Patents

Literature

65results about How to "Eliminate caking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

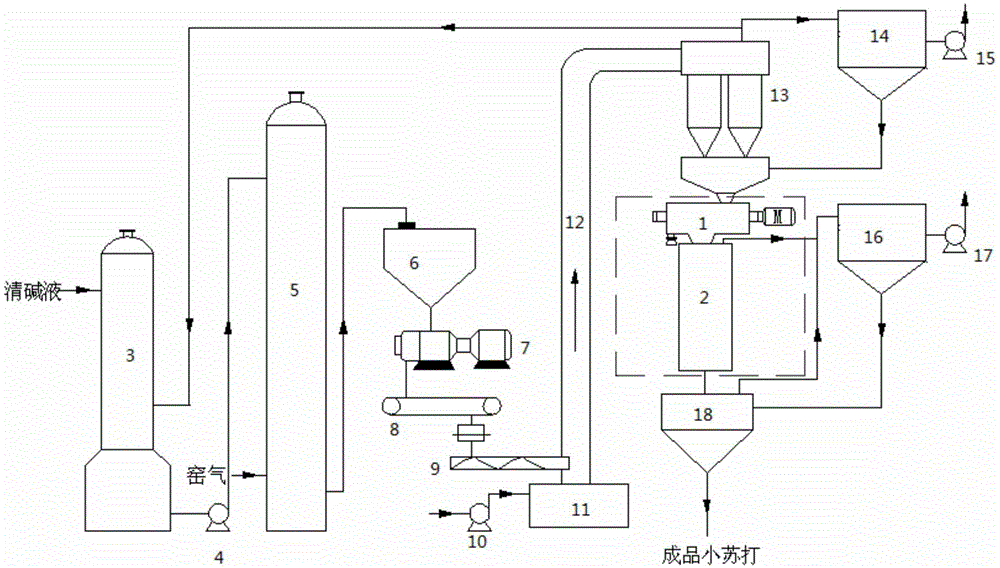

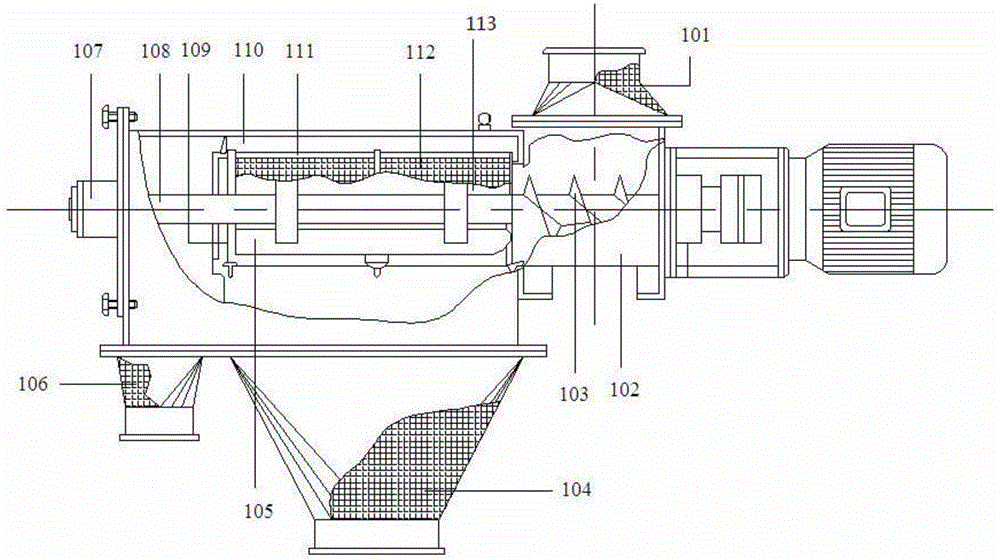

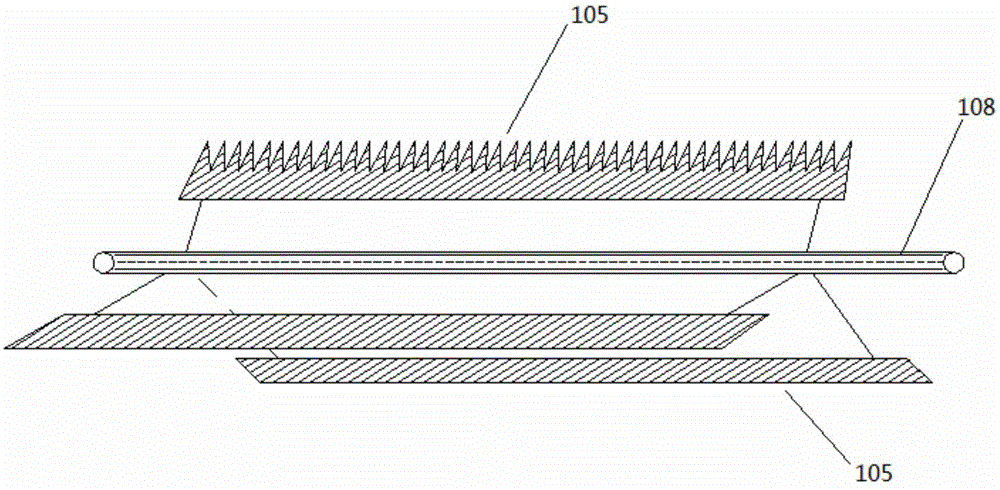

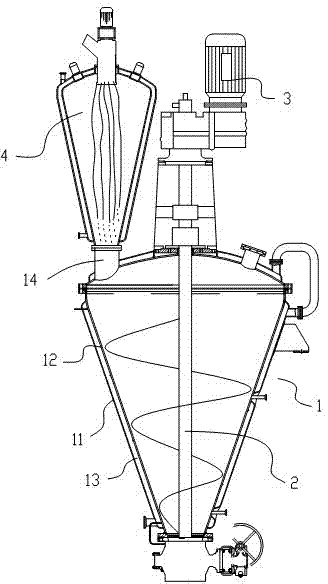

Baking soda production anti-caking process and apparatus

ActiveCN105016363ASolve the problem of clumpingClumping problem eliminatedAlkali metal carbonates moisture absorption preventionCooking & bakingCyclone

The present invention discloses a baking soda production anti-caking process and apparatus, and the main feature is that in the production process of baking soda, the dried baking soda is not directly packaged, first, agglomerates in the material are crushed by a cyclone sieve, meanwhile large particles are sieved out, the sieved material enters into a powder flow cooler for cooling and packaging. The dried baking soda is first crushed by the cyclone sieve, then cooled by the powder flow cooler, and packed, the finished baking soda agglomeration phenomenon can be eliminated; by selection of the cyclone sieve, while sieving, agglomerates formed in the drying process can be crushed, compared with a loud noise vibrating screen, the work environment is favorable to the health of an operator; the powder flow cooler has a simple structure, high heat transfer efficiency, low energy consumption, no damage of crystalline particles, no pollution emissions, low operation and maintenance costs, small floor space and other advantages; the produced baking soda product has high quality, is not contaminated, and fully meets food grade requirements.

Owner:江苏苏盐井神股份有限公司

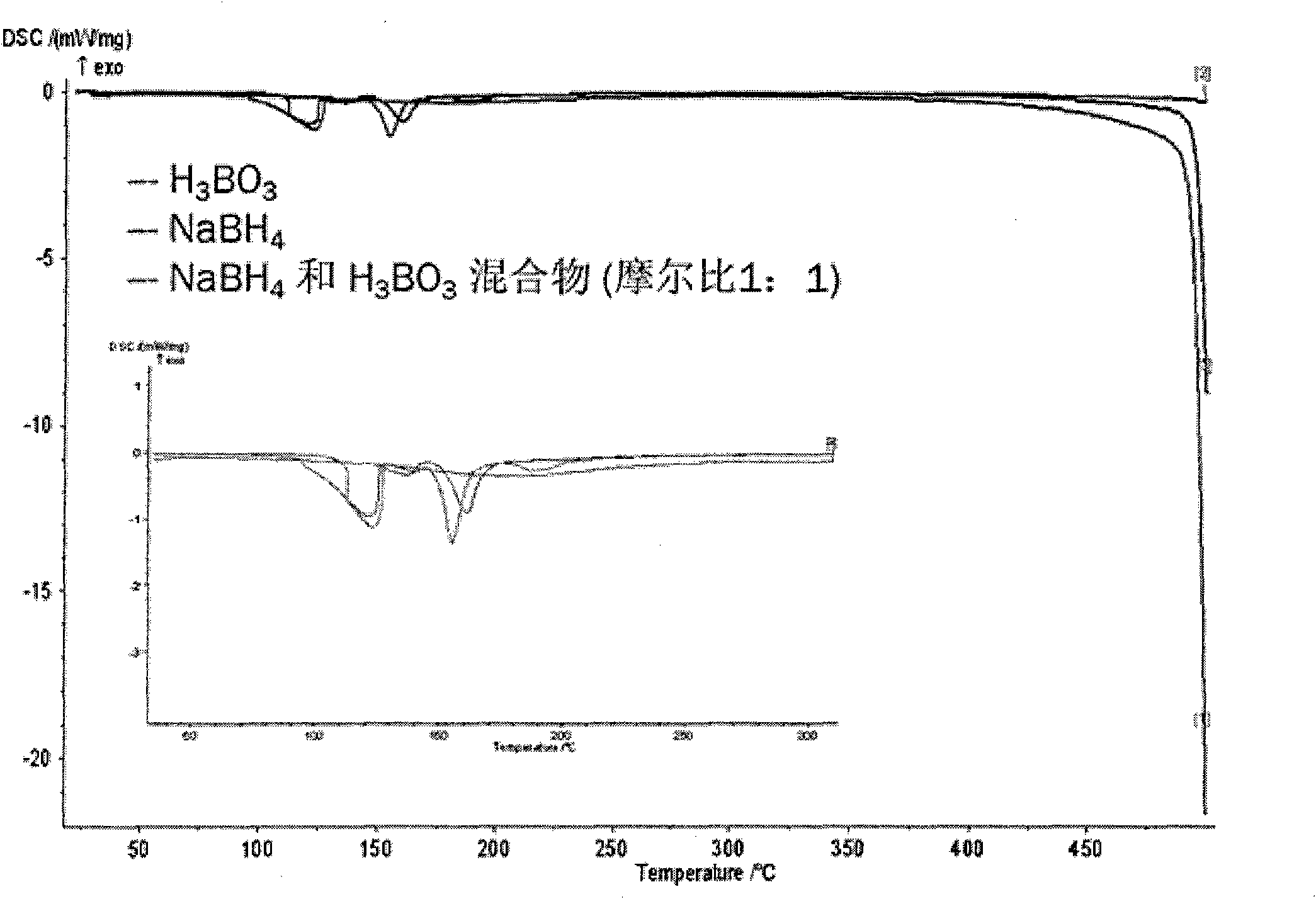

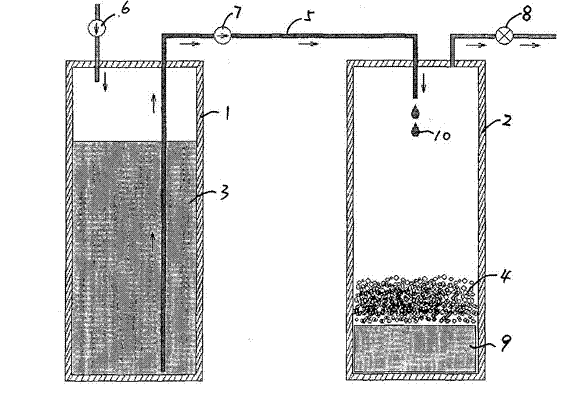

Method for producing hydrogen by hydroboron and portable hydrogen generator

InactiveCN101935018AEliminate cakingMeet the requirements of instantaneous hydrogen consumptionHydrogen productionHydrogenPhysical chemistry

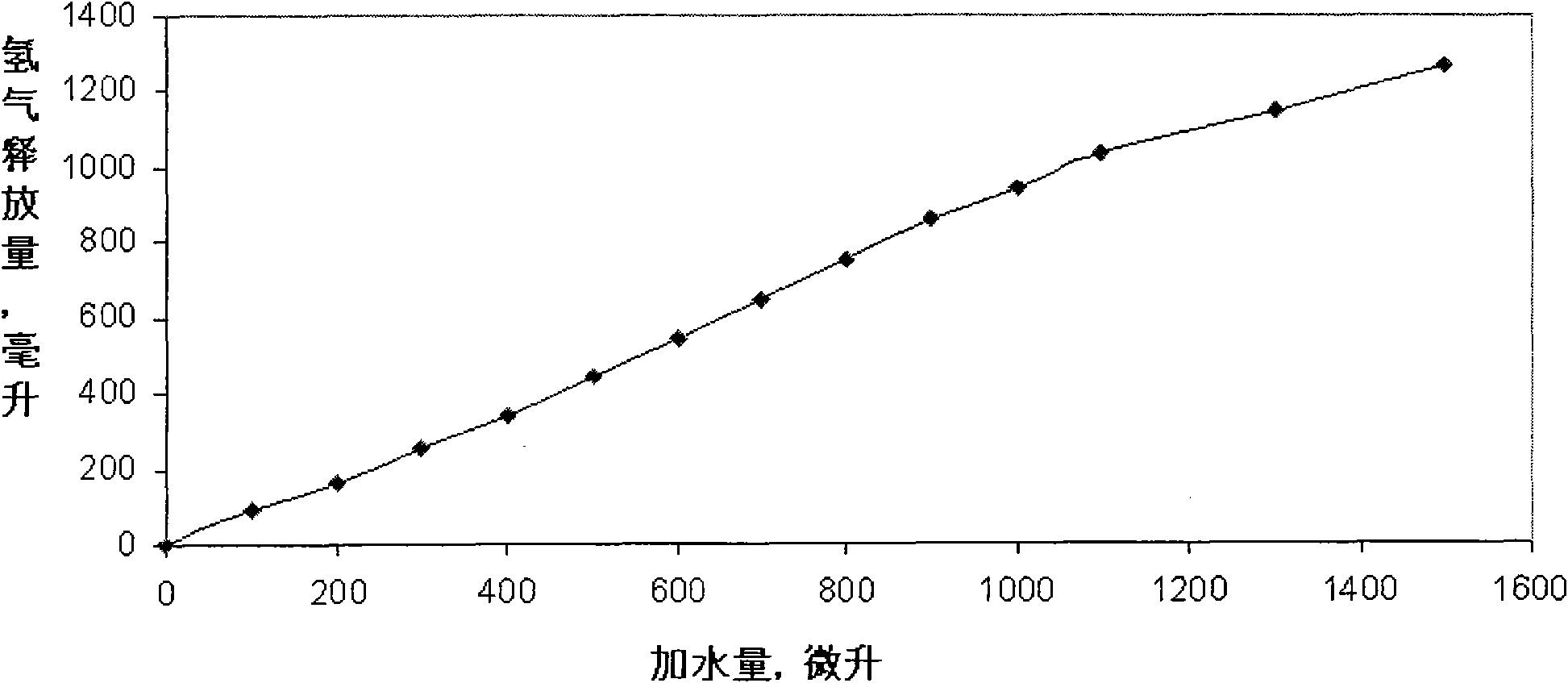

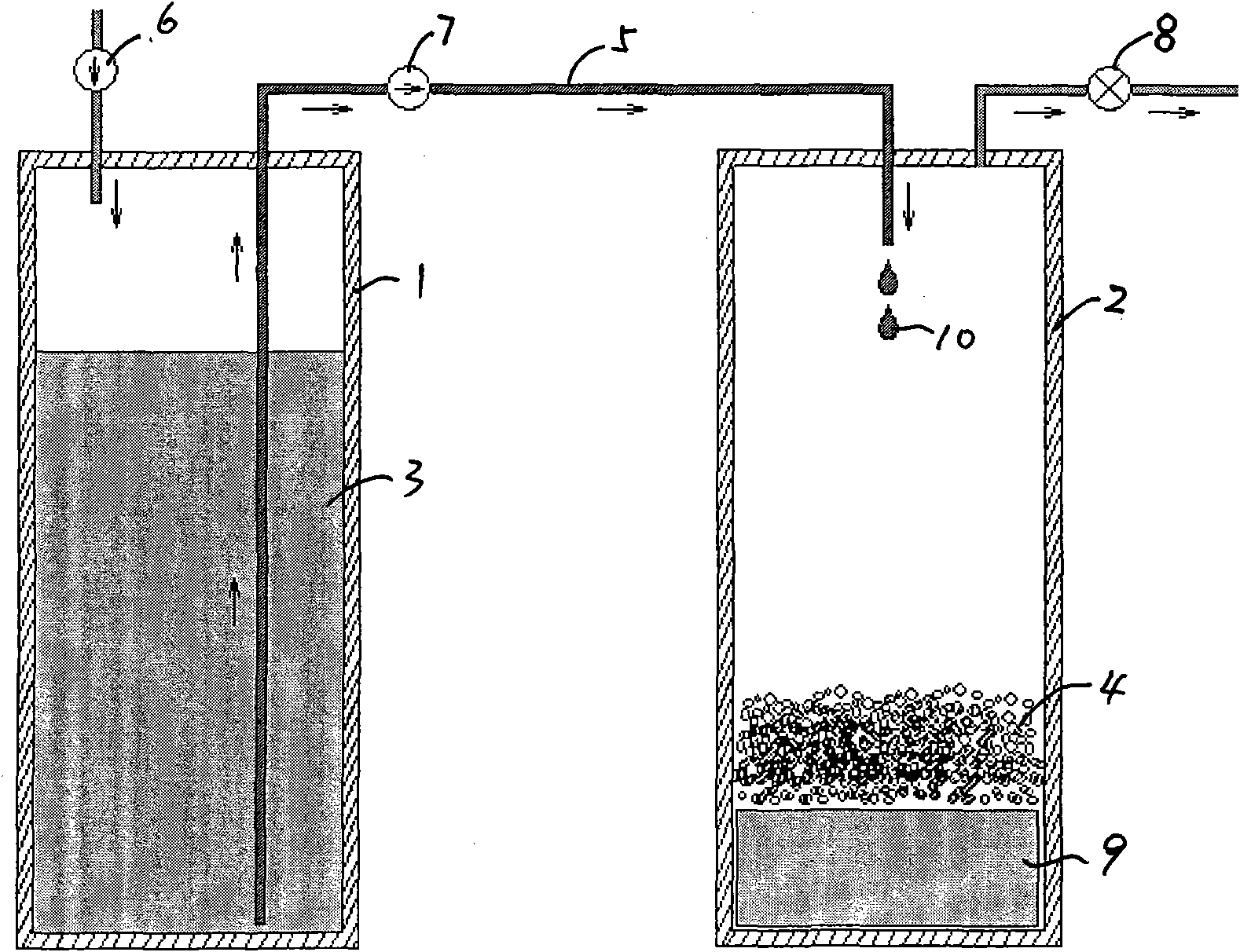

The invention relates to a portable hydrogen generator and a method for producing hydrogen by hydroboron, which has high hydrogen producing speed and high safety. The method is characterized in that the hydrogen producing hydroboron is a mixture formed by mixing the hydrogen producing hydroboron with boron and oxygen compounds according to the B atom molar ratio of 1:(4-0.5); and the hydrogen generator is provided with an air bag and / or a mechanical stirring device which is driven by utilizing pressure change under the hydrogen producing mixture in a hydrogen producing mixture storing seal container. The invention overcomes the defects of hydrolysis hydrogen preparation by a hydroboron caustic alkali solution and hydrogen preparation by using catalyst and has high hydrogen producing speed by reaction with water and can finish the reaction in 3-10 seconds; and the hydrogen producing mixture is safe and stable at normal temperature and normal pressure without automatically discharging hydrogen, therefore, the hydrogen producing mixture can be stored for a long time. The portable hydrogen generator has the advantages of simple equipment and convenient carrying and use; and because the stirring or creeping device is arranged under the position for storing the reaction hydrogen producing mixture, the portable hydrogen generator has high safety and is more beneficial to complete and thorough reaction.

Owner:应宁 +1

Shaoxing rice wine production method capable of realizing zero emission of rice milk water

PendingCN109536333AInhibit the growth of harmful microorganismsReduces biogenic amine levelsAlcoholic beverage preparationHorticultureMicrobiological growth

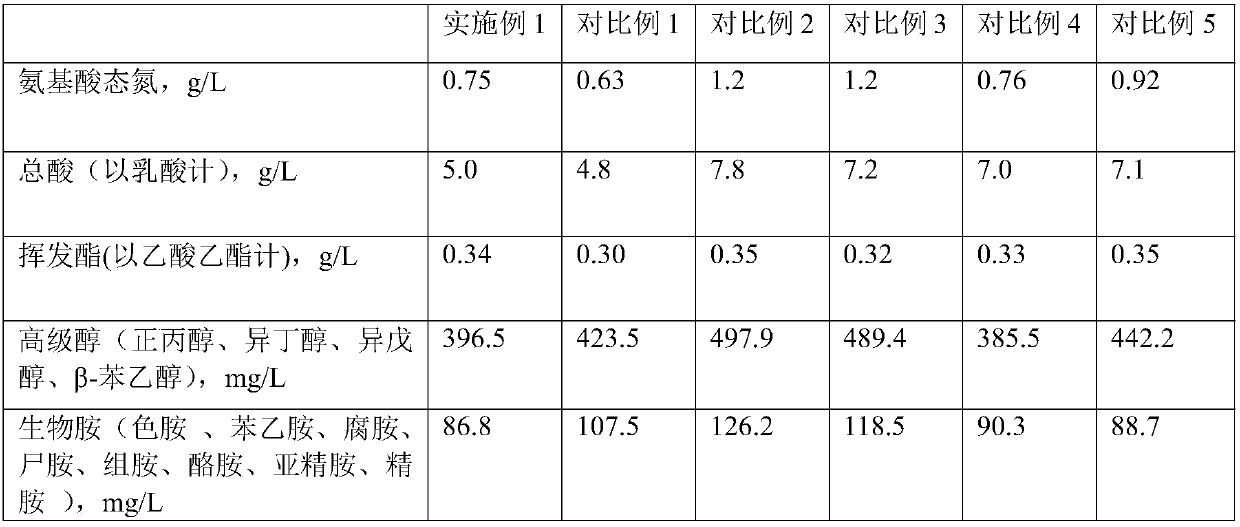

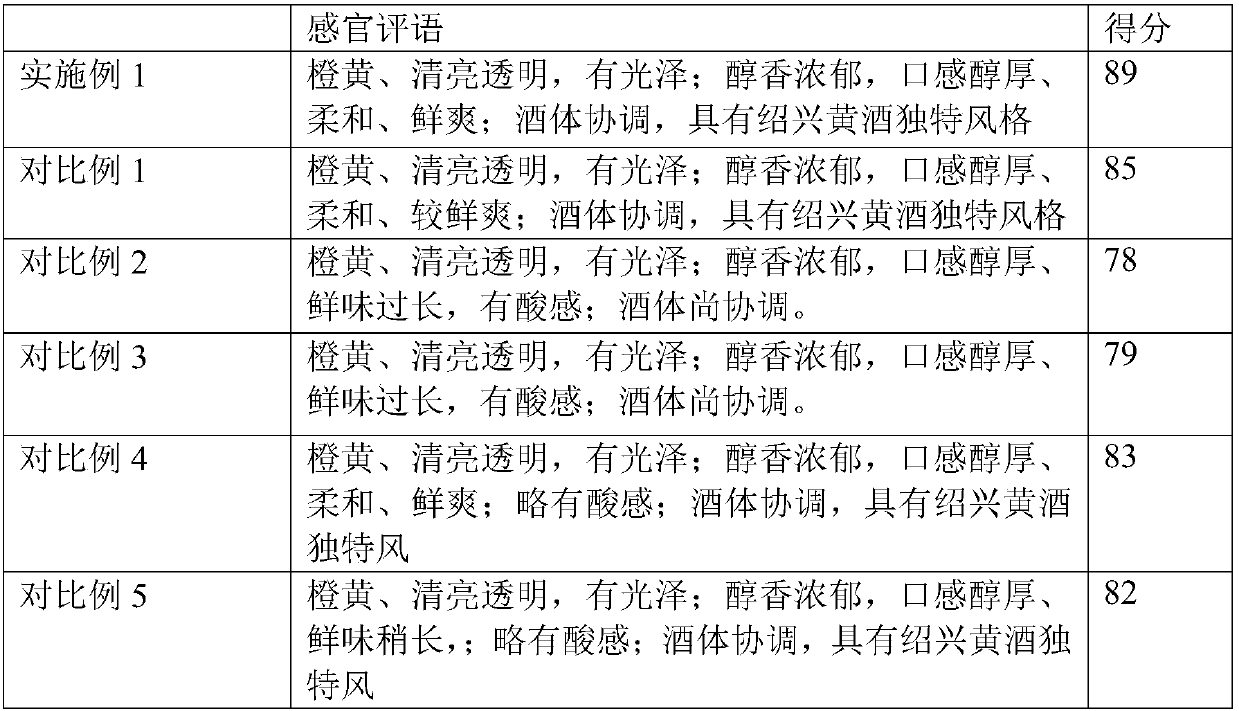

The invention discloses a Shaoxing rice wine production method capable of realizing zero emission of rice milk water and belongs to the technical field of wine making. Lactic acid bacteria which do not produce bioamine are inoculated to soak rice to inhibit the growth of harmful microorganisms, so that the content of the bioamine is greatly reduced, different smell and surface 'lap waste' of the rice milk water are eliminated and the odor of the rice milk water is pleasant; old slurry containing 45 to 50 percent of excellent lactic acid bacteria is inoculated to soak rice, so that the rice soaking time is shortened, rice grain broken sticky paste and starch loss is reduced, the steamed rice quality is improved and the wine yield is increased; and the rest 50 to 55 percent of soaking rice water serves as feeding water, the ratio of the feeding rice milk water to clean water is close to three-slurry four-water, rapid wine-making yeast is replaced by high-temperature saccharified wine yeast with high yeast activity and few infectious microbes, and the use amount of the wine yeast is increased, so that safe fermentation is guaranteed, rancidity is avoided, and the fragrance and the taste of the brewed rice wine are better than those of rice wine, in which the rice milk water is not added or all the rice milk water is used for feeding and brewing.

