IGBT (Insulated Gate Bipolar Translator) welding process method

A welding process and solder paste technology, applied in the field of IGBT welding process, can solve the problems of difficult mold removal, affecting product appearance, cavity deterioration, etc., to eliminate missing dents and agglomerations, reduce product appearance failure, reduce tin beads and tin bridge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

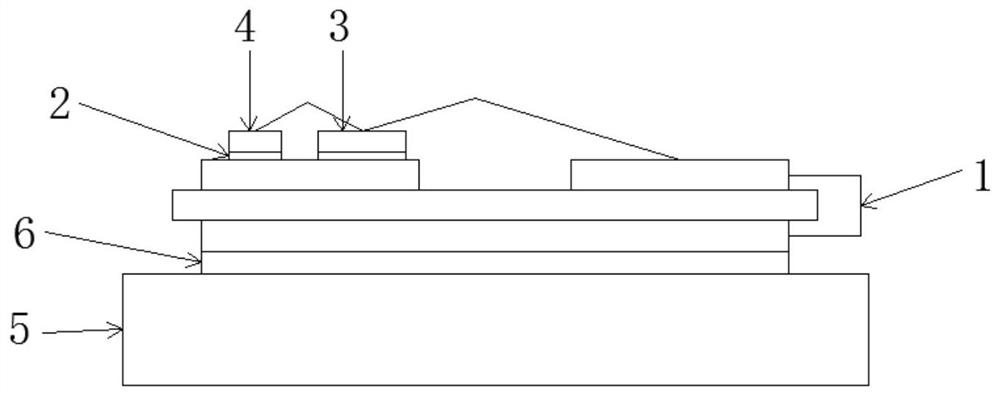

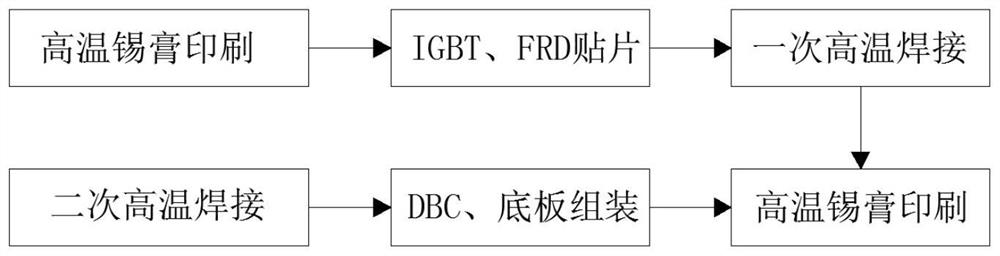

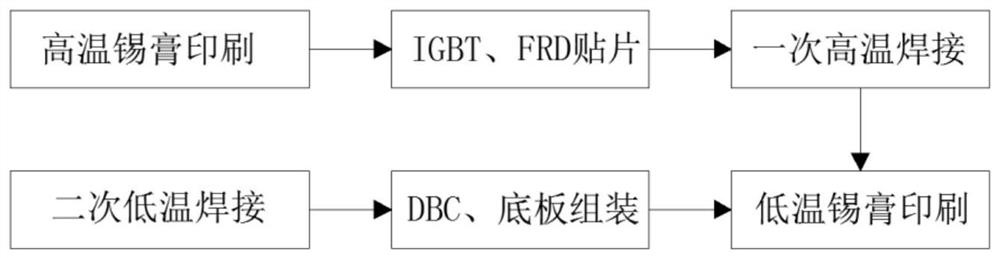

[0032] An IGBT welding process method, IGBT welding materials include DBC ceramic copper clad laminate 1, high temperature solder paste 2, IGBT chip 3, FRD chip 4, metal substrate 5 and low temperature solder paste 6, the specific steps of the welding process include the following steps:

[0033] S1: Print a layer of high-temperature solder paste 2 on the upper surface of the DBC ceramic copper clad laminate 1;

[0034] S2: Place the IGBT chip 3 and the FRD chip 4 on the high-temperature solder paste 2 by an automatic placement machine;

[0035] S3: Load the DBC ceramic copper-clad laminate 1 with the chip attached into the vacuum welding furnace, and perform a high-temperature welding;

[0036] S4: printing a layer of low-temperature solder paste 6 on the upper surface of the metal substrate 5;

[0037] S5: Assemble the DBC ceramic copper-clad laminate 1 after high-temperature welding in step S3 and the metal substrate 5 coated with low-temperature solder paste 6 on the uppe...

Embodiment 2

[0041] An IGBT welding process method, IGBT welding materials include DBC ceramic copper clad laminate 1, high temperature solder paste 2, IGBT chip 3, FRD chip 4, metal substrate 5 and low temperature solder paste 6, the specific steps of the welding process include the following steps:

[0042] S1: Print a layer of high-temperature solder paste 2 on the upper surface of the DBC ceramic copper clad laminate 1;

[0043] S2: Place the IGBT chip 3 and the FRD chip 4 on the high-temperature solder paste 2 by an automatic placement machine;

[0044] S3: Load the DBC ceramic copper-clad laminate 1 with the chip attached into the vacuum welding furnace, and perform a high-temperature welding;

[0045] S4: printing a layer of low-temperature solder paste 6 on the upper surface of the metal substrate 5;

[0046] S5: Assemble the DBC ceramic copper-clad laminate 1 after high-temperature welding in step S3 and the metal substrate 5 coated with low-temperature solder paste 6 on the uppe...

Embodiment 3

[0050] An IGBT welding process method, IGBT welding materials include DBC ceramic copper clad laminate 1, high temperature solder paste 2, IGBT chip 3, FRD chip 4, metal substrate 5 and low temperature solder paste 6, the specific steps of the welding process include the following steps:

[0051] S1: Print a layer of high-temperature solder paste 2 on the upper surface of the DBC ceramic copper clad laminate 1;

[0052] S2: Place the IGBT chip 3 and the FRD chip 4 on the high-temperature solder paste 2 by an automatic placement machine;

[0053] S3: Load the DBC ceramic copper-clad laminate 1 with the chip attached into the vacuum welding furnace, and perform a high-temperature welding;

[0054] S4: printing a layer of low-temperature solder paste 6 on the upper surface of the metal substrate 5;

[0055] S5: Assemble the DBC ceramic copper-clad laminate 1 after high-temperature welding in step S3 and the metal substrate 5 coated with low-temperature solder paste 6 on the upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com