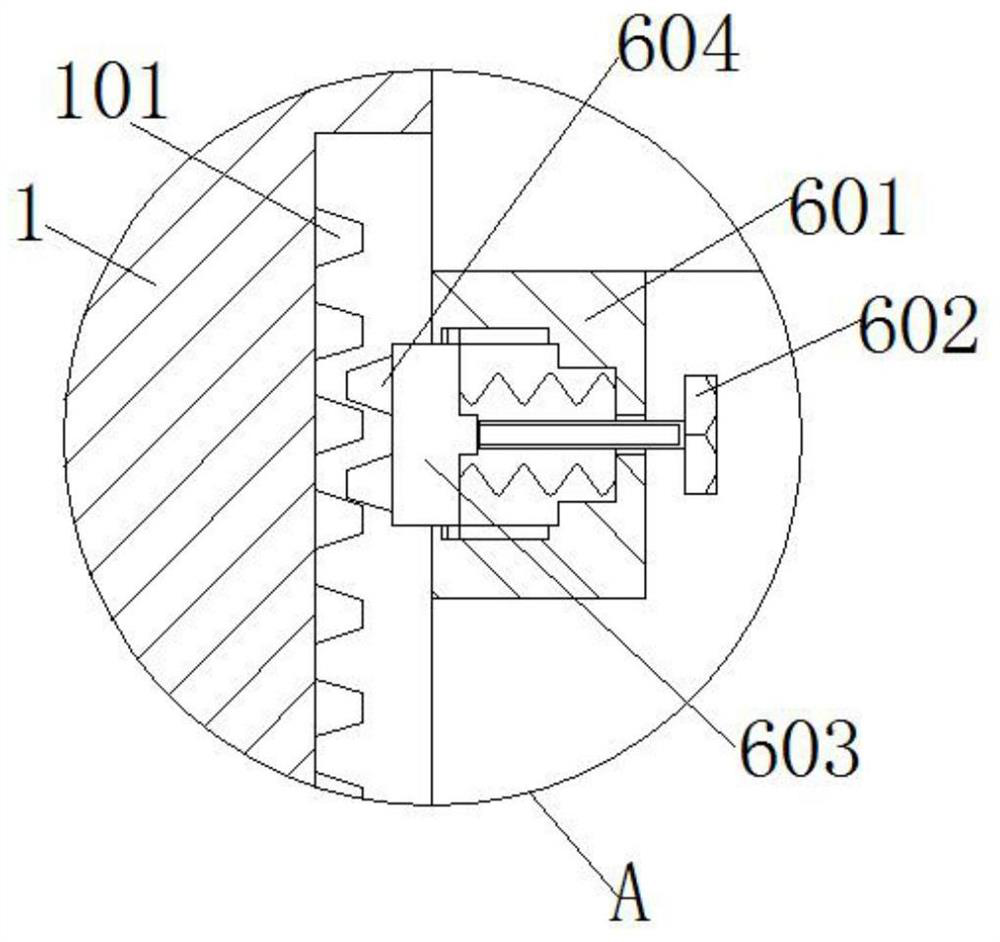

Environment-friendly brick manufacturing device and manufacturing method thereof

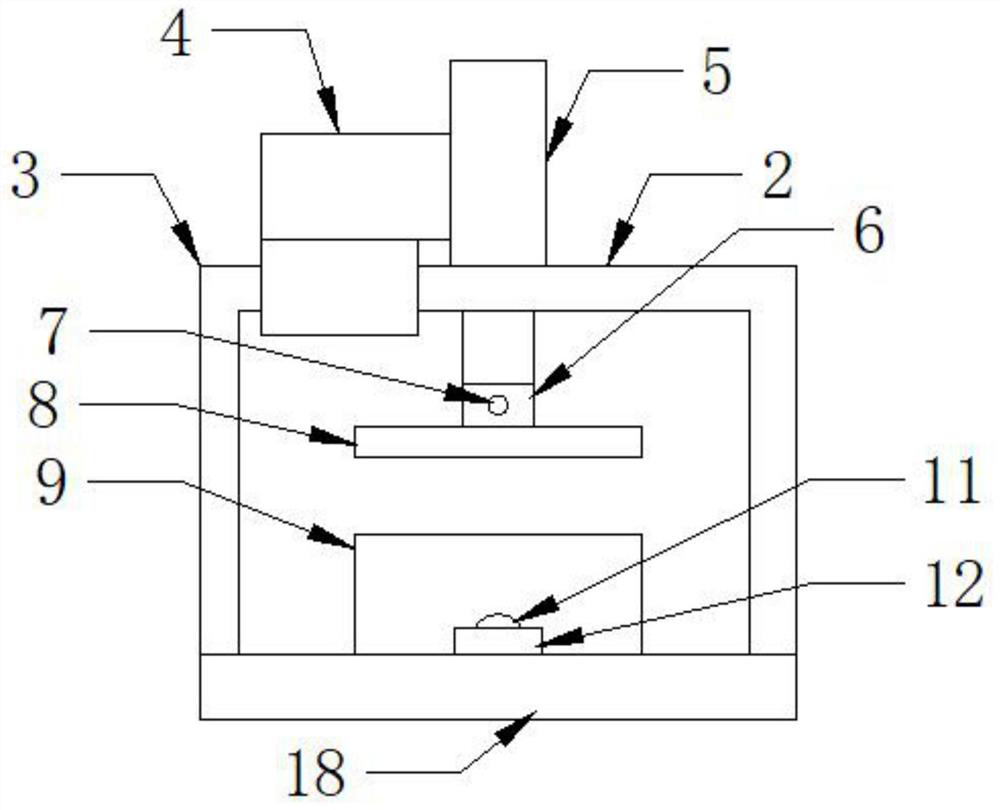

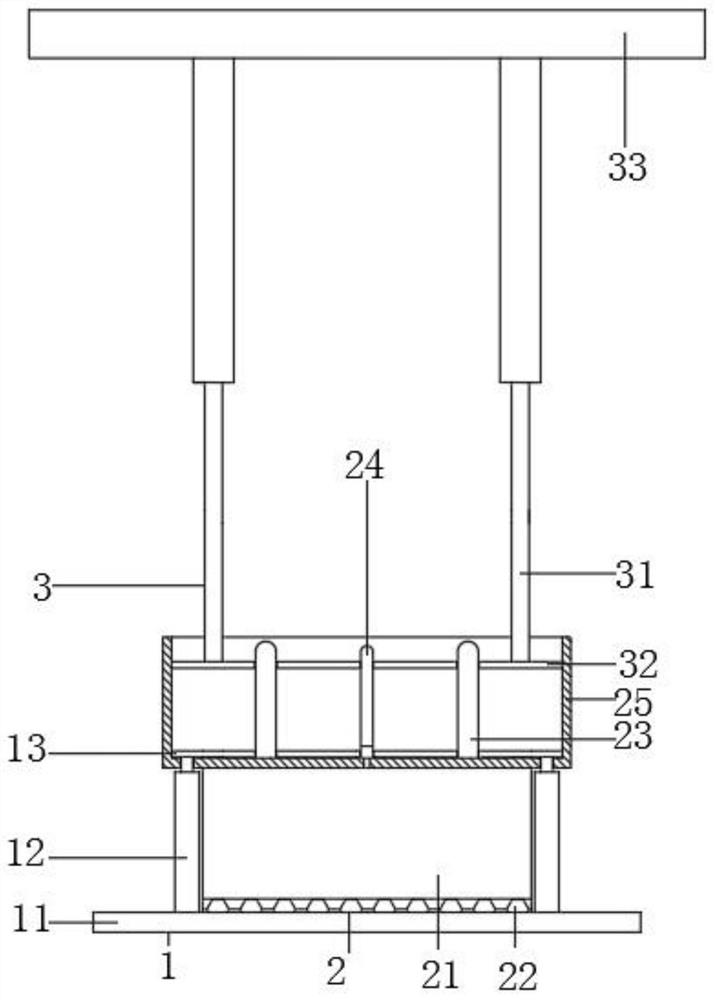

The invention discloses an environment-friendly brick manufacturing device and a manufacturing method thereof. The environment-friendly brick manufacturing device comprises a base, wherein a groove isformed in one side of the top end of the base; a raw material treatment box is embedded in the groove; and a plurality of buffer mechanisms are fixedly installed at the groove bottom of the groove atequal intervals and composed of T-shaped columns, sleeves, buffer air bags and connecting plates; the bottom ends of the sleeves are fixedly connected with the groove bottom of the groove; the multiple buffer air bags are fixedly installed in the sleeves; the connecting plates are fixedly installed at the top ends of the multiple buffer air bags; and the T-shaped columns are fixedly installed atthe top ends of the connecting plates. According to the environment-friendly brick manufacturing device and the manufacturing method thereof provided by the invention, a crushing mechanism and a screening mechanism are installed in the raw material treatment box, so that raw material crushing and screening integration is facilitated, and the original environment-friendly brick manufacturing process that crushing is conducted firstly and then screening is conducted through a vibrating screen so as to affect the environment-friendly brick manufacturing efficiency and increase the environment-friendly brick manufacturing cost is replaced.