Owner:ZHEJIANG SHUREN COLLEGE ZHEJIANG SHUREN UNIV

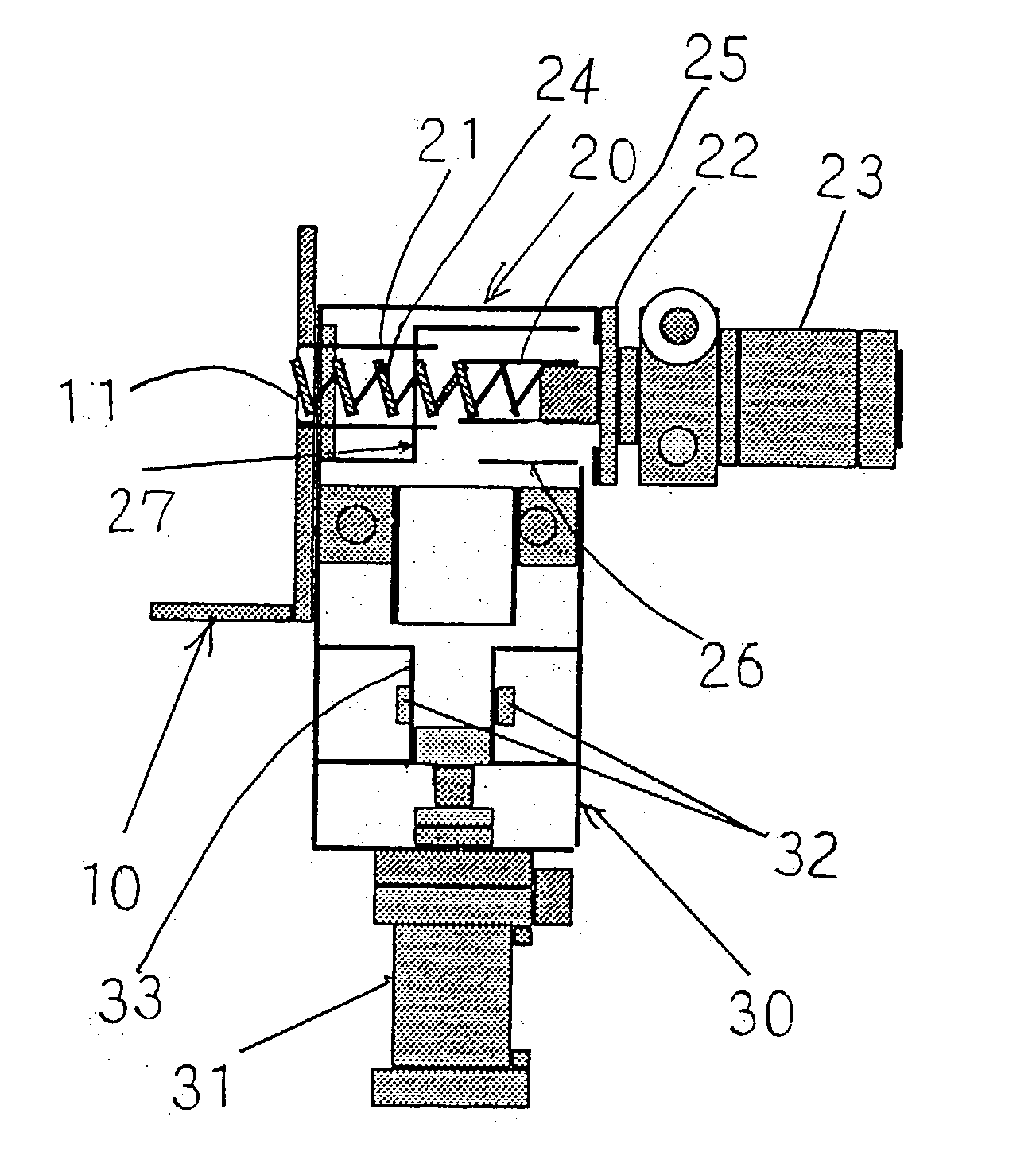

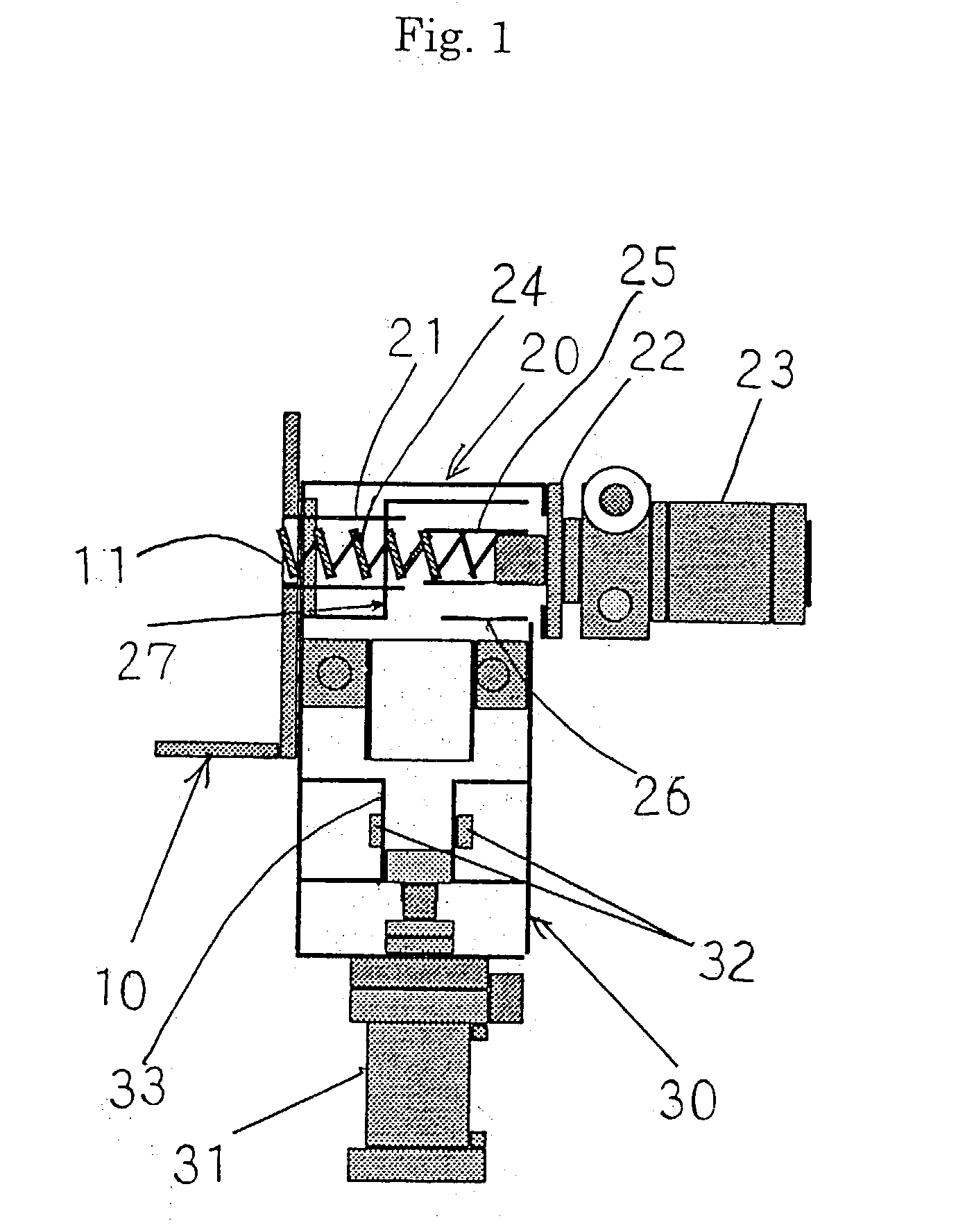

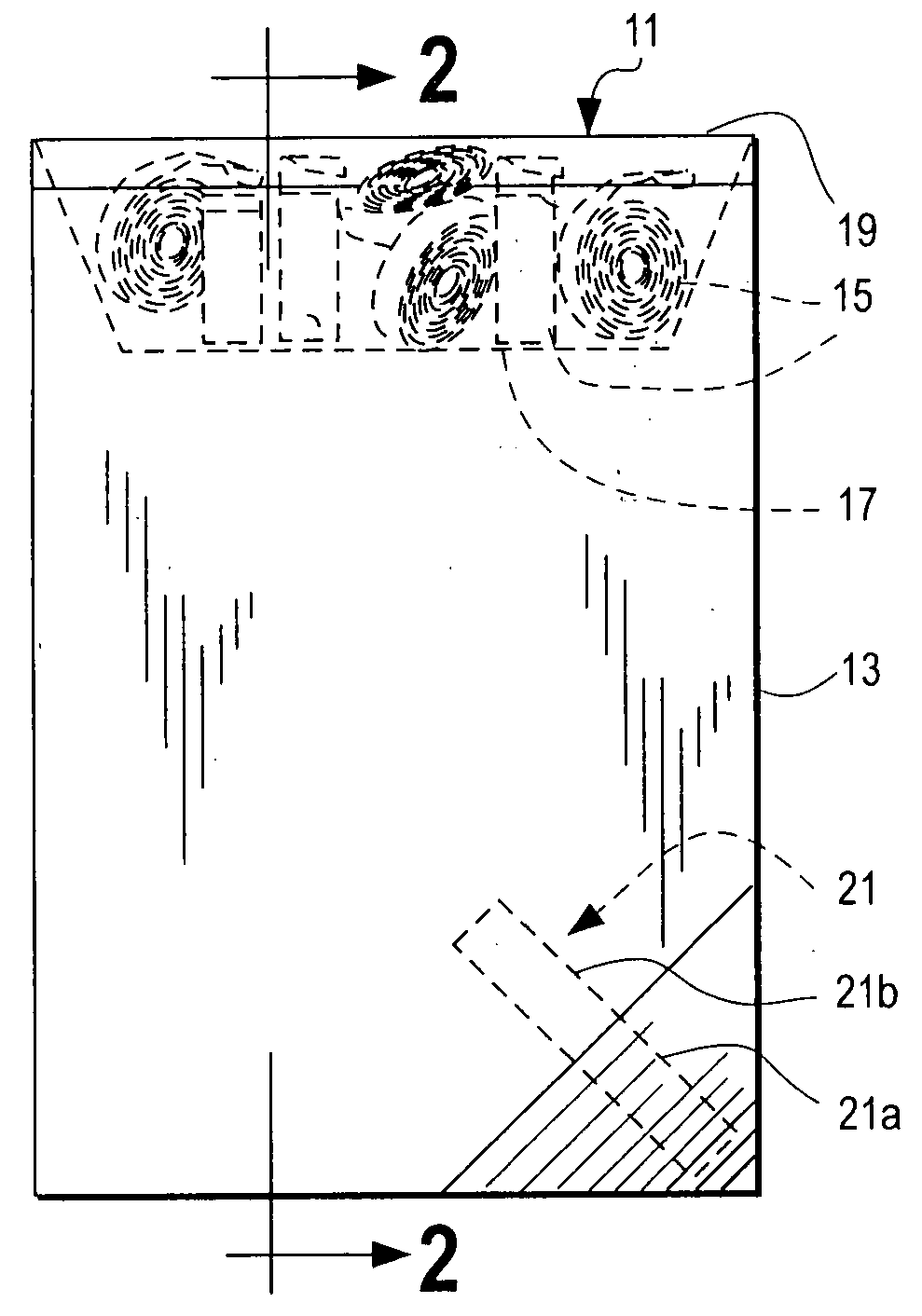

Method and apparatus for supplying sample sand from a mixing machine to a sand-property-measuring apparatus

InactiveUS20040104151A1Accurate supplyEliminate cakingWithdrawing sample devicesFoundry mouldsCompressibilityEngineering

A method and apparatus for supplying sample sand from a mixing machine to a sand-property-measuring apparatus so that sample sand having no clump of sand is sampled, and so that the value of the compactibility correlates with the value measured by conventional sand-property-measuring apparatus.

Owner:SINTOKOGIO LTD

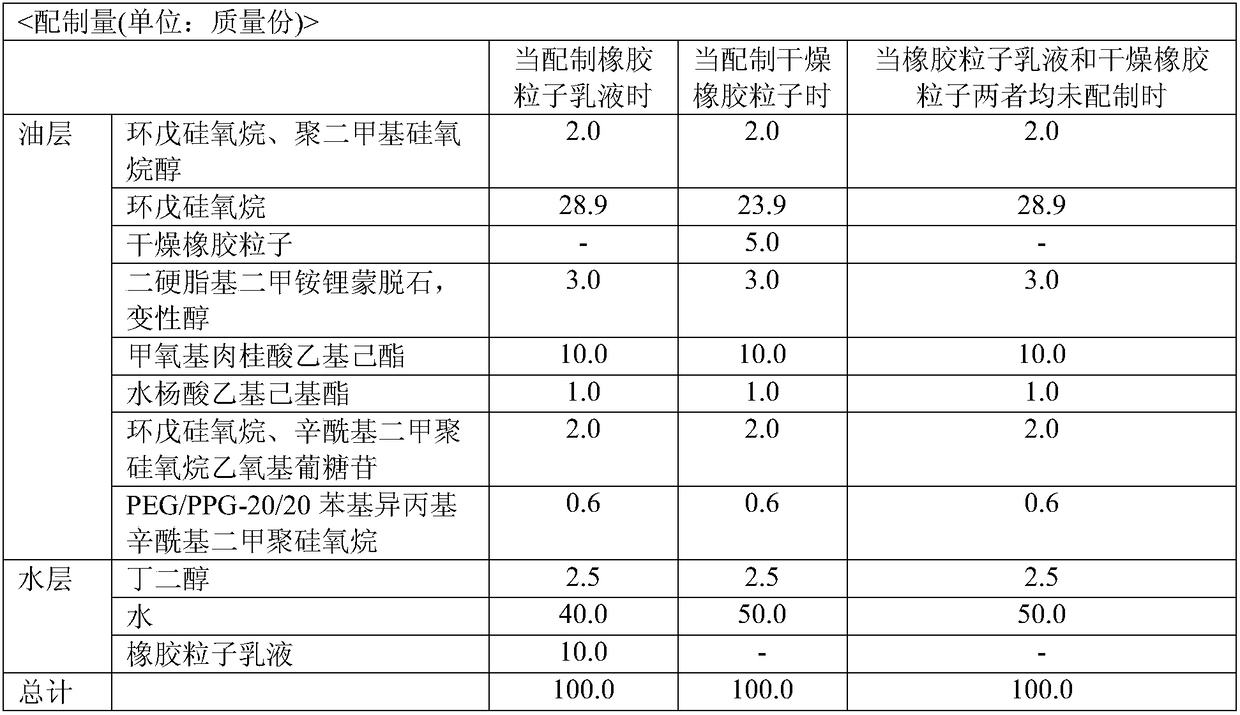

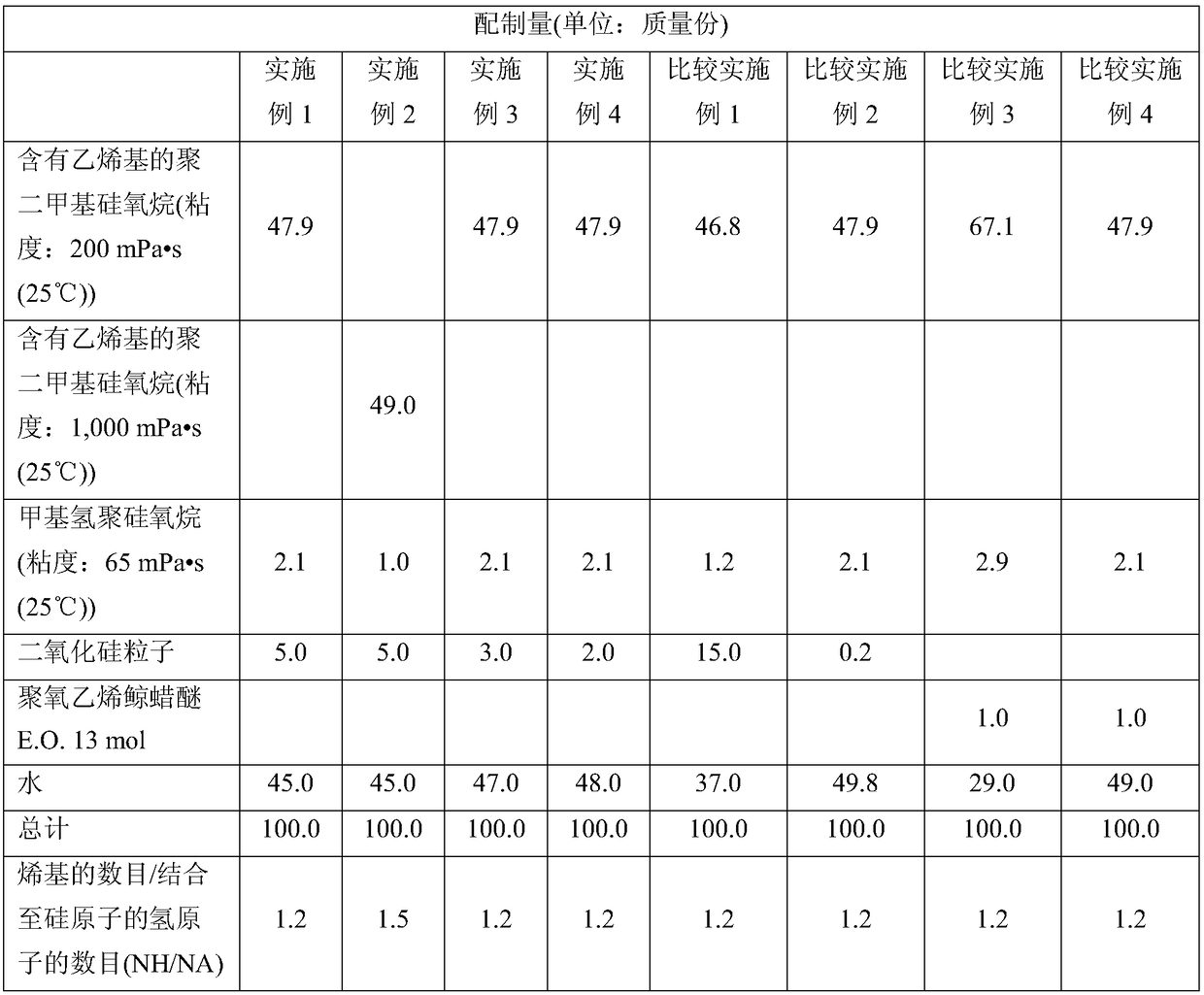

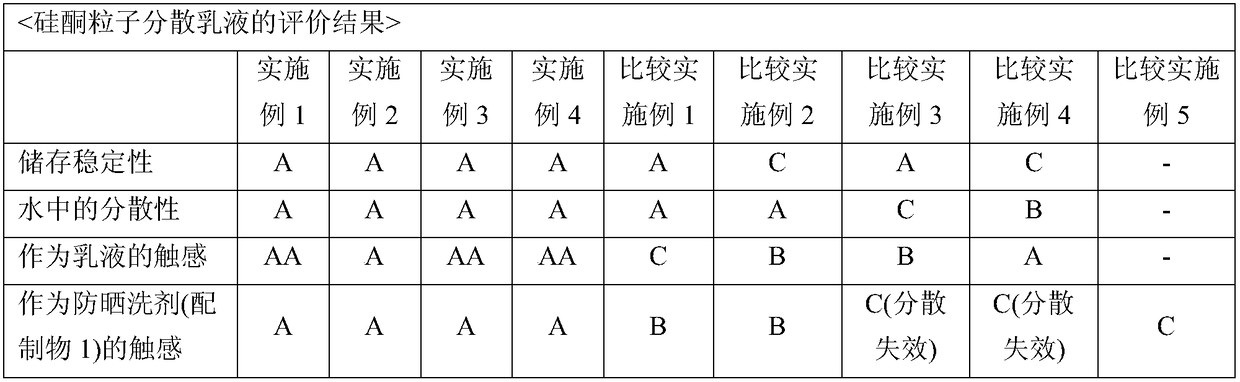

Silica-coated silicone rubber particles and cosmetic

ActiveCN108699247AGood dispersionStable separationPigmenting treatmentCosmetic preparationsSilica particlePolymer science

To provide particles that are free of particle blocking, that have a particle shape close to a perfect sphere, that are also industrially advantageous and allow easy reaction control, and that have exceptional properties such as dispersion stability, stability during particle isolation, and physical stability. These silica-coated silicone rubber particles have silicone rubber particles, and a coating layer that covers the surface of the silicone rubber particles and that comprises silica particles. The coating level of the coating layer is from 2.0 * 10-9 to 3.2 * 10-6 kg / m<2>, and the sphericity is from 0.8 to 1.0.

