Environment-friendly brick structure and production method thereof

A production method and technology of environmentally friendly bricks, applied to roads, pavements paved with prefabricated blocks, pavement details, etc., can solve the problems of inconvenient installation, not environmentally friendly, single function, etc., and achieve the effect of convenient installation and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

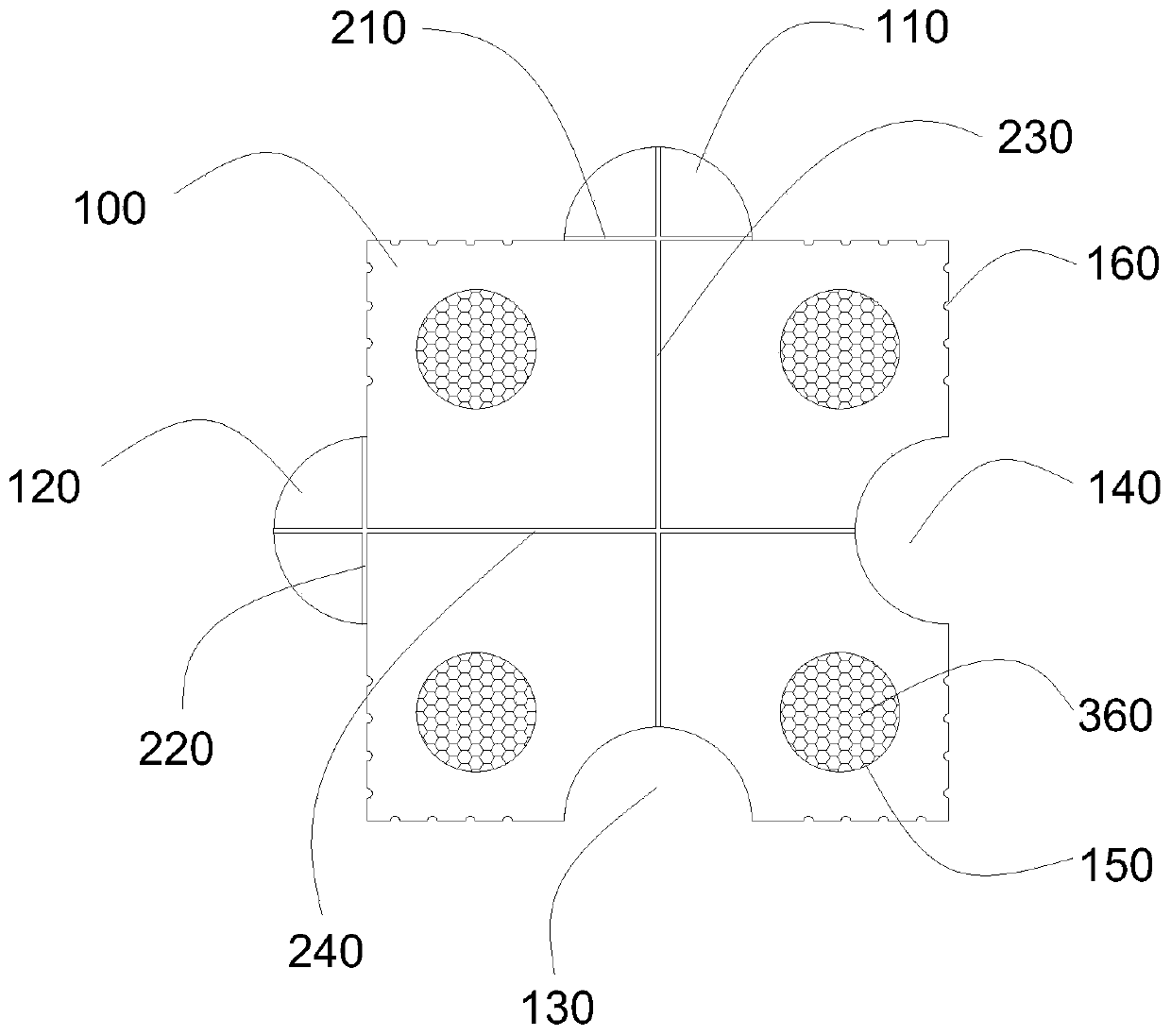

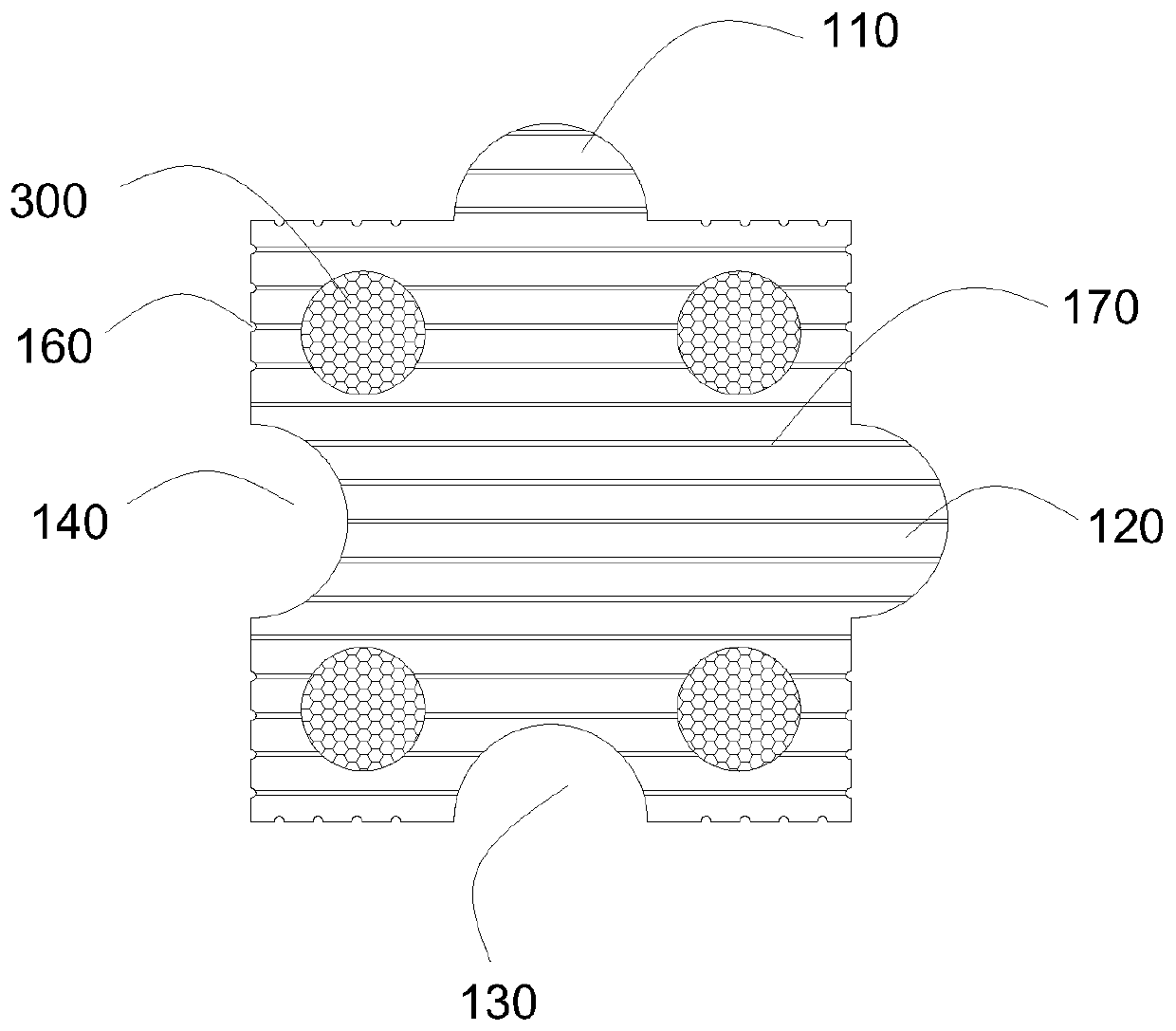

[0026] like figure 1 , figure 2 As shown, an environmentally friendly brick structure is disclosed in a specific embodiment of the present invention, including a brick body 100, a side wall of the brick body 100 is fixedly provided with a first bump 110, and any adjacent side wall is fixedly provided with The second bump 120, the first bump 110 and the second bump 120 are all located at the center of the corresponding side wall; the side wall of the brick body 100 is opposite to the first bump 110 and the second bump The two bumps 120 are respectively provided with a first notch 130 and a second notch 140, the first notch 130 matches the shape of the first bump 110, the second bump 120 and the second notch 140 Compatible; the top surface of the connection between the first bump 110 and the brick ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com