Owner:林华胜

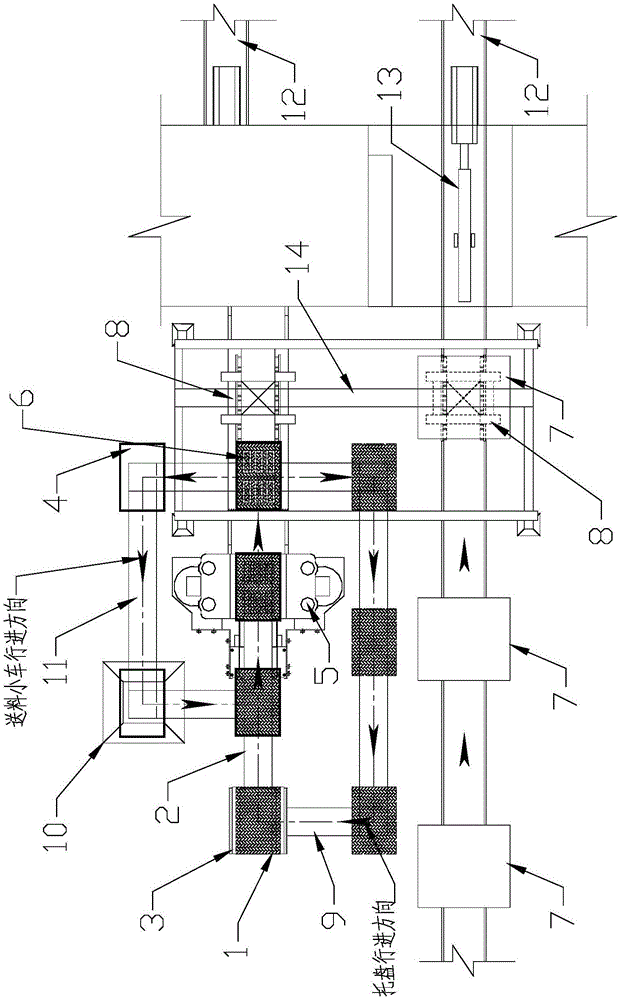

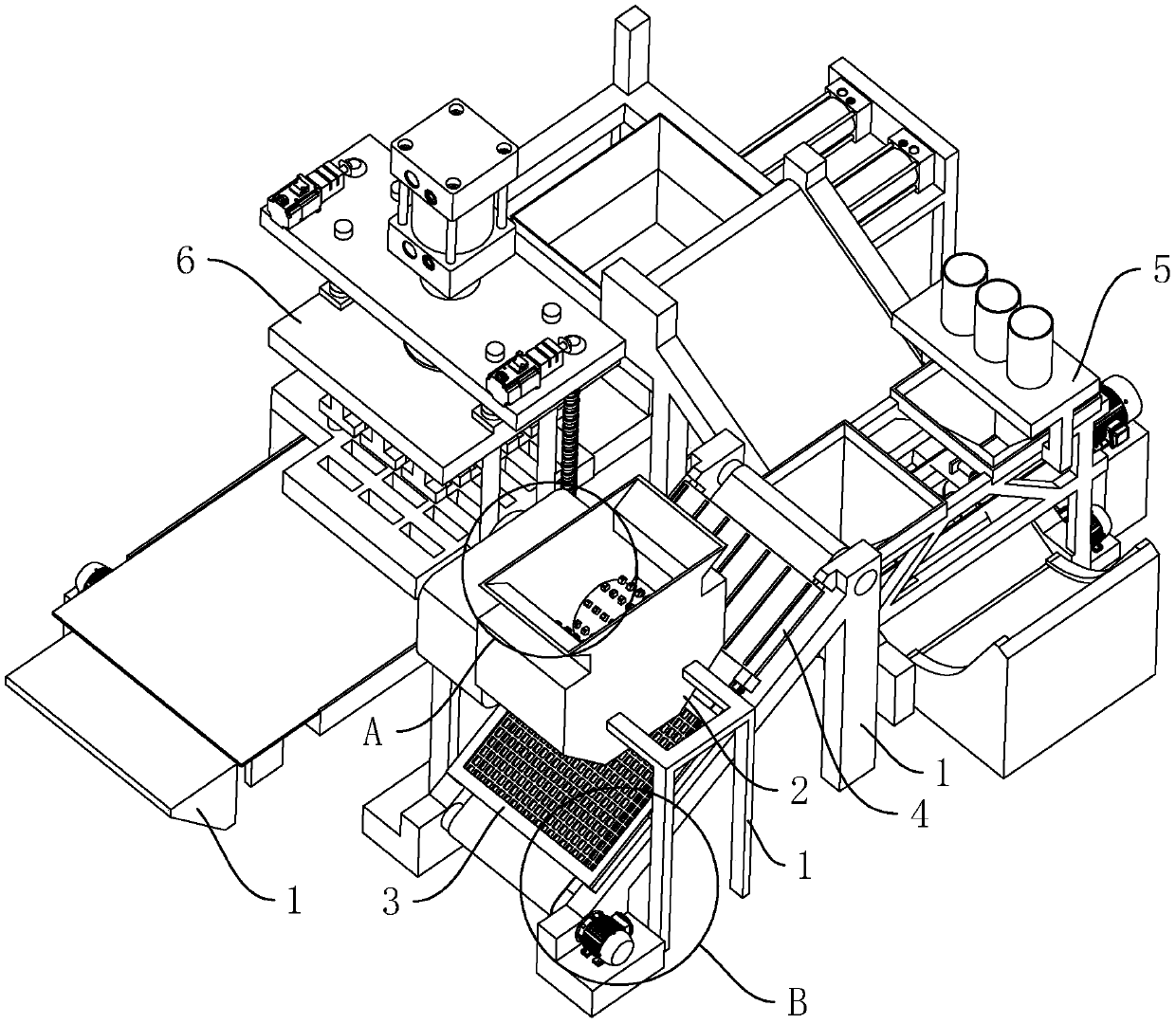

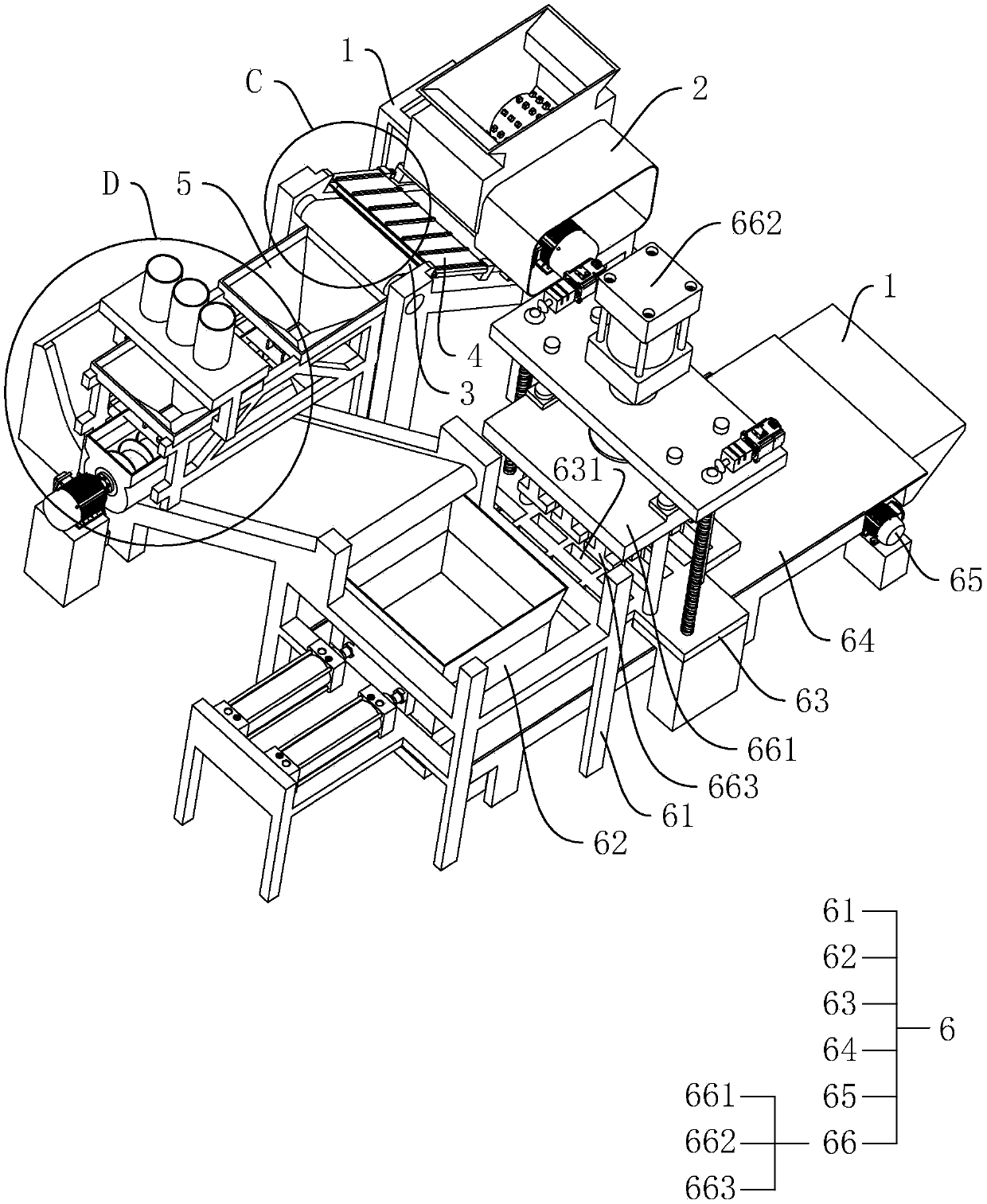

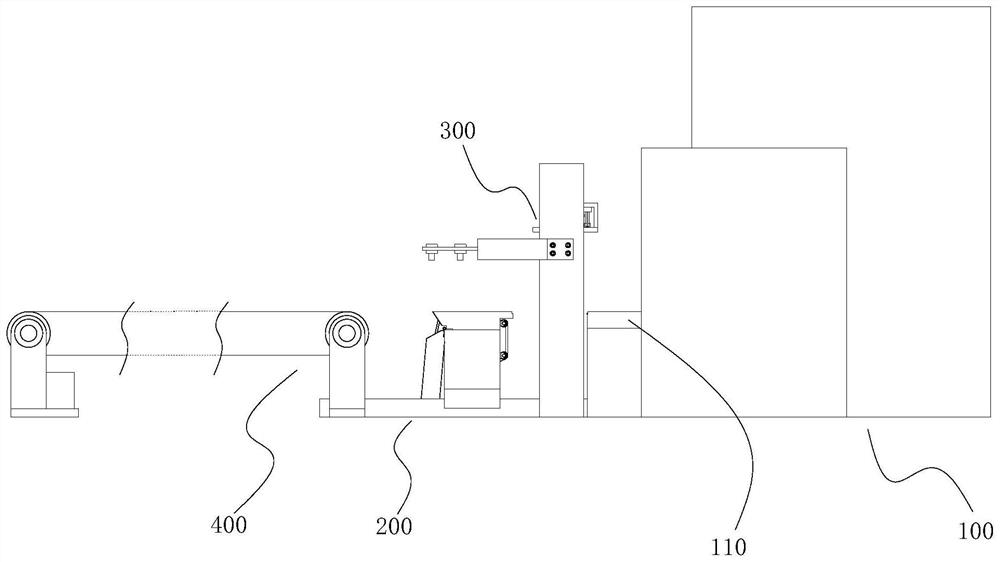

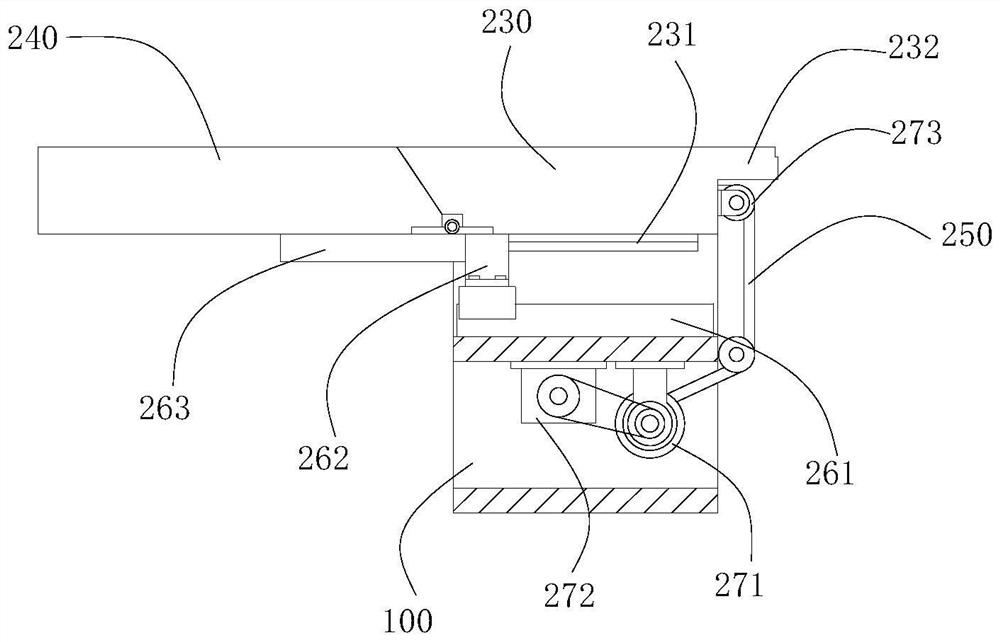

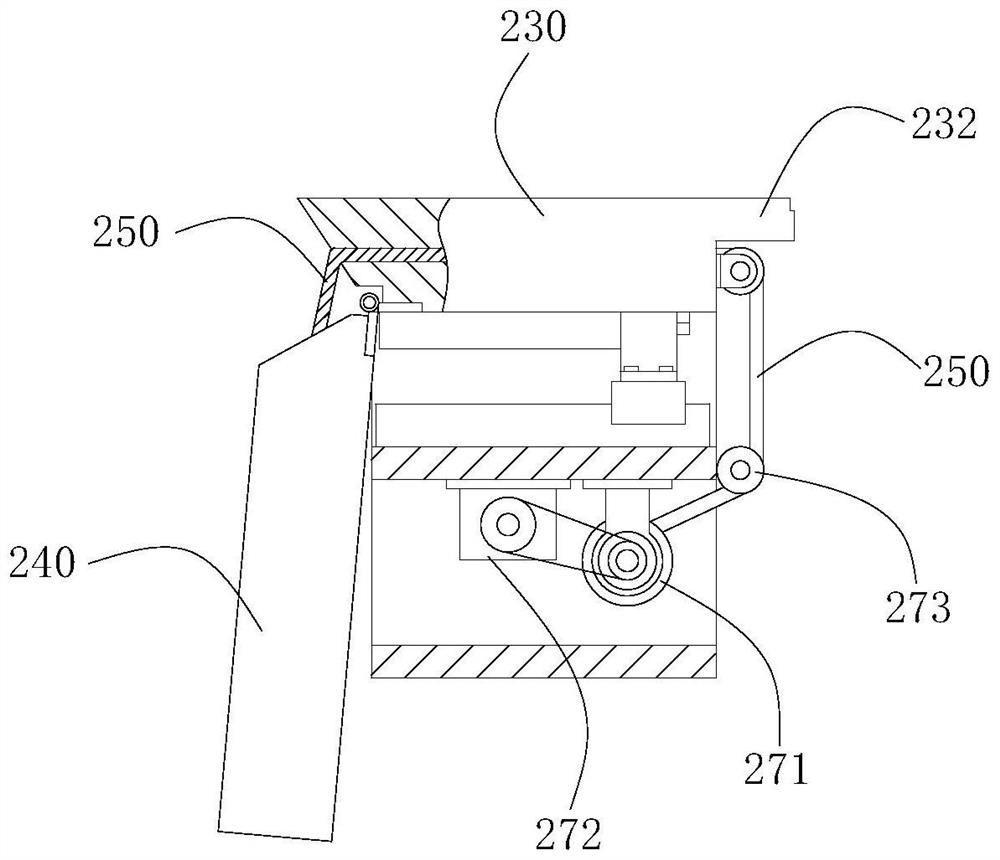

Environment-friendly brick pressing system and method

InactiveCN106113249AImprove efficiencyQuality improvementDischarging arrangementCeramic shaping plantsProduction lineBrick

An environment-friendly brick pressing system high in efficiency and good in quality comprises at least one pressing production line. Each pressing production line comprises a tray stacker crane used for loading a tray to the head end of a conveying belt, a first drive device used for conveying a feeding trolley loaded with raw materials to the position below the tail end of the conveying belt, a second drive device used for conveying the feeding trolley loaded with the raw materials and the tray to the pressing position of a press, a mechanical arm used for taking green bricks pressed through the press out of the tray and transferring the green bricks to a steamed oxygen trolley, a first conveying device used for taking out the tray, in which the green bricks are taken out, on the feeding trolley and conveying the tray back to the tray stacker crane, and a second conveying device used for conveying the feeding trolley in which the tray is taken out back to the position of the feeding device so as to load raw materials. The environment-friendly brick pressing system comprises a ferrying trolley used for distributing the steamed oxygen trolleys, loaded with the green bricks, on steamed oxygen trolley work lines into at least one still kettle.

Owner:安徽省炜思煜智能科技有限公司

Environment-friendly brick and preparation method thereof

The invention discloses an environment-friendly brick, which contain the following components in parts by weight: 15-24 parts of coal ash, 0.5-1.5 parts of brown sugar, 1-3 parts of glutinous rice powder, 25-45 parts of steel slag, 10-25 parts of marble waste slurry, 2-5 parts of resin, 1-4 parts of polyethylene glycol, 8-15 parts of natural fibrous material, and 0.2-0.8 parts of vitrified microbeads. The invention also discloses a preparation method of the brick. The product disclosed by the invention has the following advantages: the source of raw materials is wide, the preparation method is simple, and the product is suitable for large-scale industrial production. The product uses coal ash, steel slag, marble waste slurry and natural fibrous material as main raw materials, which meets the environment-friendly requirements for resource reutilization, and glutinous rice powder, resin, polyethylene glycol and vitrified microbeads are used as auxiliary materials, the main raw materials and the auxiliary materials are mixed, molded and fired, and the obtained product has good overall properties and wide market prospect.

Owner:合肥蔚然花绿化工程有限公司

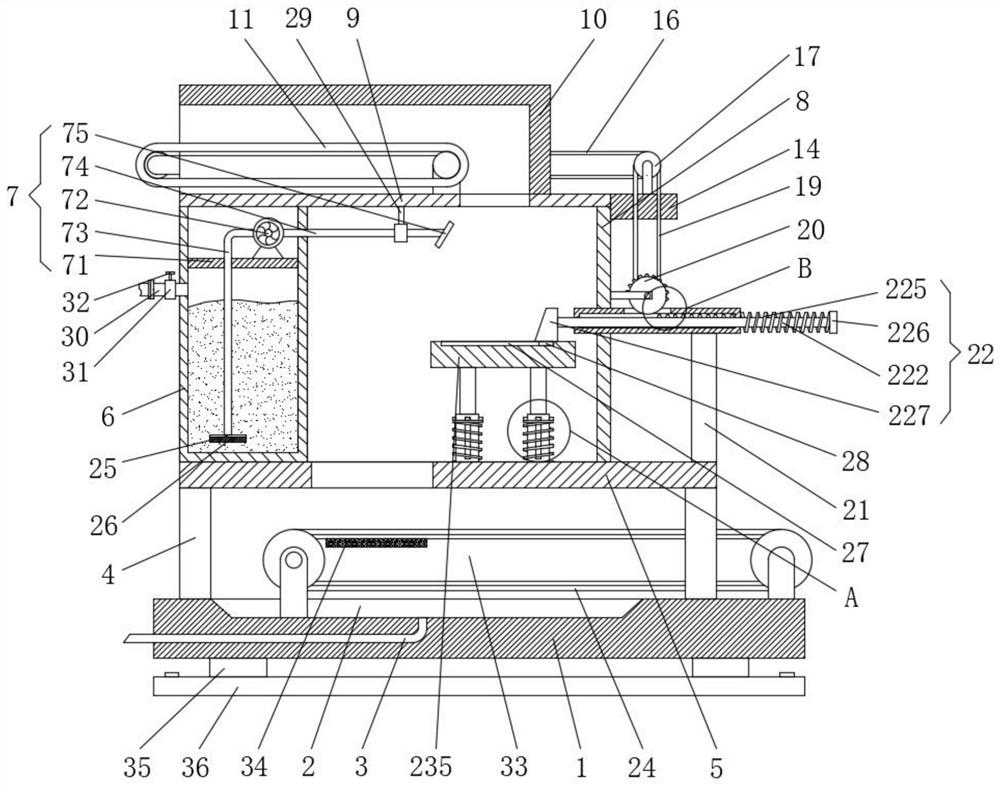

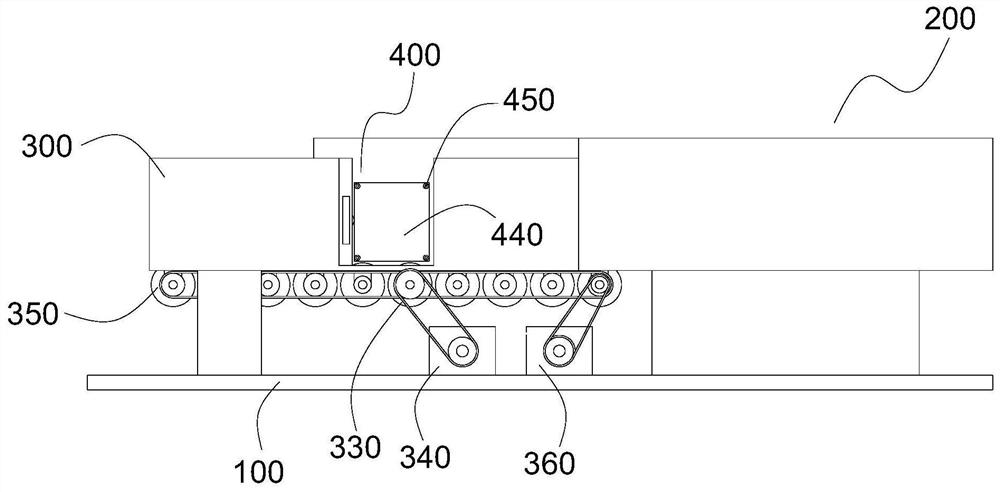

A brick material conveying device for the production of environmentally friendly bricks

ActiveCN112298923BAvoid damageExtended service lifeCleaning using liquidsConveyor partsBrickArchitectural engineering

The invention discloses a brick conveying device for environmental protection brick production. The outer side of the base, the top of the base is equipped with a support column, the number of the support column is four, the top of the support column is welded with a partition, one side of the top of the partition is bolted with a water tank, the water tank A flushing structure is installed in the interior of the clapboard, and a support plate is welded on the other side of the top of the partition; the invention can buffer the bricks, reduce the damage to the device, and clean the bricks, so the service life is longer. It solves the problem that due to the heavy brick material, the equipment is easily damaged during transportation after the production of the brick material, and at the same time, it is easily polluted during transportation, and the transportation device cannot clean the environmental protection brick, resulting in a decrease in the service life of the equipment.

Owner:常德东旺建材科技有限责任公司

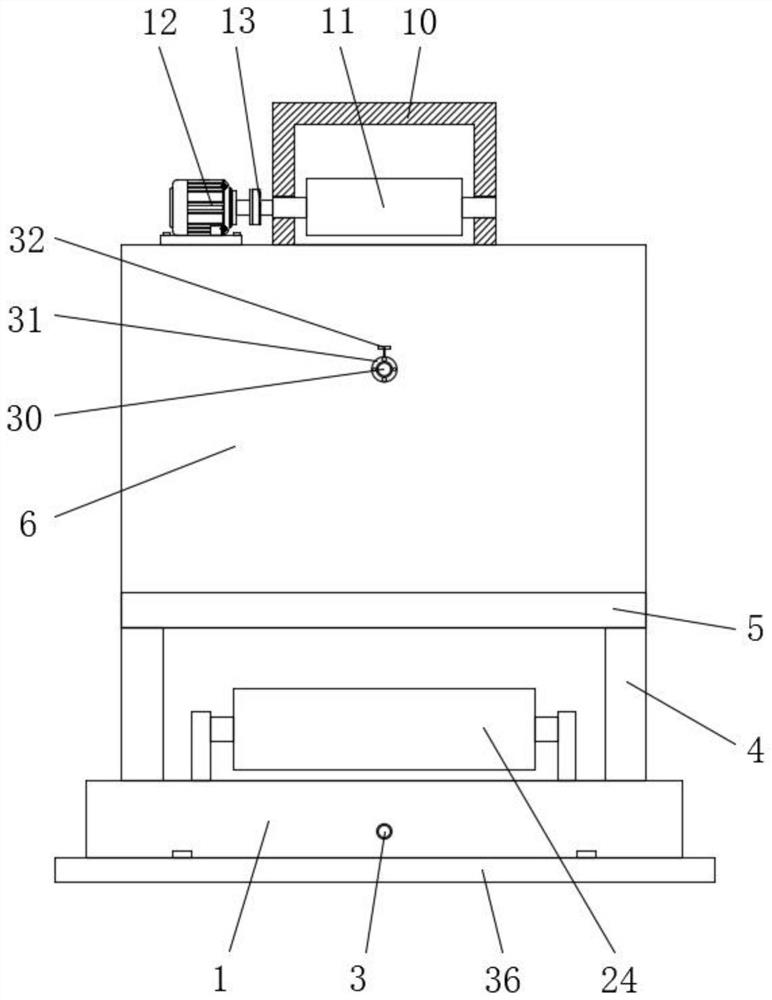

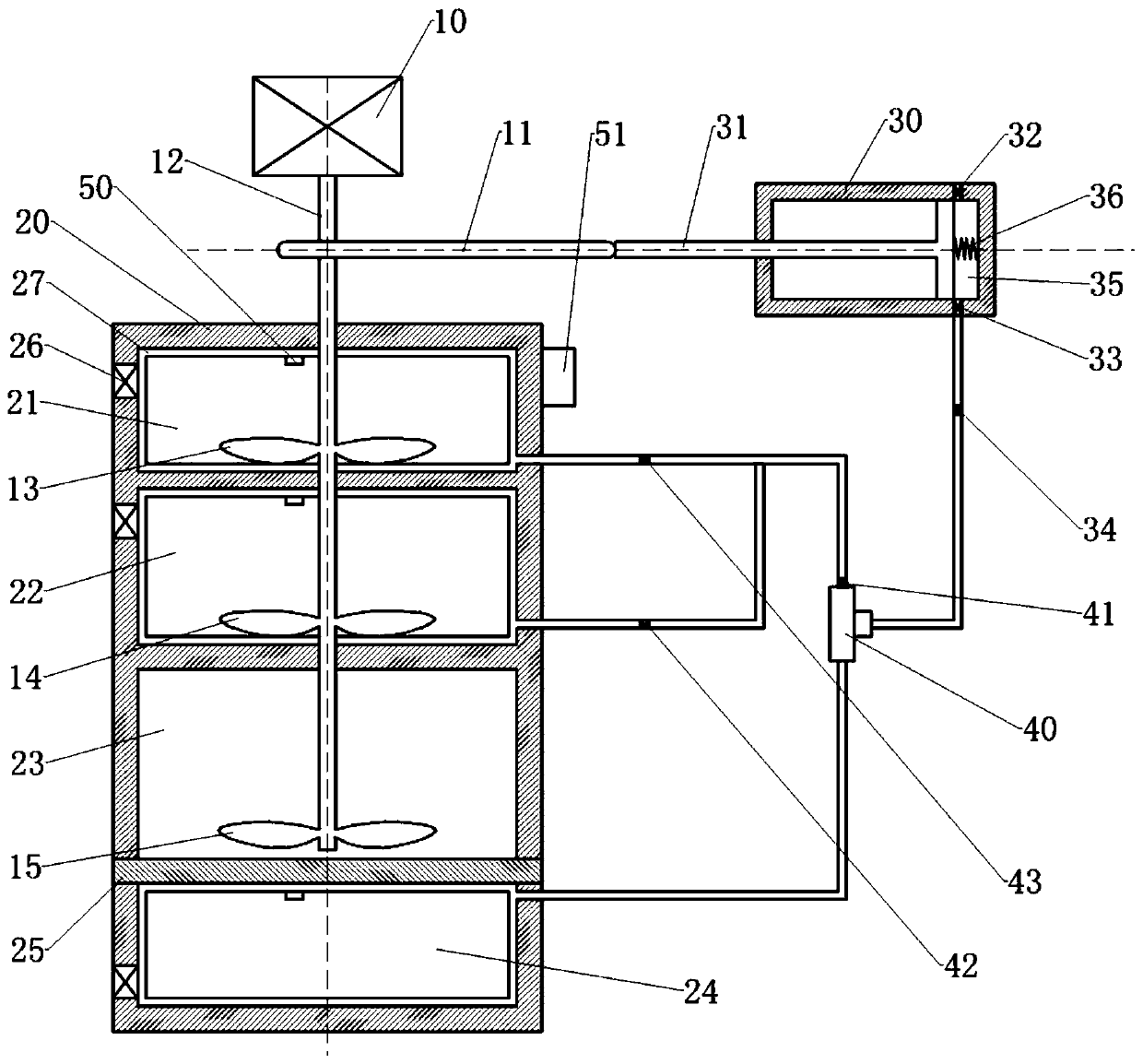

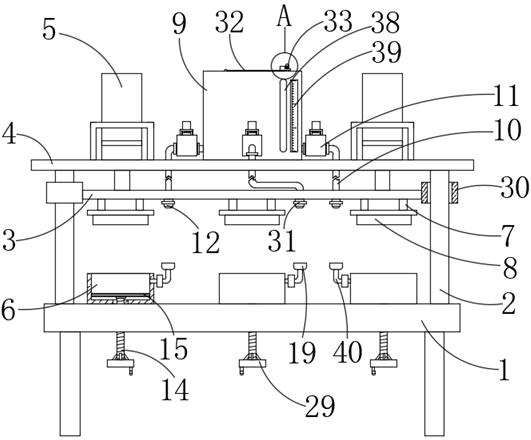

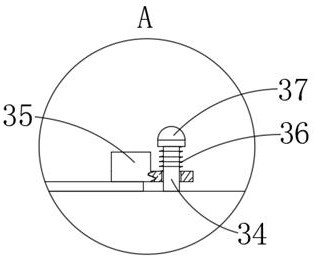

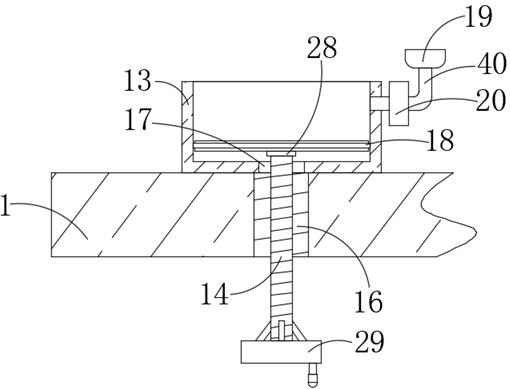

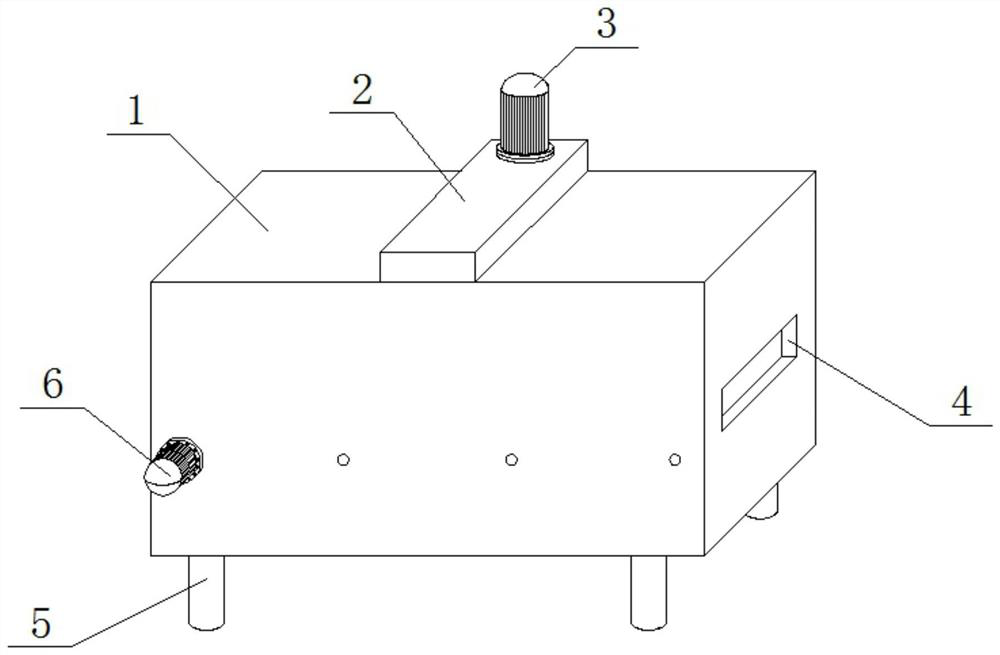

A raw material preparation device for environmentally friendly bricks

ActiveCN109465960BShort manufacturing timeIncreased preparation rateClay mixing apparatusBrickGas cylinder

The invention belongs to the field of building brick production, and particularly relates to a raw material preparation device for an environment-friendly brick. The raw material preparation device comprises a drive device, a stirrer, a piston cylinder and a vortex tube, wherein the drive device comprises a motor and a stirring column; the lower portion of the stirring column extends into the stirrer; a first stirring paddle, a second stirring paddle and a third stirring paddle are arranged on the stirring column; the stirrer is a sealing device, and is sequentially equipped with a first stirring room, a second stirring room, a third stirring room and a static cooling room from top to bottom; the drive device further comprises a cam which is fixedly connected onto the stirring column; a piston rod is arranged in a gas cylinder, and the cam fits to the piston rod; a piston cylinder supplies gas to the vortex tube; a hot gas outlet end of the vortex tube separately communicates with thebottom of the first stirring room and the bottom of the second stirring room; and a cold gas outlet end of the vortex tube communicates with the upper part of the static cooling room. The raw materialpreparation device aims to solve the problems that raw material preparation speed for producing the environment-friendly brick by a conventional device is low, devices are various and operation difficulty is great.