Owner:WACKER CHEM GMBH

Air propelled party streamer device

InactiveUS20050075043A1Reduction in pressurized volumeExcessive pressureToysEngineeringElectrical and Electronics engineering

Owner:LORENZANA MOISES B

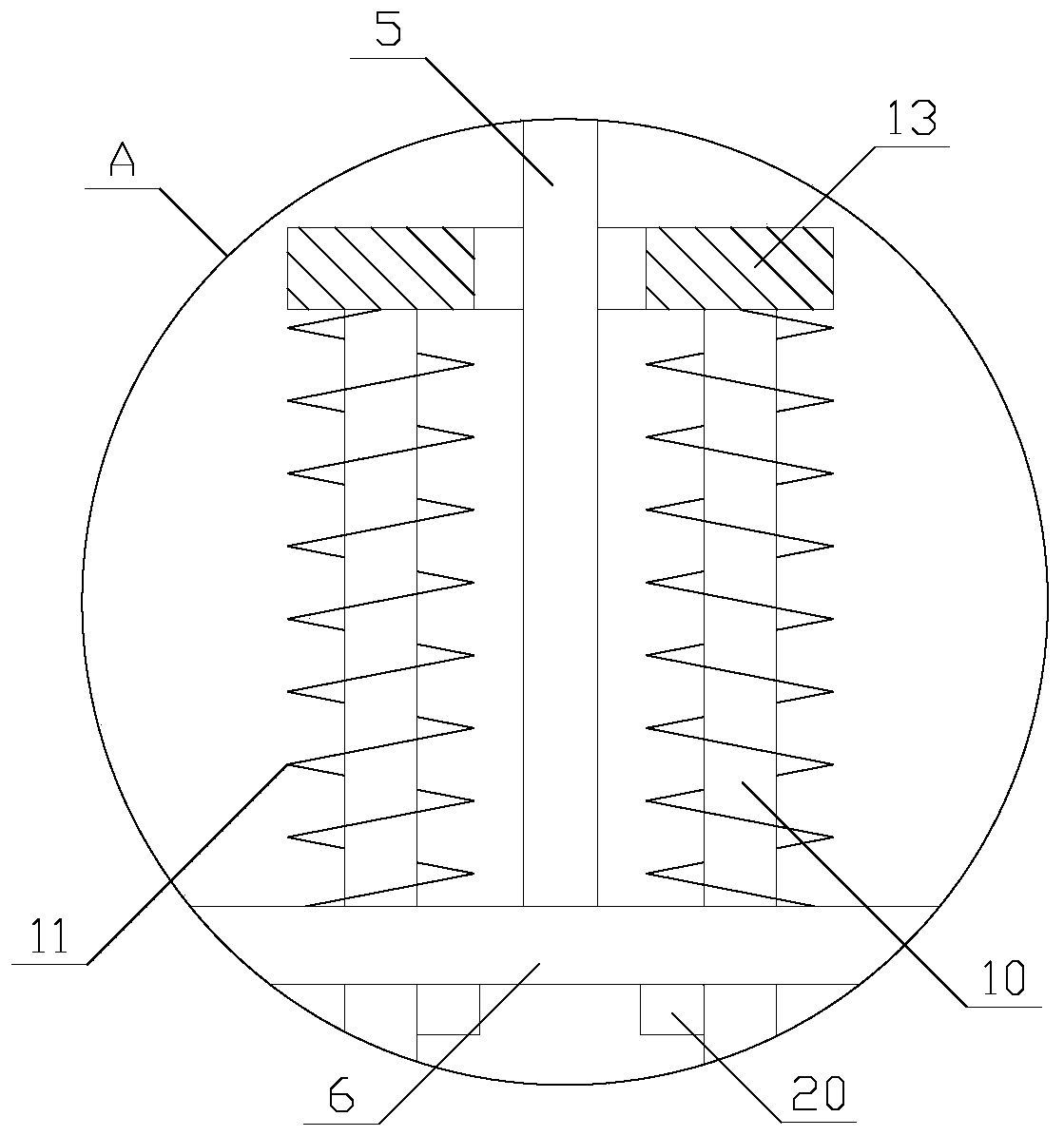

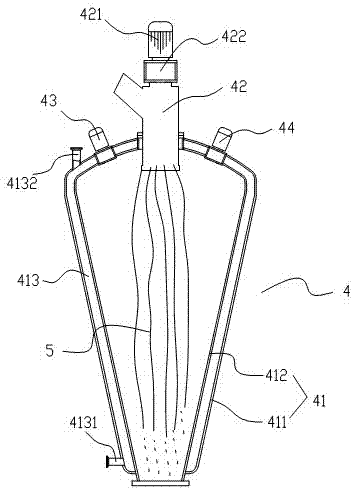

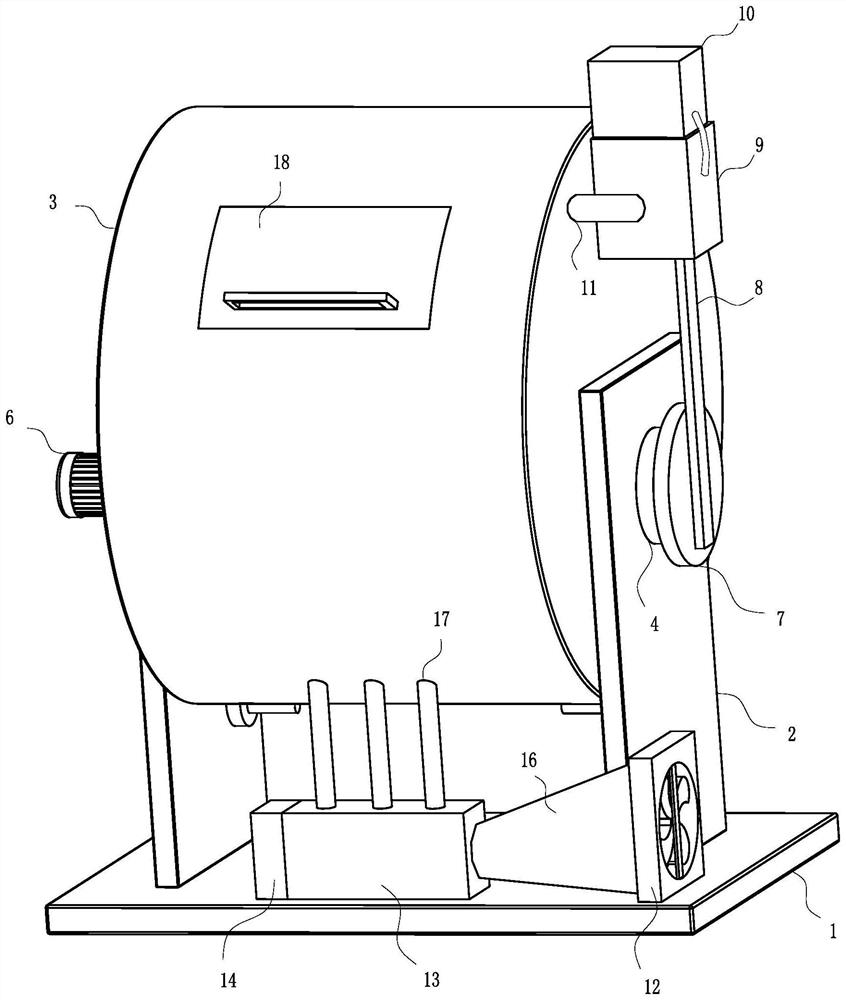

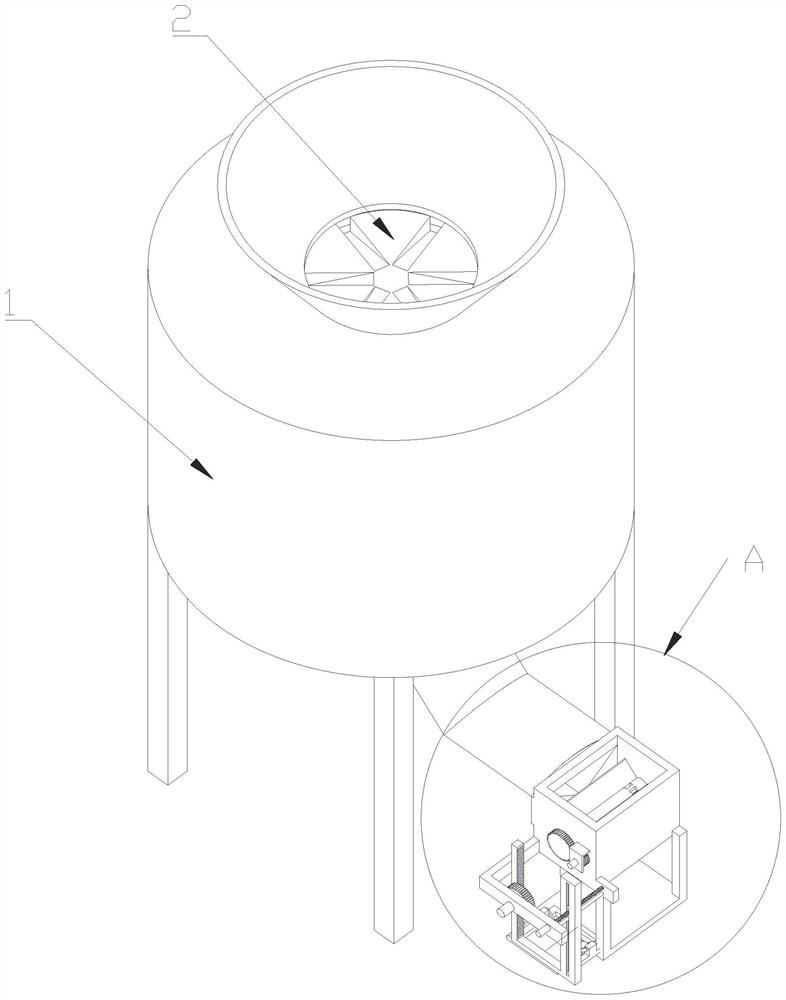

Graphene preparation device with high mixing uniformity

InactiveCN110385052AImprove the mixing effectEliminate cakingRotary stirring mixersTransportation and packagingCvd grapheneDrive motor

The invention relates to a graphene preparation device with high mixing uniformity. The graphene preparation device comprises a main body, a feeding pipe and a discharging pipe, the main body is in acylinder shape, the feeding pipe is arranged at the top end of the main body, and the discharging pipe is arranged at the bottom end of the main body; a stirring mechanism and an assisting mechanism are arranged in the main body, the stirring mechanism comprises a driving motor, a transmission shaft, a driving friction disc, a rotating disc, a connecting rod, a stirring rod and two transmission assemblies, and a mounting hole is formed in the top of the main body 1; the transmission assemblies comprise sliding rods, springs, electromagnets and connection holes; and the assisting mechanism comprises a fixing ring, two rotating rods and two power assemblies. According to the graphene preparation device with the high mixing uniformity, the function of stirring raw materials is achieved through the stirring mechanism, not only that, the function of eliminating agglomerations in the raw materials is further achieved through the assisting mechanism, and thus the raw material mixing effect isimproved.

Owner:何桂华

Composition and method for inhibiting caking in a urea containing fertilizer

Compositions and methods are provided for inhibiting caking or clumping in urea containing fertilizers by reducing the crystal aspect ratios of the crystals formed in the fertilizer to a level sufficient to effectively eliminate caking in a treated fertilizer.

Owner:OMS INVESTMENTS INC

Portable hydrogen generator

InactiveCN103204468AEasy to controlEasy to useHydrogen productionProcess engineeringHydrogen production

The invention discloses a portable hydrogen generator, and particularly relates to a portable hydrogen generator which is fast in hydrogen production speed and high in safety. The portable hydrogen generator comprises two airtight containers for storing a hydrogen production mixture and a liquid respectively, interconnected valve control pipelines, and respective valve control liquid supplement and hydrogen discharge channels, wherein an air pocket and / or a mechanical stirring device driven by virtue of an air pressure change is arranged below the hydrogen production mixture in the airtight container for storing the hydrogen production mixture, thus effectively eliminating product agglomeration in the reaction for hydrogen production, having extremely high safety, and omitting multiple safety protection components. The equipment is very simple, capable of being produced to be a miniaturized safety protection device, and convenient to carry and use.

Owner:张华俊 +1

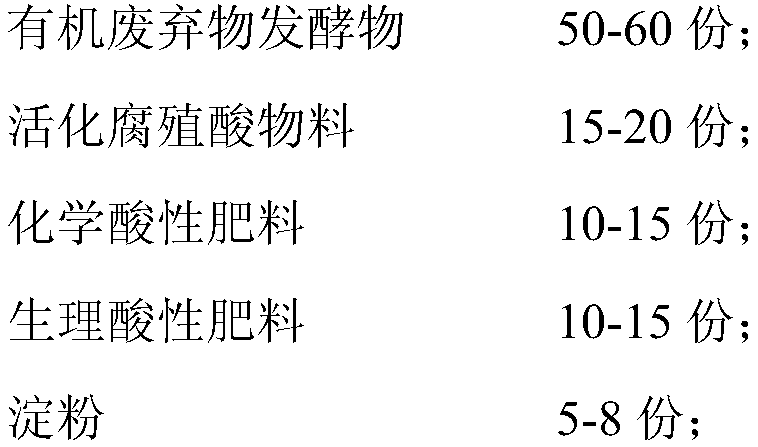

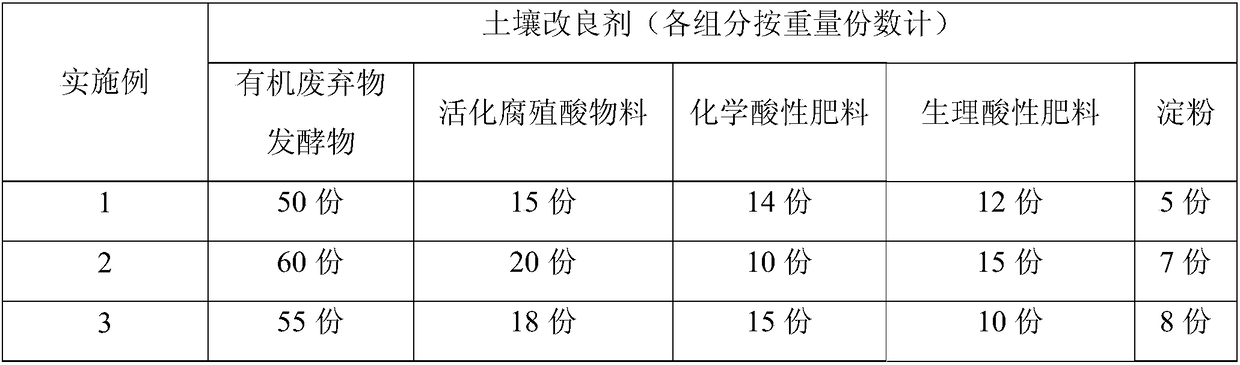

Saline-alkali land soil improvement agent and preparation method thereof

InactiveCN109504396AReduce land salinizationImprove soil fertilityAgriculture tools and machinesOther chemical processesHumic acidChemistry

The invention belongs to the field of soil improvement and specifically relates to a saline-alkali land soil improvement agent and a preparation method thereof. The saline-alkali land soil improvementagent is obtained by mixing organic waste fermented materials, activated humic acid materials, chemical acidic fertilizer, ecological acidic fertilizer and starch uniformly. The organic waste fermented materials in the soil improvement agent contain various beneficial microorganisms and organic matters, can improve the physical structure of the soil and have the function of regulating and controlling a soil biota; gram-positive bacteria in the organic waste fermented materials can kill harmful bacteria, nematode in the soil and reduce soil-borne diseases; gangue, peat and lignite in the soilimprovement agent serve as associated mineral of coal production, contain a large amount of organic matters and rich trace elements, contain nutritional elements such as carbon, nitrogen, phosphorus and potassium necessary for crops, and achieves the effects of improving the physical and chemical properties and the biological properties of the soil, improving the soil fertility and increasing theyield of the crops in the soil improvement agent.

Owner:天津艾孚森科技发展有限公司

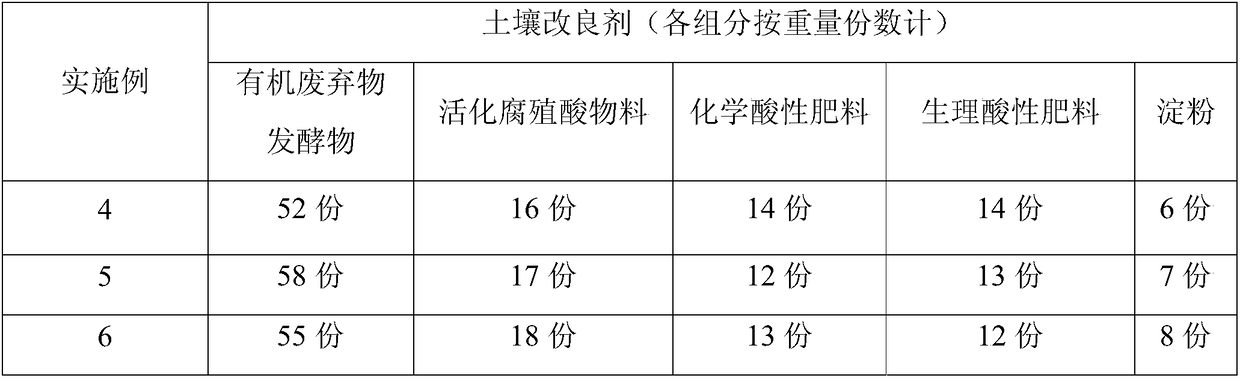

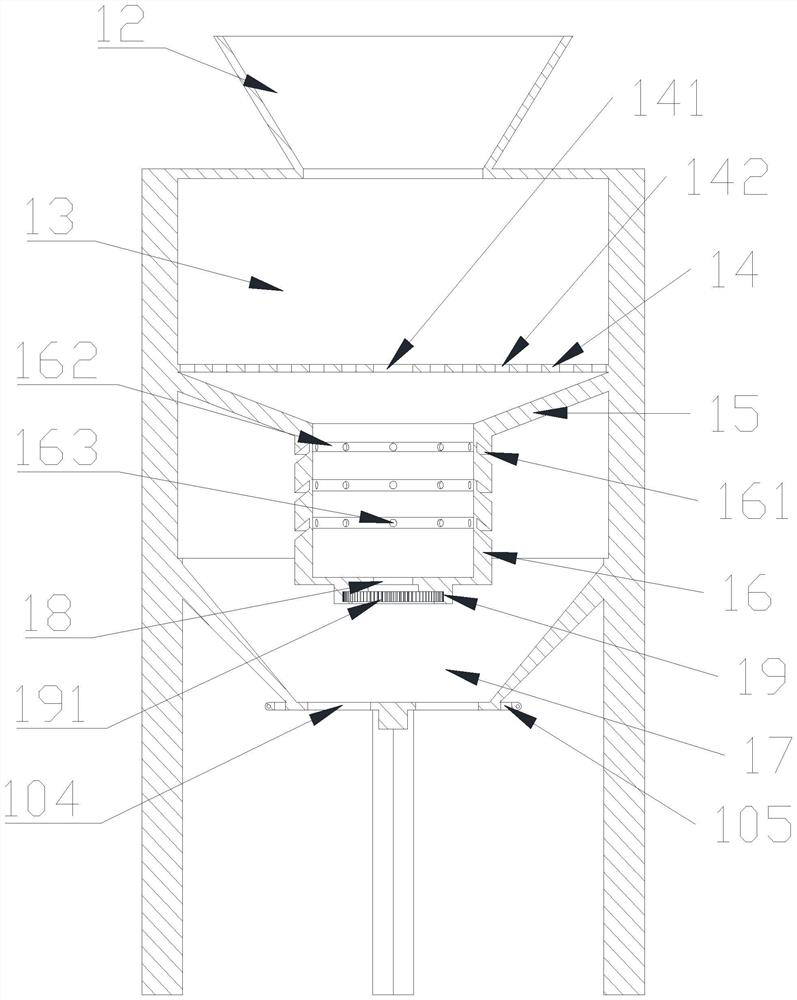

Desolventizer toaster special for tea seed meal

InactiveCN103805333AGuaranteed flexibilityGuaranteed tightnessFatty-oils/fats productionEngineeringDesolvation

The invention discloses a desolventizer toaster special for tea seed meal. The desolventizer toaster is provided with three pre-desolvation layers for pre-removal of most solvents. The fourth layer is a desolvation layer for removal of residual solvents. The fifth layer and the sixth layer are drying layers for adjustment of water in the meal, material gates have good flexibility and leakproofness, so that the consumption indexes of solvents can be reduced. By employing automatic material gates for feeding, the material layer height can be finely adjusted. The temperature for preheating desolvation of wet meal in the desolventizer toaster is controlled at about 90DEG C. Conveying can avoid shutdown caused by cake meal bridging blocking so as to affect normal production. By simplifying the whole structure, to effects of improving performance, prolonging the service life, and reducing the equipment maintenance cost can be achieved.

Owner:BEIJING ZHONGTIAN JINGU GRAIN OIL ENG TECH

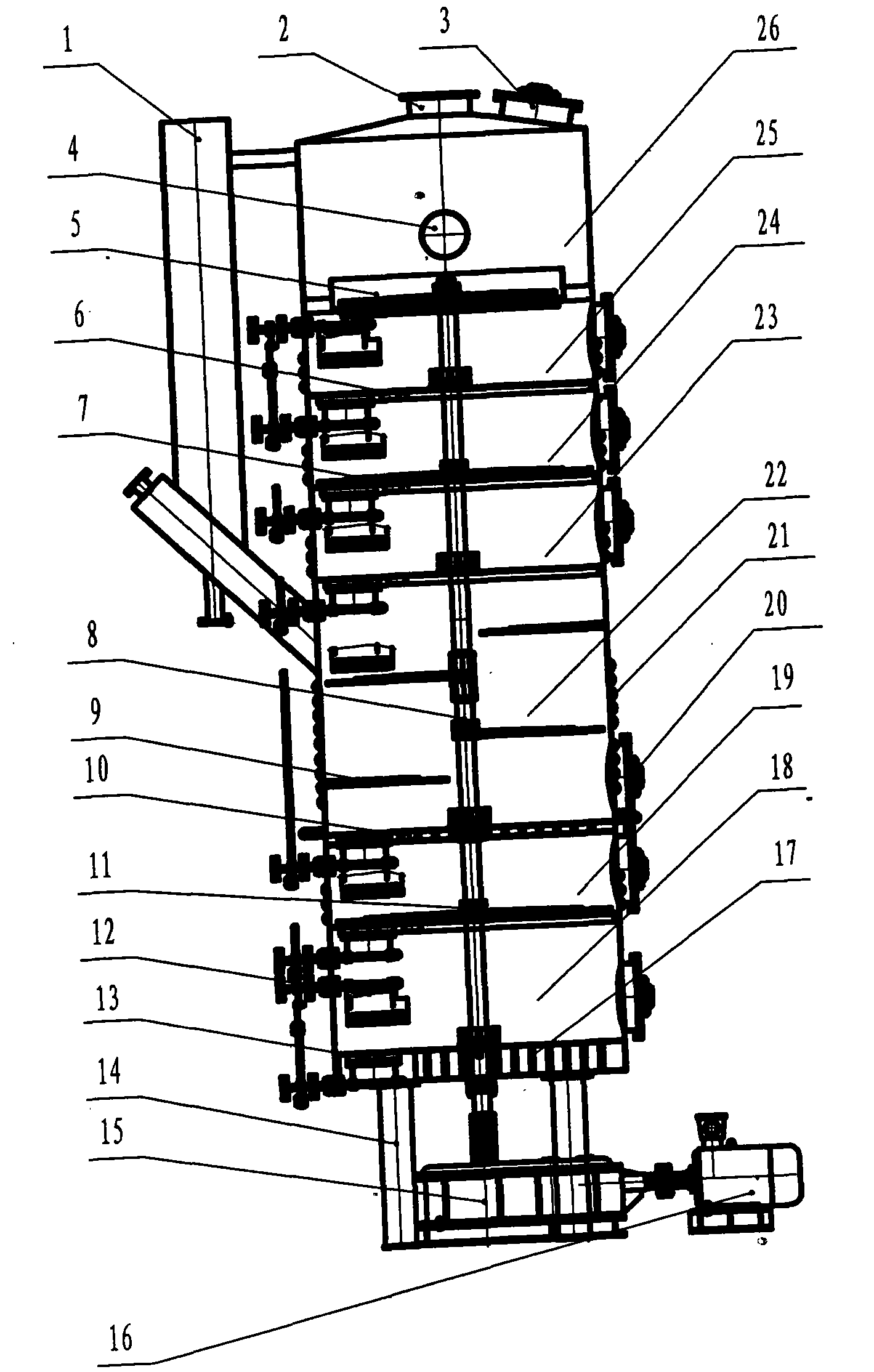

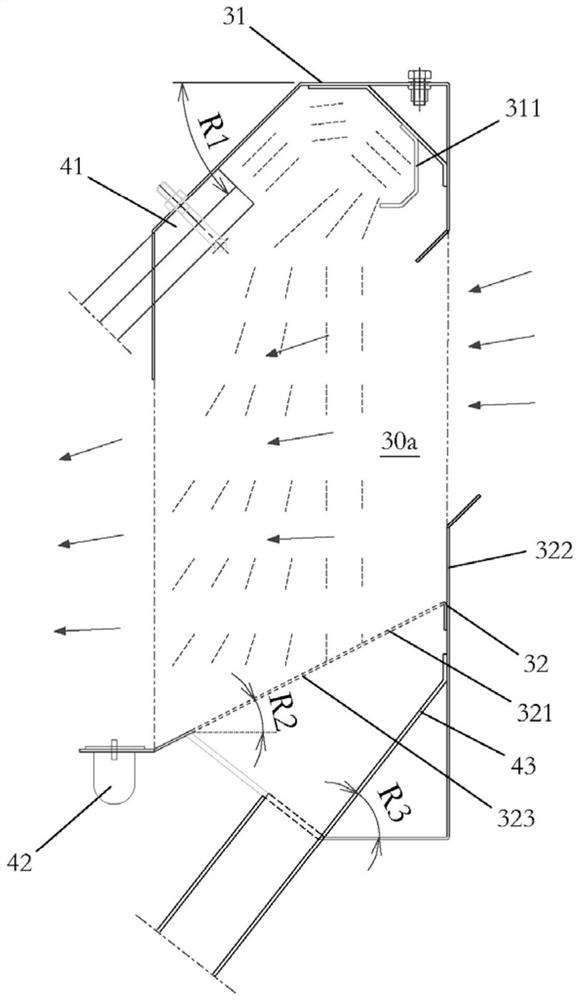

Spouted fluidized bed-fluidized bed composite reactor for producing hydrogen fluoride

InactiveCN107159066AEliminate cakingEliminate agglomerationHydrogen fluorideChemical/physical processesHydrogen fluorideStraight tube

The invention discloses a spouted fluidized bed-fluidized bed composite reactor for producing hydrogen fluoride. The reactor comprises two reaction regions comprising a spouted fluidized bed and a fluidized bed, wherein a gas distribution plate and a solid blanking pipe are arranged between the two reaction regions; the lower part of the reactor is the spouted fluidized bed; the spouted fluidized bed comprises a straight tube section and a diameter reducing section part arranged under the straight tube section. In the spouted fluidized bed reaction region, the center spouted air flow quantity is great enough, so that the impact effect on the agglomeration is strong enough; the motion of particles in the position is violent; agglomeration cannot be easily generated. On one hand, the proportion of the annular gap region fluidized flows and the spouted region flows is increased, i.e., the transformer of the total air flow to the annular gap region fluidized flows is controlled; on the other hand, the circulation gas total flow rate is increased, so that the high flow rate of the fluidized flows is maintained; the particle motion of the annular gap region is enhanced, so that the agglomeration is regulated, controlled and eliminated.

