Environment-friendly brick

An environmentally friendly brick, one-to-one correspondence technology, applied in the direction of building components, building materials, construction, etc., can solve problems such as single structure, increased labor intensity of construction workers, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

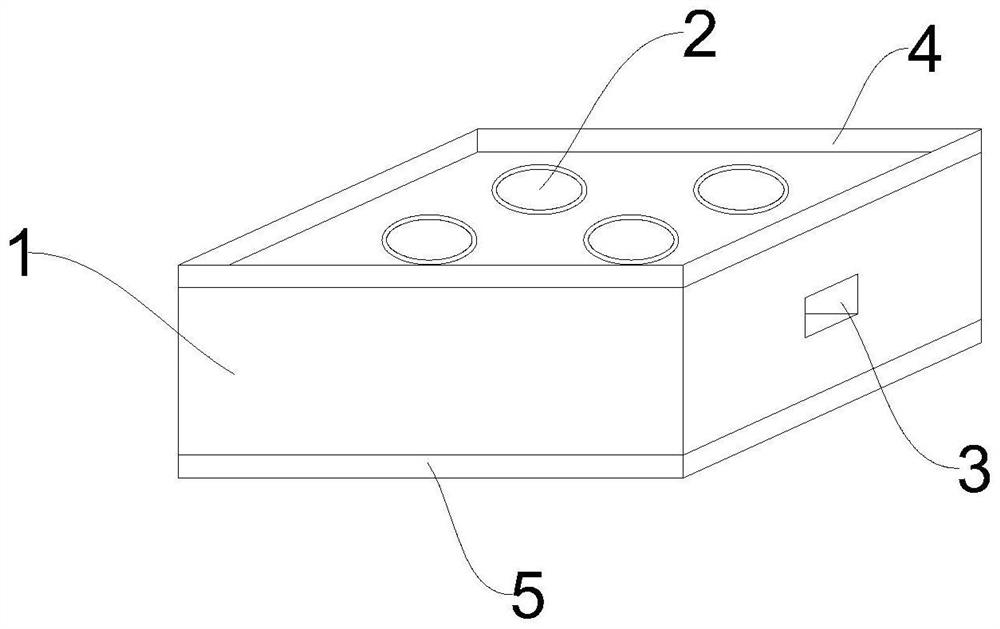

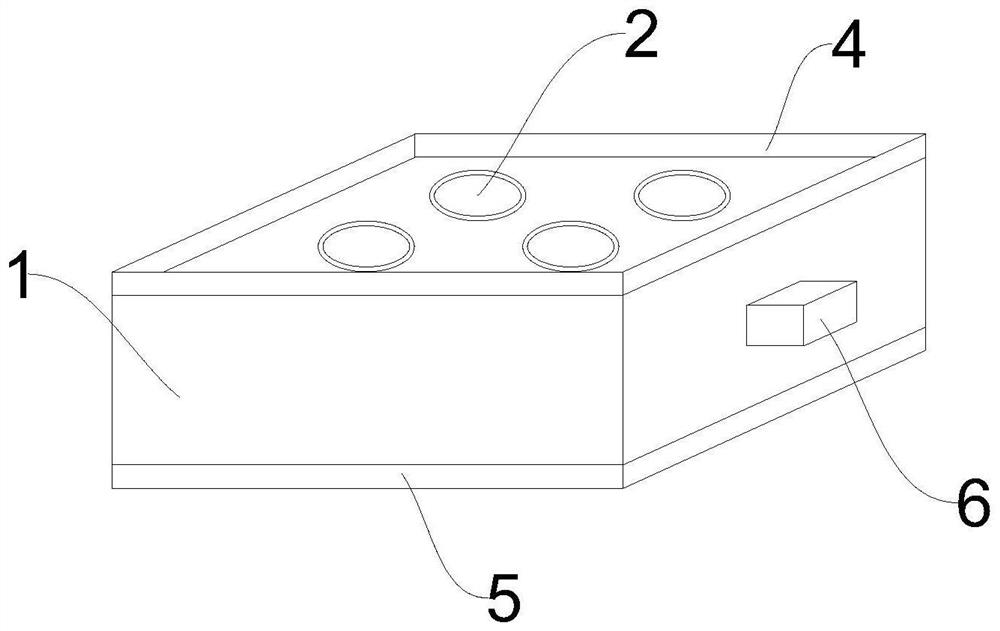

[0032] Please refer to Figure 1-Figure 2 shown. This embodiment provides an environmentally friendly brick, including an environmentally friendly brick body 1. The environmentally friendly brick body 1 is provided with a plurality of hollow columns 2. One end of the environmentally friendly brick body 1 is provided with a limiting member 6, and the other end of the environmentally friendly brick body 1 is provided with a limiter. The limit groove 3 that the position piece 6 is matched with.

[0033] In the above embodiment, an environmentally friendly brick is composed of an environmentally friendly brick body 1, wherein the environmentally friendly brick body 1 is provided with a plurality of hollow columns 2, the number of hollow columns 2 can be 9, and the hollow columns 2 are arranged according to 3*3, The hollow column 2 is set in the non-load-bearing part, and the porosity is equal to or greater than 35%. The environmental protection brick body 1 has the advantage of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com