Owner:温州陆华科技有限公司

Environment-friendly brick autoclaving production equipment

ActiveCN110815526ANovel structureReinforced Sealed ConnectionCeramic shaping apparatusSealing arrangementsHydraulic cylinderEnvironmental engineering

The invention provides environment-friendly brick autoclaving production equipment. The equipment comprises an autoclaving box and a box cover, wherein the box cover is arranged at an opening of the autoclaving box; the autoclaving box is installed on the ground through a supporting seat, and thus the connection part of the box cover and the autoclaving box is separated from the ground; the top ofthe autoclaving box is fixedly provided with a first hydraulic cylinder, and the first hydraulic cylinder drives the box cover to be opened and closed; a plurality of locking mechanisms are arrangedon the outer wall of the opening of the autoclaving box, and the locking mechanisms are used for reinforcing the connection and tightness of the box cover and the autoclaving box; a pressing block isarranged on each locking mechanism, and the pressing blocks rotate to be separated from or enter the pressing ring position of the box cover; the pressing blocks move in the longitudinal extending direction of the opening of the autoclaving box, so that the box cover is pressed and loosened; and the structure is novel, the sealing connection between a kettle cover and an autoclave can be enhanced,and good autoclaving conditions are guaranteed.

Owner:清远市榕兴新型环保建材有限责任公司

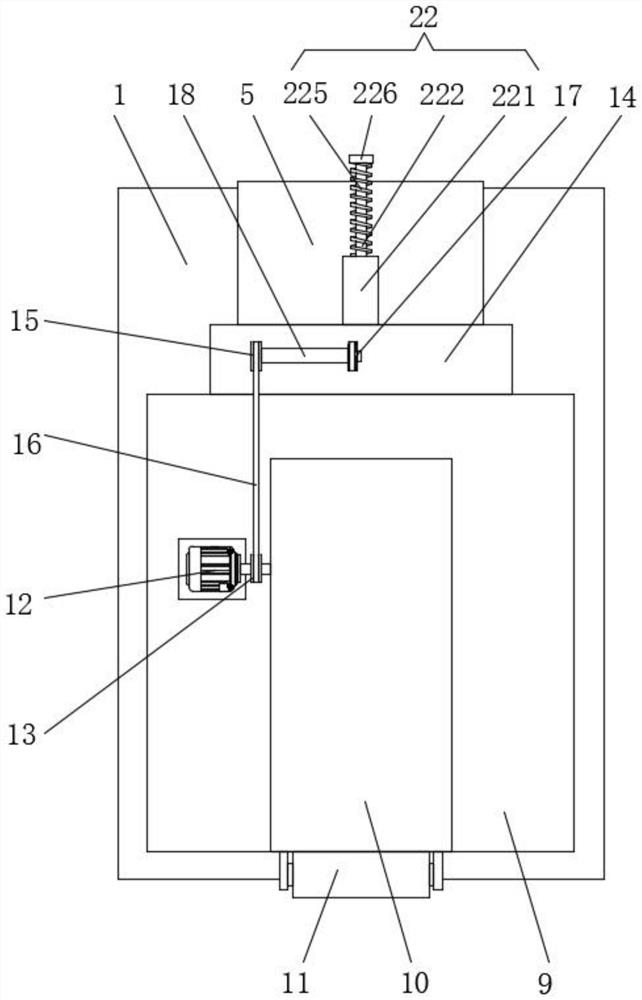

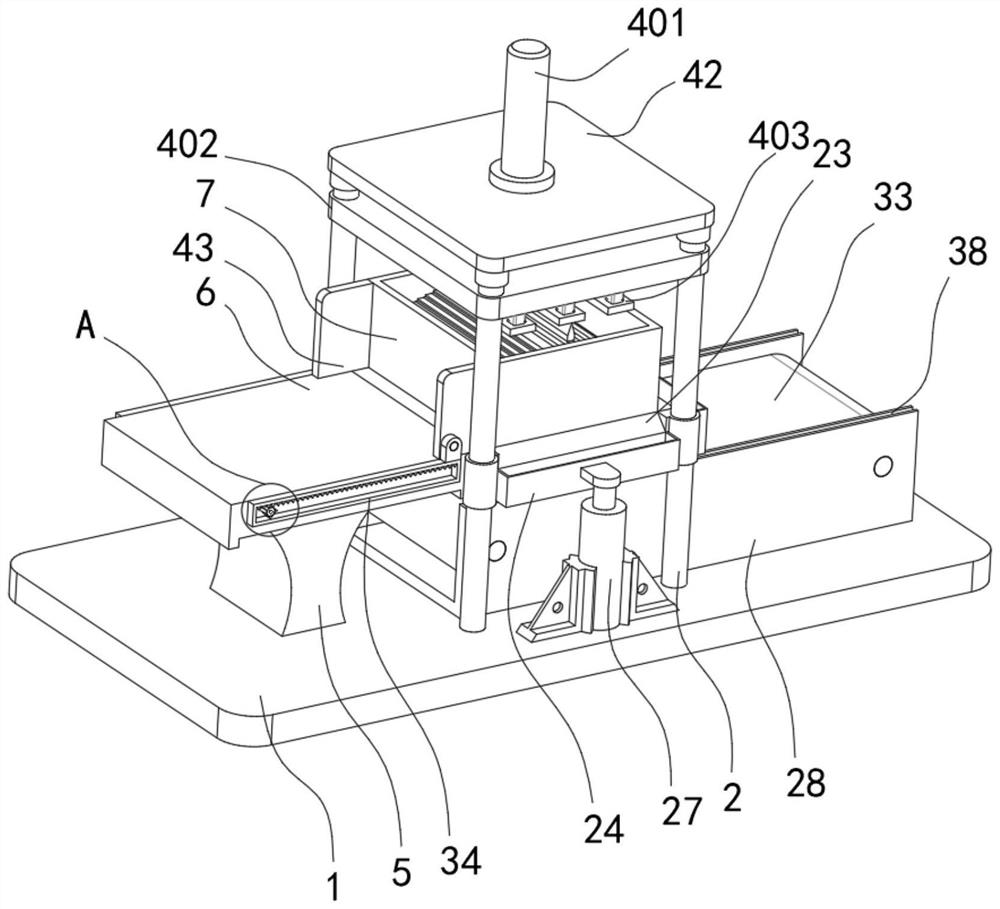

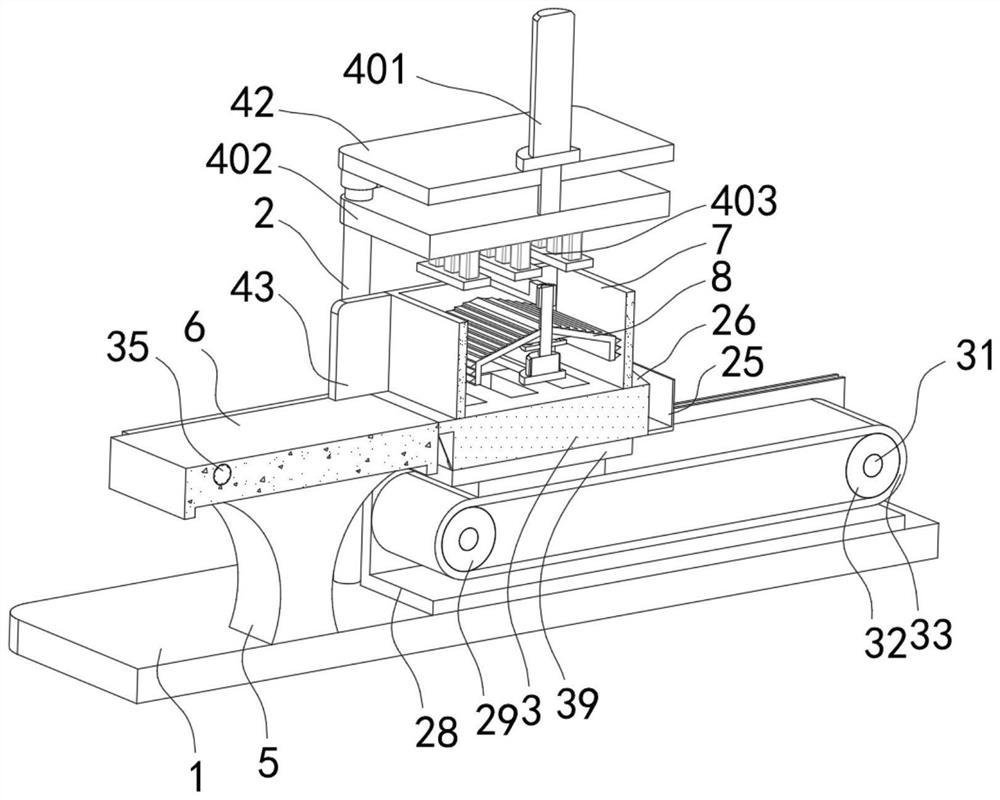

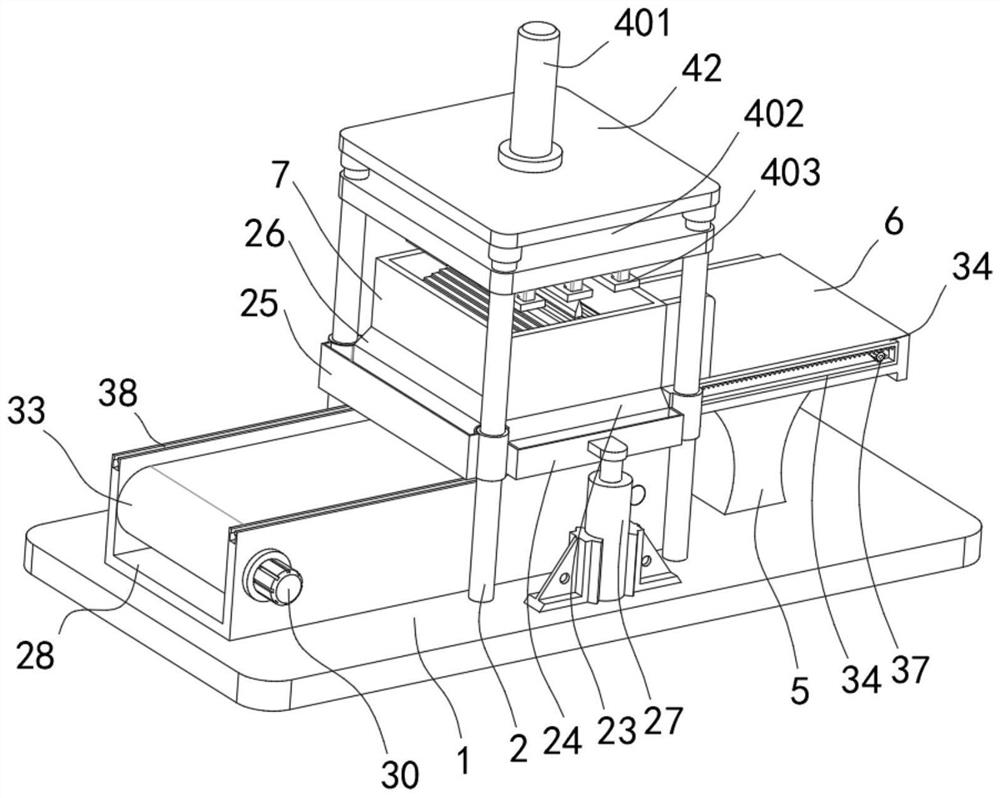

Mould pressing device for preparing environment-friendly bricks

ActiveCN114227865AEliminate cakingTo achieve the effect of crushing and looseningDischarging arrangementFeeding arrangmentsBrickElectric machine

The invention discloses a mold pressing device for preparing environment-friendly bricks in the technical field of environment-friendly brick production equipment, the mold pressing device comprises a base, fixing columns are fixedly mounted on the front side and the rear side of the top of the base, and a top plate is fixedly mounted on the tops of the fixing columns. By arranging the driving motor, the rotating disc, the fixed disc, the movable protruding blocks and the fixed protruding blocks, due to operation of the driving motor, the rotating disc can drive the movable protruding blocks to rotate, at the moment, the movable protruding blocks can move between the fixed protruding blocks, and the outer surfaces of the movable protruding blocks can extrude the outer surfaces of the fixed protruding blocks; the fixing disc and the vibrating frame can integrally vibrate, and under the action of vibration, the environment-friendly brick raw materials on the top of the vibrating frame can continuously fall off from top to bottom among the multiple partition plates, so that the environment-friendly brick raw materials can become loose and finally fall into the positions of the two sides of the vibrating frame. And through the lifting motion of the crushing teeth, the crushing and loosening effects can be enhanced.