Owner:ZHEJIANG UNIV

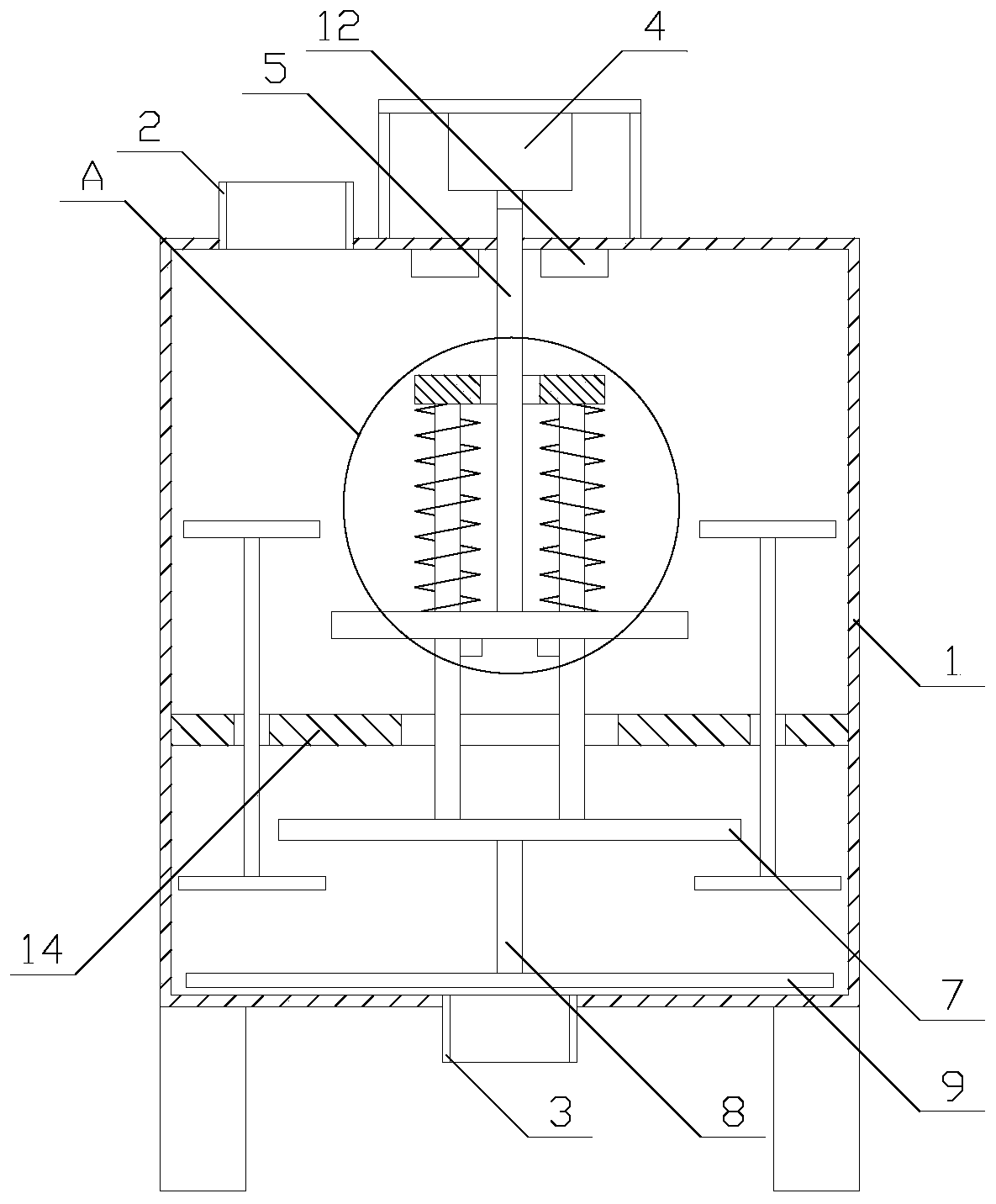

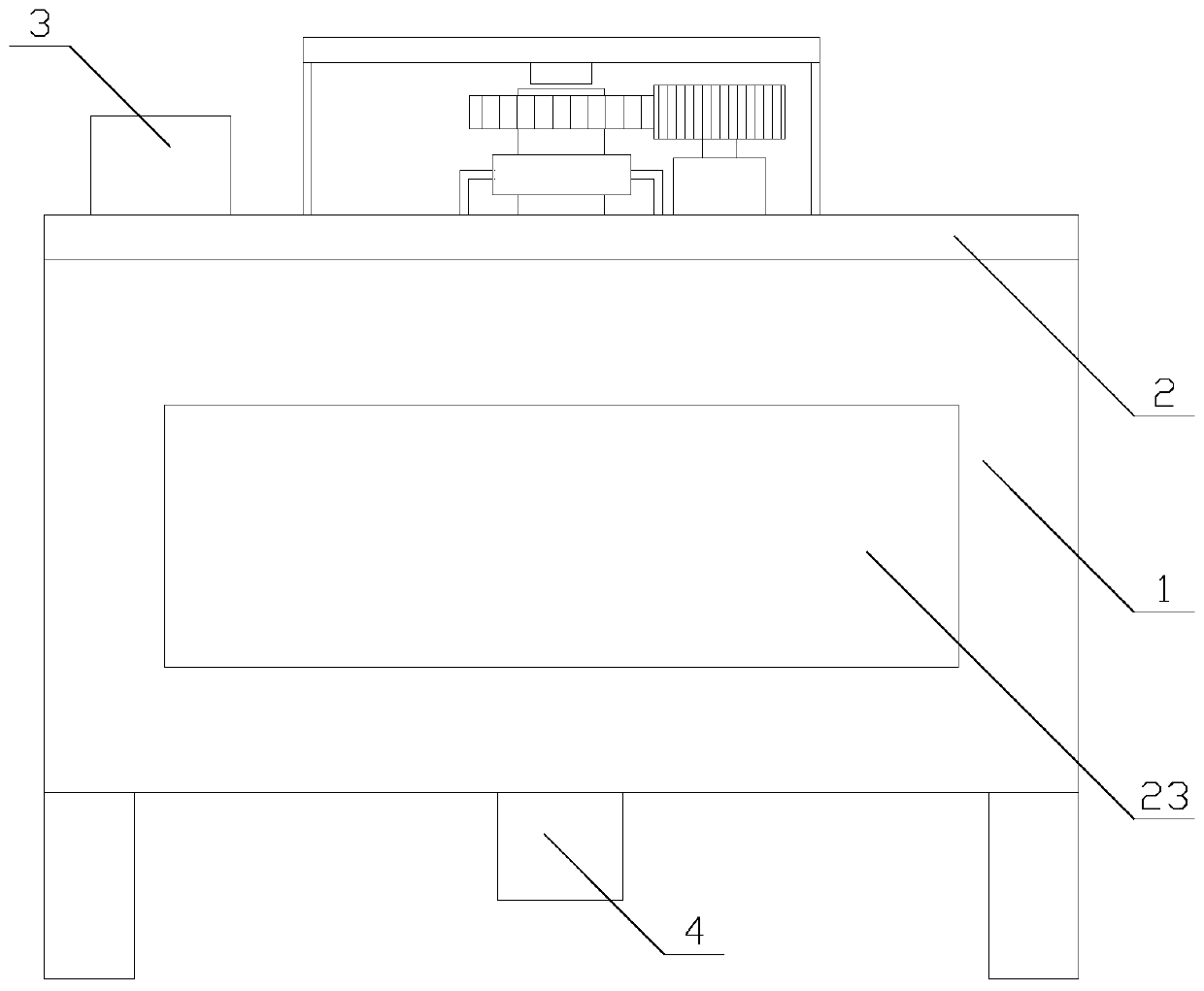

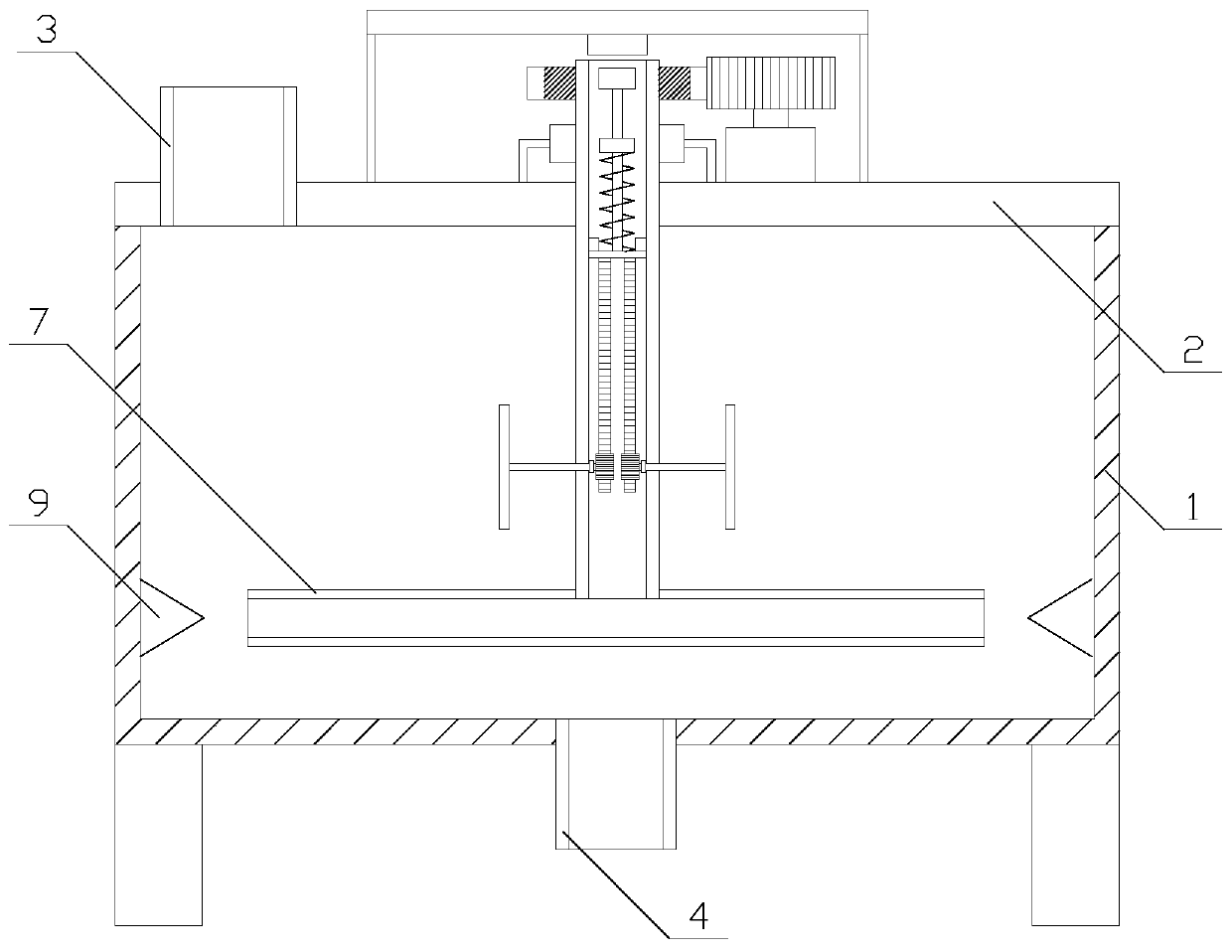

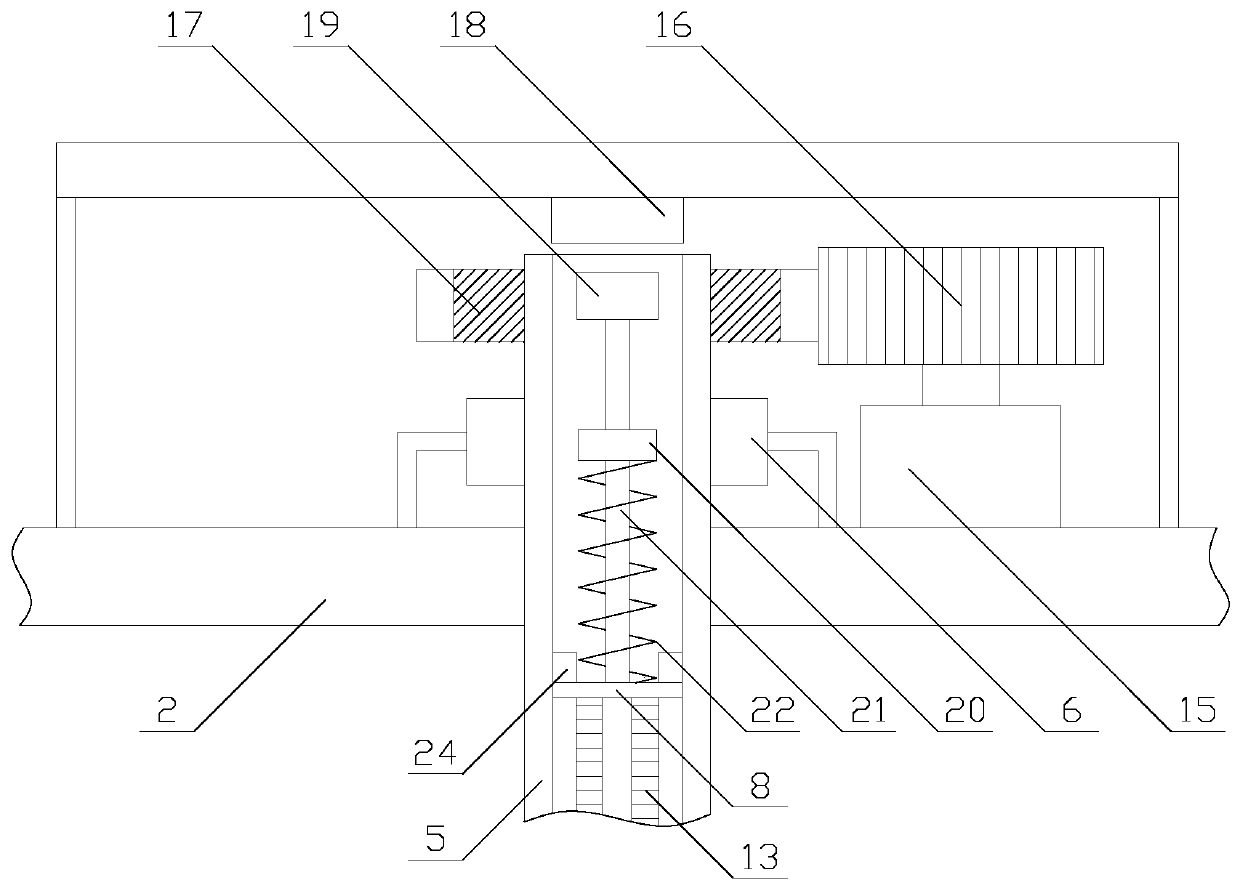

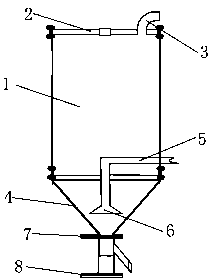

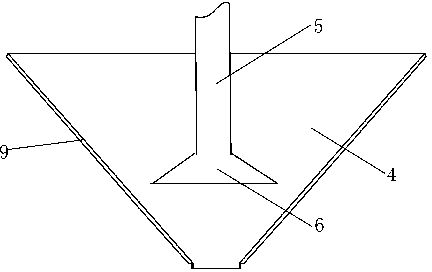

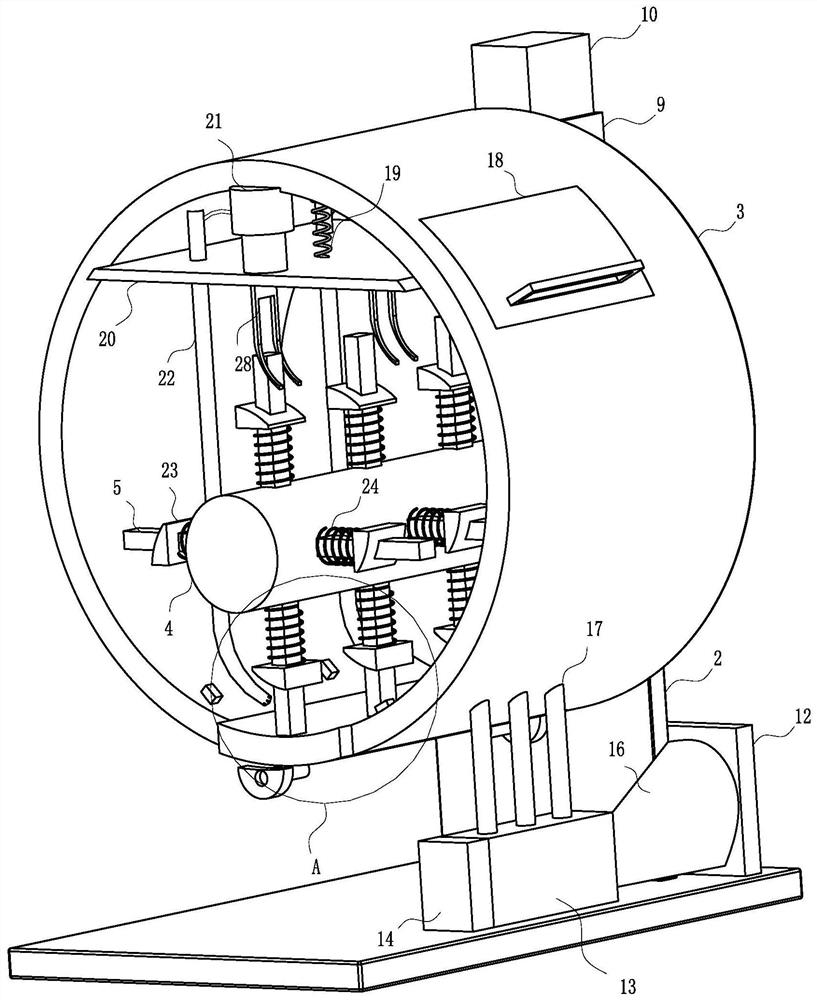

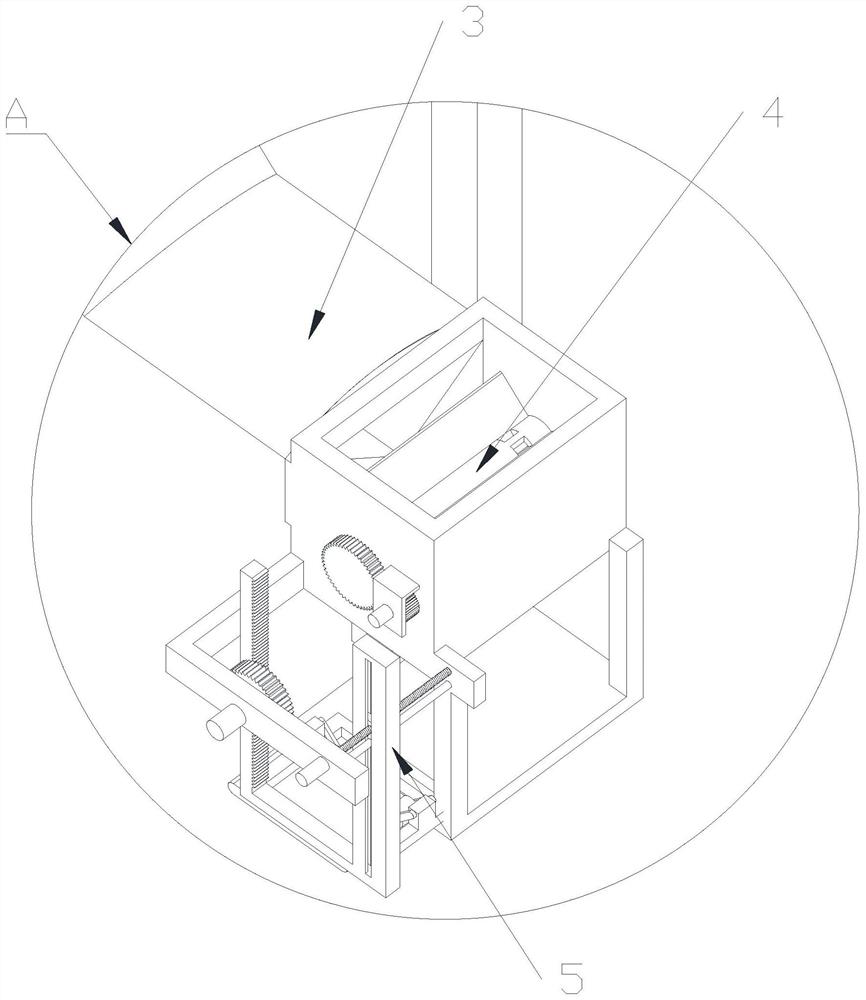

Efficient vertical shaft type forced concrete mixing equipment

ActiveCN111361010AEliminate cakingPracticalDischarging apparatusMixing operation control apparatusDrive shaftGear wheel

The invention relates to efficient vertical shaft type forced concrete mixing equipment. The efficient vertical shaft type forced concrete mixing equipment comprises a main body, a sealing cover, a feeding pipe and a discharging pipe, wherein the main body is in a cylindrical shape and vertically arranged, the sealing cover covers the top of the main body, the feeding pipe is arranged on the sealing cover, and the discharging pipe is arranged at the bottom end of the main body; a stirring mechanism and an auxiliary mechanism are arranged in the main body, wherein the stirring mechanism comprises a rotating pipe, a first bearing, a connecting pipe, a moving disc, a driving assembly, a lifting assembly and at least two auxiliary blocks, the auxiliary mechanism comprises two auxiliary assemblies, and the auxiliary assemblies are circumferentially and uniformly distributed on the rotating pipe by taking the axis of the rotating pipe as a center; and each auxiliary assembly comprises a stirring rod, a transmission shaft, a second bearing, a rack, a rotating gear and a through hole. According to the efficient vertical shaft type forced concrete mixing equipment, a stirring function is achieved through the stirring mechanism, and in addition, the working efficiency is improved through the auxiliary mechanism.

