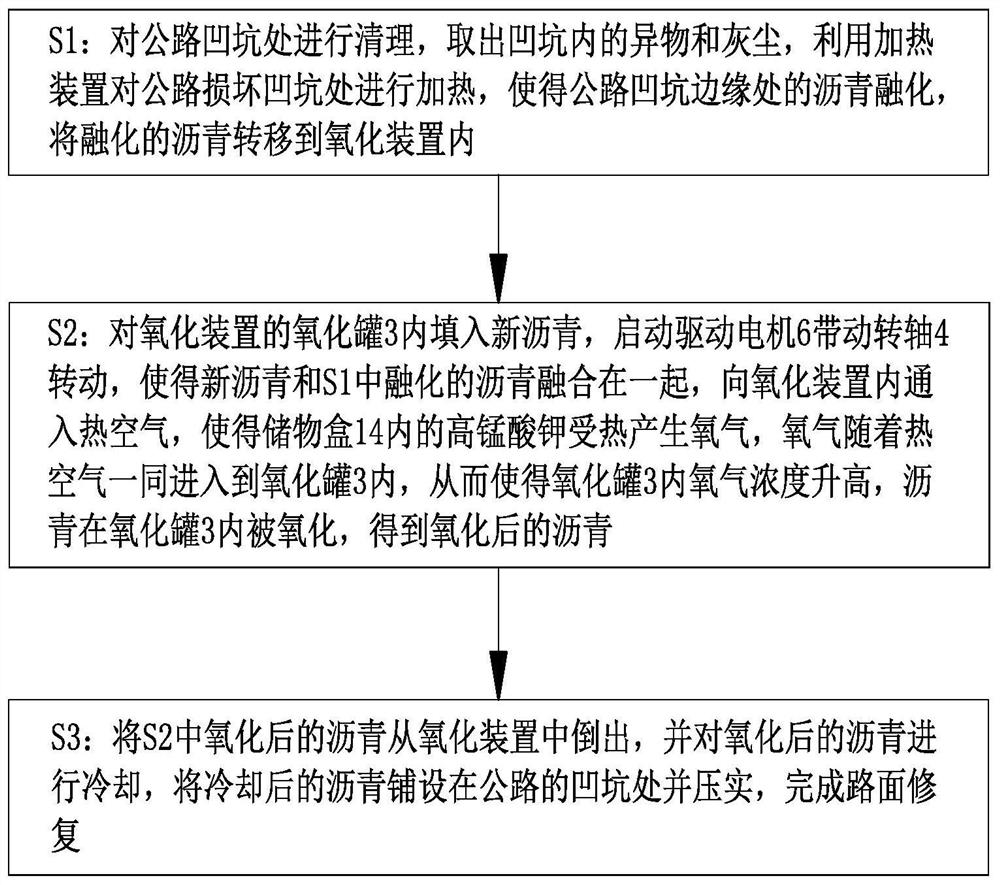

Highway asphalt oxidation treatment process

A technology of asphalt oxidation and treatment process, which is applied in the field of asphalt production, can solve the problems of asphalt oxidation treatment, the inability to improve the effect of oxidation treatment, and affect the quality of highway asphalt, so as to improve the efficiency of road surface repair, improve the oxidation efficiency, and increase the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

