Dustless feeding, granulating, sieving and smashing system

A pulverizing system and screening technology, applied in the field of dust-free feeding and whole-grain screening and pulverizing system, can solve the problems of easy sticking of materials on the inner wall of the collector, material waste, and reduction of pulverized materials in closed conveying, so as to improve the pulverization work. Efficiency, does not occupy extra space, and reduces labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

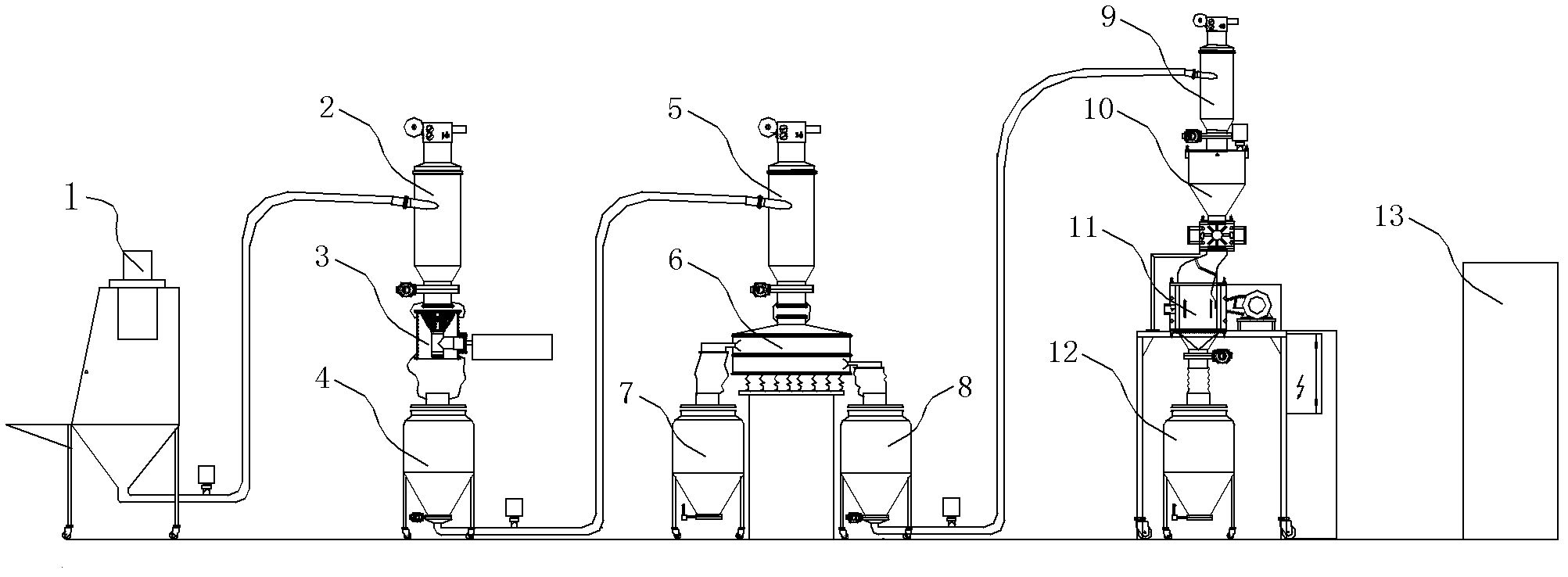

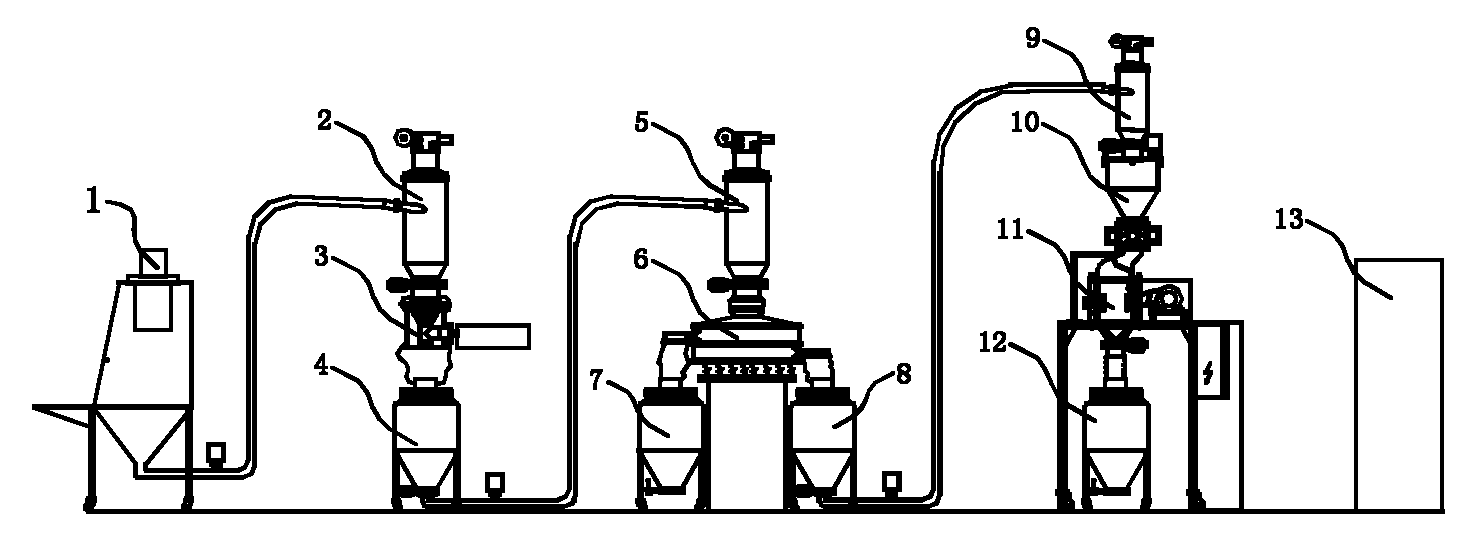

[0019] see figure 1 , the dust-free feeding, sizing, screening and crushing system includes a feeding device 1, a granulating device 3, a screening device 6 and a crushing device 11, wherein the four devices are airtightly connected through a vacuum conveying device.

[0020] The granulator 3 among the present invention can be a commercially available granulator, and it is mainly for breaking up the agglomerated material put into the feeding device 1, so that the follow-up screening device 6 can sort out qualified materials as much as possible, The workload of the crushing device 11 is reduced. The granulation device 3 rotates quickly through the mixing knife inside, and the agglomerated materials are broken up, and then flow out through the screen holes in the granulation device 3 .

[0021] The role of the vacuum conveying device is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com