Owner:衡阳市升旺混凝土有限公司

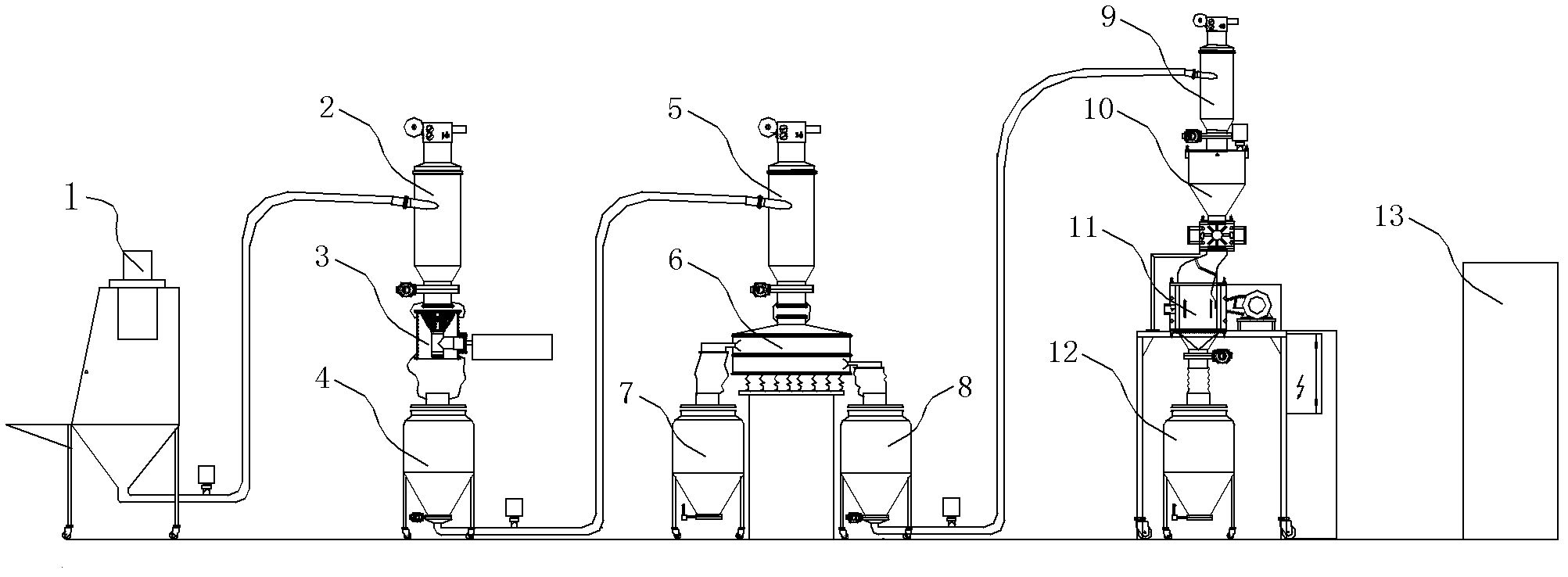

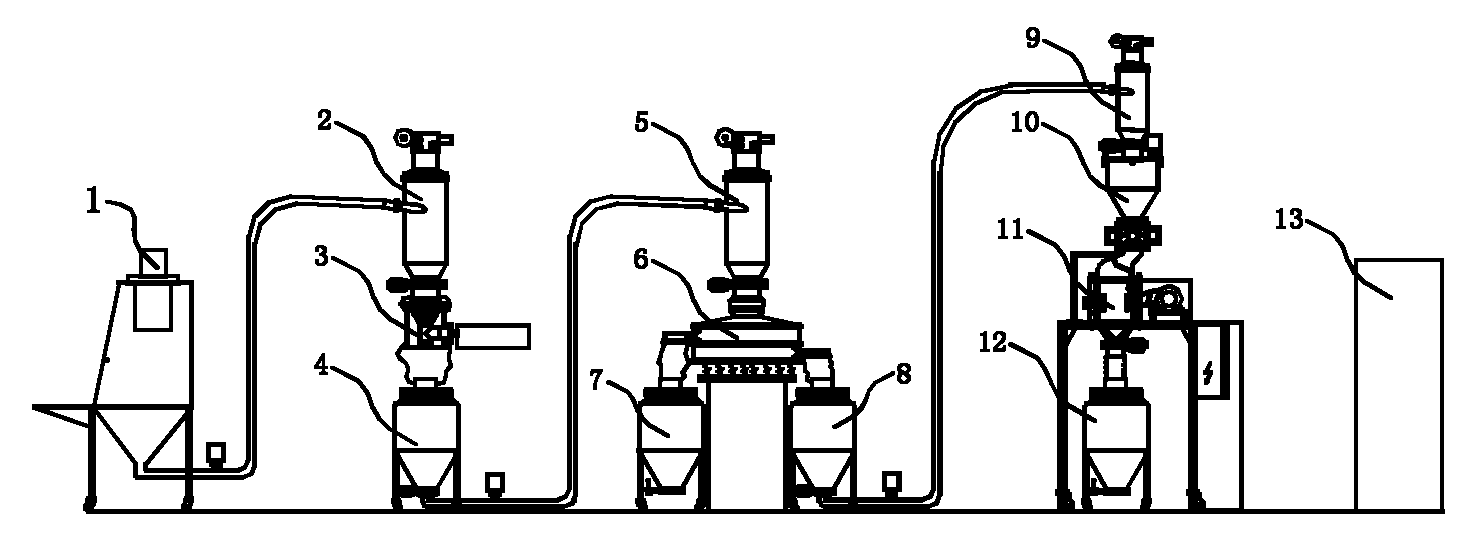

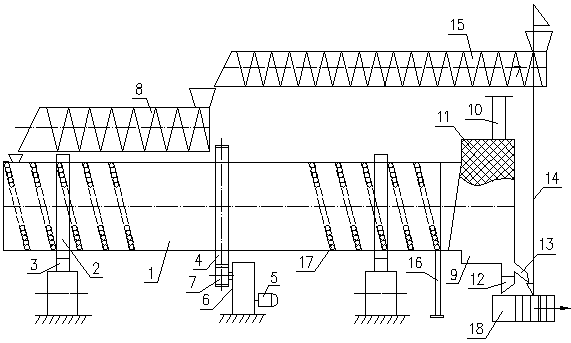

Dustless feeding, granulating, sieving and smashing system

ActiveCN102626667AWhole grain fastReduce crushing timeGrain treatmentsWorking environmentEngineering

The invention belongs to the technical field of material sieving and smashing equipment, and particularly discloses a dustless feeding, granulating, sieving and smashing system, which comprises a feeding device, a granulating device, a sieving device and a smashing device, wherein the four devices are connected hermetically through a vacuum conveying device respectively. The entire dustless feeding, granulating, sieving and smashing system is formed by introducing dustless feeding, dustless granulating, dustless sieving and dustless smashing into the system, materials are granulated rapidly, and agglomerates among materials are eliminated, so that a part of granulated qualified particles are directly fed into a first qualified product storage bin in a material sieving process, unqualified materials are correspondingly reduced after sieving, and the workload of a subsequent smashing device is reduced simultaneously; the working time and overall material smashing time of the system are reduced, the smashing working efficiency is increase, and the labor intensity of smashing procedure workers is lowered; and meanwhile, the vacuum conveying device is mainly used for conveying materials in the entire system, so that a good working environment is created.

Owner:重庆市易特杰机械制造有限公司

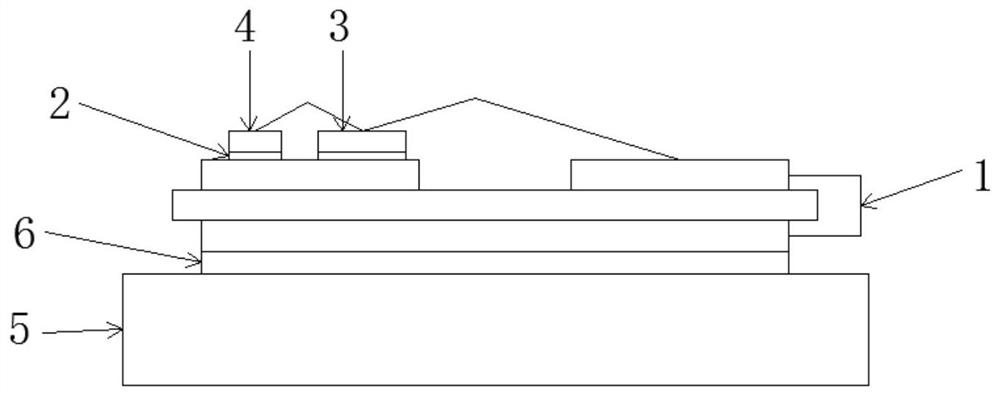

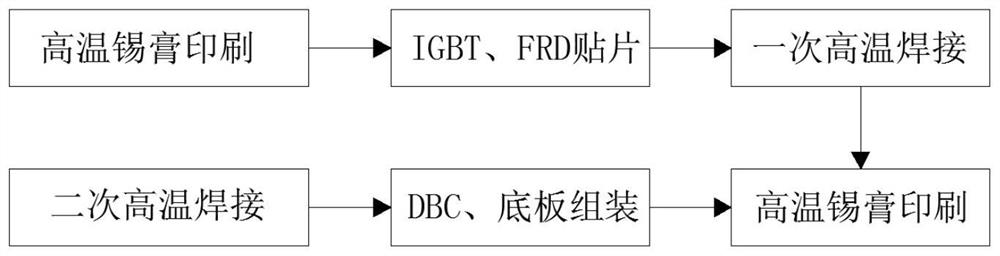

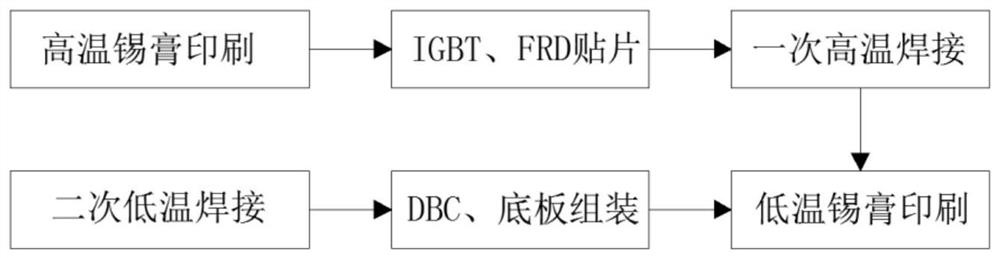

IGBT (Insulated Gate Bipolar Translator) welding process method

PendingCN114192915ANo secondary meltingNo deteriorationSoldering apparatusMetal working apparatusSurface mountingSolder paste

The invention discloses an IGBT (Insulated Gate Bipolar Translator) welding process method, which comprises the following steps of high-temperature solder paste printing, IGBT and FRD (Fast Recovery Diode) surface mounting, primary high-temperature welding, copper substrate printing, low-temperature solder paste printing, DBC (Direct Bonding Copper) and bottom plate assembling and secondary low-temperature welding. According to the method, SnPbAg low-temperature solder paste is adopted for secondary welding, after the melting point of the solder paste is reached, secondary melting of soldering tin on a first backflow face is avoided, the phenomenon of deterioration of cavities is avoided, the yield of IGBT products is improved, SnAgCu is adopted as high-temperature solder paste, the melting point of the high-temperature solder paste is 217 DEG C, SnPbAg is adopted as low-temperature solder paste, the melting point of the low-temperature solder paste is 179 DEG C, the melting point is higher than the bearable limit temperature of a chip, the reliability of the products can be guaranteed, and the reliability of the products is improved. The low-temperature solder paste is used for secondary welding, so that tin beads and tin bridges can be reduced, the mold is easy to disassemble, product appearance failure caused by process problems is reduced, the low-temperature solder paste has excellent printability, the phenomena of missing, sinking and caking in the printing process can be eliminated, and the service life of the steel mesh is prolonged.

Owner:YANTAI TAIXIN ELECTRONICS TECH CO LTD

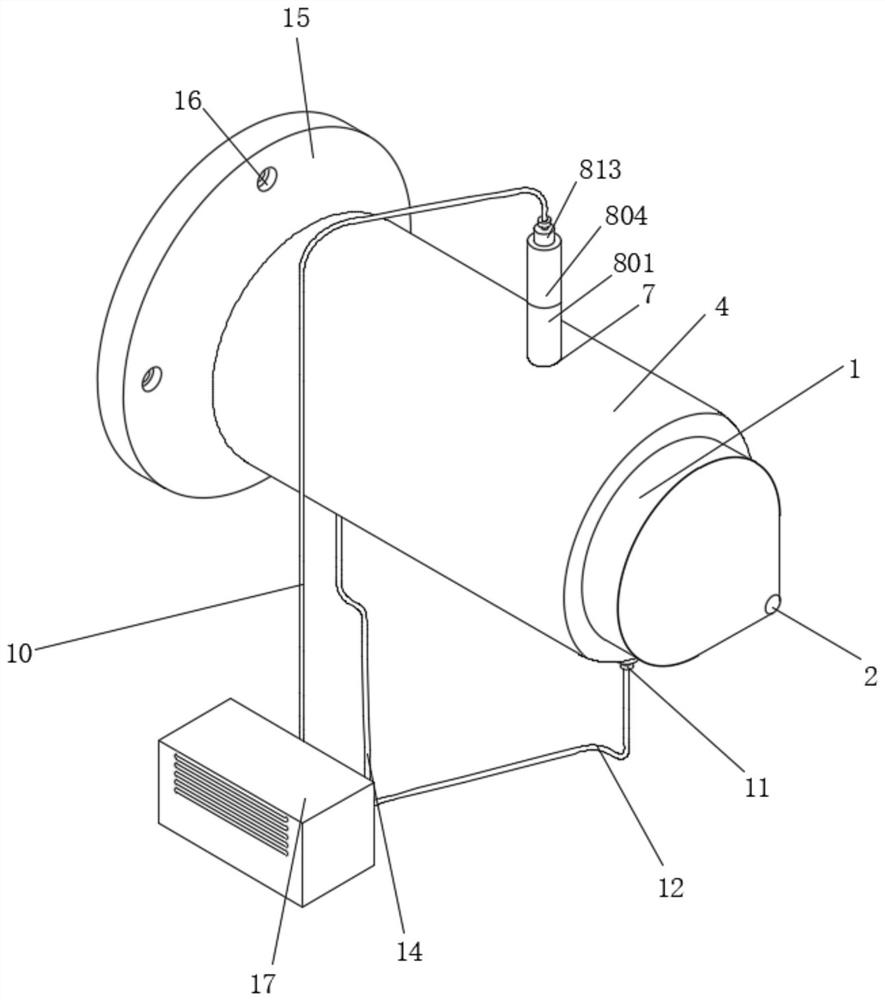

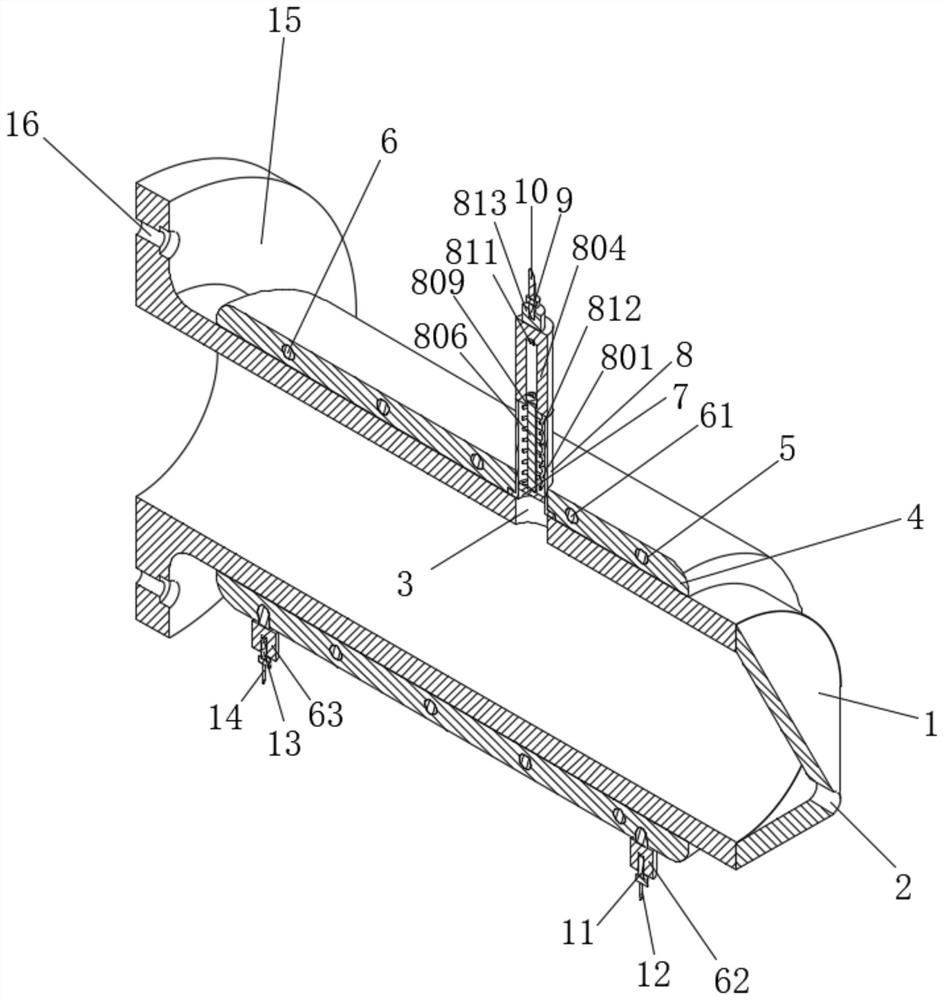

Aqueous gypsum drying and calcining device and process

PendingCN108709408AEliminate liquidationEliminate knotsRotary drum furnacesCharge treatment typeReduction driveReducer

The invention discloses an aqueous gypsum drying and calcining device. The aqueous gypsum drying and calcining device comprises a roller, rolling rings connected to the roller, supporting wheel sets,a ring gear, a motor, a reducer and a gear, wherein the motor is connected with the reducer. A discharge hole of a screw conveyor is connected with a feed inlet of the roller, and the discharge end ofthe roller is connected with a discharge chamber. An exhaust outlet is formed in the upper end of the discharge chamber, and two discharge openings are formed in the lower end of the discharge chamber. One of the discharge openings is connected with a feed inlet of a returning charge screw conveyer, and a discharge hole of the returning charge screw conveyor is connected with a feed inlet of thescrew conveyor. A spiral pipe is arranged in the roller, the rear end of the spiral pipe is connected with steam inlets, and the front end of the spiral pipe is located outside the roller. The invention further discloses aqueous gypsum drying and calcining process. The aqueous gypsum drying and calcining device has the advantages of multi-function, less equipment, small land occupation, low energyconsumption and high thermal efficiency, has high production efficiency and reliable performance, and can safely operate for a long time.