Owner:浙江金州科技有限公司

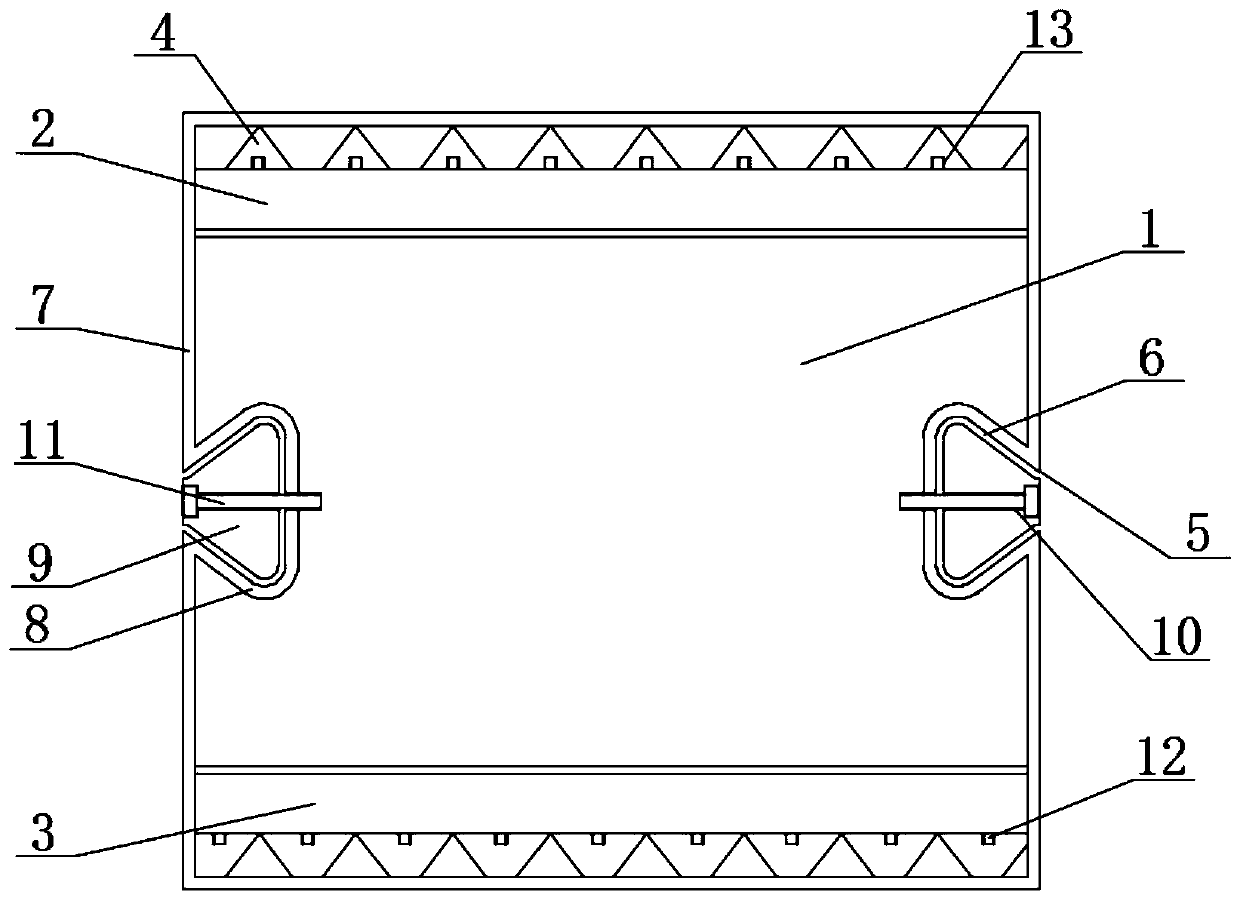

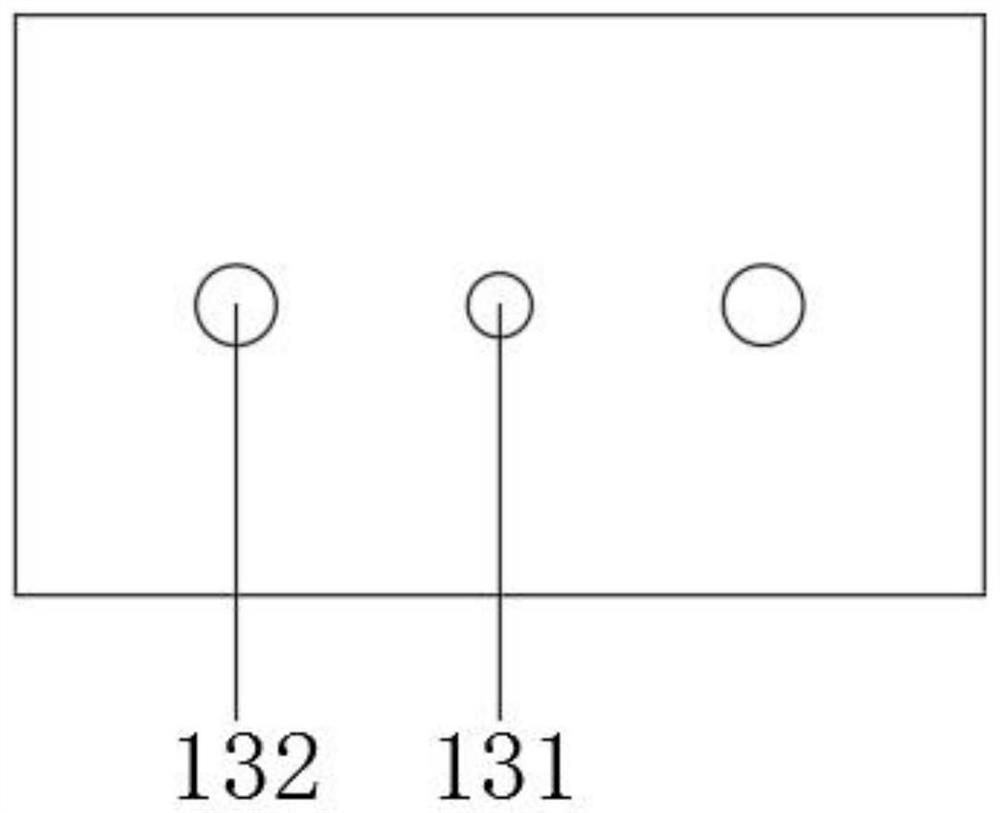

Environment-friendly brick structure and production method thereof

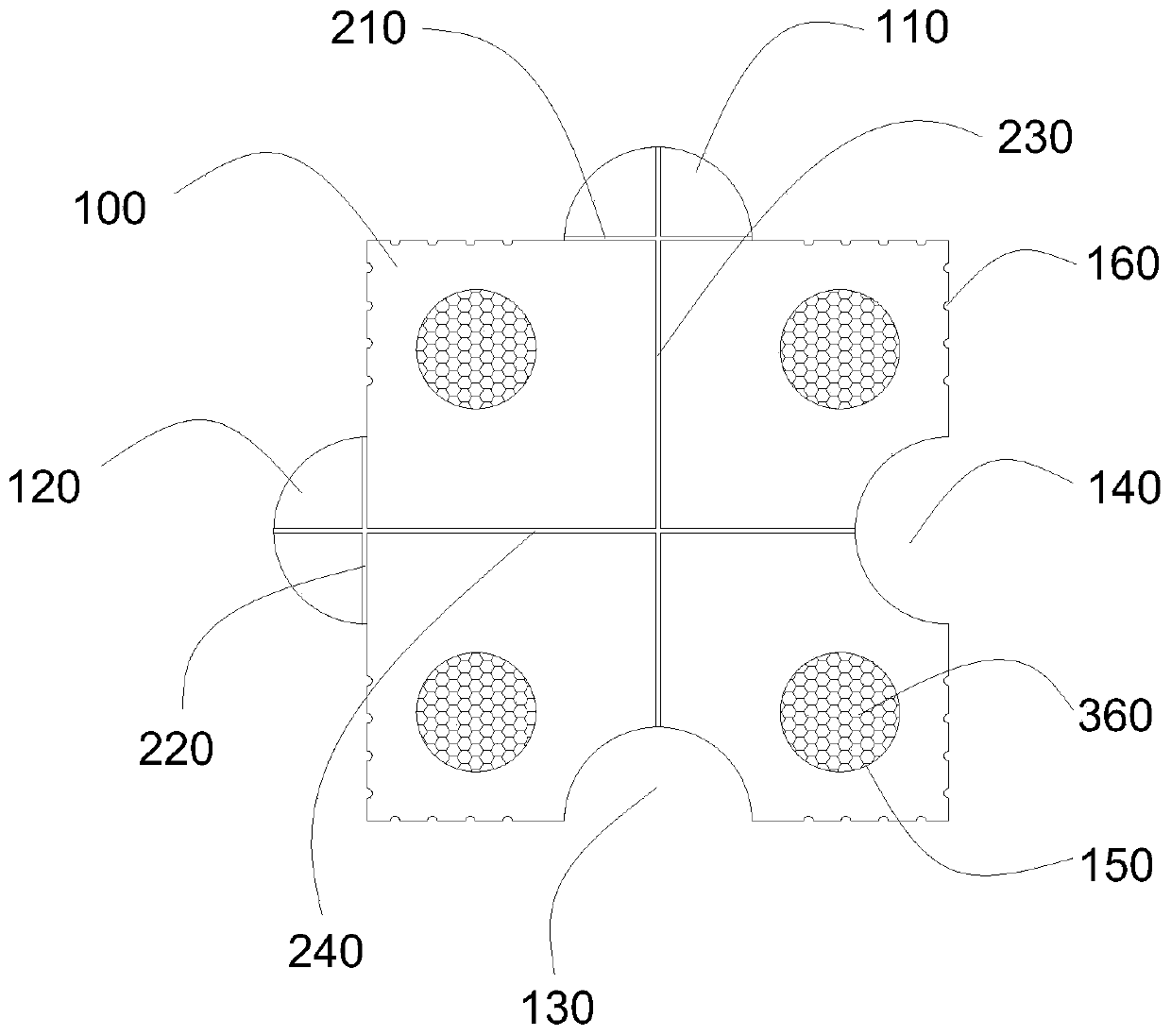

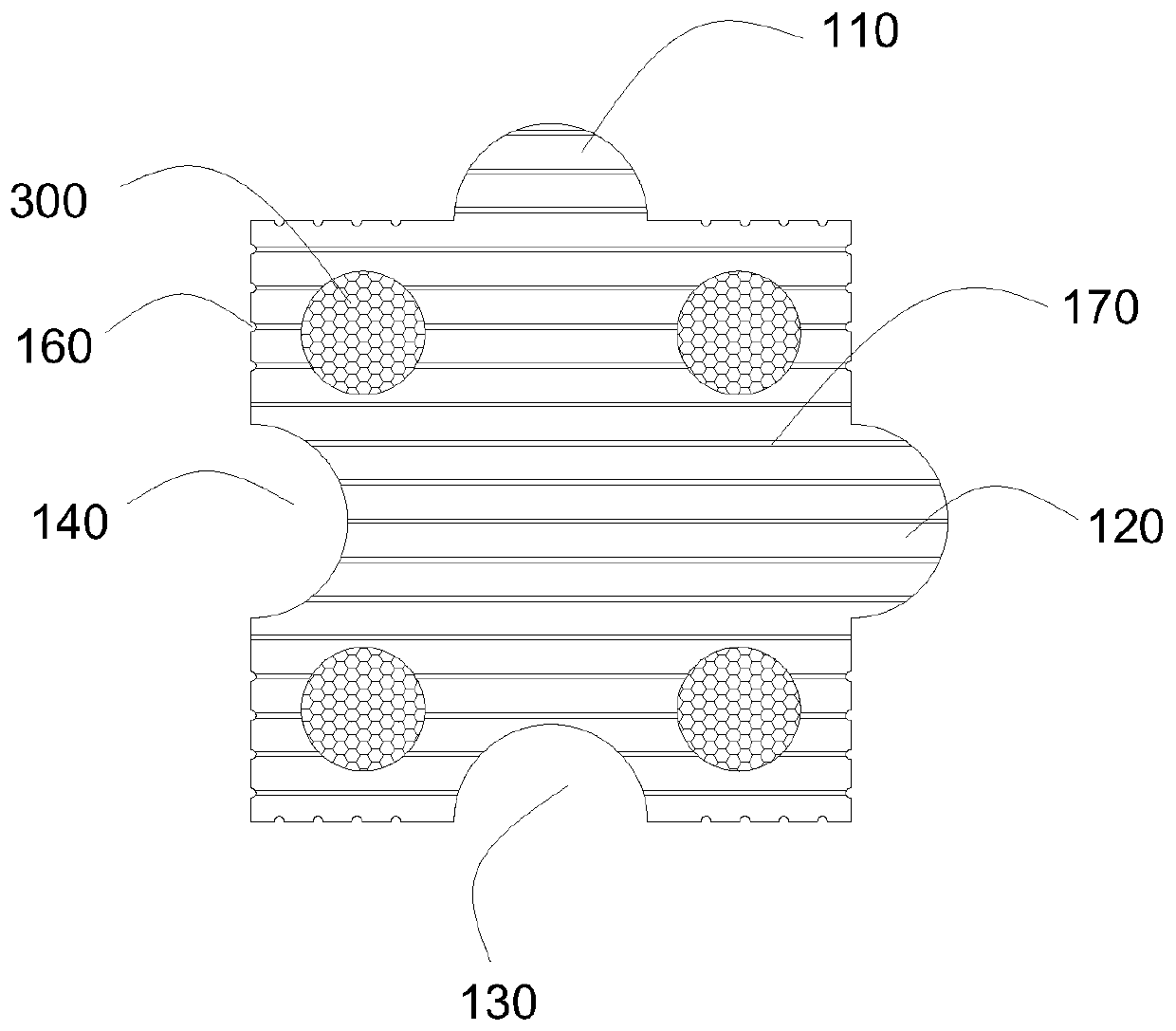

InactiveCN110835875AEasy to cutNovel structureSingle unit pavingsPaving gutters/kerbsBrickEngineering

The invention provides an environment-friendly brick structure and a production method thereof. The environment-friendly brick structure includes a brick body, wherein a first bump is fixedly arrangedon one side wall of the brick body, and a second bump is fixedly arranged on any adjacent side wall; the first bump and the second bump are both located at the center positions of the corresponding side walls; a first notch and a second notch are formed in the side walls of the brick body relative to the first bump and the second bump correspondingly, the first notch is matched with the shape ofthe first bump, and the second bump is matched with the second notch; a first cut mark is arranged on the top surface of a connection position between the first bump and the brick body, and the two ends of the first cut mark extend to the two ends of the first bump; and a second cut mark is arranged on the top surface of a connection position between the second bump and the brick body, and the twoends of the second cut mark extend to the two ends of the second bump. The structure of an environment-friendly brick is novel, quick splicing can be carried out, and cutting is convenient, sot thatpractical construction applications are convenient.

Owner:清远市榕兴新型环保建材有限责任公司

Environment-friendly brick preparation process

The invention discloses an environment-friendly brick preparation process which comprises the following preparation steps: S1, raw material preparation: quantitatively taking building solid waste, crushing to obtain a granular solid waste raw material, grinding a part of the granular solid waste raw material, and screening to obtain a powdery solid waste raw material; quantitatively taking desulfurized gypsum and crushing to obtain a granular desulfurized gypsum raw material; S2, raw material stirring: mixing and stirring the granular solid waste raw material, the granular desulfurized gypsumraw material, the powdery solid waste raw material, an additive and cement by utilizing stirring equipment to obtain a mixed and stirred raw material. According to the manufacturing process, the urbanbuilding solid waste is taken as the main raw material to manufacture the environment-friendly brick, the discharge amount of the building waste can be reduced, the production cost of the environment-friendly brick can be reduced, and large-scale industrial production is facilitated. The invention effectively solves the defects of the traditional environment-friendly brick, enhances the quality of the environment-friendly brick, has the advantages of low raw material source price and environment friendliness, and effectively reduces the production cost of the environment-friendly brick.

Owner:桐乡市德功庵建材有限公司

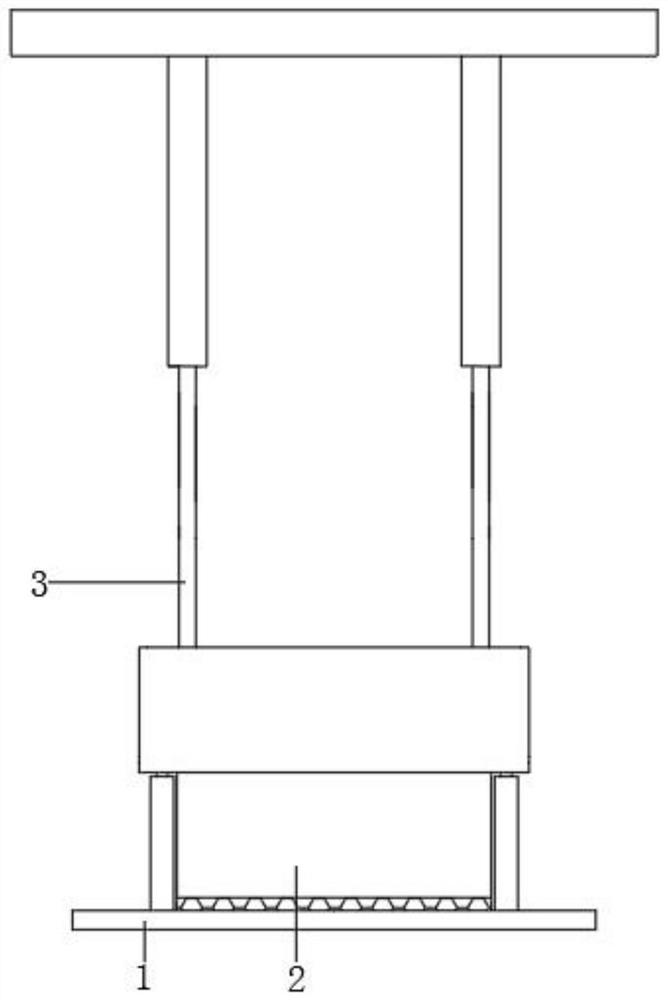

Green brick forming equipment for environment-friendly bricks

The invention discloses green brick forming equipment for environment-friendly bricks, which comprises a die and a stamping die body, and the die comprises an upper die and a lower die; the upper die is externally connected to a hydraulic lifting mechanism; and a punch forming assembly is arranged in the upper die and comprises a vibration base plate and a vibration excitation block, a roller is arranged on the upper portion of the vibration base plate and can move up and down, and a protruding block is arranged on the outer circle face of the roller. When the roller is in the working position, the distance between the upper surface of an arc groove and the axis of the roller is smaller than the sum of the height of the protruding block and the radius of the roller and larger than the radius of the roller. When the roller is in an idle position, the distance between the upper surface of the arc groove and the axis of the roller is larger than the sum of the height of the protruding block and the radius of the roller. According to the equipment, the friction force among blank particles can be reduced during green brick pressing, the flowability is improved, all faces of a pressed green brick product are consistent in density, and the product quality is improved.

