Aqueous gypsum drying and calcining device and process

A technology of calcining device and gypsum, which is applied in heating devices, drying solid materials, and drying goods processing, etc., can solve the problems of high energy saving and environmental protection requirements, large floor space, and difficult operation, and achieves short processing flow and high production efficiency. , multi-functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

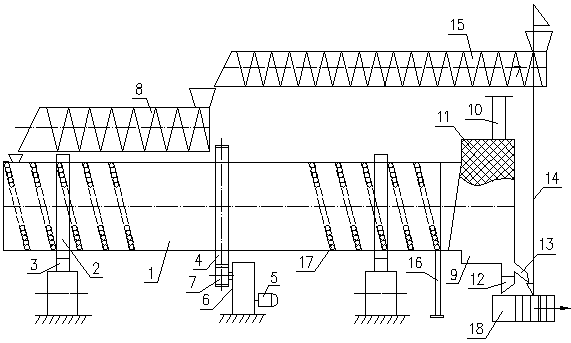

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the hydrated gypsum drying and calcining device includes a horizontally arranged drum 1, two roller rings 2 connected to the drum 1, supporting wheel sets 3 matched with the respective roller rings 2, and a ring gear 4 connected to the outside of the drum 1. , the connected motor 5 and the reducer 6, the output shaft of the reducer 6 is connected with the gear 7 meshed with the ring gear 4, the discharge port of a screw conveyor 8 is connected with the feed port of the drum 1, and the feed port of the drum 1 The discharge end is connected with a discharge chamber 9, the upper end of the discharge chamber 9 is provided with a steam exhaust port 10, the discharge chamber 9 is provided with a gas purification filter 11, and the lower end of the discharge chamber 9 is provided with a vertical discharge port 12 And the inclined d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com