Owner:自贡市德明电站锅炉有限公司

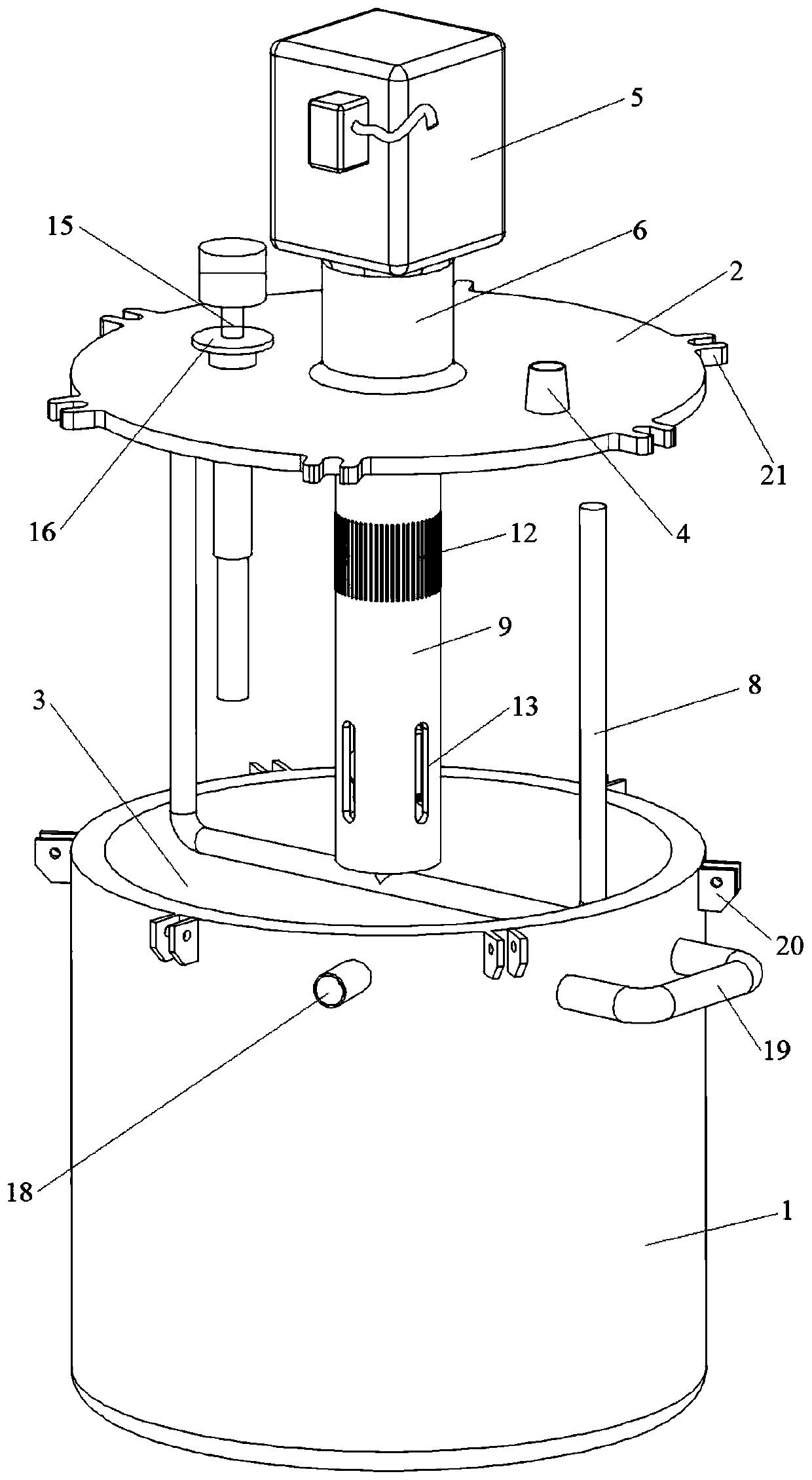

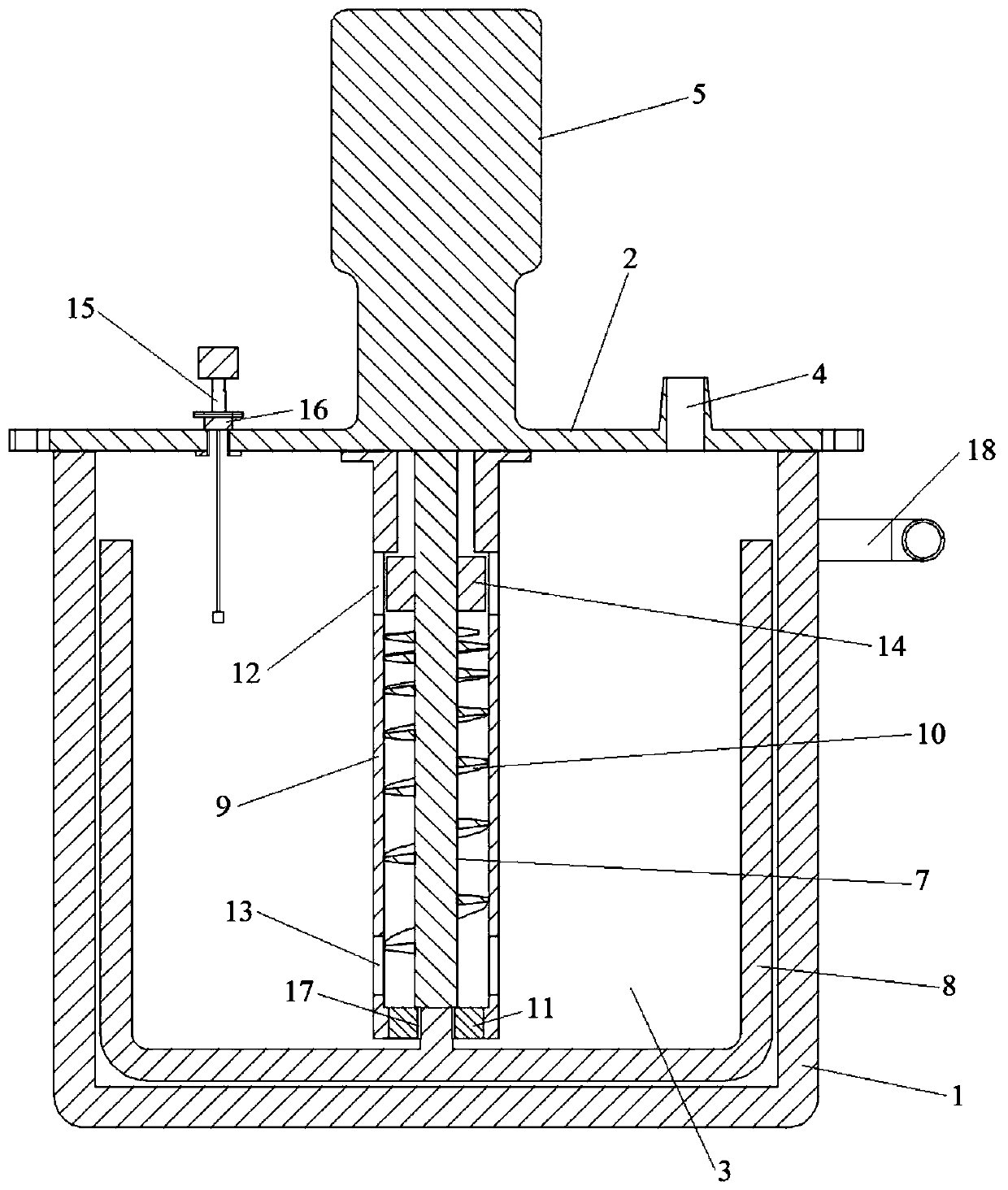

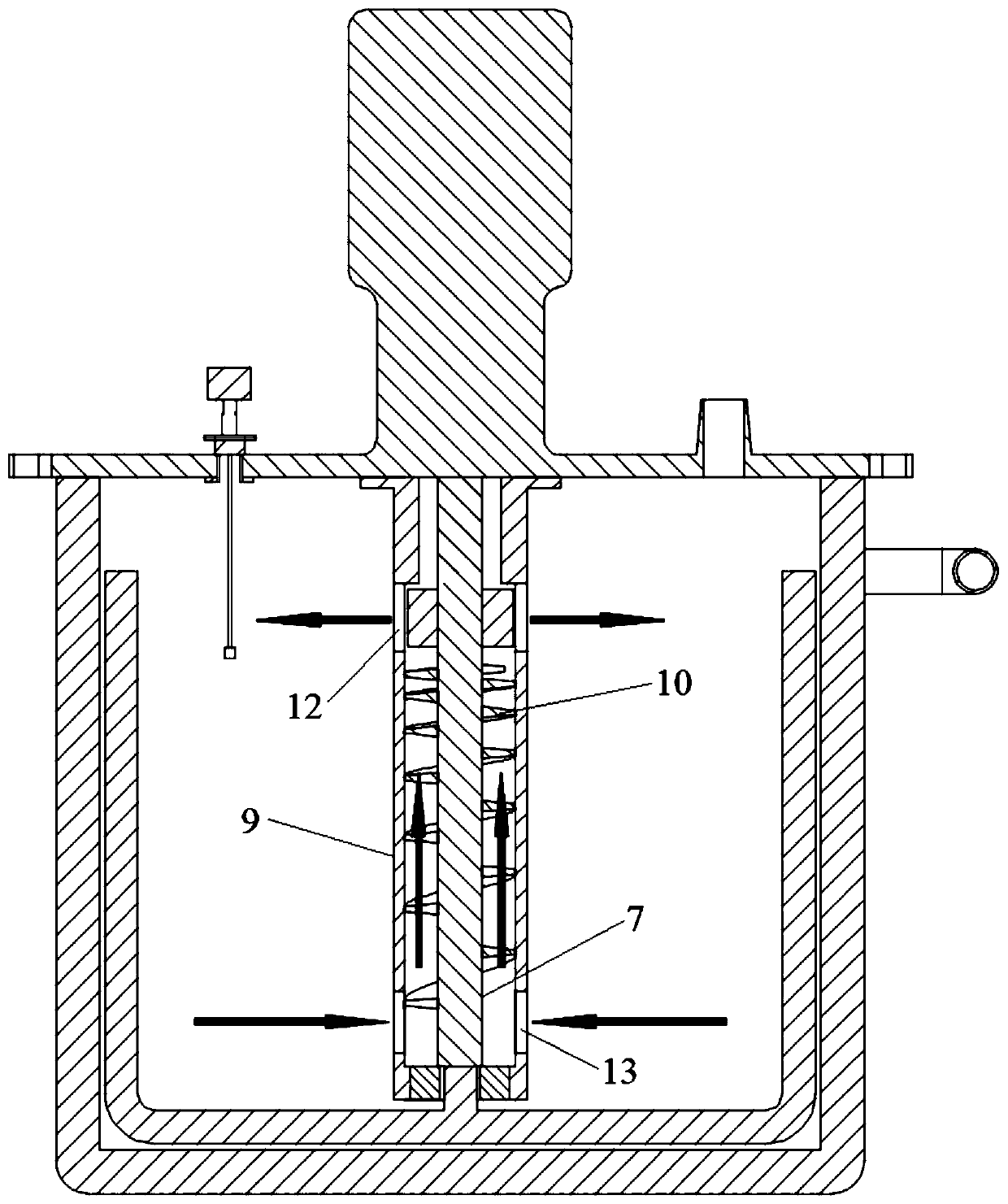

Lithium battery slurry defoaming and grinding method and device

InactiveCN111085321AAchieving stirringAchieve grindingRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention relates to the technical field of lithium battery production, and provides a lithium battery slurry defoaming and grinding method and device. The lithium battery slurry defoaming and grinding device comprises a tank body and a cover body, wherein an accommodating cavity for storing lithium battery slurry is formed in the tank body; the cover body is arranged at the open end of the tank body in a sealing and covering manner; a vacuumizing opening and a stirring and grinding mechanism are arranged on the cover body; the vacuumizing opening is communicated with the accommodating cavity; and the stirring and grinding mechanism extends into the accommodating cavity and is used for stirring and grinding the lithium battery slurry in the accommodating cavity. The lithium battery slurry defoaming and grinding method comprises the following steps: vacuumizing the accommodating cavity filled with the lithium battery slurry in real time through the vacuumizing opening; stirring andgrinding the lithium battery slurry in the accommodating cavity through the stirring and grinding mechanism. According to the embodiment of the invention, the lithium battery slurry is defoamed and ground simultaneously.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

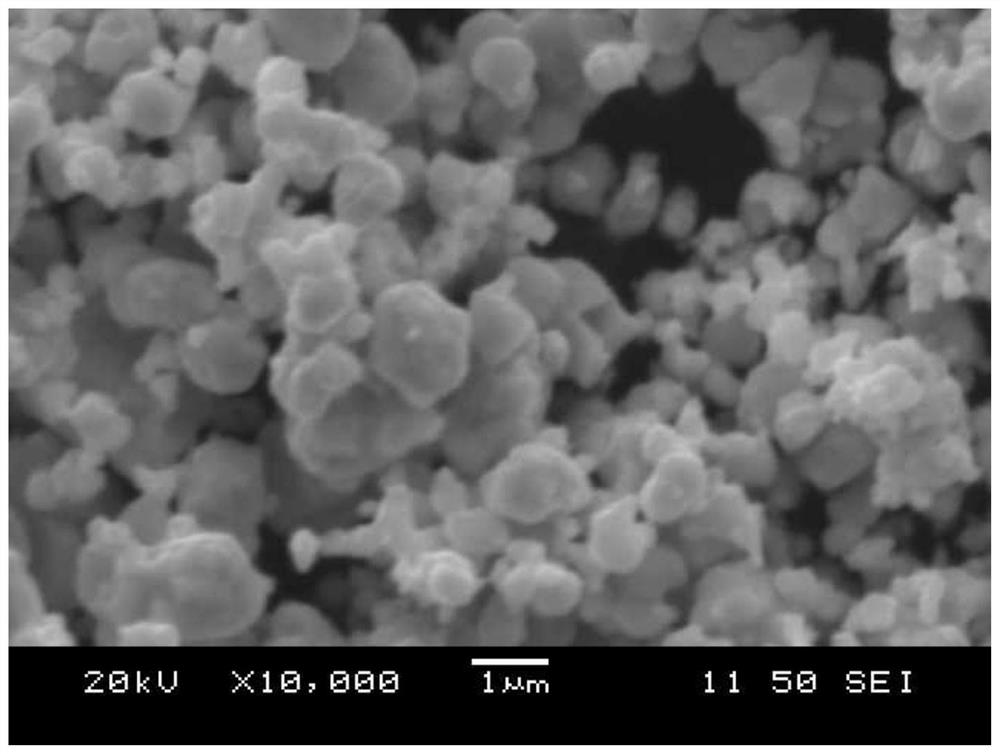

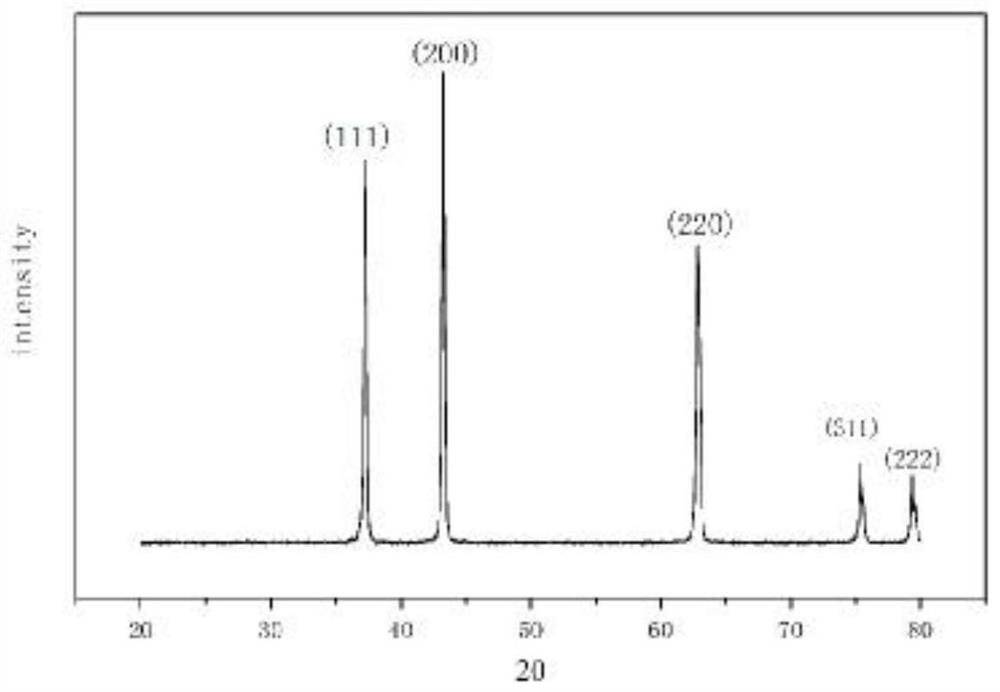

Cold isostatic pressing forming preparation method of nickel oxide-based ceramic target material

InactiveCN112456971AImprove conductivityHigh densityVacuum evaporation coatingSputtering coatingSpray driedMass fraction

The invention relates to a cold isostatic pressing forming preparation method of a nickel oxide-based ceramic target material, wherein the method comprises the following steps: A, preparing raw materials: preparing mixed powder of nickel oxide powder and doped source powder, wherein the total mass fraction of doped source elements in the mixed powder is not more than 10%, wherein the doping sourceelement is selected from one or more of 0-6% of Li, 0-0.3% of Na, 0-1.0% of Mg, 0-0.1% of Al, 0-0.1% of Si, 0-0.15% of K, 0-12% of Zn, 0-1.5% of Zr, 0-1.2% of Mn, 0-10% of Cu, 0-1.2% of Cr, 0-0.3% ofV, 0-10% of W and 0-2.5% of Ti; B, carrying out spray drying; C, compacting by vibration; D, feeding a mold into a cold isostatic pressing chamber for pressing; E, degumming a biscuit; F, sintering;G, cooling after heat preservation is finished; and H, machining or not machining according to needs. The preparation method can be used for preparing the nickel oxide-based ceramic which is good in conductivity, relatively high in purity and fine in grain size.

Owner:北京航大微纳科技有限公司

Granulating type single-cone dryer

InactiveCN103196284AEliminate cakingSmooth runningDrying solid materials with heatDrying machines with non-progressive movementsElectric machineryPulp and paper industry

The invention discloses a granulating type single-cone dryer. The dryer comprises a single-cone conical dryer body composed of a heat insulating layer and a heating layer. A spiral stirring paddle is arranged in the dryer body and driven by a motor at the top of the dryer body to rotate; and a charging port of the dryer body is provided with a granulating type pre-drying continuous feeding apparatus which comprises a feeding barrel, a top inlet of the feeding barrel is provided with an extruder for feeding, and a bottom outlet of the feeding barrel is communicated with the charging port of the dryer body directly. According to the granulating type single-cone dryer, a pre-drying apparatus is arranged at the charging port of the single-cone dryer, so that materials are pre-dried to form particles which are then led into the single-cone dryer, wall sticking and caking phenomena are eradicated in the material drying process, smooth operation of the single-cone dryer is guaranteed, and the moisture content or the menstruum content in final materials obtained through drying can meet prescribed residual quantity requirements.

Owner:马锡林

Small masterbatch drying device

The invention relates to the technical field of drying and protecting devices, in particular to a small masterbatch drying device. The small masterbatch drying device comprises a heat-preserving barrel body, wherein a barrel cover is arranged at the upper end of the heat-preserving barrel body; an exhaust port is formed on the barrel cover; a conical barrel is connected to the lower end of the heat-preserving barrel body; a dry and hot air conveying pipe is arranged on the side wall of the heat-preserving barrel body, and enters the heat-preserving barrel body to stretch into the conical barrel; a flared air outlet is formed at one end of the dry and hot air conveying pipe inside the conical barrel; a gate valve is arranged at the bottom of the conical barrel; and a screen plate is arranged below the gate valve. The small masterbatch drying device solves the problems of non-uniform drying and high energy consumption cost, eliminates a caking phenomenon in a masterbatch drying process, and reduces influence of the non-uniform moisture content of masterbatch on color yarn production.

Owner:ZHEJIANG WELONG NEW MATERIAL

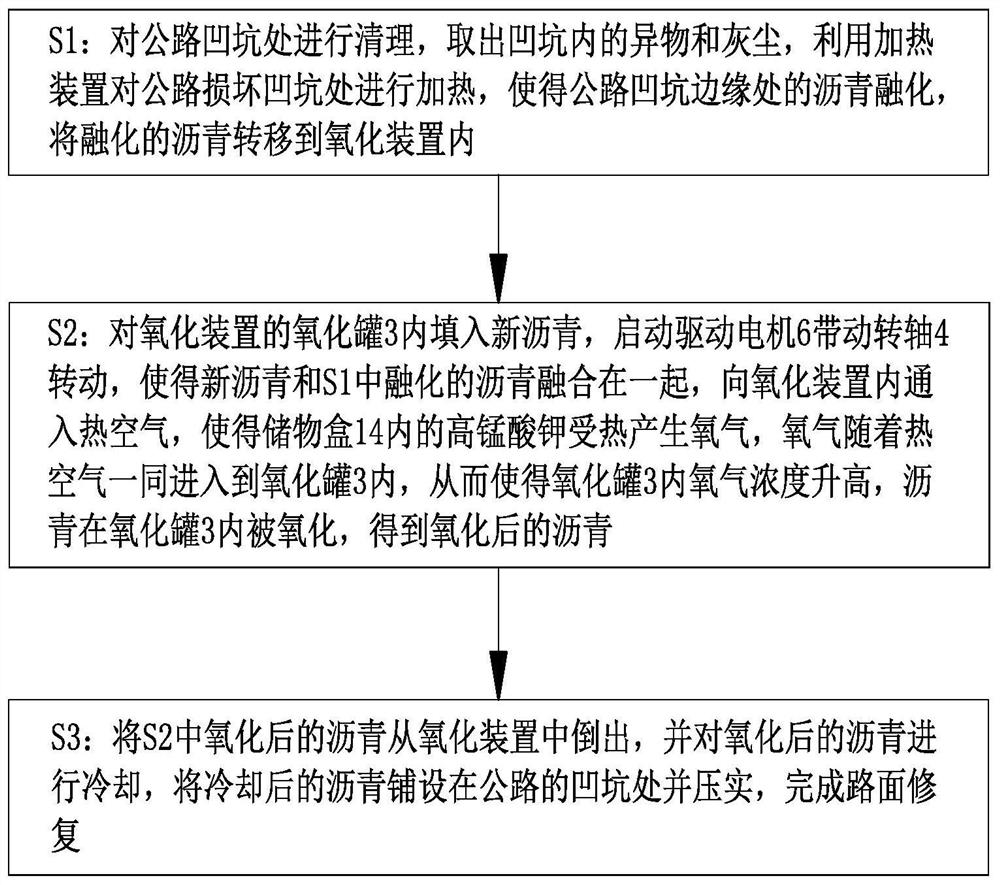

Highway asphalt oxidation treatment process

InactiveCN112195035AImprove oxidation efficiencyIncrease oxygen concentrationWorking-up pitch/asphalt/bitumen by chemical meansWorking-up pitch/asphalt/bitumen by meltingEnvironmental engineeringAsphalt

The invention belongs to the technical field of asphalt production, and particularly relates to a highway asphalt oxidation treatment process. According to the invention, an oxidation device used in the method comprises a base, two supporting plates are fixed at the top end of the base, an oxidation tank is fixed between the two supporting plates, a heating ring is arranged on the inner side wallof the oxidation tank, the heating ring is embedded into the inner side wall of the oxidation tank, a rotating shaft is rotationally installed between the two supporting plates and penetrates throughthe oxidation tank, and two or more shifting block sets are arranged on the side wall of the rotating shaft at equal intervals in the circumferential direction of the rotating shaft. According to theinvention, hot air is introduced into the oxidation tank, potassium permanganate is heated to generate a large amount of oxygen to improve the oxygen concentration of the hot air, and asphalt in the oxidation tank is fully oxidized, so that the highway asphalt oxidation treatment process is suitable for areas with low oxygen concentration in air, the application range of the process is widened, and the oxidation efficiency of the asphalt is further improved.