Owner:HUAIHUA YONGGU ENERGY SAVING WALL MATERIAL

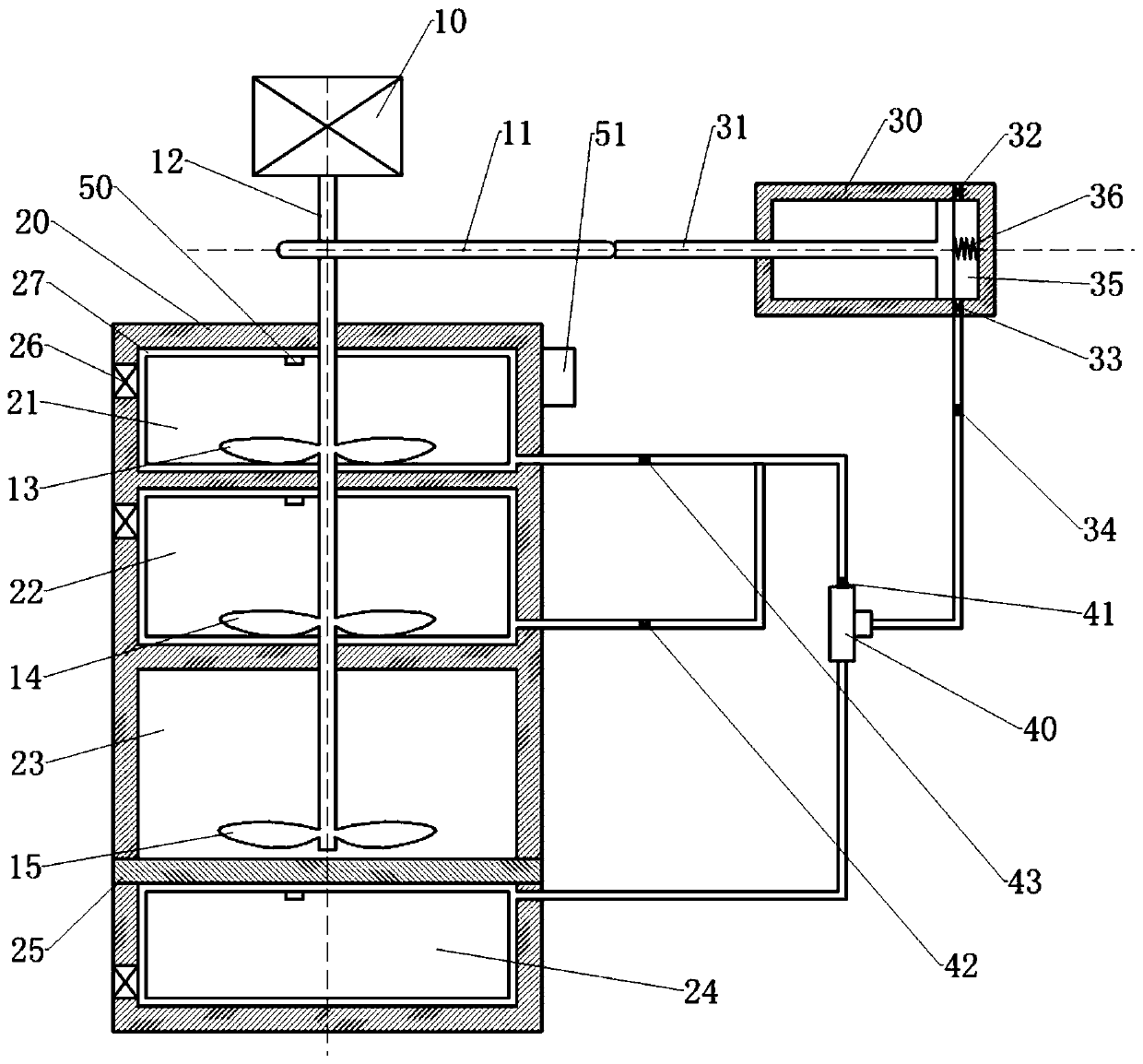

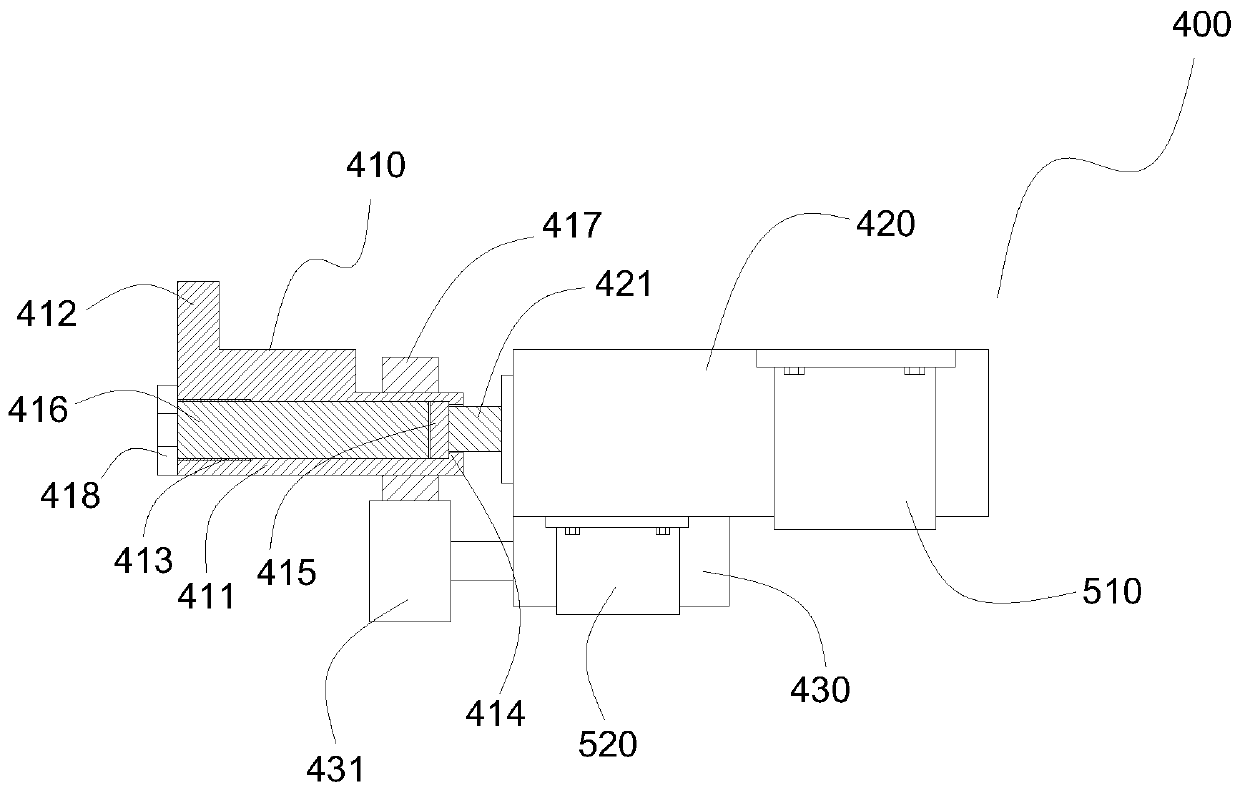

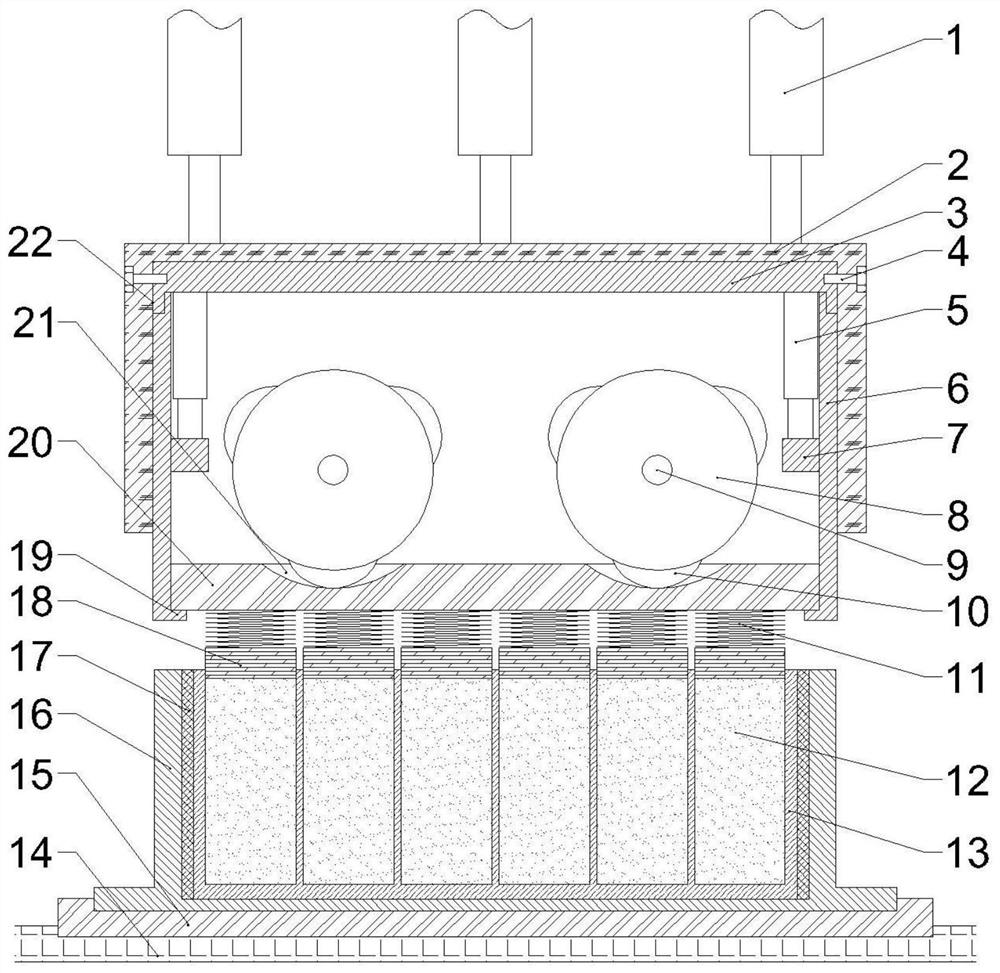

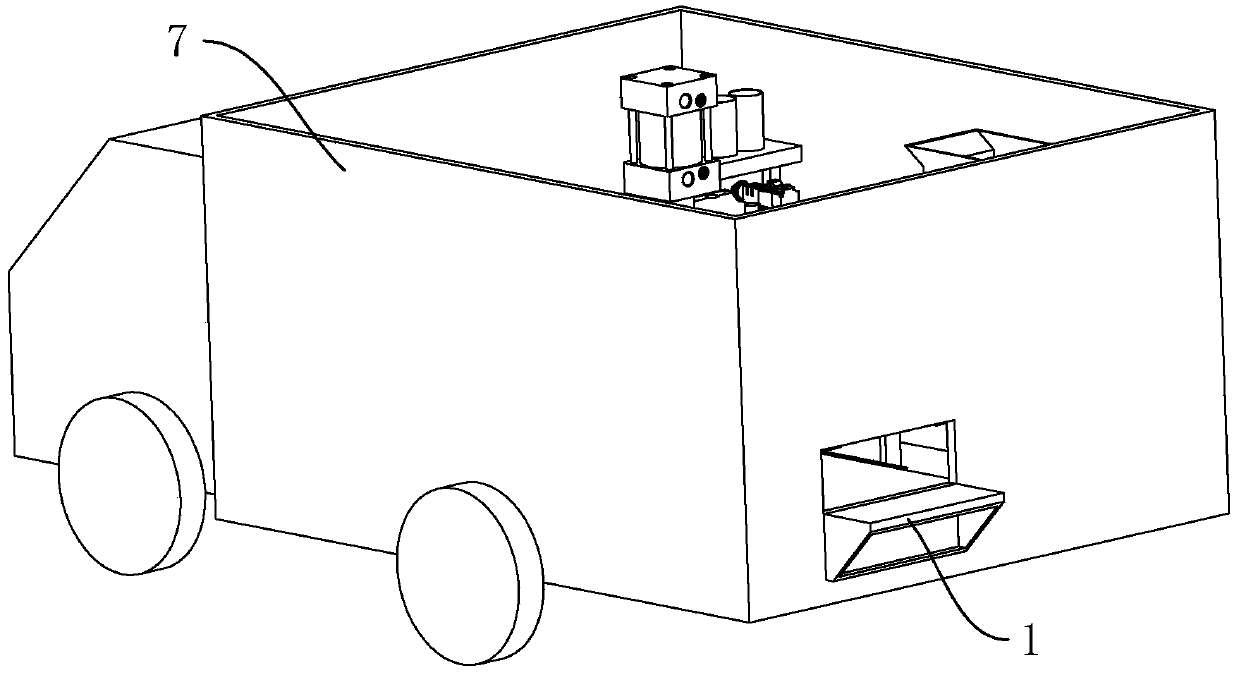

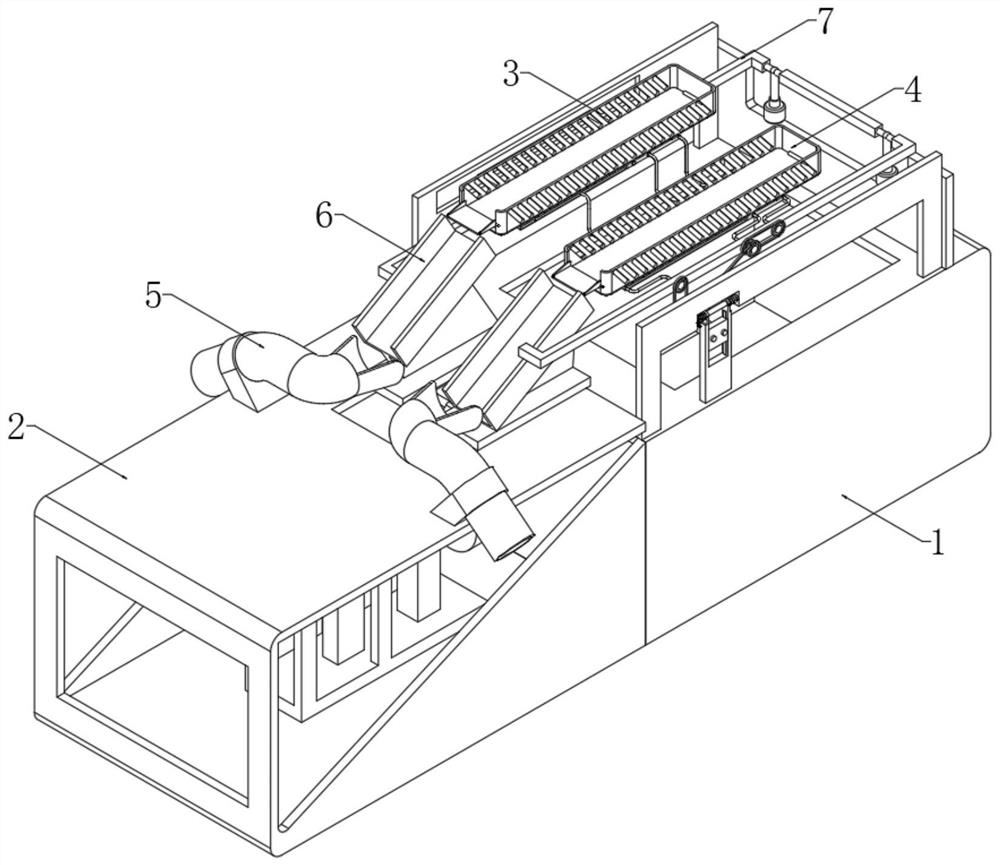

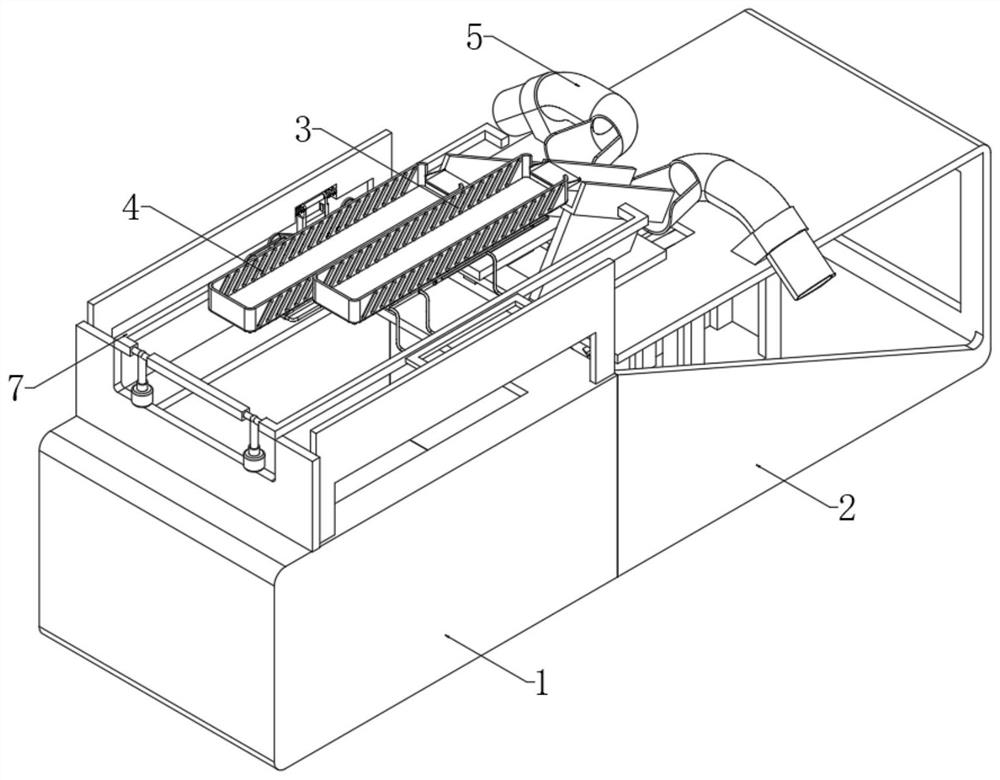

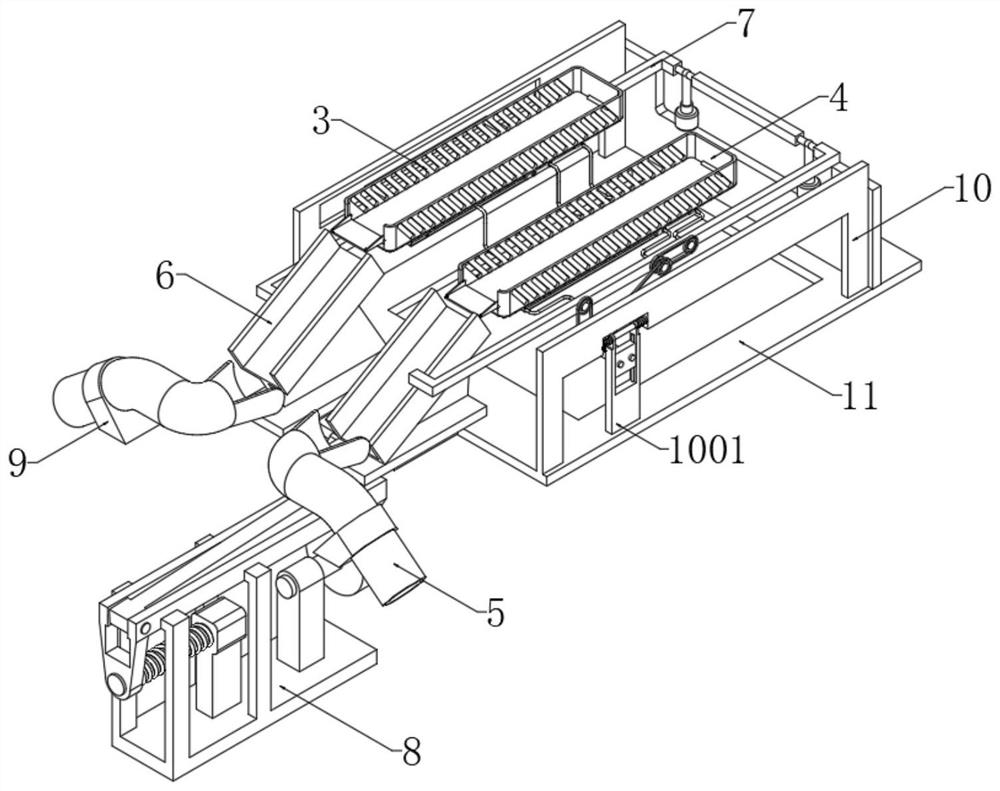

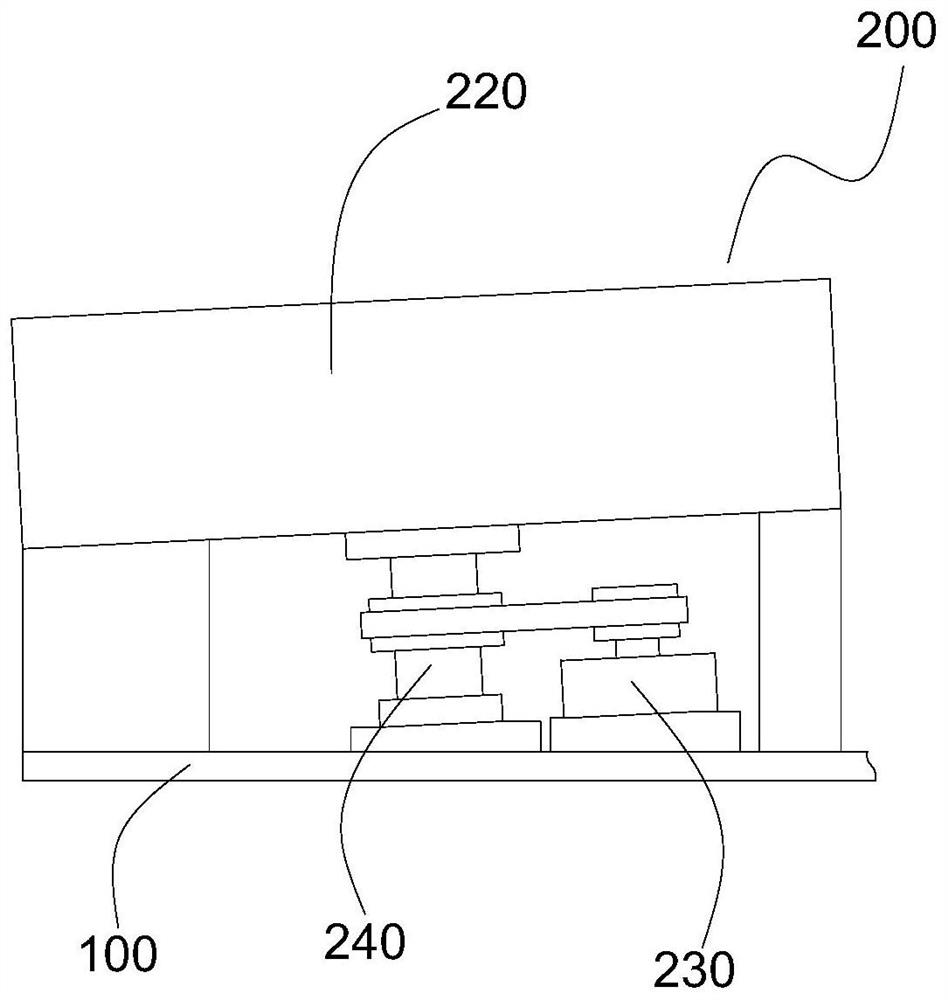

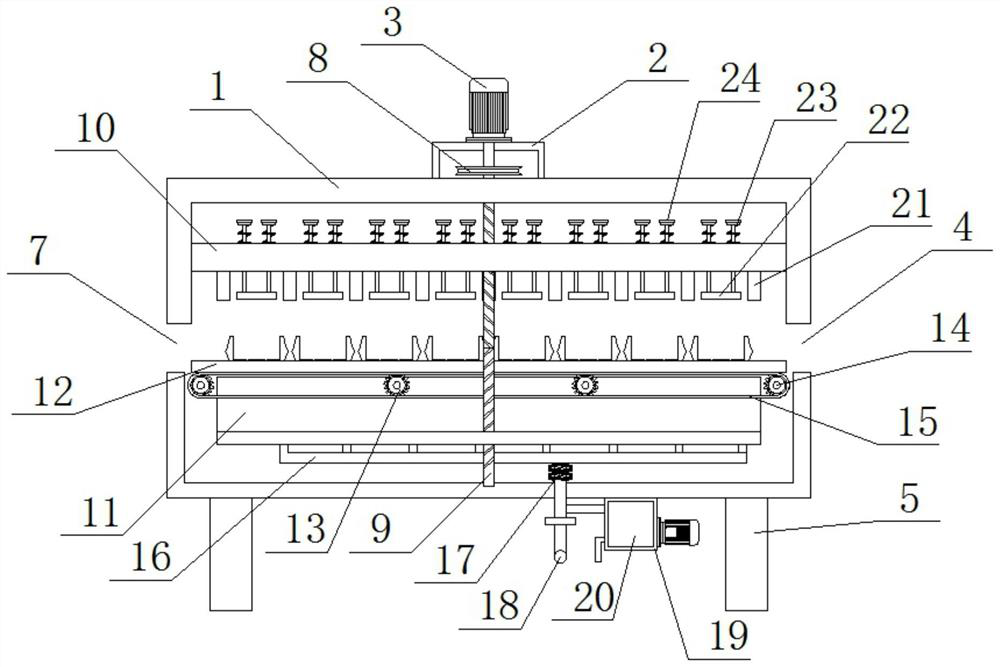

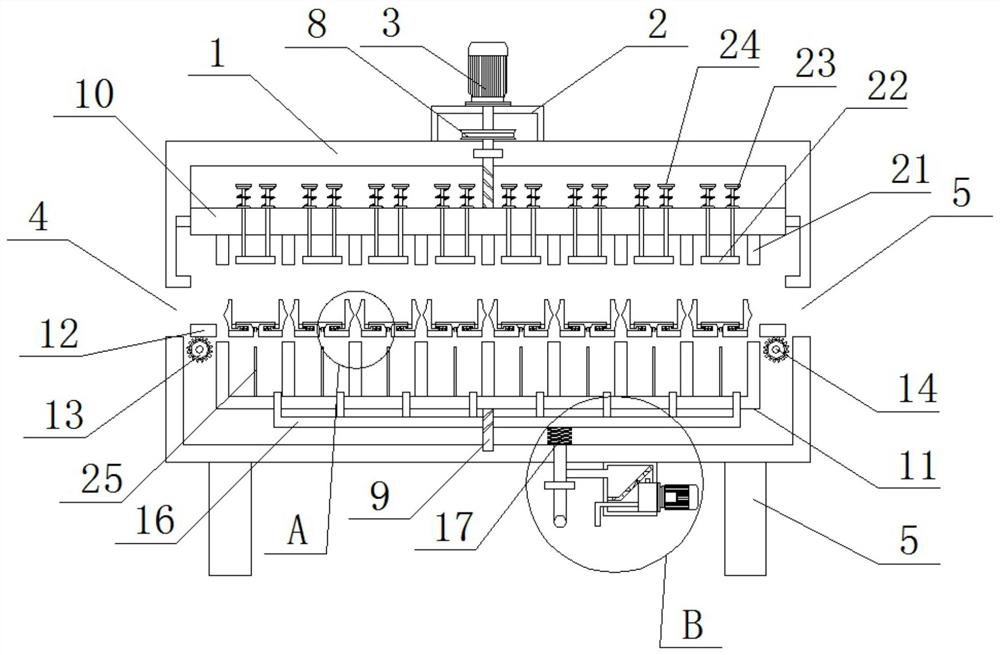

Environment-friendly brick production system and environment-friendly brick production method

ActiveCN108970699BReduce manufacturing costReduce the cost of multiple shipmentsCeramic shaping apparatusMagnetic separationMobile vehicleBrick

Owner:广东合韵达建筑工程有限公司

Environment-friendly brick brick pressing machine

InactiveCN112571580AEasy to assemble and disassembleEasy to useMouldsMould fastening meansHydraulic cylinderBrick

The invention provides an environment-friendly brick pressing machine. The environment-friendly brick pressing machine comprises a conveying belt, a chassis, a hydraulic cylinder telescopic rod, a compression plate, a first mold, a second mold, a sliding mechanism is arranged on the surface of the chassis, a first clamping plate is arranged on the surface of the chassis, a first mold is arranged on the inner side of the first clamping plate, the sliding mechanism is arranged on the outer side of the first clamping plate, and the and a second clamping plate is arranged on the surface of the chassis, a second mold is installed on the inner side of the second clamping plate, the sliding mechanism is installed on the outer side of the second clamping plate, a front pillar is fixed on the frontend surface of the conveying belt, and a rear pillar is fixed on the rear end surface of the conveying belt. Compared with the prior art, the environment-friendly brick pressing machine has the following advantages that: the sliding mechanism, the conveying belt, the first clamping plate and the second clamping plate are added, the molds are convenient to disassemble and assemble, so that the machine is more convenient to use, a next brick can be directly pressed after pressing is completed, the pressed brick is manually taken out during mechanical pressing, a large amount of time is saved, and the brick pressing efficiency is improved.

