Spouted fluidized bed-fluidized bed composite reactor for producing hydrogen fluoride

A technology of spouted fluidized bed and fluidized bed reaction, which is applied in the fields of hydrogen fluoride, fluorine/hydrogen fluoride, chemical instruments and methods, etc., and can solve problems such as difficult recovery, channel short circuit, system collapse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

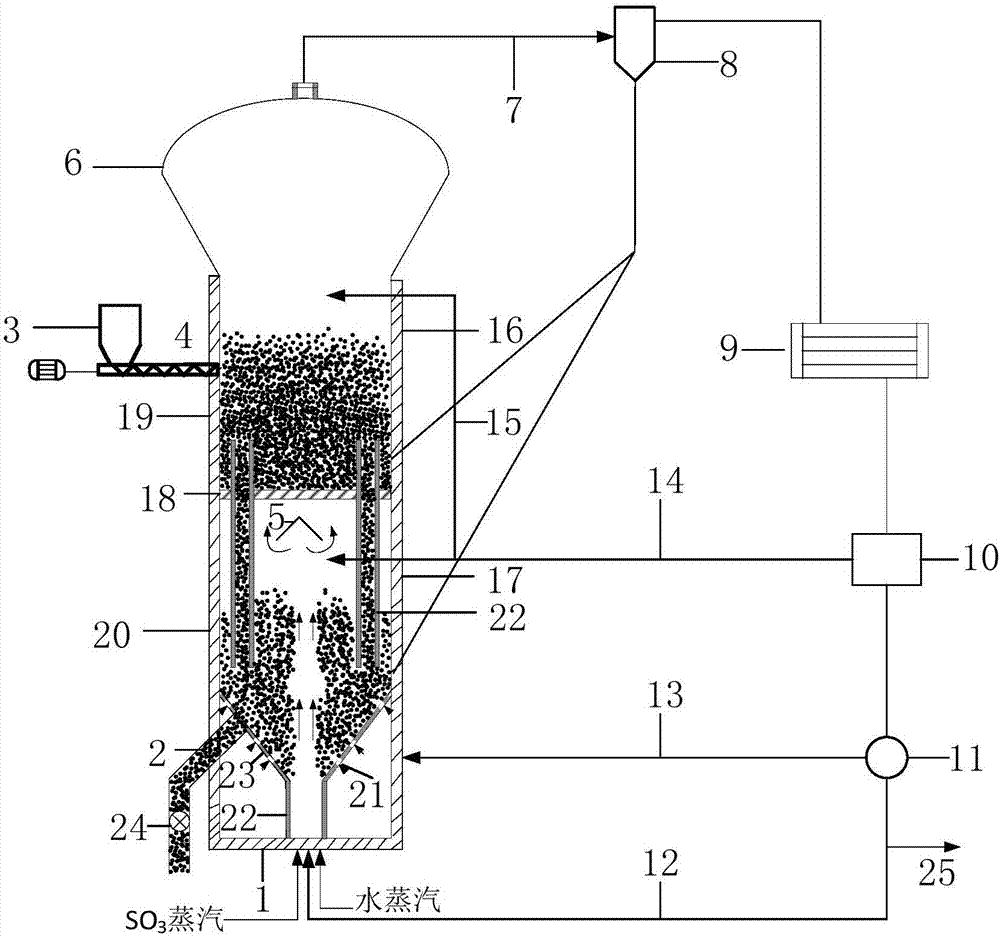

[0031] use as figure 1 The shown spouted fluidized bed-fluidized bed composite reactor is used to produce hydrogen fluoride, and the composite reactor is mainly composed of a spouted fluidized bed 20 at the bottom of the reactor, a fluidized bed 19 at the upper part, and a gas circulation unit. The spouted fluidized bed 20 is composed of a straight tube section cylinder 17, a diameter-reducing section 23 below the cylinder, and an air inlet 22, while the fluidized bed 19 is composed of a straight tube section 16 and an enlarged section 6 above the straight tube section. There is a heating furnace 1 outside the composite reactor.

[0032] The circulation unit includes a cyclone separator 8, a condenser 9, a gas-liquid separator 10, a splitter 11, a liquid delivery pipeline 14, gas delivery pipelines 12, 13, and the like. The circulating gas flows out from the gas outlet at the top of the reactor, and the entrained fine powder particles are separated by the cyclone separator 8,...

Embodiment 2

[0035] The same spouted fluidized bed composite reactor as in Example 1 was used to produce hydrogen fluoride. The superficial fluidization velocity and other conditions of the injection zone and the annulus zone are kept consistent with that of Example 1. The following conditions are mainly changed: the molar ratio of fluorite particles to sulfur in the feed is 1.0:1, and the temperature range in the reactor is still 200-400°C.

[0036] After the above reaction process was carried out for 2 hours, the hydrogen fluoride content was analyzed through the flow splitter line 25, and the results are shown in Table 1.

Embodiment 3

[0038] Maintain the same reaction conditions as in the examples, such as reaction temperature, reaction pressure, molar ratio of fluorite particles to sulfur in the feed, and the like. Effective control of agglomeration in the spouted fluidized bed region is achieved by changing the flow ratio of the sprayed stream, the fluidized stream and the product hydrogen fluoride stream. The gas volume in the fluidized stream, that is, the annulus area, accounts for 30%-50% of the total gas volume at the bottom inlet, and the gas volume in the injection area is guaranteed to remain unchanged at 40%.

[0039] Under the conditions of different annulus gas volumes, after the reaction was carried out for 2 hours, calcium sulfate was sampled through pipeline 2 for 0.5 hours, and particles with an equivalent diameter of 50.6 μm100 μm are regarded as large agglomerates. The mass fraction wt% of various agglomerates was counted to characterize the regulating effect of the gas volume in the annu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com