Feeding method and equipment for warehouse pump in pneumatic conveying system

A technology of pneumatic conveying system and feeding method, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., and can solve the problem of arching at the discharge port of the silo, affecting the continuous system output of the pneumatic conveying system, and the feeding of the silo pump. Problems such as poor material flow, to achieve the effect of eliminating arching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

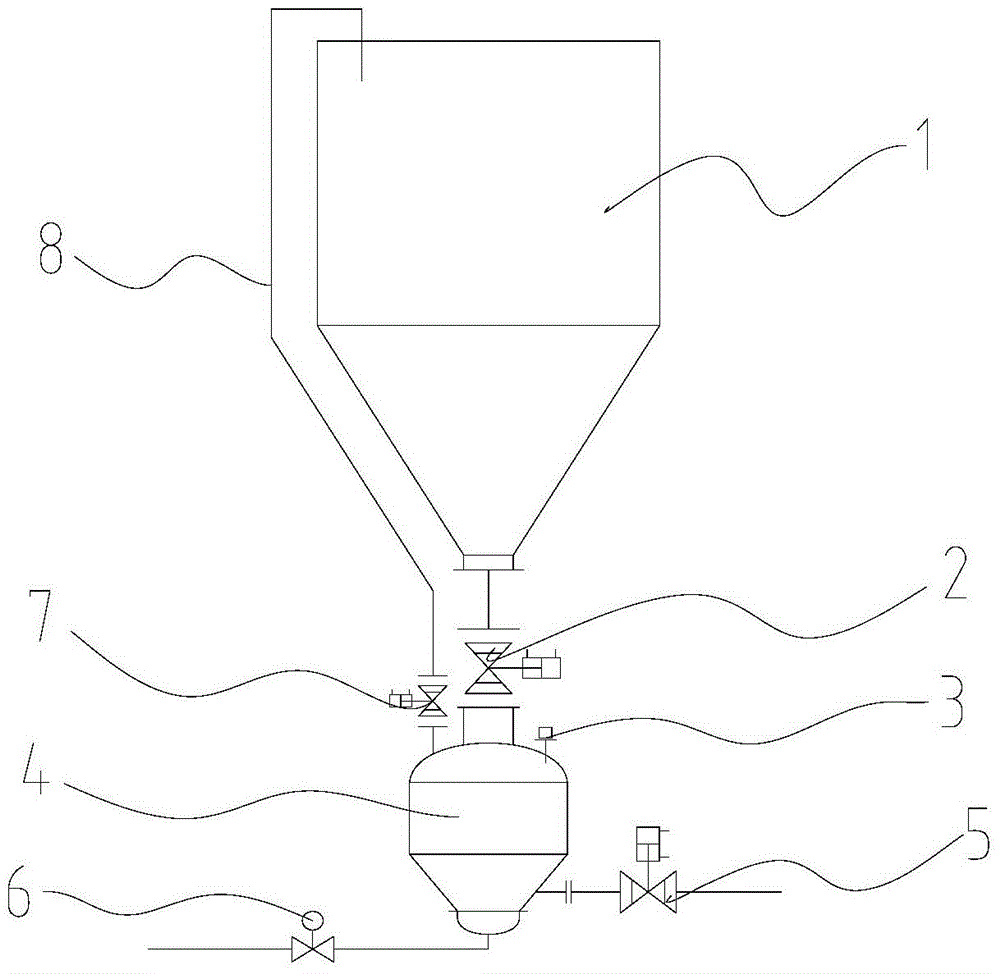

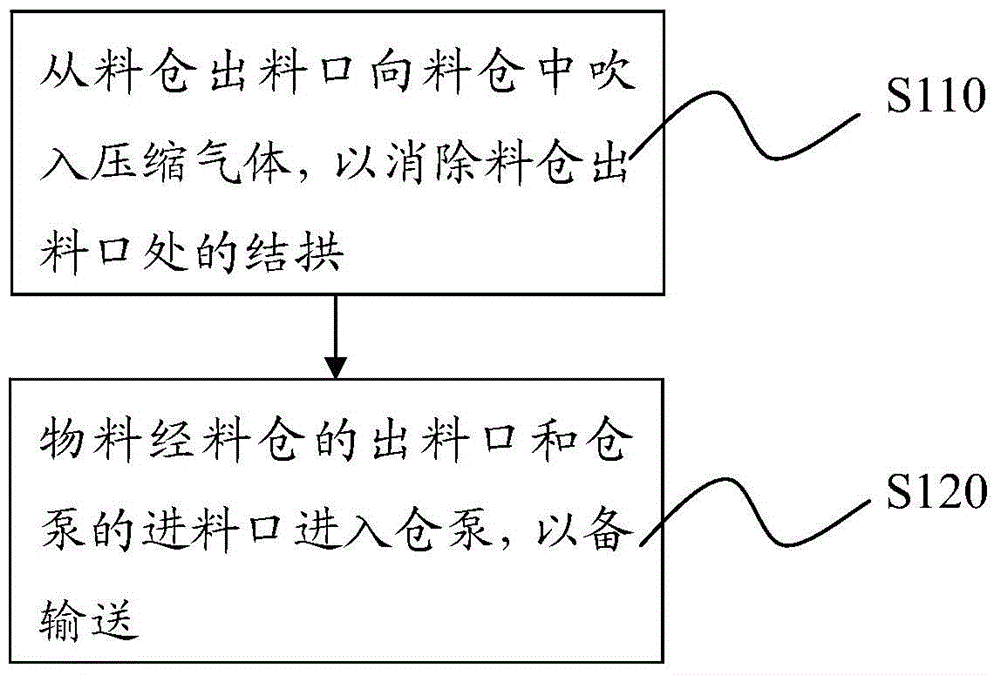

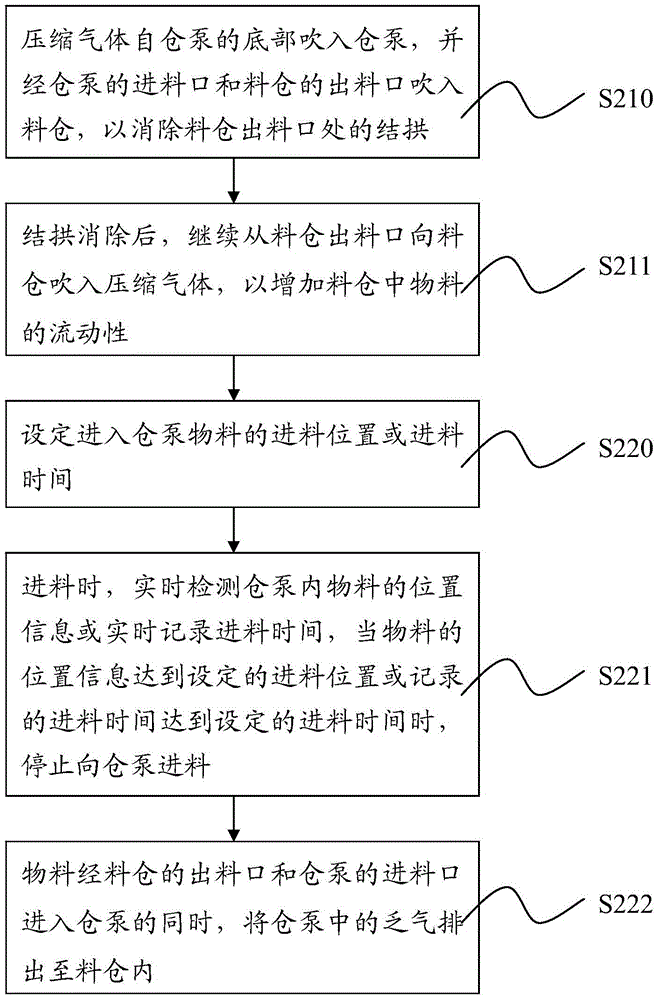

[0032] The core of the present invention is to provide a feeding method and feeding equipment for a warehouse pump in a pneumatic conveying system. The method and equipment use the pressure of compressed air to break through the material at the arch of the silo to eliminate the arch, and at the same time compress the air It can also fluidize the material at the discharge port of the storage bin, improve the fluidity of the material, shorten the feeding time of the warehouse pump, improve the operating efficiency of the warehouse pump, and avoid the leakage of the material due to condensation on the exhaust pipe and exhaust valve. Sticking and clogging.

[0033] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] The feeding equipment of the bin pump in the pneumatic convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com