Owner:邵阳县黄土坝环保建材有限公司

A kind of preparation method of environmental protection brick

The invention discloses a method for preparing an environmentally friendly brick. The technical proposal includes: pouring a certain amount of rice husk, sawdust and rubber particles into a certain amount of sewage, adding sludge produced by Fenton oxidation, biochemical sludge and powder Coal ash, stirring to obtain a mixture A of rice husk, sawdust, rubber particles, sludge produced by Fenton oxidation, biochemical sludge and fly ash, transfer the mixture A to a hydrothermal reactor, control the reaction temperature and time, and naturally Cool, filter off the supernatant to obtain mixture B and supernatant; weigh a certain amount of mixture B, add a certain amount of supernatant, and add polypropylene fiber and cement to it, stir and filter to obtain mixture C; The mixture C is transferred to a brick-making mould, which is subjected to compression molding and steam curing to obtain an environmentally friendly brick. The environmentally friendly brick includes porous carbide, iron oxide, harmless sludge, fly ash polypropylene fiber, and cement. It has the advantages of light weight and high strength, reaching MU25 grade.

Owner:张勇

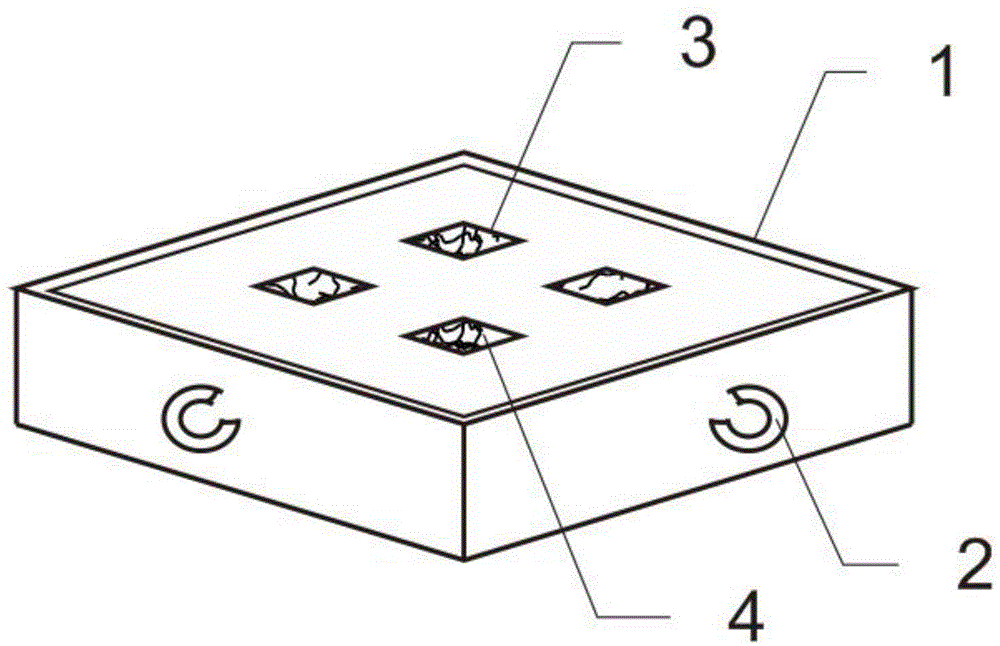

A box-shaped ecological block for ecological slope protection

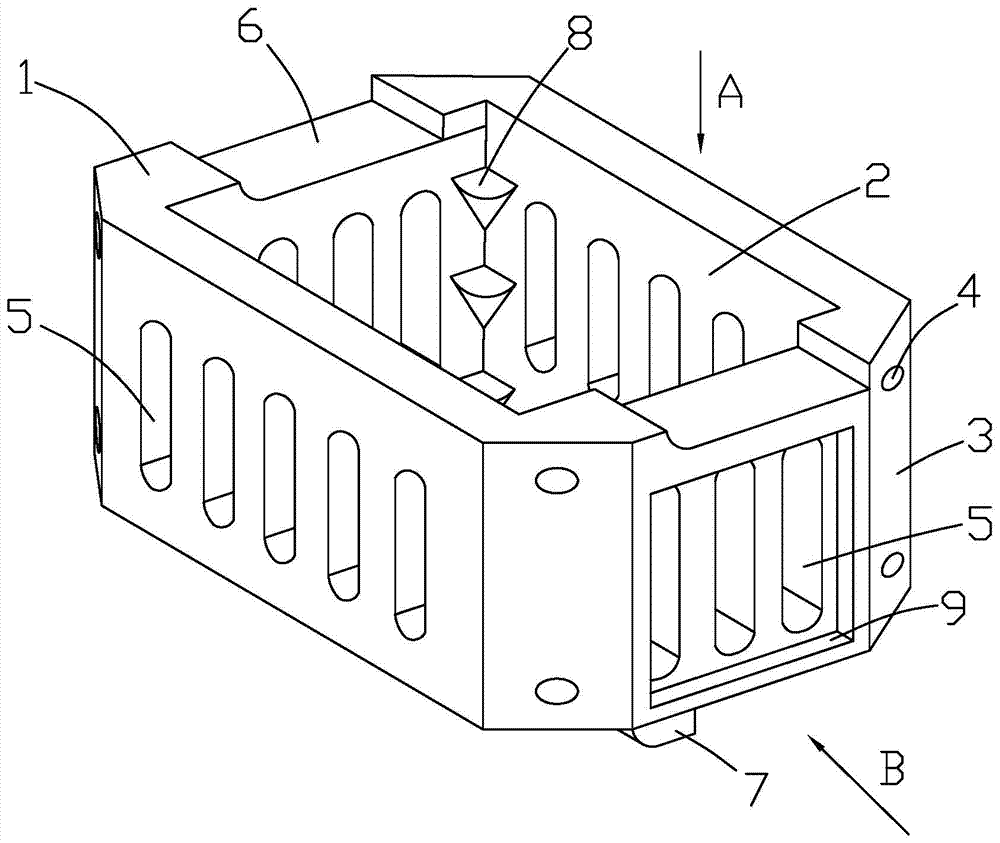

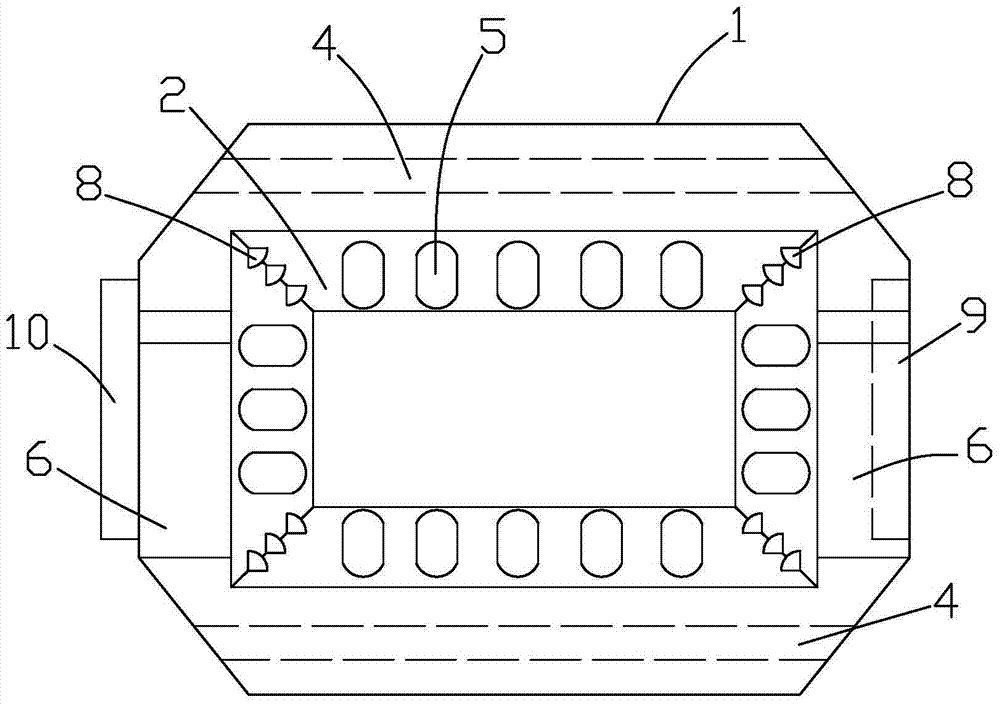

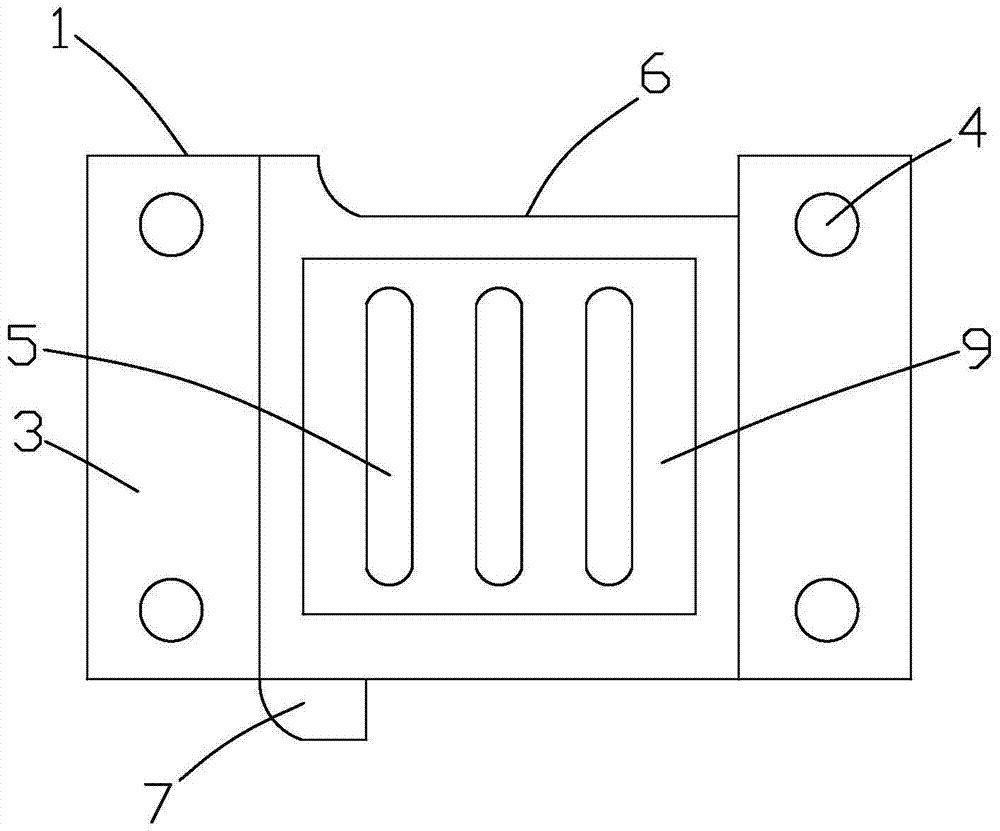

InactiveCN105544466BReduce usageReduce weightCoastlines protectionVegetative propogationEconomic benefitsWater flow

The invention discloses box-type ecological building blocks used for ecologically protecting a slope. The box-type ecological building blocks comprise building block single bodies. A packing groove is formed in the center of each building block single body. The four inner side faces of each packing groove are all provided with water through grooves. Circular-arc steps are evenly arranged at the corners of each packing groove from top to bottom. Guiding sliding grooves are formed in the two side edges of the top face of each building block single body. Limiting protrusions are arranged on the two side edges of the bottom face of each building block single body. A rectangular limiting groove is formed in one side of each building block single body, and a rectangular clamping block is arranged on the other side of the corresponding building block single body. Every two adjacent building block single bodies are fixedly connected through connecting pipes. The box-type ecological building blocks are simple in structure and high in practicability. The slope protection function of existing ecological building blocks is achieved, and water flow can also be maintained in a flowing state, so that scour of the water flow to the building blocks is reduced and the overall stability and strength are improved. Meanwhile, usage quantities of materials are reduced, and the weight of each building block single body is reduced, so that transportation is facilitated, the manufacturing cost is reduced and the economic benefits are remarkable.

Owner:浙江景昌建设有限公司

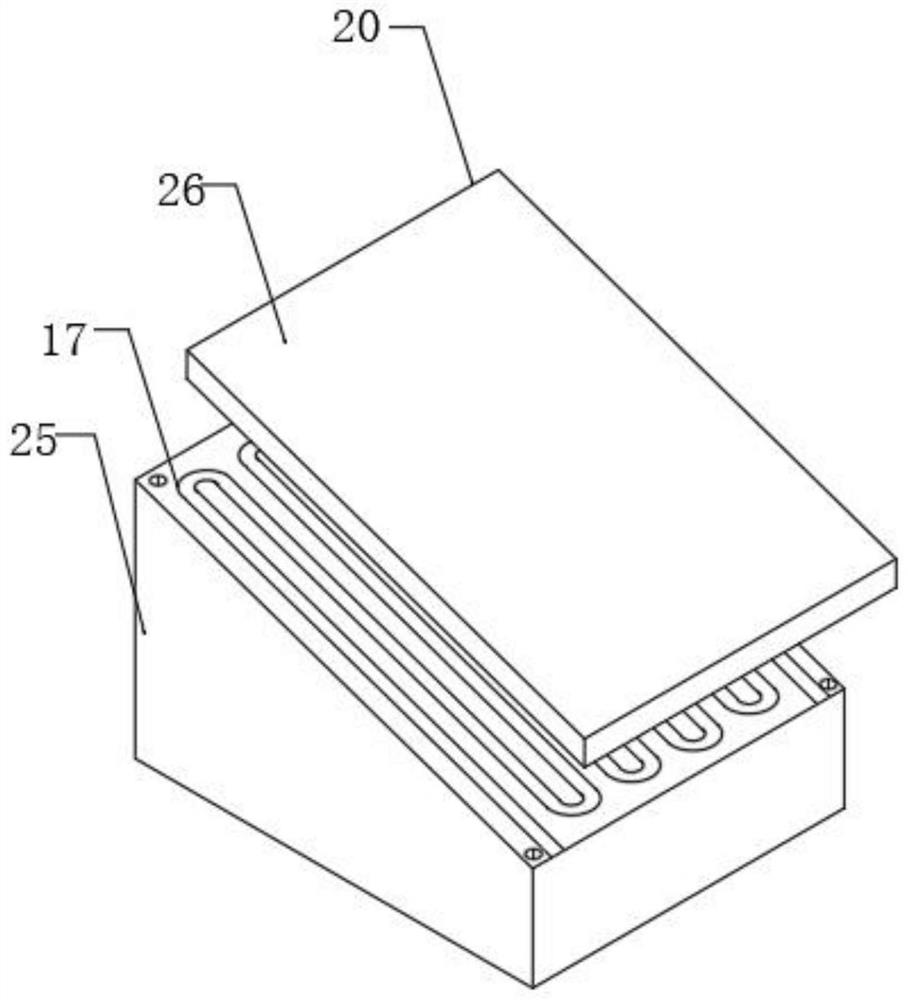

Raw material screening device for environment-friendly brick preparation

ActiveCN113926701AAchieve sievingRealize independent screeningSievingScreeningBrickStructural engineering

The invention discloses a raw material screening device for environment-friendly brick preparation, and belongs to the technical field of environment-friendly brick preparation. The raw material screening device for the environment-friendly brick preparation comprises a mounting box, a material collecting box is fixedly connected to the front side of the mounting box, a material screening frame A and a material screening frame B are arranged above the material collecting box, the material screening frame A and the material screening frame B are connected into the material collecting box through a transmission assembly B, and a discharging opening is formed in the lower portion of the material collecting box; a mounting frame is arranged on the upper portion of the interior of the material collecting box, a discharging channel is arranged on the front side of the mounting frame, a mounting base is fixedly connected to the rear side of the discharging channel, and the mounting base is arranged on the upper side of the mounting box; and the discharging channel is obliquely arranged, a discharging pipe is correspondingly arranged at a lower port of the discharging channel, and the center of the discharging pipe is fixedly connected with the upper side of the mounting box through a connecting piece. The problem that non-interfering screening operation cannot be carried out on different types of batch materials or batch materials with non-uniform particle size difference simultaneously is solved.

Owner:颍上县和顺新型环保建材有限公司

Environmental protection fiber ecological revetment brick

PendingCN106149633AIncrease vegetation greeningIncrease mountain soilCoastlines protectionHorticultureVegetationFiber

The invention discloses an environmental-friendly fiber ecological revetment brick, which comprises a revetment block body made of concrete and steel bars. The revetment block body is rectangular. The four sides of the revetment block body are respectively provided with steel bar hooks, and the steel bar hooks are connected to the revetment block body. The internal steel bars are connected; the revetment block body is provided with a through hole; a fiber ecological block made of fiber material is arranged at the through hole. The environmental protection fiber ecological revetment brick of the present invention can not only stabilize the revetment, but also increase vegetation greening. Plant seeds and slow-release fertilizers can be stored in the set fiber ecological block, which can be used on mountain slopes and other places. It can not only stabilize the mountain soil, but also increase the vegetation ecology, and can grow grass and flowers.