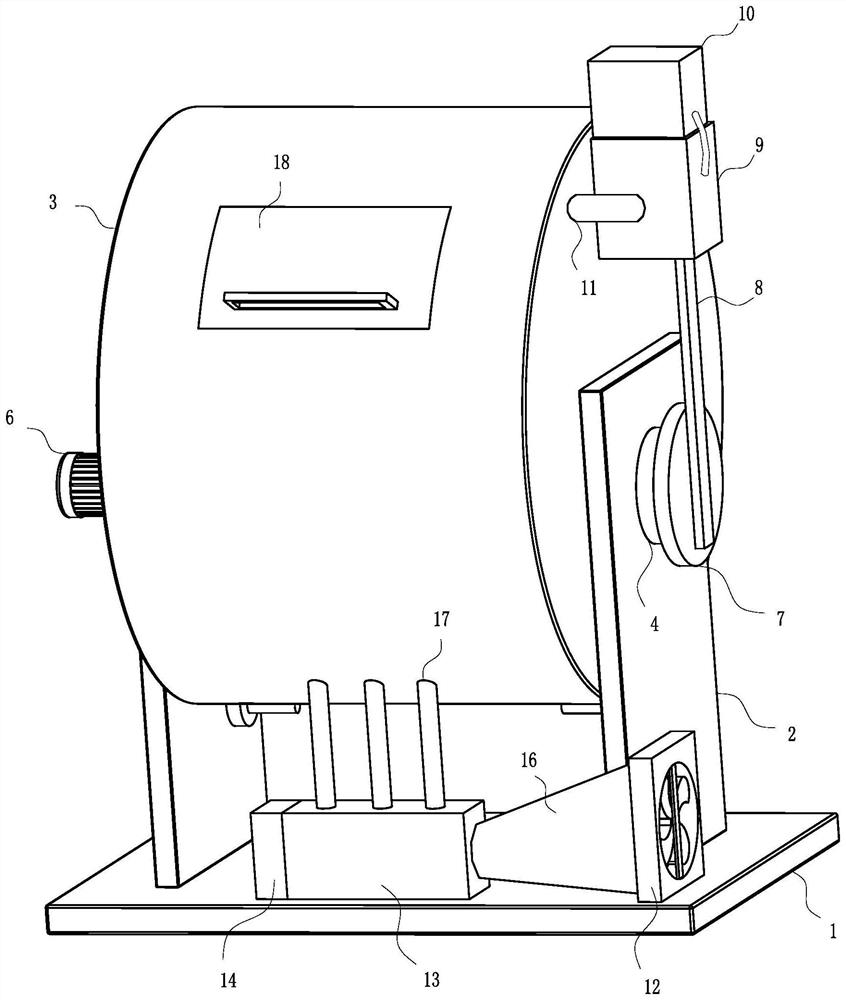

Examples

Embodiment approach

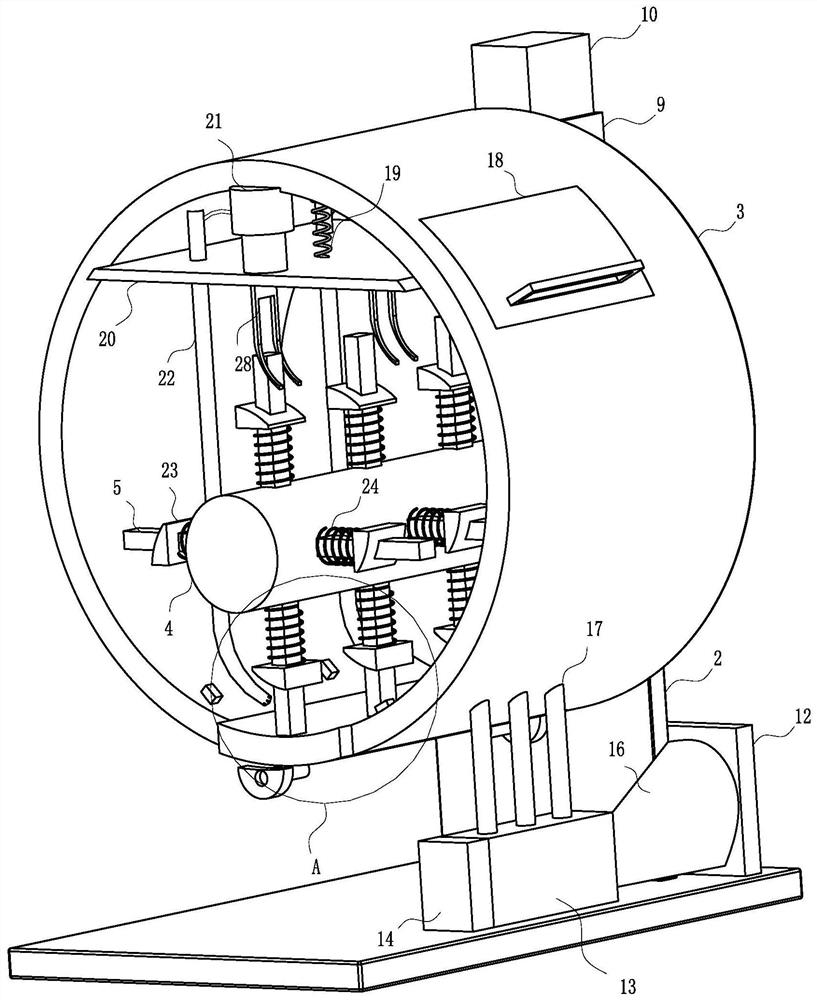

[0043] As a specific embodiment of the present invention, the bottom of the sealing plate 20 is equidistantly fixed with two or more elastic plates 28 along the length direction of the rotating shaft 4. The bottom of the bottom is provided with a curved arc, and the elastic plate 28 is used to scrape off the asphalt on the shift block 5 and prevent the block 23 from moving smoothly; when in use, the surface of the shift block 5 may be adsorbed with a large amount of Asphalt, so that the briquetting block 23 cannot move under the action of the asphalt agglomeration, which in turn affects the grinding effect of the briquetting block 23 on the asphalt; by being provided with an elastic plate 28, the sealing plate is made 20 moves downward, and the sealing plate 20 drives the elastic plate 28 to move downward so that the elastic plate 28 is on the moving path of the briquetting block 23; Deformation, the elastic plate 28 also exerts force on the briquetting block 23 while deformin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com