Baking soda production anti-caking process and apparatus

A baking soda and anti-caking technology, applied in the direction of alkali metal carbonate to prevent moisture absorption, can solve the problems of difficult operation control, complex process structure, poor product quality, etc., to achieve low operation and maintenance costs, improve product quality, Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

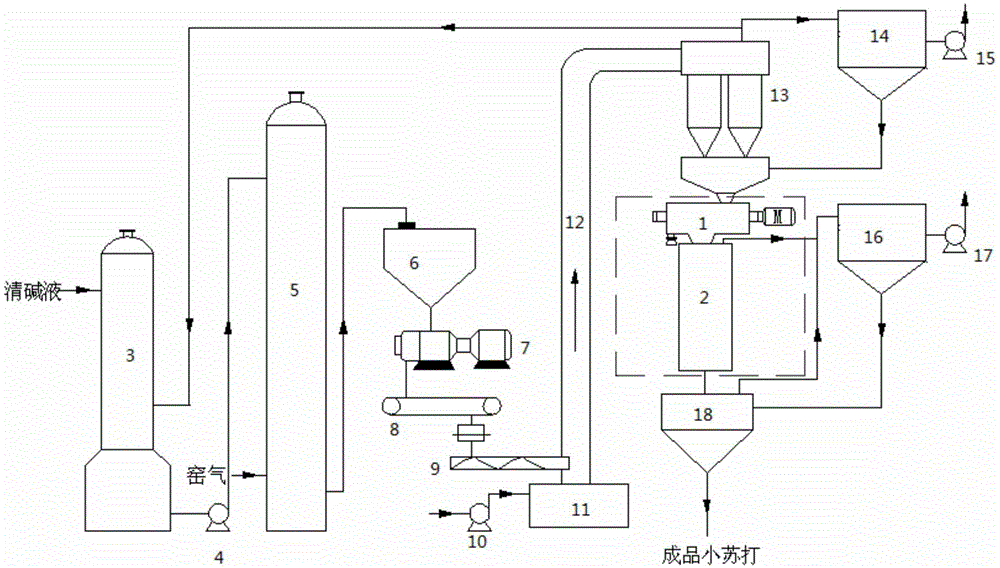

[0031] figure 1 It is the production process flow chart of baking soda. The lye clearing liquid enters the carbonization tower 5 through the lye pump 4, then enters the thickener 6, is centrifuged by the centrifuge 7, and the belt conveyor 8 is transported to the feeding screw 9, and the feeding screw 9 transports the material It is transported to the air heater 11 connected with the blower 10, then enters the drying pipe 12, and then is separated by the cyclone separator 13, enters the cyclone sieve 1 to realize crushing and sieving, and then cools through the powder flow cooler 2 and enters the silo 18, wherein the cyclone separator 13 is connected to the bag filter 14 and the induced draft fan 15, and is also connected to the tail gas dedusting tower 2, and the powder flow cooler 2 and the silo 18 are connected to the bag filter 16 and the induced fan 17.

[0032] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com