Owner:西安以锵电子科技有限责任公司

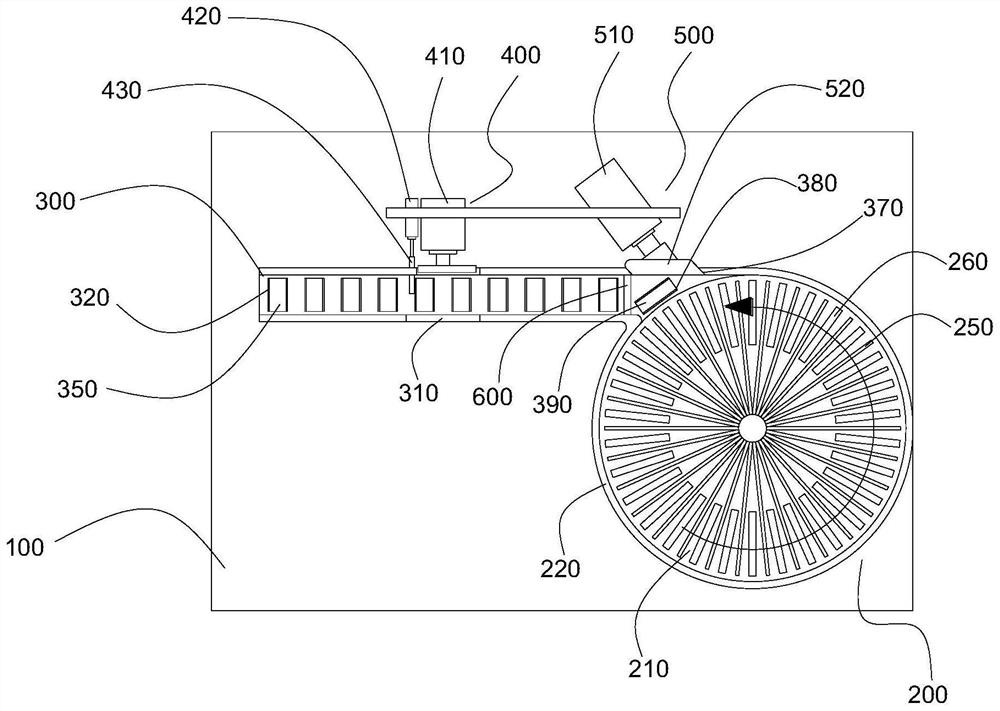

Environment-friendly brick conveying device

PendingCN112012508ANovel structural designStable deliveryBuilding material handlingBrickStructural engineering

The invention discloses an environment-friendly brick conveying device. The environment-friendly brick conveying device comprises a feeding rotary barrel and a feeding groove; the feeding rotary barrel comprises a rotary disc, the rotary disc is obliquely arranged, and the outer side of the rotary disc is provided with a protective cylinder in a covered mode; the feeding groove communicates with the protective cylinder on the higher inclined side of the protective cylinder, the feeding groove is formed in the rotating tangential direction of the rotating disc, and the rotating disc rotates tofeed materials into the feeding groove; a detection pushing structure is arranged on one side of the feeding groove, and the detection pushing structure is used for detecting brick bodies and pushingthe incomplete brick bodies away from the feeding groove; and an anti-blocking pushing structure is arranged at the communication position of the rotating disc and the feeding groove and used for pushing the brick bodies retained at the communication position back into the feeding rotary barrel. According to the environment-friendly brick conveying device, disorderly stacked bricks can be separated and conveyed, and the smoothness of the conveying process can be effectively improved; and in the conveying process, the brick bodies can be detected and selected, incomplete brick bodies are removed, and the construction and production efficiency is improved.

Owner:清远市榕兴新型环保建材有限责任公司

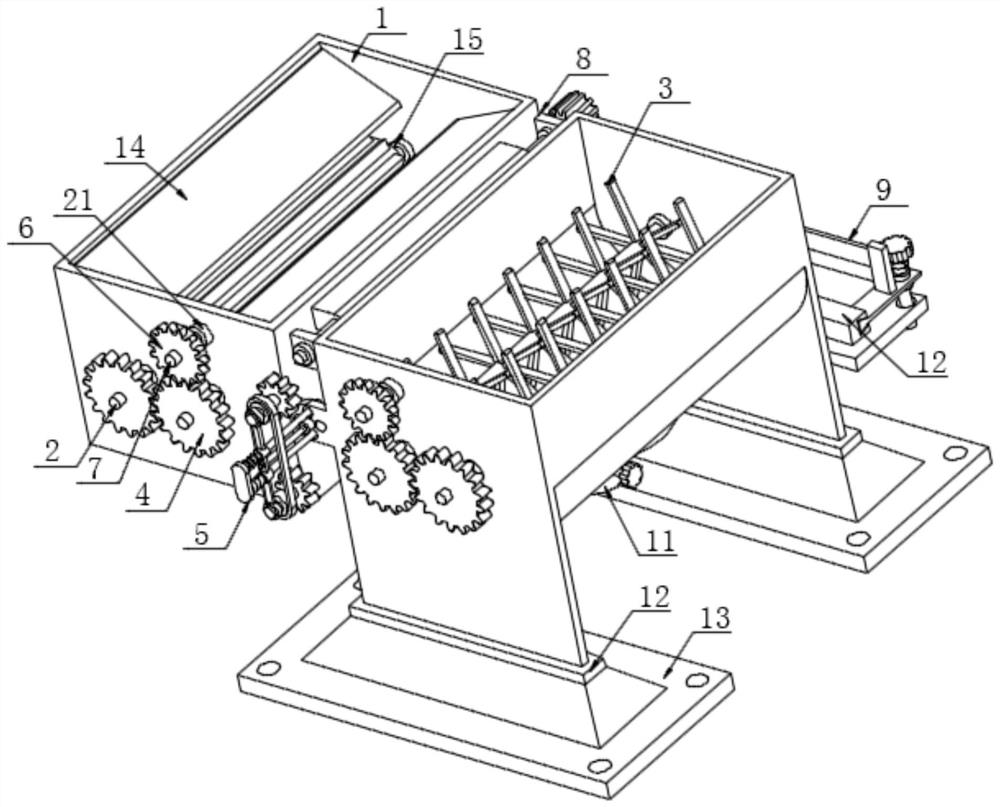

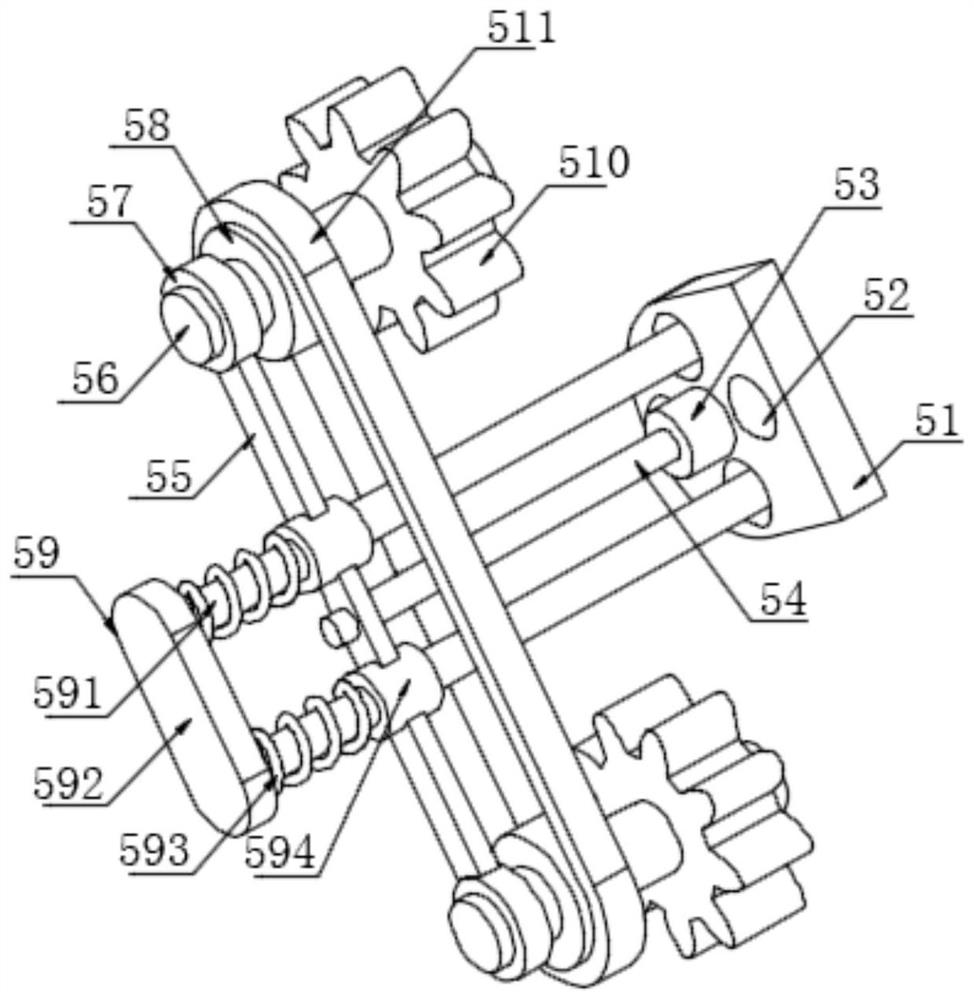

A kind of environmental protection brick preparation device and using method thereof

ActiveCN113731275BMesh meetGuaranteed meshingSolid waste managementTransportation and packagingBrickSynchronous control

The invention discloses a device for preparing environmental protection bricks and a method for using the same, and in particular relates to the technical field of preparation of environmental protection bricks. The invention can realize the meshing of the fourth gear and the fifth gear on both sides respectively through the operation of adjusting the left and right positions of the motor, respectively. Then, the material mixing or mixing operation can be selectively carried out according to the actual situation. At the same time, under the rotating motion of the connecting structure, the first gears on both sides can be connected to achieve power transmission, and then the operation of the crushing roller and the stirring shaft can be controlled synchronously to meet the needs of The synchronous control of material mixing and pulverization operation can be realized, and the operation of classification operation can be realized, and the two processing boxes can be combined to ensure the meshing of the two second gears, so as to meet the operation of mixing after pulverization. On-site requirements can meet the mixing and pulverizing operations in various situations, and can reduce the investment of driving equipment and reduce costs, so as to achieve better application value.

Owner:江苏聚优新型建材有限公司

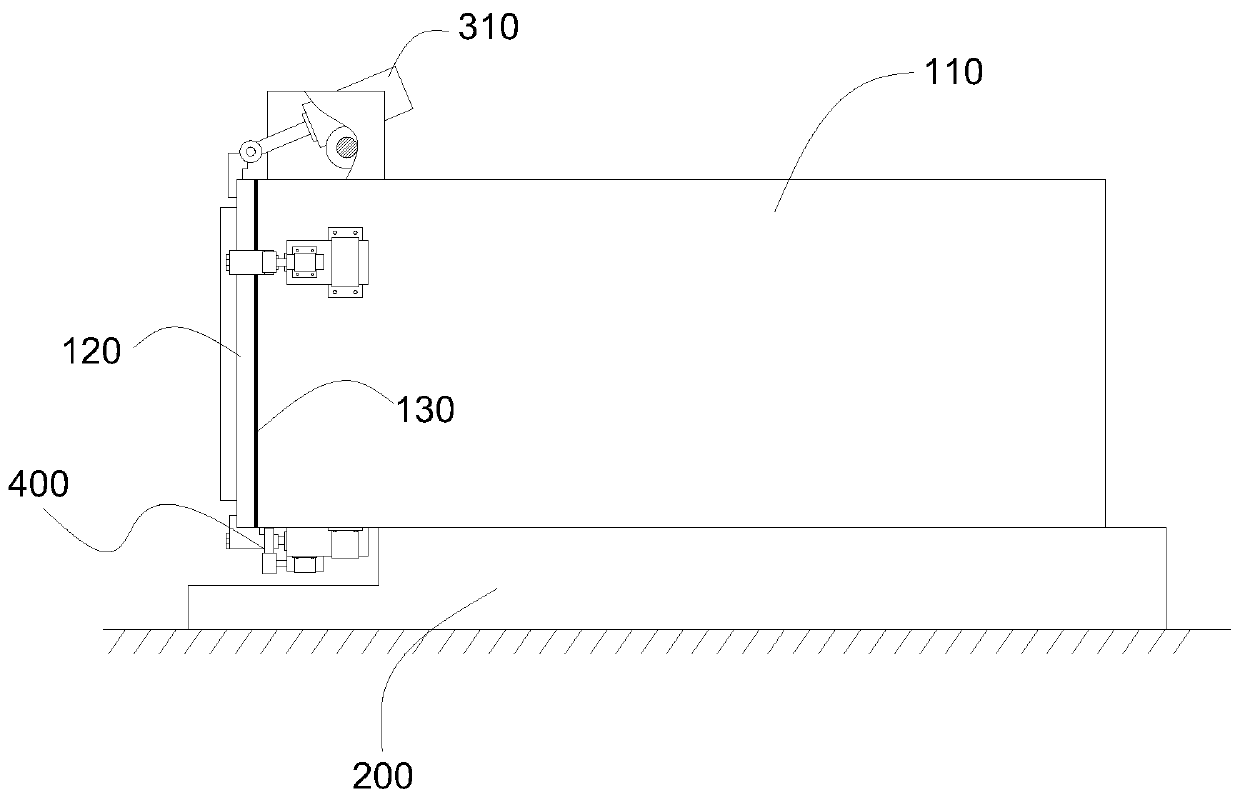

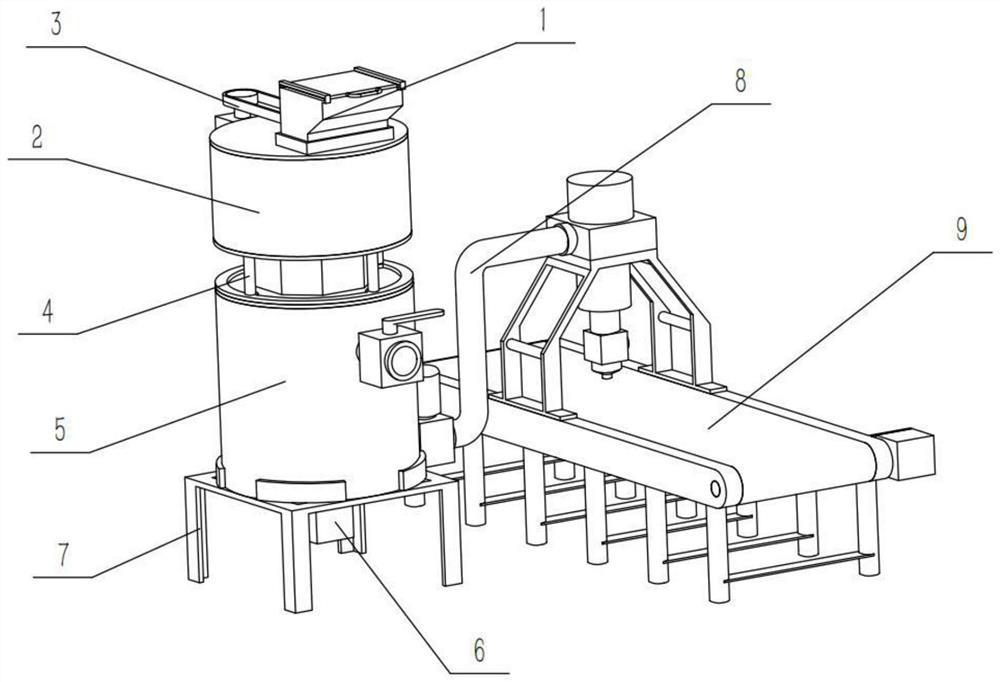

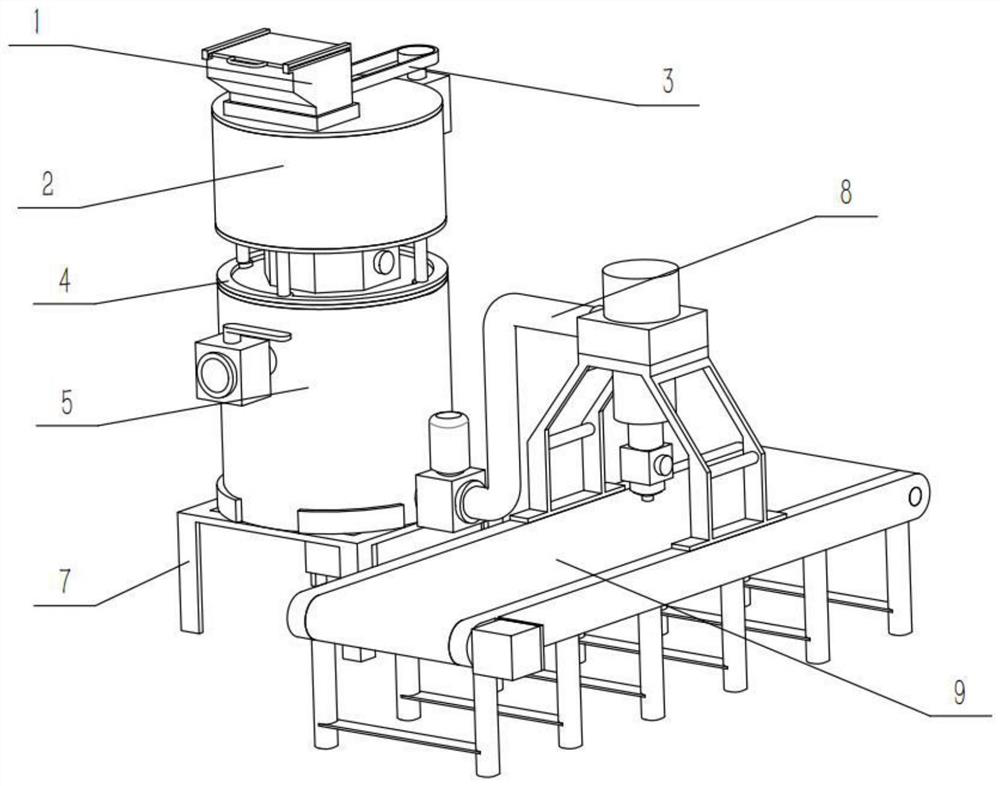

Environment-friendly brick processing system

PendingCN111688015AQuality improvementImprove crushing effectCeramic shaping plantsBrickWorking environment

The invention relates to the technical field of environment-friendly brick processing equipment, in particular to an environment-friendly brick processing system. The environment-friendly brick processing system comprises a connecting frame, a supporting frame and a conveying mechanism, the environment-friendly brick processing system further comprises a feeding mechanism, a storing and carrying mechanism, a crushing mechanism, a stirring barrel, a stirring mechanism and a slurry pumping mechanism, the feeding mechanism is fixedly connected to the upper end of the storing and carrying mechanism, the crushing mechanism is rotationally connected to the middle of the upper end of the storing and carrying mechanism, the stirring barrel is fixedly connected to the lower end of the storing and carrying mechanism, the connecting frame is fixedly connected between the storing and carrying mechanism and the stirring barrel, the stirring mechanism is fixedly connected to the middle of the lowerend of the stirring barrel, the supporting frame is fixedly connected to the lower end of the stirring barrel, and the slurry pumping mechanism is fixedly connected with the stirring barrel and a conveying mechanism. According to the environment-friendly brick processing system, the crushing effect of waste residues can be improved, waste materials are crushed more thoroughly, the quality of environment-friendly bricks is improved, meanwhile, the sealing performance of the environment-friendly brick processing system is good, and the working environment is protected.

Owner:徐胜男

Extrusion molding device for environment-friendly brick production

InactiveCN112720802ARealize pumpingRealize injectionMouldsFeeding arrangmentsBrickStructural engineering

The invention discloses an extrusion molding device for environment-friendly brick production. The extrusion molding device comprises a base table, wherein two sets of stand columns are symmetrically welded to the upper end of the base table, a lifting plate is slidably connected between the two sets of stand columns, a supporting plate is fixedly welded to the upper ends of the two sets of stand columns, a first electric push rod is fixedly installed on the supporting plate through a fixing frame, one end of a piston rod of the first electric push rod penetrates through the supporting plate and is fixedly connected to the upper surface of the lifting plate, a forming assembly is fixedly installed at the upper end of the base table, the lower end of the lifting plate is fixedly connected with a cover plate used in cooperation with the forming assembly through a connecting column, and a storage box is arranged at the upper end of the supporting plate and communicates with three sets of discharging pipes. A piston block is driven by a second electric push rod to ascend and descend, the ascending and descending of the piston block can adjust the pressure in a shell, in cooperation with one-way valves arranged on a first material pipe and a second material pipe, material pumping and injecting from a material storage box are achieved, and the problem that existing manual extrusion and injecting cannot ensure the same extrusion amount each time is solved.

