An environmentally friendly brick autoclaved production equipment

A technology for production equipment and environmentally friendly bricks, applied in sealing devices, ceramic molding machines, manufacturing tools, etc., can solve problems such as high sealing performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

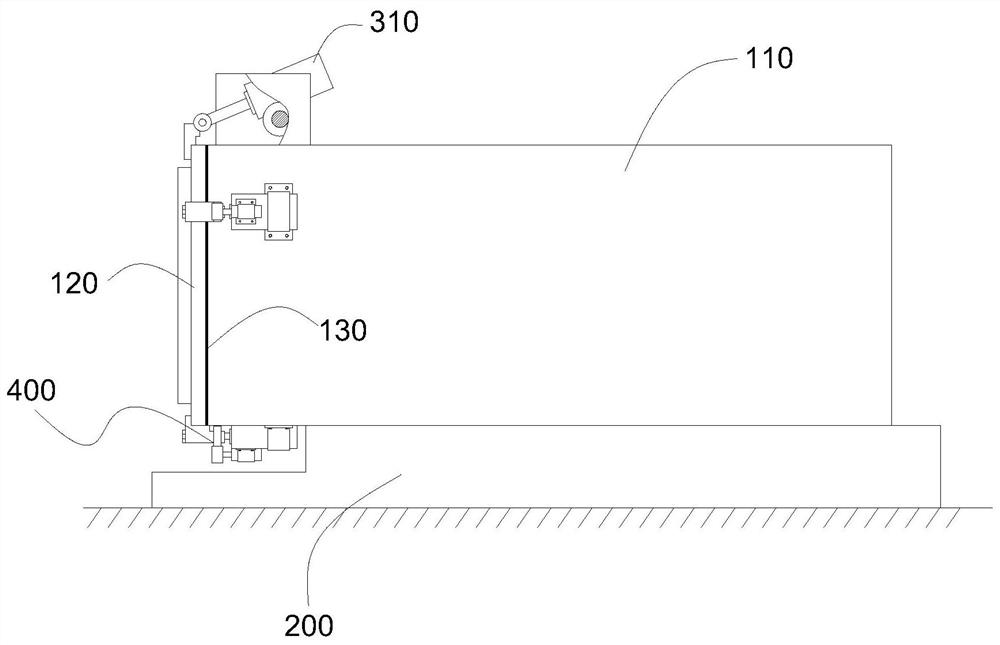

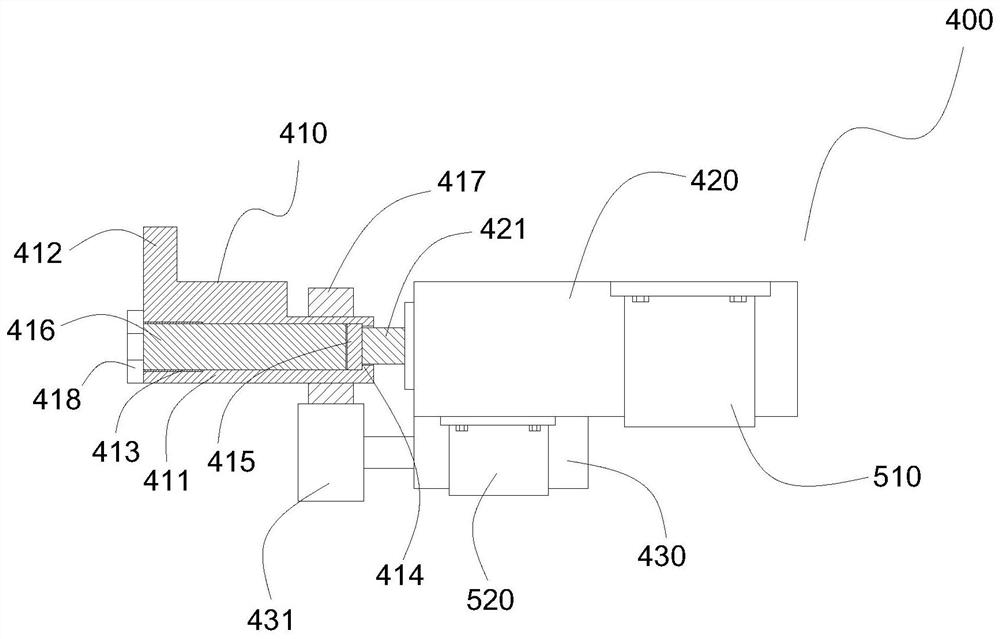

[0018] Such as figure 1 , figure 2 As shown, a specific embodiment of the present invention discloses an environmentally friendly brick autoclaved production equipment, including an autoclave box 110 and a box cover 120 located at the opening of the autoclave box 110, and the autoclave box 110 is supported by The seat 200 is installed on the ground so that the junction of the box cover 120 and the autoclave 110 is off the ground; the top of the autoclave 110 is fixedly equipped with a first hydraulic cylinder 310, and the first hydraulic cylinder 310 Drive the opening and closing of the lid 120; the outer wall of the opening of the autoclave 110 is equipped with a plurality of locking mechanisms 400, and the locking mechanisms 400 are used to reinforce the lid 120 and the autoclave. 110 connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com