Granulating type single-cone dryer

A dryer and single-cone technology, applied in the direction of non-progressive dryers, drying solid materials, heating to dry solid materials, etc., can solve the problems of limited application range, material pollution, low drying efficiency, etc., to eliminate sticking walls and Effect of caking, ensuring smooth operation, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

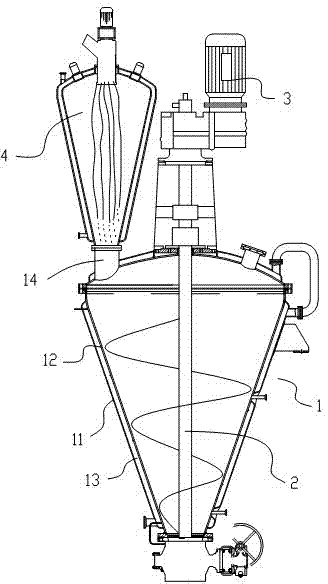

[0018] Such as figure 1 with 2 As shown, a granulating single-cone dryer includes a conical body 1 of a single-headed cone consisting of a heat-insulating layer 11 and a heating layer 12, and a helical stirring paddle 2 is arranged in the body 1, and the stirring paddle 2 It is driven to rotate by a motor 3 arranged on the top of the body. The heating layer 12 on the body 1 is provided with a heat medium passage 13, and the heat medium passage 13 is provided with a heat medium inlet and a heat medium outlet connected to the outside.

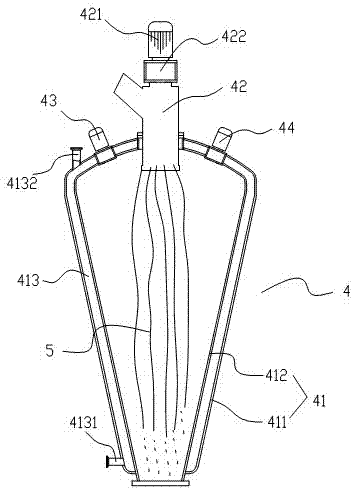

[0019] The feed port 14 of the body 1 is provided with a granulation type pre-drying continuous feed device 4 . In the present embodiment, the pre-drying feeding device 4 includes a feed barrel 41, an extruder 42 for feeding is installed at the upper inlet of the feed barrel 41, and the extruder 42 is passed by a small motor 421 Speed reducer 422 drives. The lower outlet of the feeding barrel 41 is directly communicated with the feeding por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com