Owner:宋兴动

A kind of environmental protection brick and preparation method thereof

ActiveCN107965086BSolve the problem of low connection tightnessAvoid instabilityBuilding componentsFiberEnvironmental resource management

The invention discloses an environmental protection brick, which comprises an environmental protection brick main body, a connection building block 1 and a connection building block 2 which are corresponded are respectively and fixedly arranged at an end surface and a bottom surface of the environmental protection brick main body, corresponding clamping strips are fixedly arranged at the connection building block 1 far from the environmental protection brick main body and the connection building block 2 far from the environmental protection brick main body, fiber guard net layers are arrangedat an external surface of the environmental protection brick main body, the external surface of the connection building block 1, the external surface of the connection building block 2, and the external surface of the clamping stripes, pressing grooves are arranged at central parts of two side surfaces of the environmental protection brick main body, the fiber guard net layer comprises an upper net layer and a lower net layer, two ends of the upper net layer and the two ends of the lower net layer are subjected to clamp connection and fixed in the pressing groove, and pressing strips are subjected to clamp connection and fixed in the pressing grooves. The problem that connection compactness of the environmental protection bricks during usage is not high can be solved, and the method can bewidely used in the environmental protection brick.

Owner:浙江金州科技有限公司

An environmentally friendly brick autoclaved production equipment

ActiveCN110815526BNovel structureReinforced Sealed ConnectionCeramic shaping apparatusSealing arrangementsHydraulic cylinderMechanical engineering

The invention provides an autoclaved production equipment for environment-friendly bricks, comprising an autoclave box and a box cover arranged at the opening of the autoclave box, the autoclave box is installed on the ground through a support seat, so that the box cover and The connection of the autoclave box is off the ground; the top of the autoclave box is fixedly equipped with a first hydraulic cylinder, and the first hydraulic cylinder drives the opening and closing of the box cover; the opening of the autoclave box A plurality of locking mechanisms are installed on the outer wall, and the locking mechanisms are used to strengthen the connection and tightness between the lid and the autoclave box. The locking mechanism is provided with a pressing block, and the pressing block rotates, Realize breaking away from or entering the pressing ring position of the box cover; the briquetting block moves along the longitudinal extension direction of the opening of the autoclaved box to realize the pressing and loosening of the box cover; its structure is novel and can strengthen The sealed connection between the kettle cover and the autoclave ensures good autoclave conditions.

Owner:清远市榕兴新型环保建材有限责任公司

Environment-friendly brick manufacturing process and mold

PendingCN112551955AReduce consumptionLow costSolid waste managementMouldsCompressive resistanceBrick

The invention discloses an environment-friendly brick manufacturing process and a mold, and relates to the technical field of environment-friendly brick manufacturing, the environment-friendly brick comprises raw materials and water, the ratio of the raw materials to the water is 1: 0.55, and the raw materials comprise, by weight, 75% of building recycled aggregate, 20% of stone powder, 4%-5% of cement and 0.25% of mortar. The building recycled aggregate is used as a main material to replace river sand, so that the resource consumption is reduced, the raw material cost can be reduced, a largeamount of building garbage can be consumed, and the brick compressive strength is improved; moreover, when the stirred raw materials are fed into the mold, the mold can vibrate and tamp the raw materials, so that gaps in the raw materials are reduced, and the cracking rate during green brick maintenance is reduced; meanwhile, the temperature is gradually increased during curing, and constant-temperature curing is performed, so that the cracking rate during green brick curing can be further reduced.

Owner:梅娜

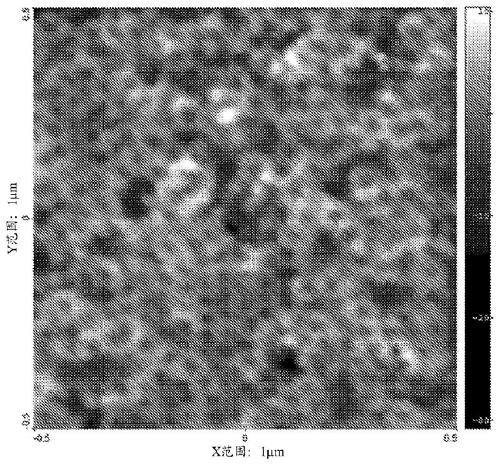

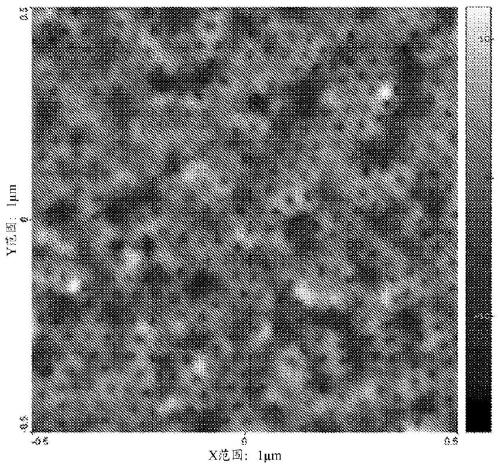

Porous membranes including pentablock copolymers and method of making same

The present disclosure provides a porous membrane made of pentablock copolymer. The porous membrane includes an ABCBA block copolymer and has a number of pores. The A block is immiscible with each ofthe B block and the C block, the B block has a glass transition temperature (Tg) of 90 degrees Celsius or greater, and the C block has a Tg of 25 degrees Celsius or less. The A block comprises a poly(alkylene oxide), a substituted epoxide, a polylactam, or a substituted carbonate; B block comprises a vinyl aromatic monomer or a polyalkylmethacrylate and C block comprises a polyacrylate, a polysiloxane or a polyisoprene. A method of making a porous membrane is also provided. The method includes forming a film or a hollow fiber from a solution including a solvent and solids containing an ABCBA block copolymer. The method further includes removing at least a portion of the solvent from the film or the hollow fiber and contacting the film or the hollow fiber with a nonsolvent.

Owner:3M INNOVATIVE PROPERTIES CO

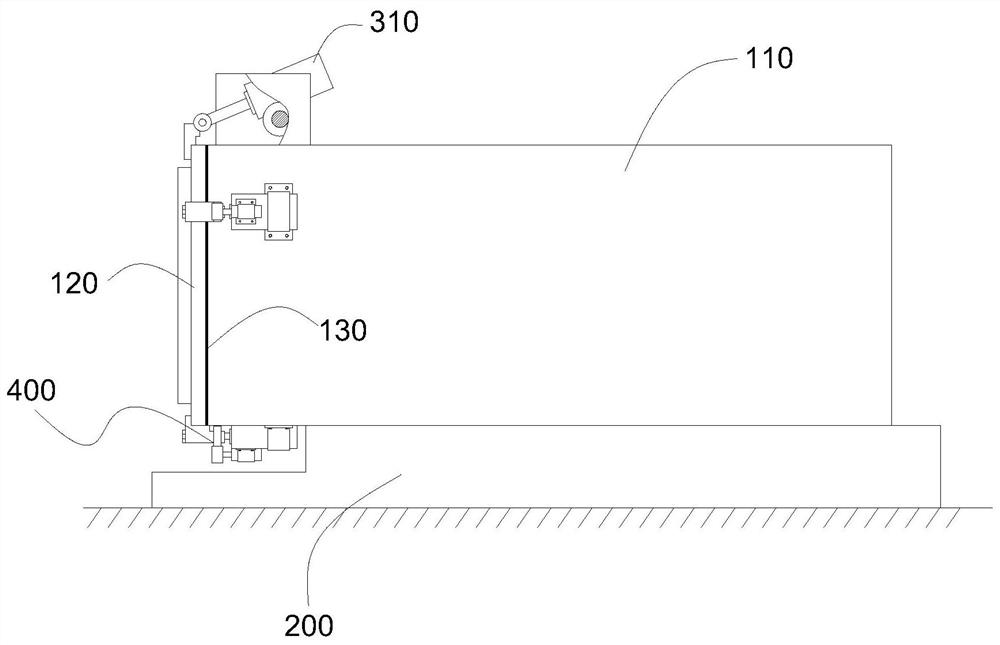

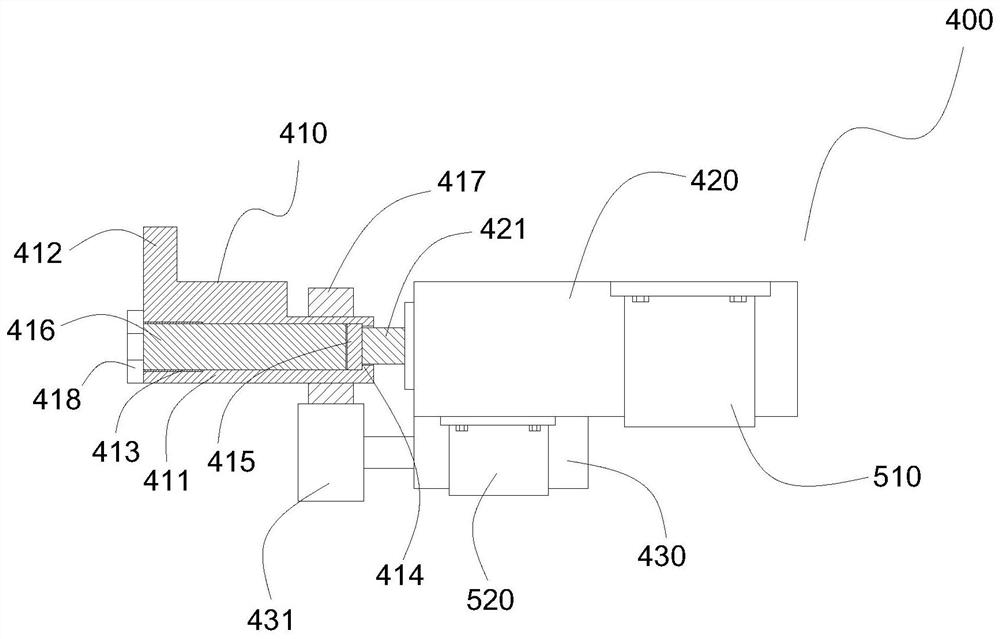

Cutting device for partitioning environment-friendly green bricks

PendingCN114683386ANovel structureGuarantee molding qualityDischarging arrangementAuxillary shaping apparatusBrickMechanical engineering

The cutting device comprises a bearing and transferring structure arranged on the outer side of a discharging port of a mud strip extruder, a cutting mechanism is arranged above the end, close to the mud strip extruder, of the bearing and transferring structure, and a conveying belt is arranged on the side, away from the mud strip extruder, of the bearing and transferring structure; the bearing and transferring structure can move to the position close to the clay strip extruder, clay strips sent out by the clay strip extruder can be sent to the bearing and transferring structure, the cutting mechanism conducts linear cutting on the sent-out clay strips, and the bearing and transferring structure transfers and sends the cut green bricks to the conveying belt. The green brick cutting device is novel in structure, cutting quality can be improved, subsequent green bricks can be fully spaced and separated conveniently, and the problem of secondary contact is prevented.

Owner:清远市榕兴新型环保建材有限责任公司

Environment-friendly brick

InactiveCN114319705AIncrease the number ofLight in massConstruction materialBrickConstruction engineering

The invention provides an environment-friendly brick, and relates to the technical field of building materials. According to the scheme, the environment-friendly brick comprises an environment-friendly brick body, a plurality of hollow columns are arranged on the environment-friendly brick body, a limiting piece is arranged at one end of the environment-friendly brick body, and a limiting groove matched with the limiting piece is formed in the other end of the environment-friendly brick body. The environment-friendly brick aligning device can assist two adjacent environment-friendly bricks in aligning, and the labor intensity of building workers is reduced.

Owner:梁国健

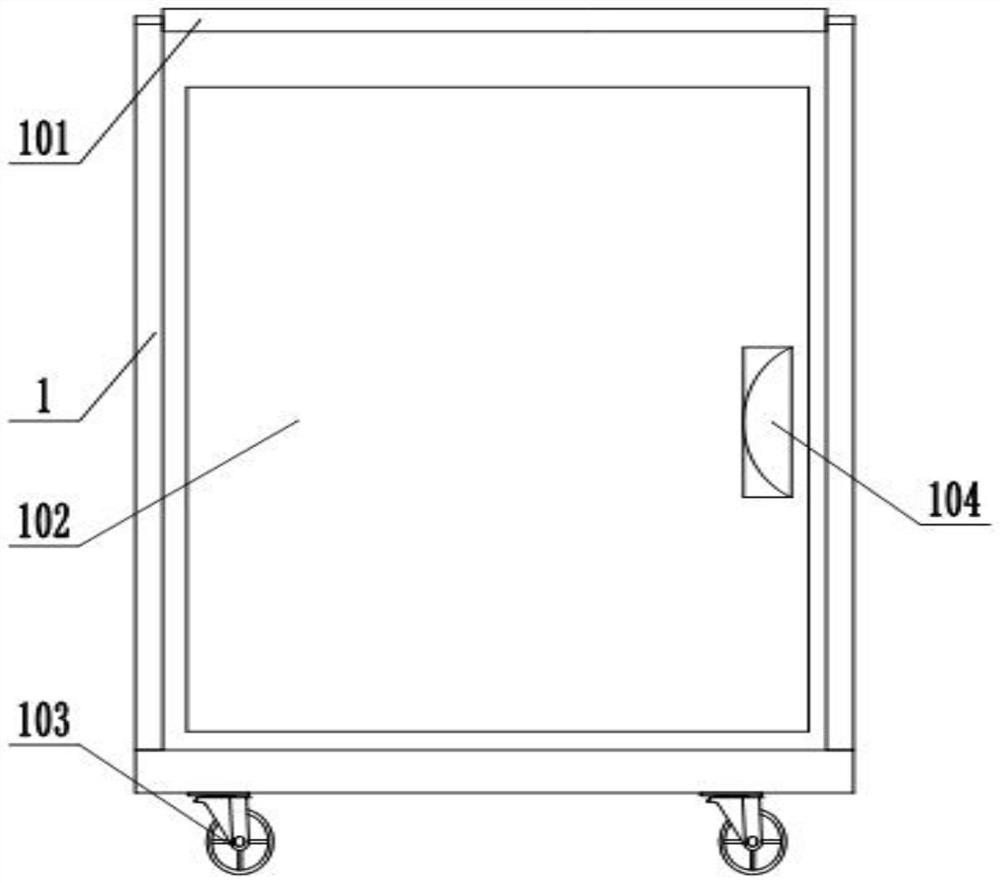

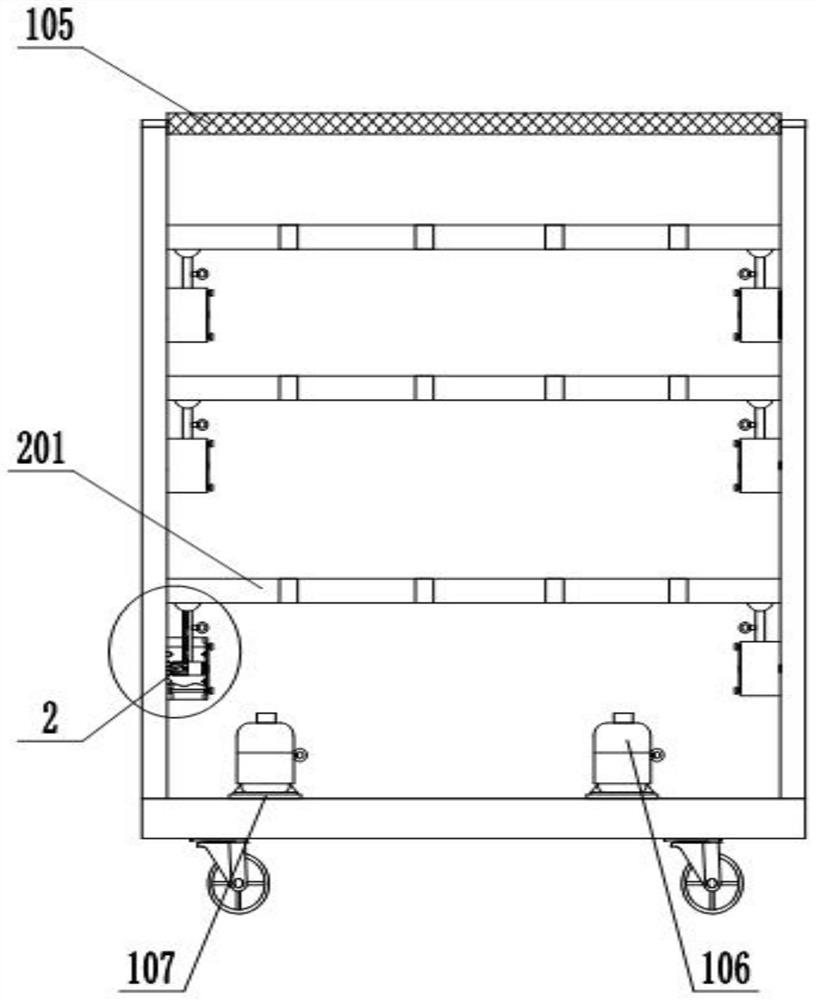

Air-drying equipment for environmental protection brick production

The invention discloses air drying equipment for environmental protection brick production. The air drying equipment for environmental protection brick production comprises a cabinet body and castors;the castors are fixedly mounted on the bottom surface of the cabinet body; a cabinet door is arranged on the front surface of the cabinet body; a handle is arranged on the surface of the cabinet door; a top frame is fixedly mounted around the top surface of the cabinet body; a vent net is fixedly mounted on the internal side of the top frame; multiple pump seats are arranged on the internal bottom surface of the cabinet body; air pumps are fixedly mounted on the pump seats; and an article placing component is arranged on the internal all of the cabinet body. The air drying equipment for environmental protection brick production has the beneficial effects that connecting rods are driven by using pull rings to lift to adjust the heights of article placing racks, self-locking is finished byclamping rolling wheels into gaps between convex blocks, and therefore, the distance heights between the article placing racks can be adjusted to adapt to environmental protection bricks with different specifications, the use applicability of the air drying equipment is improved, and the equipment is beneficial for large-range popularization and utilization of the equipment.

Owner:郭山河

Rapid drying device for environment-friendly brick processing

InactiveCN113513886AImprove isolationImprove drying efficiencyDrying gas arrangementsDrying chambers/containersBrickProcess engineering

The invention provides a rapid drying device for environment-friendly brick processing. The rapid drying device comprises a box body, a storage box, supporting legs, an upper adjusting plate, a lower adjusting plate, a tray and a filtering box, the storage box is fixedly installed at the center position of the top of the box body, and a servo motor is fixedly installed at one end of the storage box through a bolt; two bidirectional lead screws are fixedly installed on an output shaft of the servo motor, the two bidirectional lead screws are symmetrically and movably installed on the two sides of the interior of the box body, and the rapid drying device for environment-friendly brick processing can adjust the upper adjusting plate and the lower adjusting plate to form a small sealed space with the tray; and environment-friendly green bricks can be isolated and independently dried, meanwhile, the environment-friendly green bricks can be fixed and supported, the fragmentation probability of the environment-friendly green bricks is reduced, the environment-friendly green bricks make full contact with hot air, the drying efficiency of the environment-friendly green bricks is improved, and meanwhile disintegrating slag can be prevented from entering the rapid drying device.

Owner:霍邱县鑫鼎工贸有限责任公司

Briquetting device for environment-friendly brick production

InactiveCN114516109AEasy to removeNot easy to damageDischarging arrangementSolid waste managementBrickMechanical engineering

The invention discloses a briquetting device for environment-friendly brick production. The briquetting device comprises a box body, a briquetting mechanism arranged at the top of the box body, a template arranged in the box body, pushing mechanisms arranged at the two ends of the top of the template, a supporting plate arranged in the box body and positioning mechanisms symmetrically arranged at the bottom of the supporting plate and used for fixing the supporting plate to the box body. According to the brick pressing device, the positioning mechanism is additionally arranged, so that a user can conveniently and quickly take down finished bricks, the problems that the finished bricks are difficult to take down and are easily damaged by a traditional block pressing device are solved, and the yield is greatly improved.

Owner:金彪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com