Shaoxing rice wine rice recycling method

A technology for rice milk water and rice wine, applied in the field of winemaking, can solve problems such as adverse effects on safety and taste, uncoordinated wine body components, and impact on product taste, etc., so as to inhibit the growth of harmful microorganisms, improve the quality of steamed rice, and eliminate steaming. The effect of clumping rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

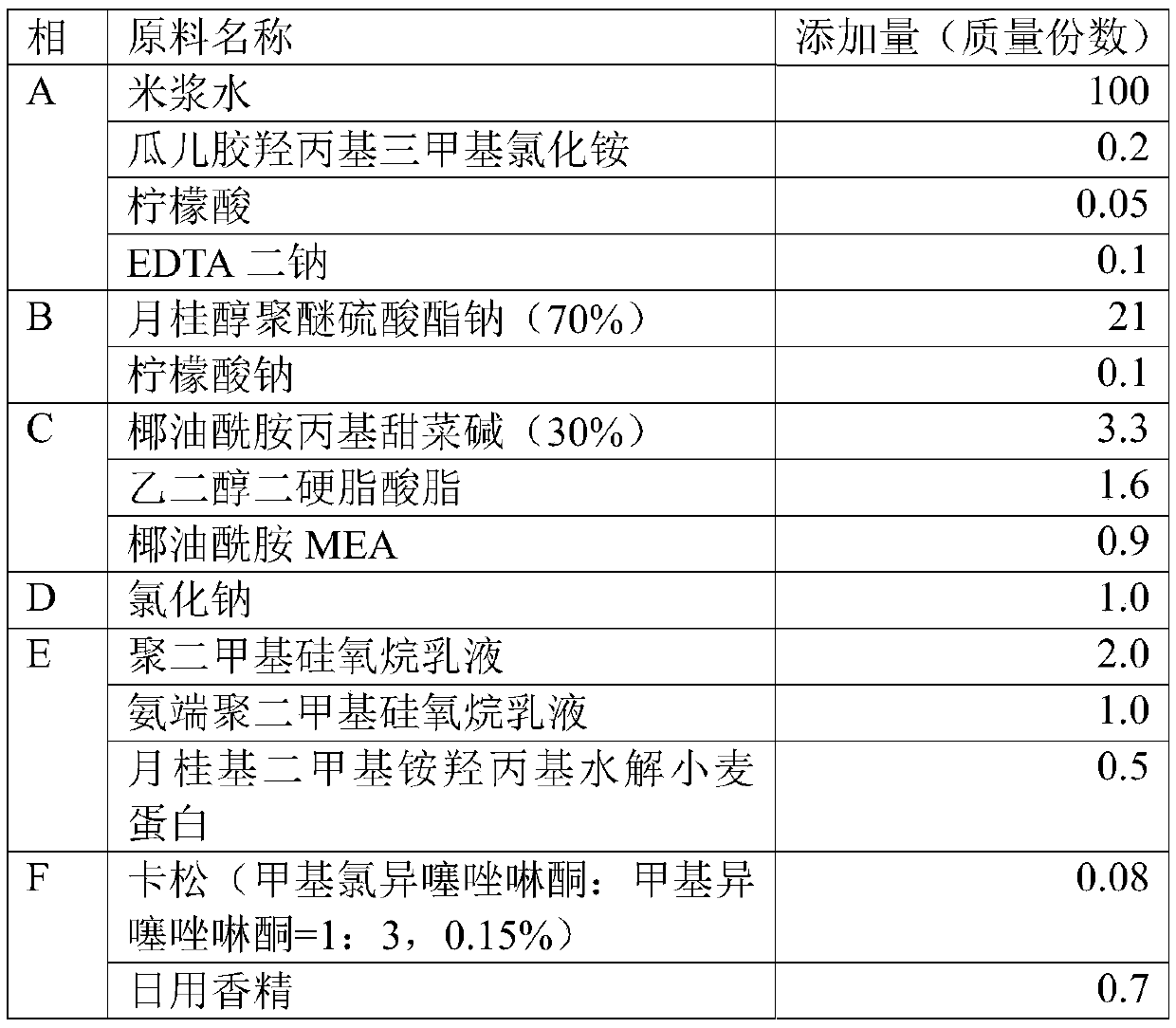

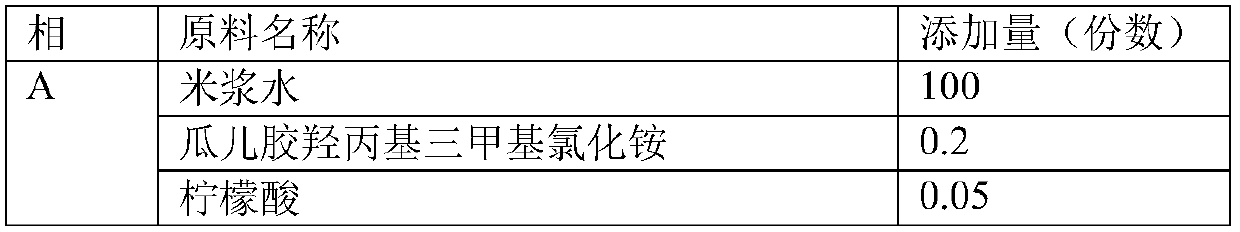

Examples

Embodiment 1

[0035] (Batch 1)

[0036] Step 1: Soak rice inoculated with lactic acid bacteria

[0037] Using CGMCC No.7184 as the strain, it is cultivated step by step in the order of solid inclined test tube, liquid triangular flask, liquid triangular flask and culture tank.

[0038] specifically:

[0039] Cultivation of bacteria in solid slant test tubes: use MRS agar medium and culture at 30°C for 4 to 5 days.

[0040] Preparation of liquid triangular flask and liquid triangular flask seeds: ①The preparation method of liquid triangular flask and liquid triangular flask seed medium is: soak glutinous rice for 36-48 hours, steam rice, add 3.5 times water according to the mass of glutinous rice, and reduce the temperature to 60 ℃, according to the mass of glutinous rice, add 3% of cooked wheat koji and 2‰ of 100,000 units of glucoamylase, stir evenly, keep warm and saccharify at 58-60°C for 4-5 hours, stir once per hour, filter, and adjust the sugar content to 6~7°Bx, put into 500ml Erl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com