Owner:浙江梓丞路桥工程设计咨询有限公司

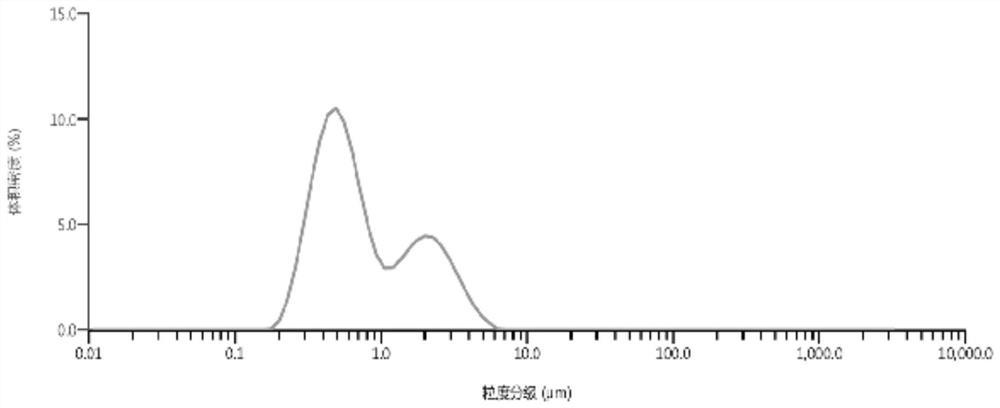

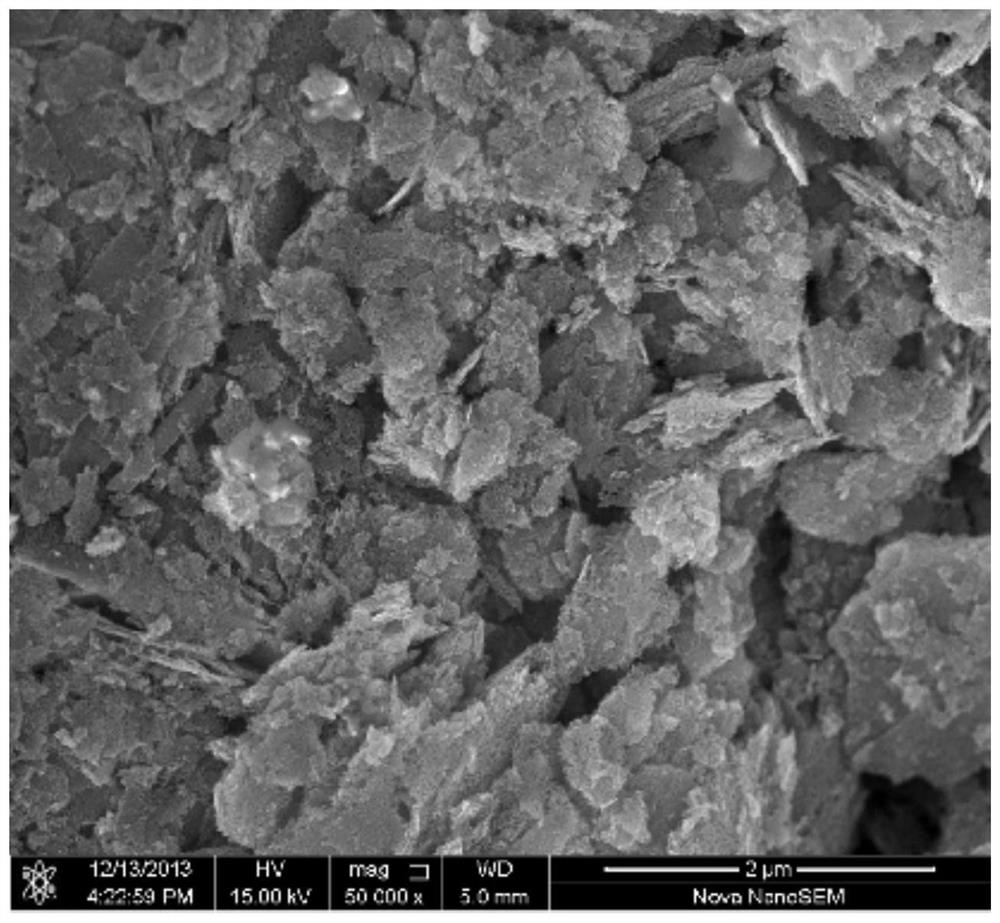

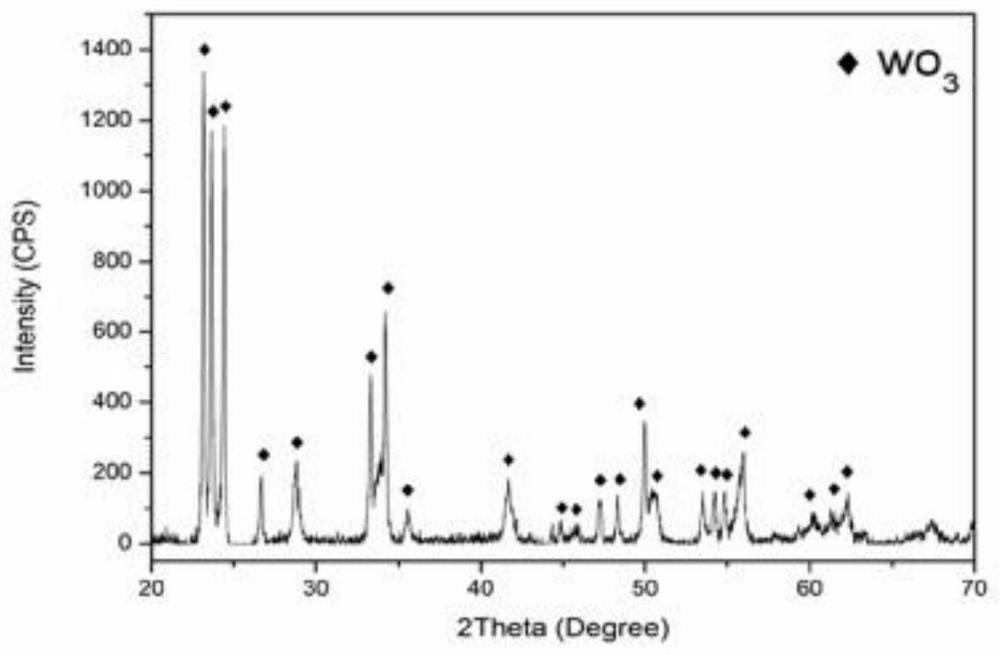

Cold isostatic pressing forming preparation method of tungsten oxide-based ceramic target material

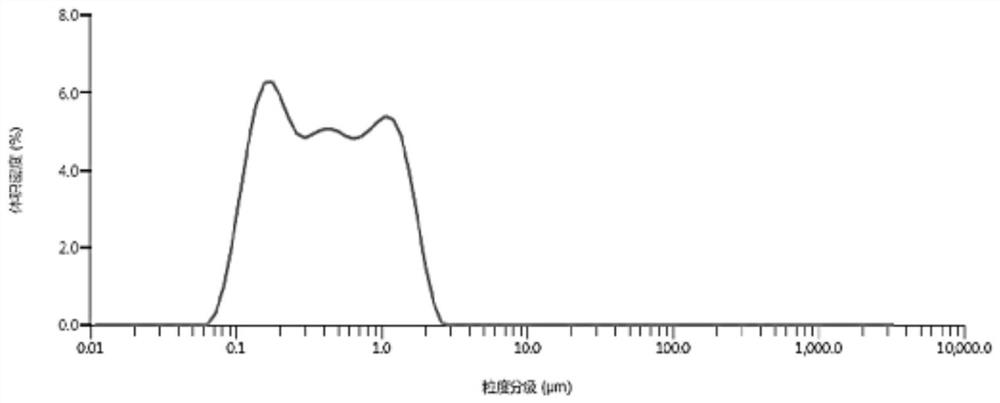

InactiveCN112479707AWide particle size distributionHigh bulk densityVacuum evaporation coatingSputtering coatingHigh densityMetallurgy

The invention relates to a cold isostatic pressing forming preparation method of a tungsten oxide-based ceramic target material, which comprises the following steps of raw material preparation: takingprimary mixed powder containing high-purity tungsten oxide and doping source powder, enabling the doping source to be selected from at least three of Ti, Mo, V, Al, Li and Zr, enabling the purity ofthe mixed powder to be greater than 99.95%, enabling the average particle size to be 500nm to 1800nm, and enabling the D50 particle size to be 200-750nm, wherein the quantitative relation of M1, M2, M3, M4 and M5 conforms to the formula as described in the specification, conducting spray drying, powder filling and compaction, pressing, biscuit degumming and sintering, taking out the sintered blankafter heat preservation, and conducting or not conducting machining according to needs. The cold isostatic pressing forming preparation method can be used for preparing the tungsten oxide-based ceramic target material with good conductivity, higher purity, fine grain size and high density.

Owner:北京航大微纳科技有限公司

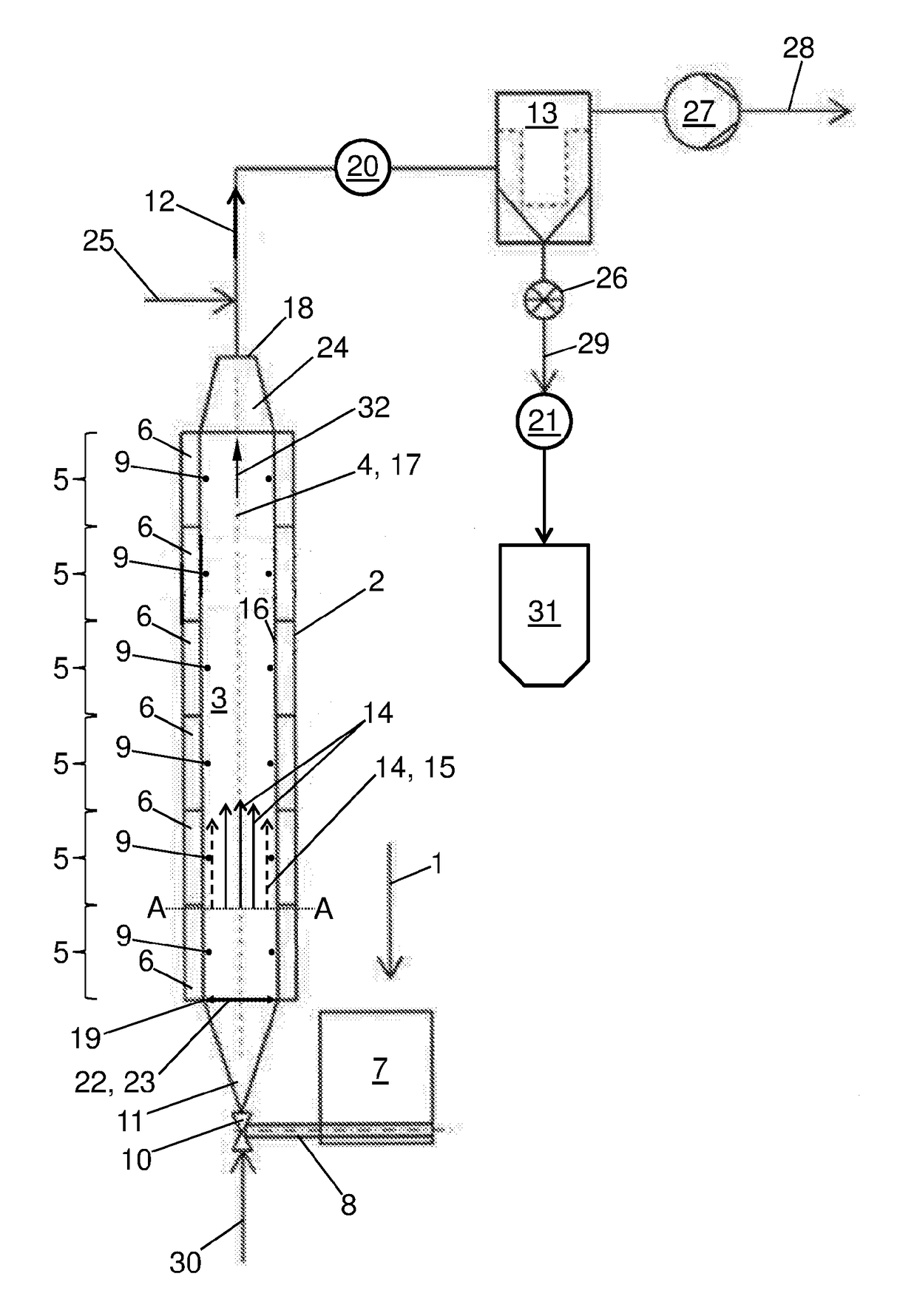

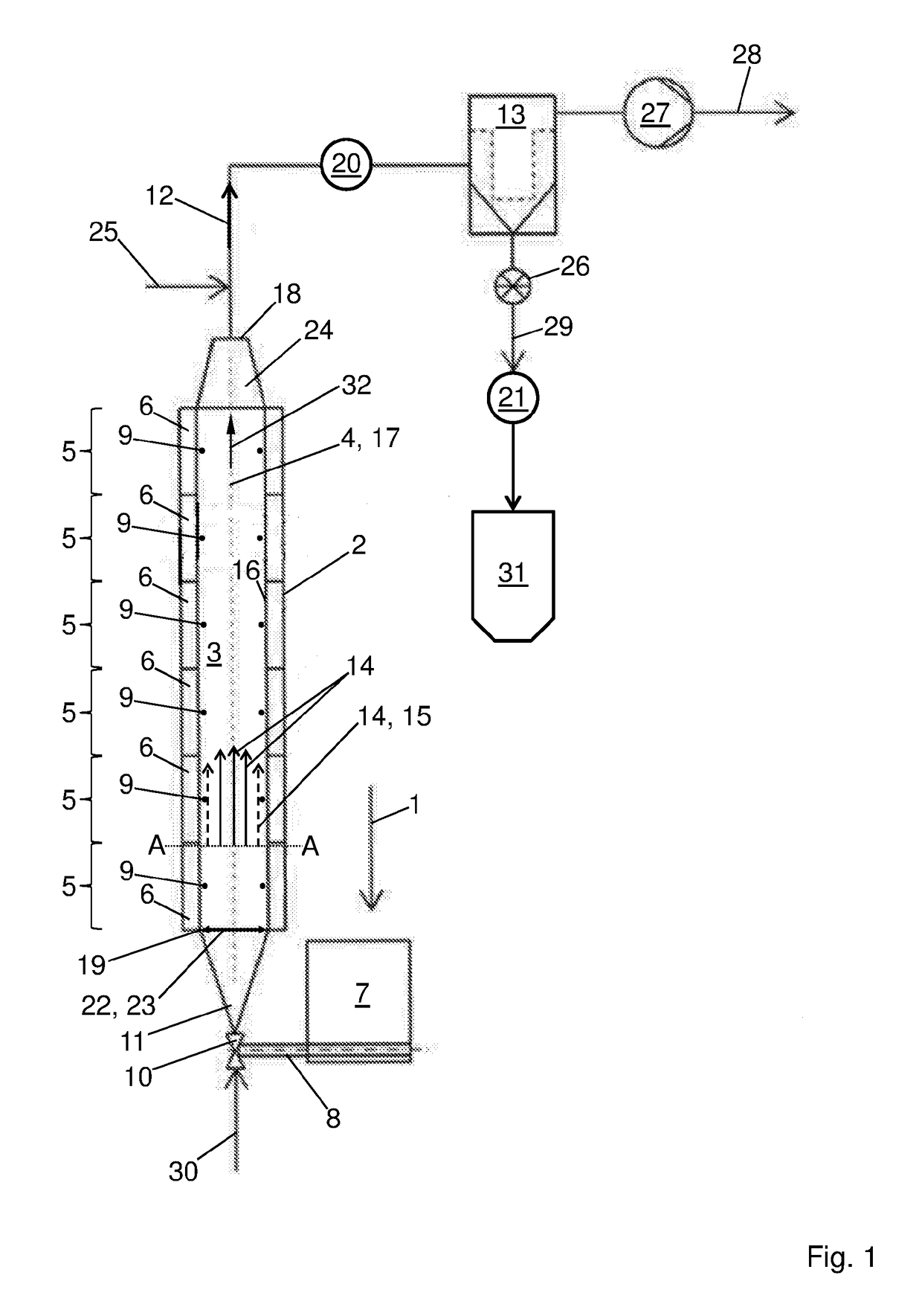

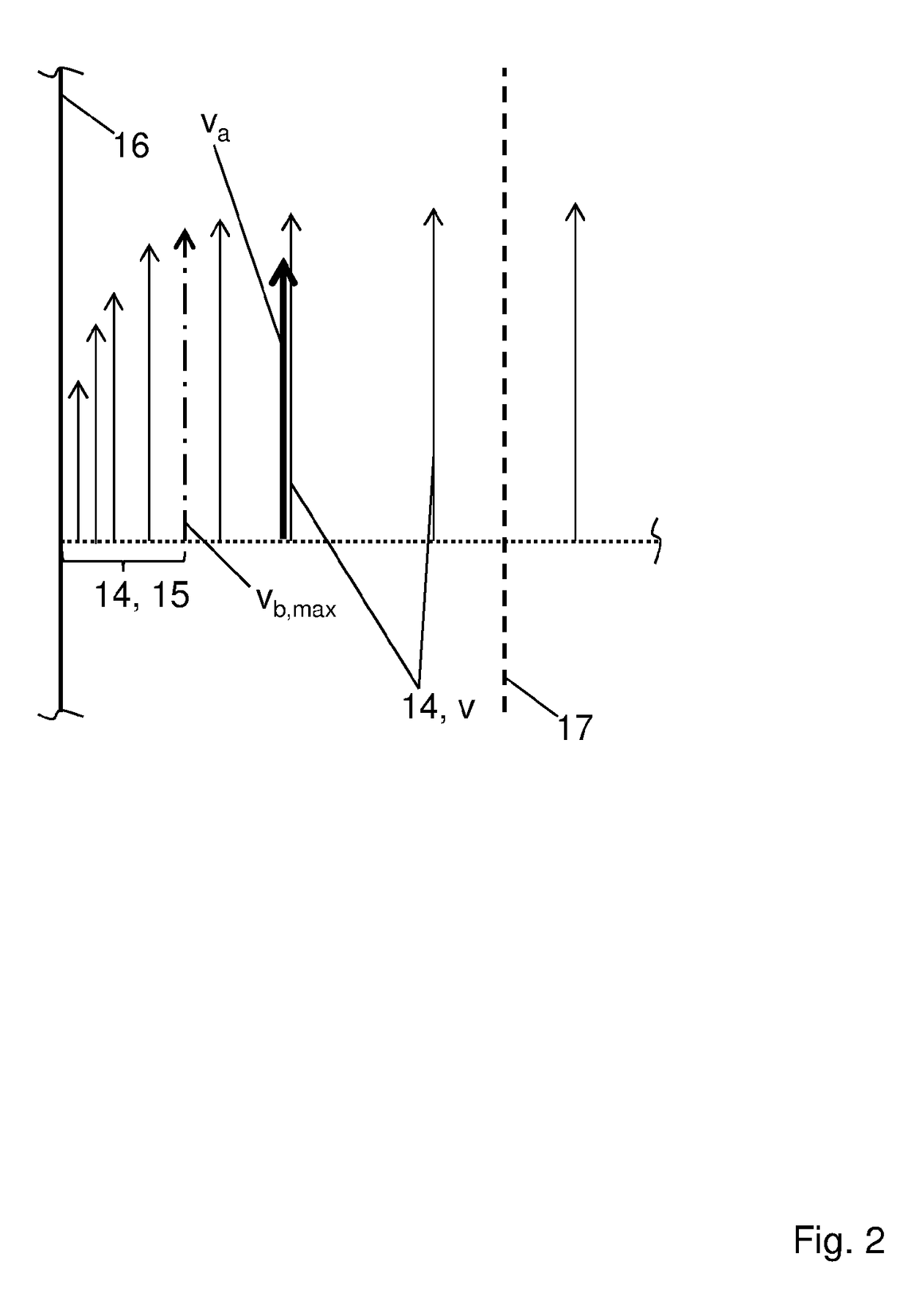

Method and device for producing an expanded granulate

ActiveUS20180141862A1Avoid disadvantagesIncrease material concentrationCharge manipulationVertical furnacesMining engineeringPellets

The invention relates to a method for producing an expanded granulate (29) made of a sand grain-shaped mineral material (1) using a propellant; wherein the material (1) is fed to a substantially upright furnace (2); wherein the material (1) is conveyed along a conveying path (4) through a plurality of vertically separated healing zones (5) in a furnace shaft (3) of the furnace (2), wherein each heating zone (5) can be heated by at least one independently controllable heating element (6); wherein the material (1) is heated to a critical temperature at which the surfaces (7) of the sand grains (1) become plastic and the sand grains (1) are expanded through the propellant. It is provided according to the invention that the material (1) is fed together with an amount of air from below, wherein the material (1) is conveyed from bottom to top along the conveying path (4) by means of the amount of air which flows from bottom to top within the furnace shaft (3) and forms an air flow (14), and wherein the expanding of the sand grains (1) occurs in the upper half, preferably in the uppermost third, of the conveying path (4).

Owner:BINDER

Method of producing alkaline-earth salts of aliphatic beta -keto compounds

InactiveUS6093844AEasy to controlEliminate cakingOrganic compound preparationCarboxylic acid esters preparationDiketoneAlkaline earth metal

PCT No. PCT / EP97 / 01156 Sec. 371 Date Sep. 15, 1998 Sec. 102(e) Date Sep. 15, 1998 PCT Filed Mar. 7, 1997 PCT Pub. No. WO97 / 34859 PCT Pub. Date Sep. 25, 1997Proposed is a method of producing alkaline-earth salts of aliphatic beta -keto compounds by reacting alkaline-earth hydroxides with aliphatic beta -ketoesters and / or beta -diketones in the absence of solvent to give the corresponding alkaline-earth salts. The beta -keto compound is added in portions to the powdered alkaline-earth hydroxide and the reaction mixture subsequently dried. Good yields are obtained of a fine-grained, light colored product.

Owner:DIETER KLAMANN JORG DR

Shaoxing rice wine rice recycling method

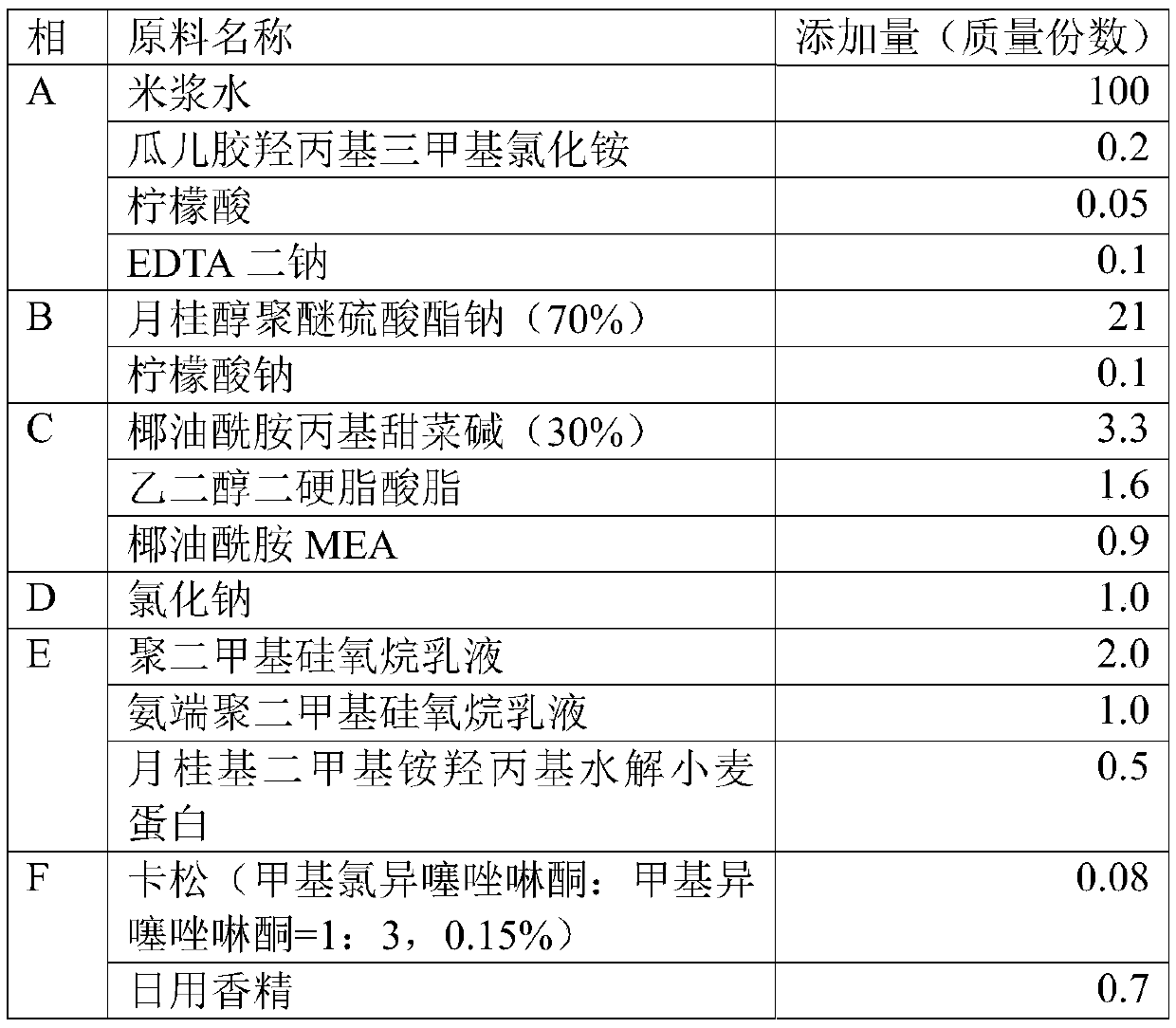

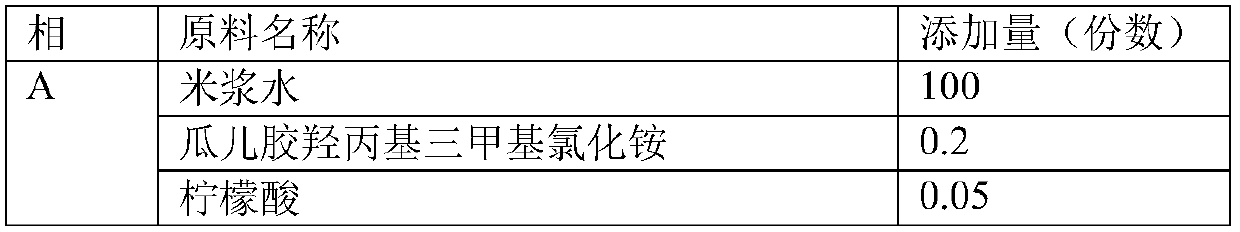

The invention discloses a Shaoxing rice wine rice recycling method and belongs to the technical field of wine brewing. According to the method, lactic acid bacteria not producing biogenic amine are inoculated to inhibit the growth of harmful microorganisms, the biogenic amine content is greatly reduced, and peculiar taste and odor of rice pulp and surface 'white flowers' are eliminated, so that the rice pulp has pleasant smell; 45-50% of aged pulp containing excellent lactic acid bacteria is used for inoculating immersed rice, the rice immersion time is shortened, breakage and pasting of ricegrains and starch loss are decreased, and the quality of steamed rice and the rate of wine production are improved; 15-25% of rice immersion water is used as feed water, except for a small increased amount of distiller's yeast, basically, the production process of yellow wine is not changed, safe fermentation is ensured, and rancidity is prevented, so that the aroma and taste of the brewed yellowwine are better than that of rice wine without rice pulp or rice wine with rice pulp wholly used for charging and brewing; 25-40% of rice immersion water is used for preparing shampoo, and the obtained shampoo can significantly improve the symptoms of hair loss.

Owner:ZHEJIANG SHUREN COLLEGE ZHEJIANG SHUREN UNIV

Method for improving filtering performance of dry spray booth

ActiveCN111821793AImprove filtering effectReduce loadCombination devicesSpraying apparatusFiltrationStructural engineering

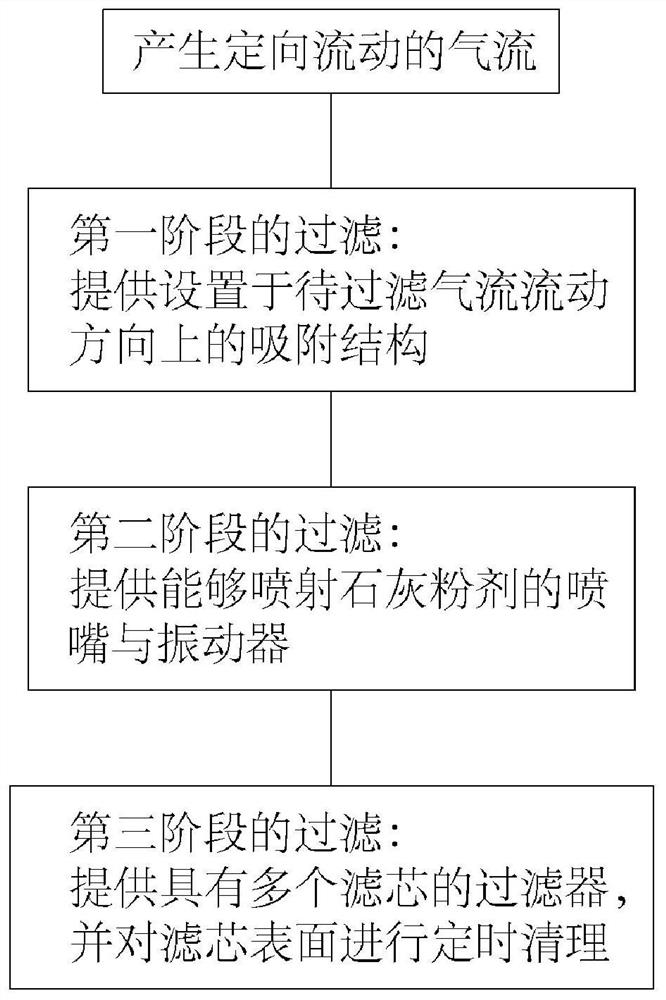

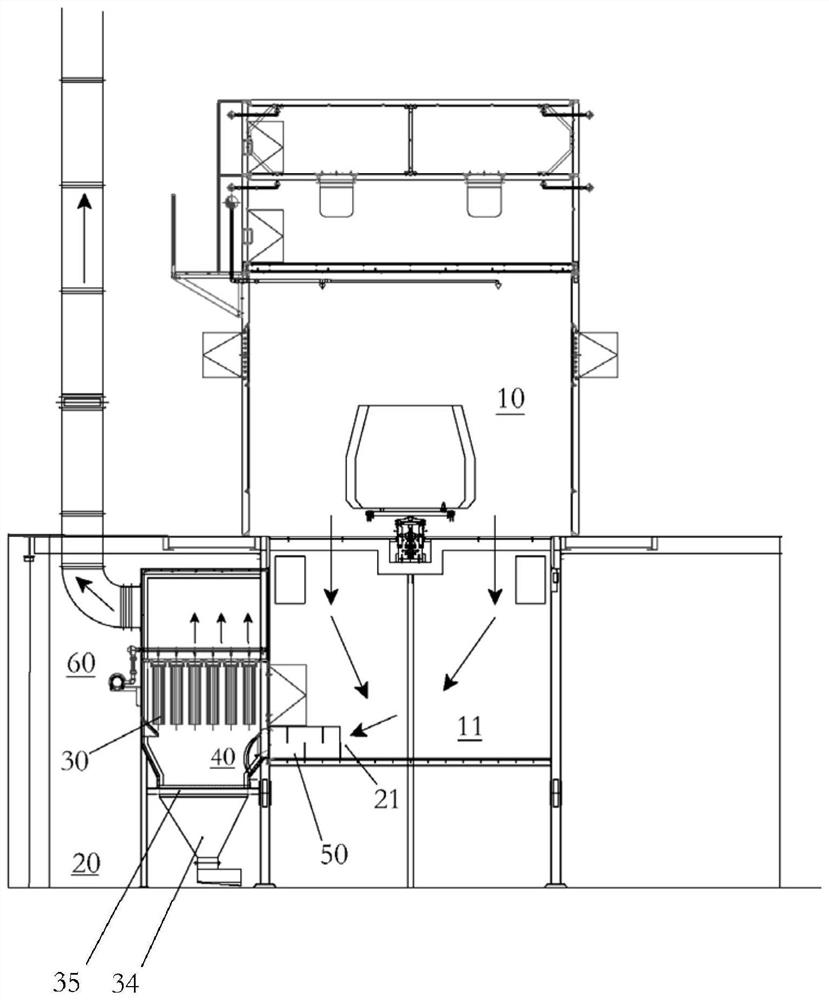

The invention provides a method for improving the filtering performance of a dry spray booth. The method includes the following steps of: forming paint particle-containing to-be-filtered airflow whichdirectionally flows from a spray booth to a windward opening of a filtering chamber through the pressure difference between the spray booth and the filtering chamber; providing an adsorption structure arranged in the flowing direction of the to-be-filtered airflow, and carrying out first-stage filtration; providing a nozzle capable of spraying powder, and enabling the nozzle to spray powder to perform second-stage filtration; settling the powder sprayed out of the nozzle on a storage structure with a plurality of through holes through gravity, providing a vibrator capable of driving the storage structure to vibrate, and under the action of the vibrator, discharging the powder accumulated on the storage structure through the through holes; and providing a filter for carrying out third-stage isolation filtering to obtain clean air, and exhausting the clean air from an air outlet of the filtering chamber. According to the invention, the filtering performance of the dry spray booth is improved by reducing the phenomena of caking and blocking of powder and paint.

Owner:DONGFENG MOTOR CO LTD

High-gluten flour subpackaging device and subpackaging method thereof

PendingCN114261545AReduce crushing pressurePrevent feeding and blockingSolid materialGrain treatmentsMoving partsEngineering

The invention discloses a high-gluten flour split charging device and a split charging method thereof.The split charging device comprises a flour processing tank, a processing part is arranged in the flour processing tank, guiding parts distributed in an array mode are arranged on one side of the flour processing tank, fixed parts are arranged in the guiding parts, moving parts are arranged on one sides of the guiding parts, and the processing part comprises a shaft rod; a vertical rod, an arc-shaped block, a crushing roller and a stirring part are arranged on the shaft rod, the two ends of the vertical rod are fixedly connected with the arc-shaped block, the crushing roller is located between the vertical rod and the stirring part, the stirring part is rotationally connected with the shaft rod, the fixing part comprises a fixing rod, an adjusting mechanism for controlling the split charging amount is arranged on the fixing rod, and the adjusting mechanism comprises a driving part, an adjusting part, a shifting plate and a limiting rod. One end of the fixing rod is connected with the driving piece, the other end of the fixing rod is connected with the adjusting piece, and the limiting rod is arranged in the fixing rod and connected with the shifting plate in a fastened mode. According to the split charging device, the processing part carries out material distribution and multi-stage crushing on high-gluten flour, the stirring part prevents blanking blockage, and the fixing part controls the split charging amount.

Owner:ANHUI UNIV OF SCI & TECH

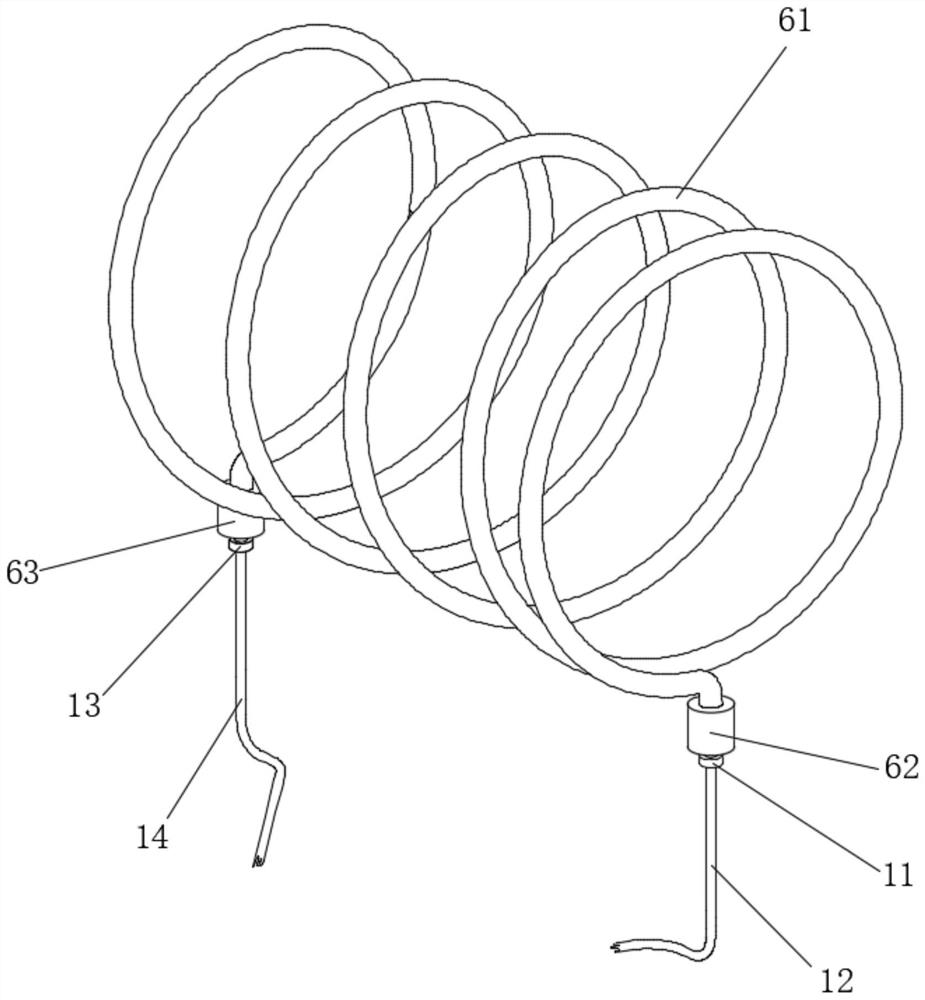

A temperature control system for an injection molding machine

ActiveCN111391260BAvoid problems where adjustments cannot be made individuallyReduces the chance of clumpingTemperature controlInjection port

The invention relates to the technical field of intelligent production, and discloses a temperature control system for an injection molding machine, comprising an injection molding tube, one end of the injection molding tube is provided with an injection port, one side of the injection tube is provided with a pressure guiding hole, and the outer surface of the injection molding tube is The heat conduction sleeve is fixedly connected, and a heat conduction hole is opened inside the heat conduction sleeve, and a heating device is fixedly sleeved inside the heat conduction hole. The heating device includes a spiral heating rod, and one end of the spiral heating rod is fixedly installed with a first socket. The other end is fixedly installed with a second socket, the first plug is fixedly socketed on one end of the first socket, and the second plug is fixedly socketed on one end of the second socket. The plastic solution in the injection molding tube can be heated independently through the spiral heating rod, which avoids the problem that the temperature in the injection molding port cannot be adjusted independently due to the same temperature control structure for the material guide tube and the injection molding tube.

Owner:浙江博创机械有限公司

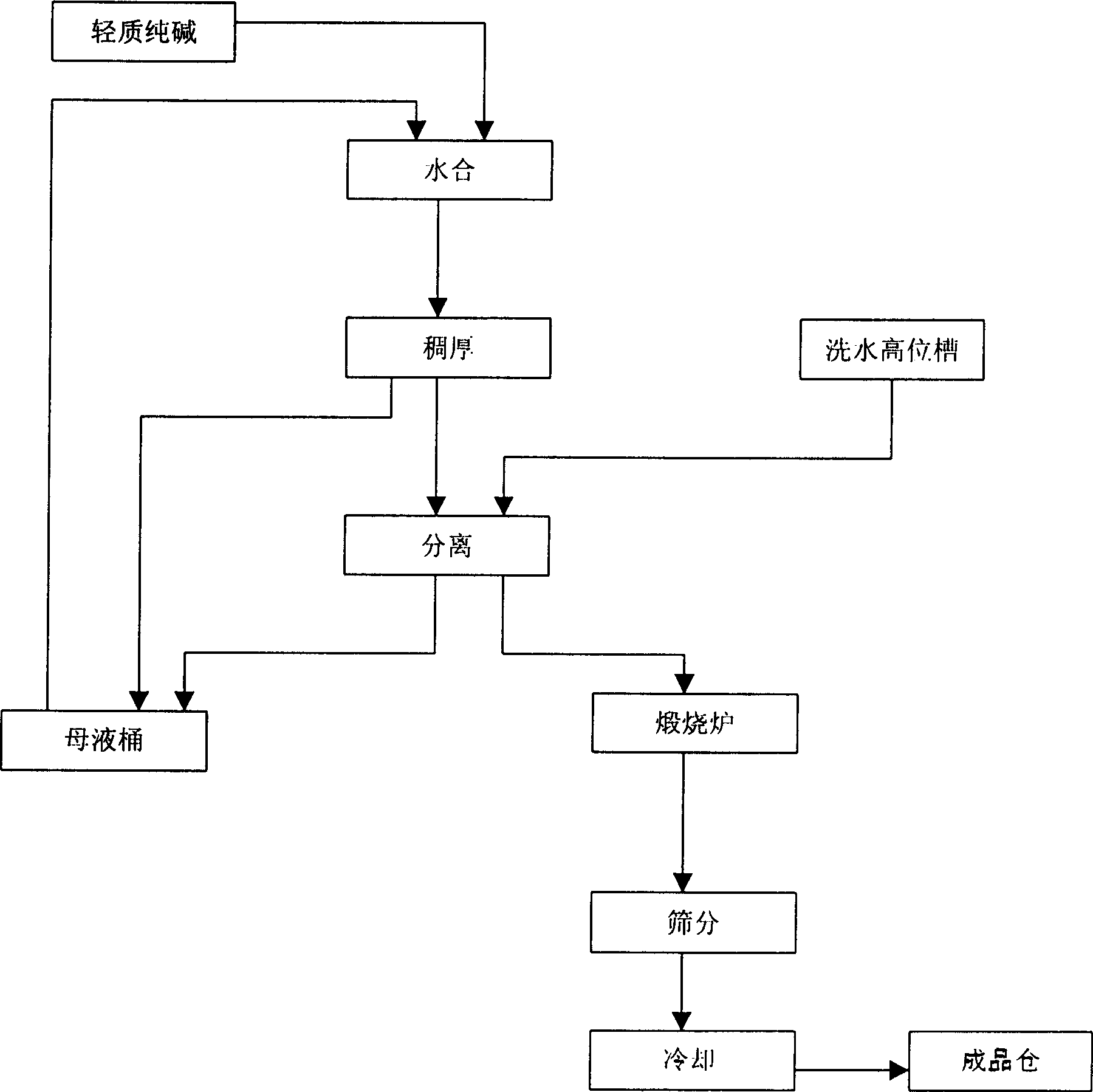

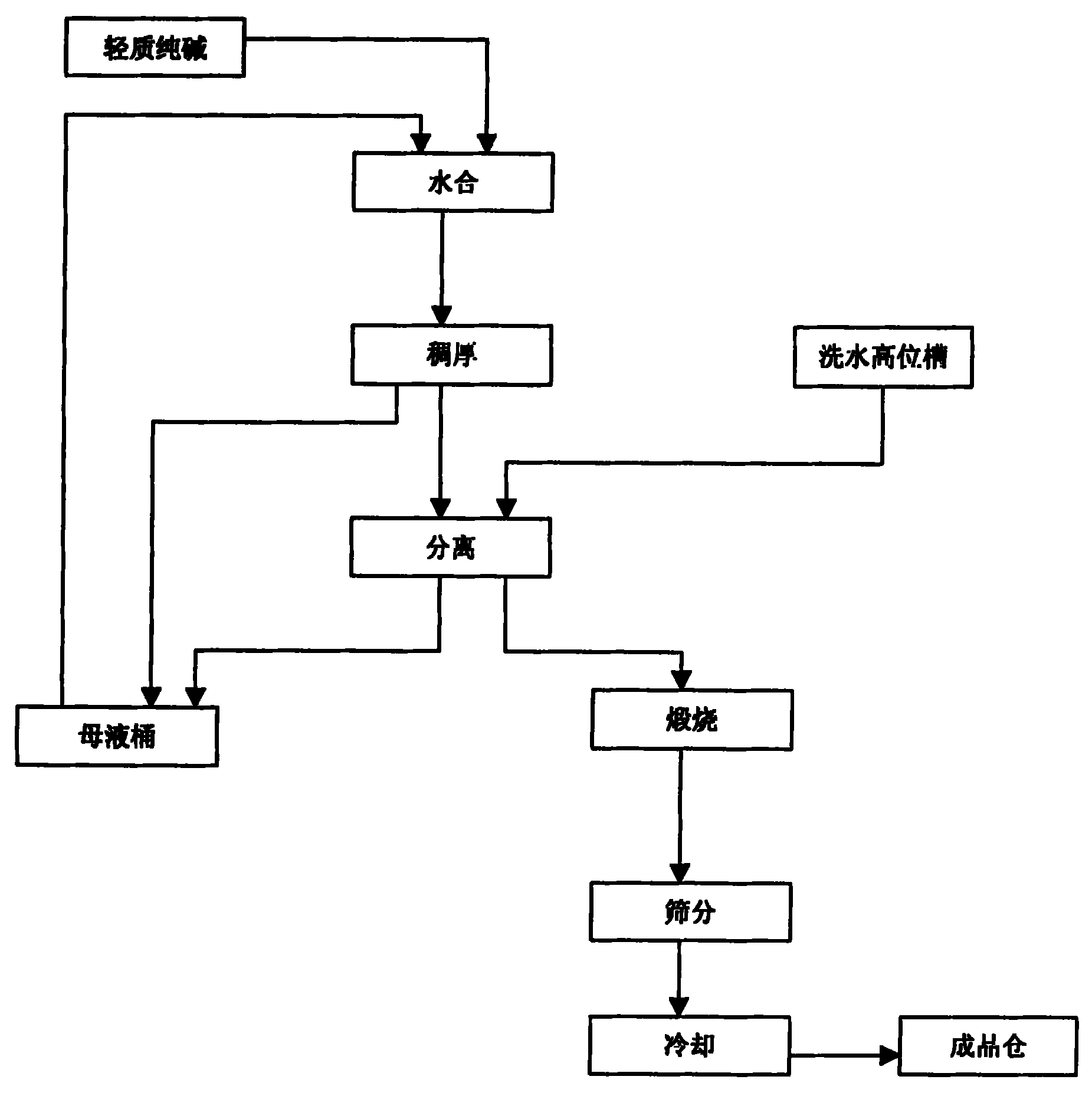

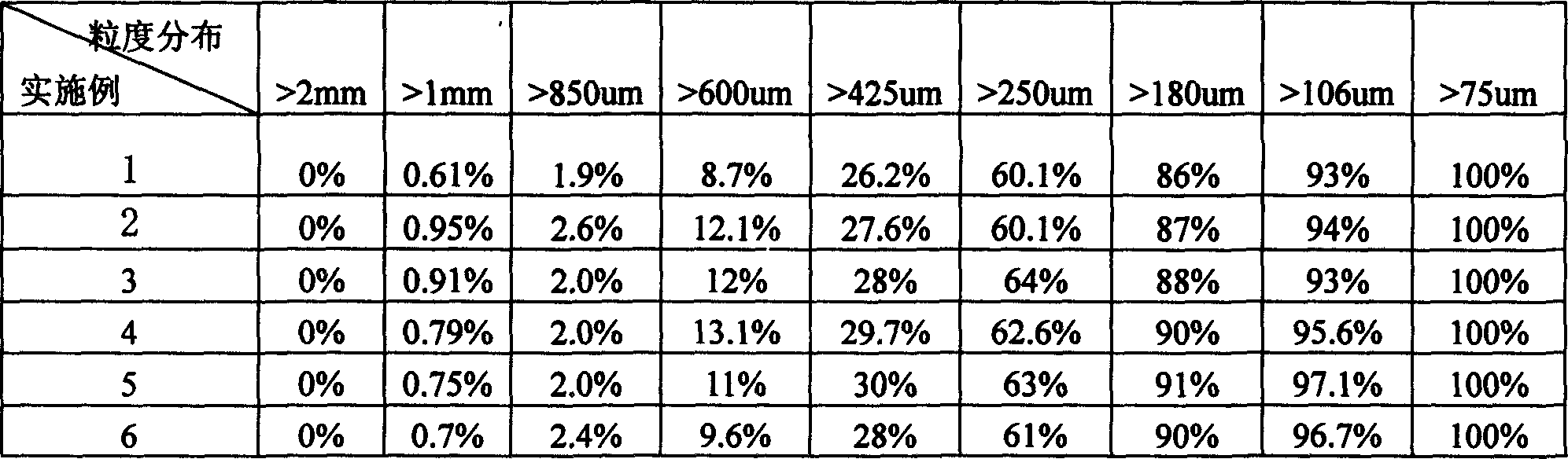

Production process of heavy soda ash

The production process of heavy sodium carbonate includes the following steps: hydration and crystallization of light sodium carbonate and saturated sodium carbonate solution in a hydration crystgallizer for 5-10 min, densifying the crystal slurry after hydration in a densifier; solid-liquid separation in a centrifugal while adding water to wash off partial salt and impurity; calcining in a heavy sodium carbonate calcining furnace, sieving, and cooling to obtain heavy sodium carbonate. The said process can obtain product with homogeneous grain size, low salt content and less scaling in the crystallizer.

Owner:TIANJIN BOHUA YONGLI CHEM IND

Method for producing nickel button by constant current

ActiveCN1936084AEliminate graining on the edge of nickel buckleNickel buttons grow uniformly and orderlyPhotography auxillary processesEngineeringMetallic Nickel

The invention relates to a method to produce nickel buckle by using constant current. The diameter of nickel buckle conductive column is 15mm, and the neighbor two columns center distance is 30mm, current density is 300-350A / m2, and current intensity is 7000-8000A. The invention decreases actual current density through expanding actual conductive area. Thus, the edge effect in electrolytic process would be decreased. It has the advantages of equal, easy to operate, low electric device invest, high single groove yield, etc.

Owner:JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com